Flexure Stage Accessories: Top Plates

- Designed for Use with Our Family of Multi-Axis Stages

- Stage-Mounted Top Plates

- Compatible with a Wide Range of Accessories

AMA011

Top Plate with

Right-Angle Design

Adds a Side Mounting Surface

RB13P1

Top Plate with 1/4"-20 (M6)

and 8-32 (M4) Tapped Holes

MMP1

Top Plate with Our

Standard 'Crossed

Groove' Design and

AMA10 Cleats

Please Wait

Thorlabs offers a variety of top plates compatible with our Microblock™, RollerBlock™, and NanoMax™ stages, including the MMP1(/M) grooved top plate for mounting accessories with a key-way, the RB13P1(/M) plate with 1/4"-20 (M6) and 8-32 (M4) tapped holes, and the AMA011(/M) right-angle top plate for adding a side mounting surface. The MMP1(/M) grooved mounting plate is included with all flexure stages. The other plates featured here are optional replacements to increase the mounting options available for our stages.

Thorlabs also offers a large selection of extension platforms for increasing the working surface on our stages.

| Multi-Axis Stage Accessories | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Fiber Mounts |

Fiber Rotators |

Waveguide Mounts |

Diode Mounts |

Fixed Mounts |

Kinematic Mounts |

Top Platesa |

Extension Platforms |

Fiber Chucks |

Slide Holdersa |

Kinematic Platforms |

Adapter Plates |

| Posted Comments: | |

| No Comments Posted |

Click to Enlarge

HCS030 Optic Mount Mounted to an MMP1 Top Plate Using AMA010 Cleats (Included with Mount)

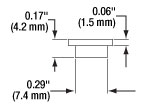

- 'Crossed Groove' Design Necessary for Many Stage Accessories

- Array of Nine 8-32 (M4), Sixteen 6-32 (M3), and Four 4-40 (M2) Tapped Holes

The MMP1(/M) Mounting Plate is included with all NanoMax, MicroBlock, or RollerBlock stages and features a 'crossed groove' design, which is necessary for many flexure stage accessories (e.g., HCS030 Optics Mount shown opposite). They also allow imperial stages to be converted to metric variants and vice versa.

Click to Enlarge

RB13P1 Top Plate Shown Replacing the MMP1 Crossed Groove Mounting Plate on a Flexure Stage

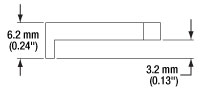

- Array of 1/4"-20 (M6) and 8-32 (M4) Tapped Mounting Holes

- Replaces the Movable Top Plate of Our NanoMax™ or MicroBlock™ 3-Axis Stages

- Allows One to Switch Between an Imperial and Metric Mounting Surface on Our Stages

The RB13P1(/M) Mounting Plate can be used as an alternative to the top plate included with our 3-axis flexure stages. It has a generous array of both 1/4"-20 (M6) and 8-32 (M4) mounting holes to adapt the NanoMax, MicroBlock, or RollerBlock stages to general-purpose optical table translation stages.

Click to Enlarge

AMA011/M Angle Bracket Attached to a NanoMax Stage with the Stage's MMP1/M Top Plate Attached to the Side Face

- Right-Angle Bracket Adds a Side Mounting Surface

- Replaces the Movable Top Plate of Our NanoMax™ or MicroBlock™ 3-Axis Stages

- Top Surface Contains Our Standard Groove along with Seven 8-32 (M4) and Eight 6-32 (M3) Tapped Holes

The AMA011(/M) Right-Angle Bracket can be used to replace the top plate of our 3-axis flexure stages (NanoMax or MicroBlock) stages. The bracket then provides a convenient, side mounting surface for attaching other components or accessories to the stage.

Shown to the right is an AMA011/M angle bracket attached to a NanoMax stage, with the MMP1/M Top Plate (included with the stage) attached to the side of the stage. Note that moving the platform on the stage will also move any mounted accessories.

Click for Details

Accessories mounted in close proximity using the AMA110 Mounting Block.

- Secures Components to NanoMax, MicroBlock, or RollerBlock Stages

- Cleats for Mounting Single Components

- Mounting Blocks and Clamps for Close Proximity Mounting of Multiple Components

The AMA010(/M) Cleats have a flat milled along one side. To lock an accessory along the center alignment groove, rotate the cleat so that the flat is facing the groove. Place the accessory into the groove between the cleats, rotate the cleat so that the rounded edge covers the edge of the mount, and lock down the 6-32 (M3) locking screw and washer. The cleats can be rotated without needing to remove the locking screws. See the animation to the right for details. The included screws are 5/16" (8 mm) long and are used with a 3/32" (2.5 mm) hex key.

For mounting multiple components in close proximity, we offer the AMA110 mounting blocks. These mounting blocks feature a line of nylon-tipped setscrews to secure components, and allow for easy repositioning and very close mounting. The blocks are secured via two holes and are supplied with either 6-32 or M3 cap screws.

The AMA111 Narrow Device Mounting Clamps offer an alternative solution when devices need to be mounted close together. They are secured using an M3.5 or M3 washer and a 6-32 or M3 cap screw, compatible with a 7/64" or 2.5 mm hex key, respectively.

Products Home

Products Home

Zoom

Zoom

Top Plates

Top Plates