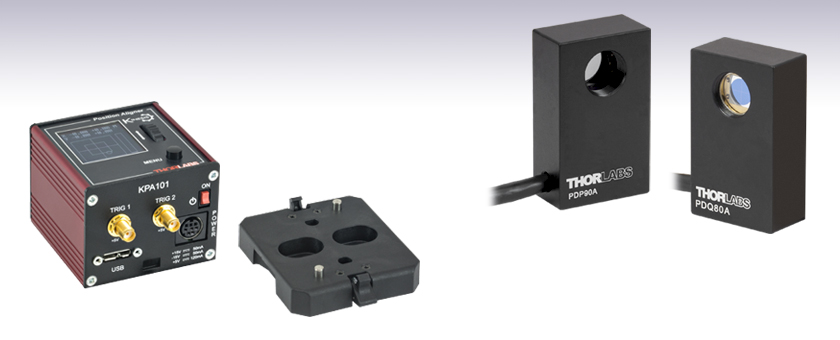

Kinesis® K-Cube™ Position Sensing Detector (PSD) Auto Aligner

- Enables Auto Alignment in Closed-Loop Mode

- Provides Position Measurement in Open-Loop Mode

- Operation via Local Panel Controls or Remote PC via USB

KPA101

Power Supply

Sold Separately

PDP90A

2D Lateral

Effect PSD

PDQ80A

Segmented

Quadrant PSD

Detectors

Available Separately

Table Mounting Plate

(Included with KPA101)

OVERVIEW

Click to Enlarge

Back and Top Views of the KPA101 K-Cube™

(See the Pin Diagrams Tab for More Information)

| Item # | KPA101 |

|---|---|

| X & Y Difference Outputs | -10 to 10 V, SMA Connectors |

| Sum Output | 0 to 10 V, SMA Connector |

| Position-Sensing Detector Input |

6-Pin Hirose Connectora |

| Closed-Loop Bandwidth |

Up to 1 kHzb |

| Open-Loop Bandwidth (-3.0 dB) |

100 kHz |

| USB Connector Type | USB 3.0 |

| USB Connection Speed | USB 1.1 Full Speed (12 Mbps) |

| Dimensions (W x D x H) |

60.0 mm x 60.0 mm x 49.2 mm (2.36" x 2.36" x 1.94") |

Click to Enlarge

KCH601 USB Controller Hub with Installed K-Cube Modules

Features

- Compact Footprint: 60.0 mm x 60.0 mm x 49.2 mm

- Auto Alignment of Beam to Center of Sensor when in Closed-Loop Mode

- Beam Position Measurement when in Open-Loop Mode

- OLED Menu and Position Display for Complete On-Unit Control

- Voltage Outputs for Sum, Difference, and Feedback Signals

- Full Kinesis® Software Control Suite (See Kinesis Software Tab for Details)

- Software Compatible with other Kinesis Controllers for Integrated Systems Development

- Power Supply Sold Separately

- Multi-Axis Expansion Using USB Controller Hubs (Sold Separately)

- Magnetic, Clip-On Optical Table Mounting Adapter Included

The KPA101 K-Cube™ Beam Position Aligner is a part of Thorlabs' new and growing Kinesis® line of high-end, compact controllers. It interfaces with our range of Quadrant and Lateral Effect Sensor Heads (see the Typical Application tab above for more information) and can be used either to measure the position of the beam on the sensor (in Open-Loop Mode) or to generate a signal that can be used as the input for an automated beam steering element (in Closed-Loop Mode). When combined with the KPC101 K-Cube Piezo Controller and Strain Gauge Reader, this unit is ideal for such closed-loop beam-steering applications. Please contact Tech Support for details on how the KPA101 can be used with sensors from other manufacturers.

Embedded software allows this unit to communicate with position sensing detectors (PSDs) either using the on-unit menu button, display, and control wheel or using external trigger signals. In addition to the on-unit controls, USB connectivity provides simple PC-controlled operation with our Kinesis software package.

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, C++, Matlab, LabWindows/CVI, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. For more details, please see the Kinesis Software and Kinesis Tutorials tabs.

The unit has a highly compact 60.0 mm x 60.0 mm x 49.2 mm footprint, allowing it to be positioned close to the system for added convenience when using the top panel controls. Tabletop operation also allows minimal drive cable lengths for easier cable management. Each unit contains a front-located power switch that, when turned off, saves all user-adjustable settings. Please note that this switch should always be used to power down the unit. For convenience, a 1.5 m long Type A to Type Micro B USB 3.0 cable is included with the KPA101 cube.

