Motion Control Capabilities

Please Wait

Our team of experts is dedicated to creating high-quality

motion control systems.

Click to Enlarge

Dial indicators check for wobble as a stage translates.

Motion Control Design and Manufacturing Process

Thorlabs' motion control systems are designed, manufactured, and tested in our Ely, Cambridgeshire, United Kingdom facility. Our team develops mechanics that are machined to precise tolerances, electronics that are customized for specific applications, and software that has been stress tested in house and proven in customer deployments. Please explore this webpage to learn more.

Design of Motion Control Systems

Key Capabilities

- Mechanical, Electronic, and Software Engineers Experienced in Meeting Strict Requirements

- Three-Dimensional Modeling and Finite Element Analysis Allow Detailed Design Analysis

- 3D Printer Quickly Generates Samples for Evaluation

Our motion control systems are designed by a collaborative, experienced team of specialists with over 30 years of experience. We develop the form factors and manufacturing processes for all our parts, as well as their associated electronic control systems and software interfaces. Our group is accustomed to meeting strict requirements for repeatability, accuracy, and reliability in a variety of positioning systems: linear and rotational, manual and automated, small and large, from simple components to fully integrated systems.

The vast majority of our electromechanical designs begin from scratch in order to achieve the standards our customers request. In addition, team members constantly work to ensure that the final product is reliable, repeatable, and compact. To meet these challenges, our mechanical, electronic, and software engineers consult with each other continuously during the design process. Their tight collaboration ensures that potential problems are addressed as early as possible in the development cycle.

The feasibility of a design is first tested in SolidWorks, and Finite Element Analysis (FEA) is employed to determine the load capacity of our stages, check for material deformation, and perform other kinds of analyses. The SolidWorks model can be directly turned into a sample with a 3D printer in roughly 2 - 8 hours, depending upon the part's complexity. 3D prints reveal fit and form problems not evident from computer modeling and allow our engineers to get a sense for the finished housing. At the same time, our engineers work to design the layout and firmware for the printed circuit board (PCB). By working on several aspects of the design simultaneously, Thorlabs is able to deliver new products to customers quickly.

Prototyping and Testing of Motion Control Systems

All Designs are Rigorously Tested for

| Specific Products are also Measured for

|

Testing Equipment

- Renishaw Laser Interferometer Accurately Tests All Specifications

- Real-World Experimental Setups Confirm Stage Performance in a Variety of Applications

- Force Gauges, Torque Gauges, Dial Indicators, a Temperature Chamber, and Other Instruments Are Used

Once a prototype of the proposed design has been assembled, we begin extensive testing on the part. For example, we run endurance tests called "soak tests." Soak tests simulate use over the lifetime of a product and identify faults that only occur after repeated use. In addition, real-world experimental setups are built on top of the stages, monitored with cameras, and analyzed for behavior in two and three dimensions. We also employ a temperature chamber in a Faraday enclosure to test for drift under repeated temperature cycling.

Our linear stages undergo a battery of tests to check their performance in linear translation applications. For example, we use a Renishaw laser interferometer to verify the straightness of our stages over their entire range of travel. The interferometer also helps us minimize angular displacements (pitch and yaw), which are undesirable in linear translation. Rotation stages are subjected to a similarly rigorous array of tests. In particular, we check rotation stages for undesired out-of-plane motions (runout).

Together, these tests verify that the finished part will meet its design specifications for repeatability, accuracy, and reliability in a variety of contexts, providing a complete picture of the performance of the product.

Production for Motion Control Systems

Machine Shop in Ely, Cambridgeshire, United Kingdom

|

Key Capabilities

- In-House Machine Shop with Experienced, Knowledgeable Machinists (Machines Listed at Right)

- Rigorous Processes and Continual Feedback Ensure Performance Specifications are Consistently Met

- Close Collaborations with External Vendors Minimize Costs and Lead Times

Thorlabs' Ely facility has an extensive network of external vendors with whom we collaborate to minimize time to market and reduce costs for our customers. The most complex, intricate parts are made in house by our skilled machining team.

We begin to consider the manufacturability of the product at the beginning of the product cycle. Motion control stages consist of dozens of parts, all of which need to match tight specifications to provide the required performance. In particular, the thermal and mechanical stress relief requirements of the materials used in our systems must be well-matched. To meet these rigorous requirements, we take several steps:

- Extra Finishing Steps: During machining, we include steps like grinding and heat treatment that minimize variations between components.

- Tight Tolerances: Because tolerance variations add up, the "off-the-shelf" parts we use are made to better-than-usual tolerances.

