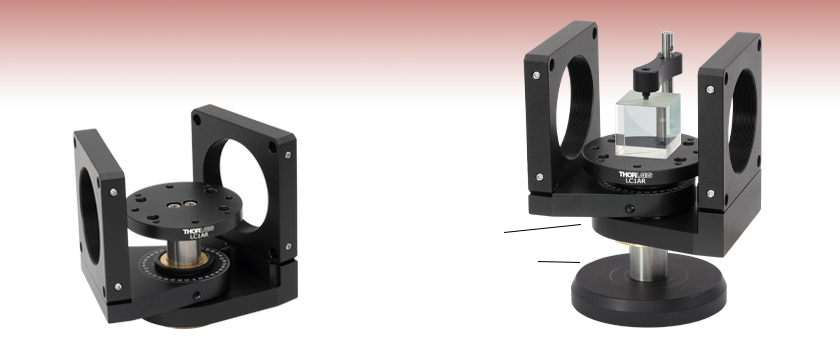

Swivel Mounts/Plates for 60 mm Cage Systems

- For Use in 60 mm Cage Systems

- ±90° Angular Displacement of Cage Axis

- Platform with 0.93" (23.6 mm) Vertical Height Adjustment

- Platform & Plates are Independently Lockable

LC1AR

LC1AR

IB3

Prism, PM4 Clamping Arm,

and IB3 Base Sold Separately

PM4

Please Wait

Features

- ±90° Angular Displacement Between Two Legs of a 60 mm Cage System

- 0.93" (23.6 mm) of Vertical Height Adjustment

- Array of Mounting Holes on Platform

- Four 1/4"-20 (M6) Tapped Holes

- Four 8-32 and Four 6-32 Tapped Holes (Imperial Version)

- Eight M4 Tapped Holes (Metric Version)

- Compatible with our PMx Clamping Arms to Easily Mount Prisms, Gratings, or Crystals

The cage assembly system provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment. See the Cage Overview tab for a full definition of this widely adapted construction standard. Cage assembly plates are the primary mounting component used to house cage assembly rods.

Click to Enlarge

LC1AR Packaging

| Item # | % Weight Reduction |

CO2-Equivalent Reductiona |

|---|---|---|

| LC1AR | 4.76% | 0.08 kg |

| LC1AR/M | 4.76% | 0.29 kg |

Smart Pack

- Reduce Weight of Packaging Materials

- Increase Usage of Recyclable Packing Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at waste minimization while still maintaining adequate protection for our products. By eliminating any unnecessary packaging, implementing packaging design changes, and utilizing eco-friendly packaging materials for our customers when possible, this initiative seeks to improve the environmental impact of our product packaging. Products listed above are now shipped in re-engineered packaging that minimizes the weight and the use of non-recyclable materials.b As we move through our product line, we will indicate re-engineered packages with our Smart Pack logo.

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see image below). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

| Posted Comments: | |

elopez

(posted 2018-07-10 12:00:10.437) Hello, I am looking for the possibility to place a motor on one of the swivel to have an automatic control of the rotation.

Is it posible? Do you have a motorized rotation platform that fits into this setup?

Thank you in advance.

Eneko llamb

(posted 2018-07-26 08:48:01.0) Hello Eneko, thank you for your feedback. The LC1A(/M) as it is would require redesign to incorporate motors. I will add this idea into our internal product forum for further discussion. I will reach out to you directly to discuss our motorized rotation stages as possible alternatives. james.hoyland

(posted 2018-01-11 19:06:42.76) Hi I'm looking at this product as a possible replacement for an educational manual spectrometer for first year undergraduate physics labs. While it fits the bill mechanically it is a shame the only angle measurement possible is through the low resolution angular scale on the base. Our current solution give 0.1 degree angle measurement through a vernier scale. It would be nice to see something like that on this product - without it it is much less useful. nbayconich

(posted 2018-01-16 04:23:18.0) Thank you for your feedback, this is very helpful for us to design future products. I have posted this suggestion in our internal engineering and design forum. |