Optical Table Mounting Plate

Each unit comes with a mounting plate that clips onto the base of the module. The plate contains two magnets for temporary placement on an optical table and two counterbores for 1/4"-20 (M6) cap screws for a more permanent placement on the tabletop. Please see the Mounting Options tab for how to mount the plate.

Power Supply Options

The KPA101 K-Cube, which does not ship with a power supply, can be powered using a TPS002 power supply. The TPS002 power supply plugs into a standard wall outlet and provides +15 VDC, -15 VDC, and +5 VDC for up to two K- or T-Cubes.

The KPA101 is also compatible with the KCH301 and KCH601 USB Controller Hubs. Our USB Controller Hubs have a single USB connection that provides USB connectivity to all the K-Cubes and T-Cubes connected to the hub. In addition, when the KPA101 is used in the closed-loop mode with beam-steering controllers such as the K-Cube KPC101 Piezo Controller and Strain Gauge Reader, the hub is especially useful since it allows for direct communication between the cubes connected on it. As a result, the feedback signals generated by the KPA101 in the closed-loop mode can be sent directly to the KPC101 piezo controllers being used to direct the beam steering elements.

| Detectors and Sensors | ||

|---|---|---|

| K-Cube Beam Position Aligner | Lateral Effect Position Sensor | Quadrant Position Detectors |

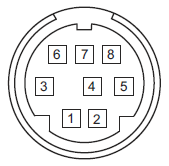

PIN DIAGRAMS

SUM, LV OUT X DIFF, and LV OUT Y DIFFSMA Female |

TRIG 1SMA Female |

TRIG 2SMA Female |

|

|

|

| 3 connectors output signals proportional to the total amount of light hitting the detector (SUM), left-minus-right (LV OUT X DIFF), & top-minus-bottom (LV OUT Y DIFF) for X- and Y-axis alignment. Output Impedance: 470 Ω X DIFF and Y DIFF: -10 V to +10 V SUM: 0 V to +10 V |

+5 V TTL | +5 V TTL |

| These connectors provide a 5 V logic level input and output that can be configured to support triggering into and out of external devices. Each port can be independently configured to control the logic level or to set the trigger as an input or output. Impedance when Configured as Input: 100 kΩ Impedance when Configured as Output: 620 Ω |

||

Power Connector

Mini-DIN Female

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | +5 V (120 mA Max) | 6 | Common Ground |

| 2 | +5 V (120 mA Max) | 7 | Common Ground |

| 3 | -15 V (50 mA Max) | 8 | Common Ground |

| 4 | +15 V (50 mA Max) | Shield | Common Ground |

| 5 | +5 V (120 mA Max) |

Computer Connection*

*The USB 3.0 port is compatible with a USB 2.0 Micro B connector if the Micro B connector is plugged into the shaded region in the photo above. A USB 3.0 type A to type Micro B cable is included with the KPA101.

MOUNTING OPTIONS

K-Cube™ Mounting Options

Two options are available to securely mount our K-Cube™ controllers onto an optical table. An optical table mounting plate, provided with every K-Cube, allows for a single controller to be attached to an optical table. Alternatively, three- and six-port USB controller hubs are offered (sold separately) that can mount and power our K-Cube controllers. These options are described in further detail below.

Optical Table Mounting Plate

Each K-Cube unit comes with a mounting plate that clips onto the base of the controller, as shown in the animation below. The plate contains two magnets for temporary placement on an optical table and two counterbores for 1/4"-20 (M6) cap screws for a more permanent placement on the tabletop.

Kinesis USB Controller Hubs

Multiple units can be mounted and connected to a single PC by using the KCH301 or KCH601 USB Controller Hubs. They each consist of two parts: the hub, which can support up to three (KCH301) or six (KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. K-Cubes simply clip into place using the provided on-unit clips, while current- and previous-generation T-Cubes require the KAP101 Adapter Plate, shown in the animation below. The hub vastly reduces the number of USB and power cables required when operating multiple controllers.

K-Cube Table Mounting Plate

Kinesis USB Controller Hubs

3- and 6-Port USB Controller Hubs allow multiple controllers to be connected to one PC for multi-axis applications. K-Cubes can be directly attached to the hubs while T-Cubes require a KAP101 Adapter Plate.