- Jigs and Standardized Work: Our engineers create equipment, processes, and documentation that ensure that every part is made the same way.

| Travel Range Statisticsa | |

|---|---|

| Mean | 33.18 mm |

| Median | 33.26 mm |

| Minimum | 30.14 mm |

| Maximum | 35.01 mm |

| Standard Deviation | 0.78 mm |

Statistical Process Control gives us an early indication when parts begin to move out of tolerance. The region shaded in the graph above denotes the tolerance range of this linear translation stage. The red line is a statistical fit that indicates that the mean travel range of our most recently manufactured stages is well within tolerance. Calculated performance information is shown in the Travel Range Statistics table.

Assembly and Lean Processes for Motion Control Systems

Key Capabilities

- Lean Manufacturing Minimizes Costs, Shortens Lead Times, and Eliminates Defects

- Statistical Process Control Proactively Prevents Defective Parts

- Kanban "Just-in-Time" Visual Controls Keep the Right Amount of Components Available

Our Ely-based assembly team consists of eleven production cells, each of which specializes in up to three of our product families. They rapidly shift between different product families in response to customer demand, ensuring that finished products are in our customers' hands as soon as possible. Each cell independently assembles products one at a time, from start to finish, using a right-first-time strategy (also known as one-touch manufacturing). This practical approach avoids waste, bottlenecks, and other problems inherent to batch processes and guarantees that all the parts we ship meet or exceed our rigorous specifications. More detail on our production cells is available in the Manufacturing Cell tab.

We eliminate variations between builds through Statistical Process Control, which we apply both internally and to our external vendors. The performance of each of our components and finished products is rigorously quantified and analyzed for trends over time. This allows deviations from the design specifications to be identified quickly, permits improved processes to be implemented continuously, and prevents issues that affect product quality and our customers.

Kanbans ensure that components are only ordered when they are needed, on a "just-in-time" basis. This reduces our overhead costs and allows us to pass these savings on to our customers. Once a predetermined quantity of a given component has been consumed, a production order is automatically sent out, allowing us to replace only what we have used. The smaller quantities of on-hand stock also allow us to more easily identify defects and maintain our high quality standards.

Layout of a Lean Manufacturing Cell

Our lean manufacturing cells provide all the needed components for assembly in a single location and are designed for efficiency. Please mouse over the picture at left or the Cell Features table below to learn more.

Mouse Over the Manufacturing Cell for Details

| Cell Features | |

|---|---|

| Cell Identifier | Each manufacturing cell has a unique identifier. |

| Computer Screen | Standardized work instructions are kept on computer, minimizing clutter and use of paper. |

| Tools Drawer | Cells only contain the tools necessary to assemble the product family of that cell. |

| Colored Parts Bin | Imperial- or metric-specific components are kept in differently colored bins to aid identification. Universal components are stored in blue bins. |

| Andon | This signal light shows the state of a cell. The assembler can change the color to red if support is needed. |

| Bins for Finished Parts | Stock is stored at the point of production and kept to a minimum to prevent waste. |

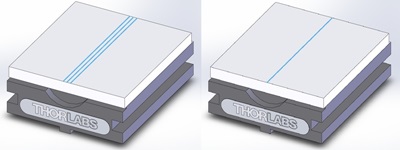

Click to Enlarge

Left: HFV001 V-Groove Fiber Holder with Two Additional Grooves

Right: Standard HFV001 V-Groove Fiber Holder

Specials and Custom Orders

Key Capabilities

- Capabilities for Photonics, Bioscience, and Industrial OEMs

- Linear Stage Modifications: Embedded Electronics, Modified and Custom Hole Patterns, and More

- Removal of Non-Critical Components, Such as Adjusters, to Create Cost-Sensitive Solutions

- Preassembled Subsystems Ready for Integration

- Customized Controller Cards

- Modifications to Standard Products for Additional Functionality and Mounting Flexibility

- Unanodized Parts, Vent Holes, Special Grease, and Other Materials for Applications in Vacuum up to 10-6 Torr

- Additional or Deeper Grooves on V-Groove Fiber Holder for Multiple or Larger Fibers

- Adapters for Different Mounting Configurations

- SolidWorks Modeling, Finite Element Analysis, and 3D Printing Reduce Lead Time of Custom Designs

With more than 30 years of design and production experience, Thorlabs' motion control scientists and engineers can draw from an extensive background to provide positioning systems or components that meet the exact needs of your application. A sample of the services that we offer is listed above. Custom orders receive individualized attention at all steps of the process. Our machine shop is uniquely qualified to handle these special requests and final assembly is performed by a dedicated lean manufacturing cell.

From simple, one-off modifications of our standard products to complete, turnkey OEM solutions, our expert team is available to discuss your individual requirements, offer advice, and provide an overview of your choices. If you have special requirements, a custom application, or general questions about our capabilities, please contact Tech Support to start a discussion.

| Posted Comments: | |

| No Comments Posted |

Products Home

Products Home

Motion Control Manufacturing

Motion Control Manufacturing