30 mm Rotating Cage Segment Plate

- Rotates a 30 mm Cage Segment About the Optical Axis

- Rotation Scale with 2° Graduations

- SM1-Threaded Bore

CPU1

Front

Back

OVERVIEW

Features

- Rotates an Entire 30 mm Cage System Subassembly Around a Fixed SM1-Threaded Bore

- Post Mountable via 8-32 (M4) Tapped Hole

- Rotation Locked with Flexure Mechanism

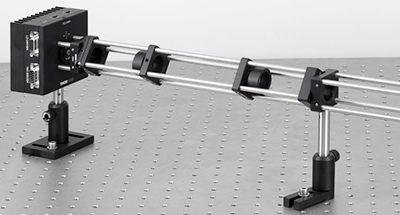

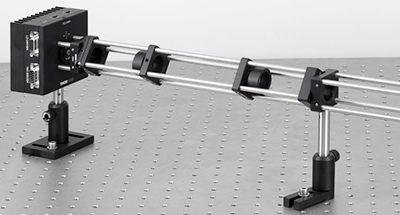

Thorlabs' CPU1 30 mm Rotating Cage Segment Plate allows an entire 30 mm cage subsystem to be rotated about the optical axis. The CPU1 consists of two plates: one attaches to a fixed cage segment, while the other rotates all attached cage elements. To rotate a cage segment between two fixed cage segments, two CPU1 plates must be used as shown in the image below. The rotating cage segment is ideal for rotating multiple optical elements where the rotation of each element must be the same (e.g., using two cylindrical lenses to change the spatial profile of a laser diode or for multi-element polarization applications).

The rotating cage segment plate features a 1" deep, SM1-threaded (1.035"-40) central bore through the part that remains fixed as the plate is rotated. Two SM1RR retaining rings are provided for direct mounting of optics.

Each side of the cage plate has four blind holes for attaching cage rods, and thus, the cage rods must terminate at this cage plate. Each rod is held in place by a side-located locking M4 setscrew, which can be secured using a 5/64" (2 mm) balldriver or hex key. An engraved scale with 2° graduations allows for reliable manual positioning. After the rotation is adjusted, a flexure locking mechanism, which is engaged with a 5/64" (2 mm) hex key, secures the rotation. The fixed side of the cage plate is equipped with an 8-32 (M4) tapped hole for mounting with our Ø1/2" posts.

Click to Enlarge

Two CPU1 plates can form a rotating cage segment between two fixed segments. In this application, two cylindrical lenses are used to circularize the output of a laser diode. For more details, see the Application Ideas tab.

This animation shows how one cage segment rotates while the other remains fixed. Note that the SM1-threaded bore does not rotate.

APPLICATION IDEAS

Click to Enlarge

The above photo shows two cylindrical lenses mounted between two CPU1 Rotating Cage Plates to circularize the output of a laser diode.

Circularizing a Laser Diode Output

Since the output of a laser diode is highly divergent, it is often necessary to collimate the output. In addition, the output is elliptical, meaning that the spatial profile of the beam must be changed if a circular beam is desired. Round optics, such as aspheric lenses, can be used for collimation, but the beam will still be elliptical. If a circular beam is desired, cylindrical lenses can be used as a one-dimensional beam expander to produce a circular output. Since the two cylindrical lenses must together be aligned to the laser diode emission, a rotating cage segment is used to align the lenses.

In the image shown to the right, a laser diode is mounted in a TCLDM9 mount, which can be driven by many of Thorlabs laser diode drivers and TEC controllers (not shown). This previous-generation mount has been replaced by our high-power laser diode mounts. A mounted aspheric lens is attached to an SM1 adapter, which is threaded onto the front of the TCLDM9. The asphere is used to collimate the beam.

Next, four ER1 cage rods are threaded into the TCLDM9, and the fixed side of a CRP1 rotating cage segment plate is attached to the other end of the rods. A rotating cage segment is built using four ER rods (the length will depend on the spacing necessary for the cylindrical lenses). One positive and one negative focal length cylindrical lens can be used to build a beam expander, which can compensate for the ellipticity of the beam.

We used Ø1" round cylindrical lenses mounted in SM1V05 adjustable lens tubes, which are threaded into CP33 cage plates. The adjustable lens tubes allow for the orientation of the lenses to be individually adjusted. The cage plates are then slid along the rotating cage segment at the proper separation, and the orientation of both cylindrical lenses can be adjusted simultaneously by rotating the CPU1. After the beam is circularized, a second rotating cage segment plate can be attached to the end of the ER rods so that additional cage segments with a fixed orientation can be attached.

Please note that the exact choice of controllers, aspheric lens, and cylindrical lenses will depend on the laser diode used. If you have any questions regarding the choices for controllers and optics for a particular laser diode, please contact tech support.

Cage Rotation Mount for Cylindrical Lenses

By pairing the CPU1(/M) Rotating Cage Segment Plate with our CYCP Cage Mount, it is possible to rotate a cylindrical lens about the optical axis defined by a 30 mm cage system (see image below). The imperial and metric lists of all items in this assembly are located in the tables below.

CAGE OVERVIEW

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see image below). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

30 mm Rotating Cage Segment Plate

Part Number | Description | Price | Availability |

|---|---|---|---|

CPU1/M | 30 mm Rotating Cage Segment Plate, Two SM1RR Retaining Rings Included, Metric | $181.75 | 3-5 Days |

CPU1 | 30 mm Rotating Cage Segment Plate, Two SM1RR Retaining Rings Included, Imperial | $181.75 | 3-5 Days |