TYPICAL APPLICATION

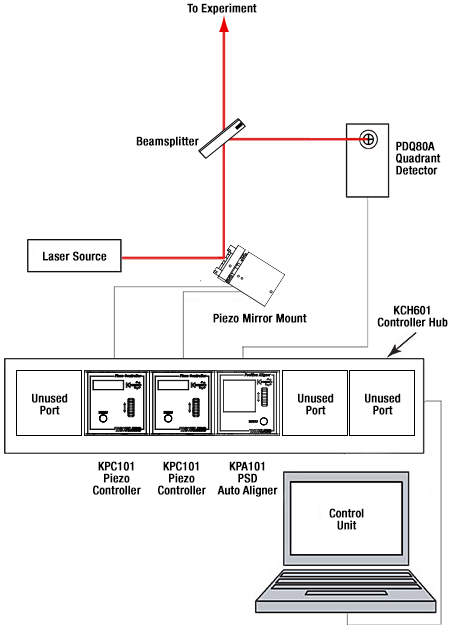

Typical Auto-Alignment Schematic

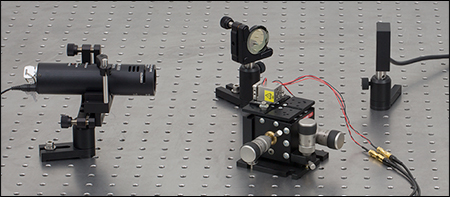

Example Auto-Alignment Setup

A basic auto-alignment schematic is shown to the right. It consists of a PDQ80A Photodiode Sensor, a KPA101 Beam Position Aligner, two KPC101 Piezo Controller and Strain Gauge Readers, a previous-generation ASM003 two-axis piezo mirror mount (alternative mounts can be found here), a laser source, and a computer. Together, the system is used to position and maintain the laser beam so that it is located at the center of the detector array with respect to the beam's power density.

Click to Enlarge

Example Auto-Alignment Setup

The experimental setup shown above was created based on the schematic to the right. An LDM635 red laser diode module emitting at 635 nm serves as the laser source. The light is incident on a previous-generation ASM003 turning mirror mount, which is mounted on an MBT616D flexure stage (center of photo). The turning mirror's X and Y motions are controlled using two KPC101 units (not shown). Please note that the piezo elements are meant for small beam alignment adjustments. The turning mirror directs light to a BP150 pellicle beamsplitter. The light transmitted by this beamsplitter will continue on to the rest of the experimental setup (not shown) while the reflected light is directed towards the PDQ80A Quadrant Sensor (right of photo), which is controlled by the KPA101 Auto-Aligner (not shown).

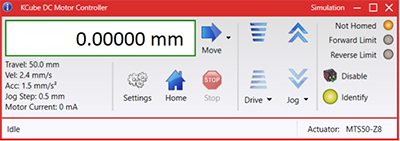

KINESIS SOFTWARE

Software

Kinesis Version 1.14.50

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

KINESIS TUTORIALS

Thorlabs' Kinesis® software features new .NET controls which can be used by third-party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications.

C#

This programming language is designed to allow multiple programming paradigms, or languages, to be used, thus allowing for complex problems to be solved in an easy or efficient manner. It encompasses typing, imperative, declarative, functional, generic, object-oriented, and component-oriented programming. By providing functionality with this common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from the low-powered, single-axis to the high-powered, multi-axis systems and control all from a single, PC-based unified software interface.

The Kinesis System Software allows two methods of usage: graphical user interface (GUI) utilities for direct interaction and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

For a collection of example projects that can be compiled and run to demonstrate the different ways in which developers can build on the Kinesis motion control libraries, click on the links below. Please note that a separate integrated development environment (IDE) (e.g., Microsoft Visual Studio) will be required to execute the Quick Start examples. The C# example projects can be executed using the included .NET controls in the Kinesis software package (see the Kinesis Software tab for details).

|

Click Here for the Kinesis with C# Quick Start Guide Click Here for C# Example Projects Click Here for Quick Start Device Control Examples |

|

LabVIEW

LabVIEW can be used to communicate with any Kinesis-based controller via .NET controls. In LabVIEW, you build a user interface, known as a front panel, with a set of tools and objects and then add code using graphical representations of functions to control the front panel objects. The LabVIEW tutorial, provided below, provides some information on using the .NET controls to create control GUIs for Kinesis-driven devices within LabVIEW. It includes an overview with basic information about using controllers in LabVIEW and explains the setup procedure that needs to be completed before using a LabVIEW GUI to operate a device.

|

Click Here to View the LabVIEW Guide Click Here to View the Kinesis with LabVIEW Overview Page |

|

K-Cube™ Position Sensing Detector (PSD) Auto Aligner

Click to Enlarge

KCH301 USB Controller Hub (Sold Separately) with Installed K-Cube™ Modules

- Control Panel and OLED Screen for On-Unit Control and Position Readout

- Two Bidirectional Trigger Ports to Read or Control External Equipment

- Interfaces with Computer Using Included USB Cable

- Fully Compatible with Kinesis® Software Package

- Compact Footprint: 60.0 mm x 60.0 mm x 49.2 mm

- Power Supply Not Included (See Below)