- ±90° Angular Displacement Between Two 60 mm Cage Plates

- Platform with 0.93" (23.6 mm) Vertical Height Adjustment

- Independently Lockable Plates and Mounting Platform

- Generous Array of Mounting Holes on Platform

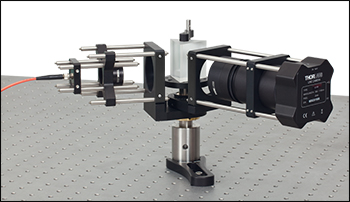

The LC1AR(/M) Swivel Mount is ideal for building spectrometers or other prism- and grating-based systems that require arbitrary angular alignment. The swivel plates are internally threaded for compatibility with our SM2 (2.035"-40) Series of Lens Tubes. In addition, the plates and mounting platform of the LC1AR(/M) mount are independently lockable.

The pedestal can rotate through a full 360° and provides 0.93" (23.6 mm) of vertical height adjustment. To aid in alignment, there is an engraved scale with 2° increments below the pedestal. The platform has an array of threaded holes, making it easy to mount a variety of optical elements, such as prisms and gratings, using our PM3(/M) or PM4(/M) clamping arms. See the drawing to the right for more details.

Click for Details

Mechanical Drawings

- Provide Clamping Force for Our Platform Mounts

- Threaded Hole on Top and Threaded Stud on Bottom of Post

- 6-32 Threads on PM3 and PM4

- 8-32 Threads on PM5

- M4 x 0.7 Threads on All Metric Versions

- Maximum Optic Heights from 0.97" to 1.65" (24.6 mm to 41.8 mm)

- Extension Posts Available to Increase Max Optic Height

- PM3SP(/M) with PM3(/M): Hold Optics up to 2.21" (56.1 mm) Tall

- PM4SP(/M) with PM4(/M): Hold Optics up to 3.61" (91.7 mm) Tall

Click to Enlarge

Clamping Arm Extension Posts with Metric Indicator Groove

Thorlabs' Clamping Arms provide clamping force to secure optics to our kinematic platform mounts, stages, and V-clamps. The PM3(/M) accommodates optics up to 0.97" tall and features a 0.69" center-to-center distance between the post and the nylon-tipped setscrew that holds the optic. The PM4(/M) accommodates optics up to 1.61" and features a 1.16" center-to-center distance between the post and the nylon-tipped setscrew. The maximum optic height of the PM3(/M) or PM4(/M) Clamping Arms can be extended using our PM3SP(/M) or PM4SP(/M) Extension Posts, respectively. These extension posts are identical to the posts included in each complete clamping arm. Each clamping arm features 6-32 (M4 x 0.7) threads. The PM3 and PM4 can be mounted in 8-32 tapped holes by using the AS6E8E thread adapter, which features internal 6-32 threads and external 8-32 threads. This thread adapter has an outer diameter of 0.24", which is the same as the PM4SP extension post and the post included with the PM4 clamping arm. This allows the clamping arm to be adjusted across the seam between either post and the adapter. The smaller diameters of the included post for the PM3 clamping arm and the PM3SP extension post cause the thread adapter to act as a stop for the clamping arm.

The PM5(/M) clamping arm is made entirely from heat-treated stainless steel, which helps maintain stability in fluctuating temperatures and provides vacuum compatibility. This clamping arm is recommended for use with the POLARIS-K1M4(/M), but it can be used with any platform mount or stage that has one or more 8-32 (M4 x 0.7) tapped holes. The PM5(/M) can hold optics up to 1.65" tall, and the distance from the post center to the contact point that holds the optic is 0.90".

Each clamping arm is attached to its post using a flexure mechanism that locks with a 5/64" (2.0 mm) balldriver or hex key. The setscrew on top of the clamping arm also accepts a 5/64" (2.0 mm) balldriver or hex key in order to clamp down on the optic. The post includes a through hole which can be leveraged for added torque when tightening down the post. Please see the diagram above for additional information.

Products Home

Products Home

Zoom

Zoom

Cage Rotation Platform

Cage Rotation Platform