- Not Recommended for Use with Pulsed Lasers

The KPA101 K-Cube™ Beam Position Aligner is designed for use with our range of Quadrant and Lateral Effect Sensor Heads. It features a top-mounted control panel with an OLED screen for on-unit control and position readouts. The OLED display includes a backlight that can be dimmed or turned off using the top panel menu options. The front of the unit contains two bidirectional trigger ports that can be used to read a 5 V external logic signal or output a 5 V logic signal to control external equipment. Each port can be independently configured to control the logic level or to set the trigger as an input or output.

The unit is fully compatible with our Kinesis software package. Please see the Kinesis Software tab for more information. Please note that this module does not ship with a power supply. Compatible power supplies are listed below.

Operation

The KPA101 K-Cube can be controlled by the manual interface on the top of the unit or via a USB connection to a computer running our Kinesis software package. The Kinesis interface allows the auto aligner to be operated in either an open- or closed-loop mode. In both modes, the K-Cube generates a left-minus-right X difference (X DIFF) signal, a top-minus-bottom Y (Y DIFF) difference signal, and a sum (SUM) signal that are displayed on the target screen.

When in open-loop mode, the X DIFF and Y DIFF difference signals shown on the target screen are not output to the SMA connectors on the back of the unit. Instead, the X DIFF and Y DIFF SMA outputs, which represent X OUT and Y OUT position demand signals, will be fixed at zero or the last closed-loop value. This mode allows for manual alignments on the detector. Once roughly aligned, the unit can be set to closed-loop mode to begin automated alignments of the system.

In the closed-loop mode, a DSP processor inside the KPA101 runs two independent feedback loops that output X DIFF and Y DIFF position demand signals. These signals will be present at the SMA connectors on the back of the unit for use as the inputs to the beam steering elements being used to center the beam on the detector. The proportional, integral, and differential (PID) constants can be adjusted to fine tune the response of the feedback loops to changes in the target position. Floating-point arithmetic allows for a greater range of PID coefficients to be used in the control loop, resulting in higher precision and lower noise (see Appendix B of the manual for details). This increases the range of actuators that can be stabilized using the auto aligner. Furthermore, the unit incorporates a notch filter that can be used to counteract the natural resonance of the specific mechanical system in which the unit is being used. This can stabilize actuators that are prone to mechanical resonances, such as piezo mirror gimbal mounts.

When the unit is controlled via the USB interface, the open-loop output of the unit is also exported digitally to the computer. Please note that stable closed-loop operation can only be achieved with continuous wave (CW) lasers. The KPA101 K-Cube is not recommended for use with pulsed lasers.

Part Number | Description | Price | Availability |

|---|---|---|---|

KPA101 | K-Cube PSD Auto Aligner (Power Supply Sold Separately) | $973.85 | 3 Weeks |

Compatible Power Supplies

- Individual ±15 V/5 V Power Supply

- TPS002: For up to Two K-Cubes™ or T-Cubes™ with Mini-DIN Input*

- USB Controller Hubs Provide Power and Communications

- KCH301: For up to Three K-Cubes or T-Cubes

- KCH601: For up to Six K-Cubes or T-Cubes

The TPS002 supplies power for up to two K-Cubes* or T-Cubes. The cubes still require individual computer connection via USB cable.

The KCH301 and KCH601 USB Controller Hubs each consist of two parts: the hub, which can support up to three (KCH301) or six (KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. The hub draws a maximum current of 10 A; please verify that the cubes being used do not require a total current of more than 10 A. In addition, the hub provides USB connectivity to any docked K-Cube or T-Cube through a single USB connection.

For more information on the USB Controller Hubs, see the full web presentation.

*The TPS002 can only support one KNA-VIS or KNA-IR controller or one KLD101 driver and should not be used to power any additional units as that may exceed current limitations.

Part Number | Description | Price | Availability |

|---|---|---|---|

TPS002 | ±15 V/5 V Power Supply Unit with Mini-DIN Connectors for up to Two K- or T-Cubes | $128.29 | In Stock |

KCH301 | USB Controller Hub and Power Supply for Three K-Cubes or T-Cubes | $598.63 | 3 Weeks |

KCH601 | USB Controller Hub and Power Supply for Six K-Cubes or T-Cubes | $724.52 | 3 Weeks |