780 nm and 1560 nm Femtosecond Fiber Lasers

- Menlo Systems' figure 9® Technology

- Laser Output in Less than 60 Seconds

- Highly Stable with Low Amplitude and Phase Noise

- 780 nm or 1560 nm Output

C-FIBER-780-HIGH-POWER

780 nm Femtosecond Fiber Laser

C-FIBER-HIGH-POWER

1560 nm Femtosecond Fiber Laser

Please Wait

Jason Reeves Menlo Systems |

Feedback? Questions? Need a Quote? Please note that these femtosecond fiber lasers are available directly from Menlo Systems. |

|

| United States Phone: +1-973-300-4490 Email: ussales@menlosystems.com |

Outside United States Phone: +49-89-189166-0 Email: sales@menlosystems.com |

|

Features

- High Stability with Low Amplitude and Phase Noise

- All-PM Fiber Solution

- Single Mode-Lock State

- Menlo Systems' figure 9® Mode-Locking Technology

- Laser Output in Less than 60 Seconds

- Factory-Set Repetition Rate from 50 to 250 MHz

- Synchronization at All Frequencies

- Compact Design

- Complete Synchronization Solution Available

- Laser and Synchronization Electronics

- Full Automation

- Hands-Free Operation

Menlo Systems’ fiber-based femtosecond laser sources integrate the latest achievements in fiber technology into easy-to-use products. Menlo Systems’ unique figure 9® design results in reproducible and long-term stable operation. It is based on the well-established nonlinear optical loop mirror (NOLM) mode-locking mechanism. Both oscillator and amplifier use polarization maintaining (PM) fiber components only, ensuring excellent stability and low-noise operation. The laser is maintenance free, user installed and ready to use at the press of a single button. Customize your laser with the available options to match the requirements of your application.

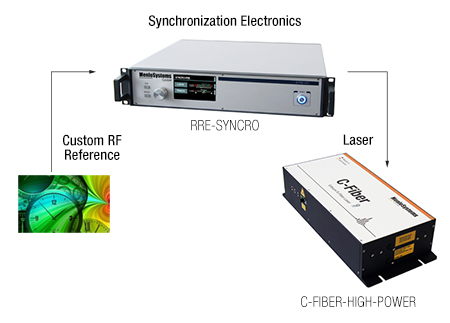

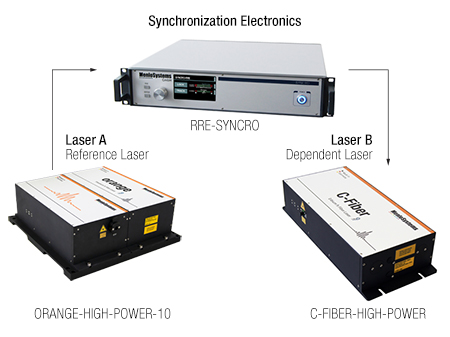

A complete synchronization solution is available with the RRE-SYNCRO Repetition Rate Stabilization Electronics. Having all components come from a single supplier reduces the time required to synchronize the elements of the system, giving more time to focus on the experiment. See the Synchronization tab for details.

Applications

C-FIBER-HIGH-POWER Applications

|

C-FIBER-780-HIGH-POWER Applications

|

Optional Packages

- SYNC100 Repetition Rate Synchronization

Variable Cavity Length through Integrated Stepper Motor and Piezo Setup Enables Tuning of Cavity by 330 kHz. This allows for synchronization of the femtosecond laser to an external clock signal using an appropriate PLL-Electronics system, such as Menlo Systems' RRE-SYNCRO (available separately). This option can not be retrofitted. Please order together with laser head. - RRE-SYNCRO Repetition Rate Stabilization Electronics

Feedback Electronics to Phase Lock Pulses to an External Clock - VARIO User-Defined Repetition Rate

Factory-Set Value Selectable in the 50-250 MHz Range - MULTIBRANCH Additional Seed Ports

Seeding of Multiple Amplifiers with Optional Subsequent Frequency Conversion to Cover Multiple Wavelengths - FEMTOSCALE Additional Compression Unit

Compression of Second Harmonic Output Pulse Length to <70 fs

| Item # | C-FIBER-780-HIGH-POWER | C-FIBER-HIGH-POWER |

|---|---|---|

| Center Wavelength | 780 ± 10 nm | 1560 ± 20 nm |

| Average Output Power | >250 mW | >500 mW |

| Pulse Energy | >2.5 nJ | >5 nJ |

| Pulse Width | <100 fs (<70 fs with FEMTOSCALE) | <90 fs |

| Repetition Ratea | 100 MHz (50-250 MHz with VARIO) | |

| Repetition Rate Instability | <1 ppm Over 20 Hours at Constant Temperature | |

| Timing Jitter | <2 fs (rms, 10 kHz, 10 MHz) | |

| Output Port | Free Space | Free Space |

| Auxiliary Output Portb | Free Space, 1560 nm, >500 mW | - |

| Additional Fiber-Coupled Seed Port | 1 (up to 4 with MULTIBRANCH) | - |

| Polarization | Linear, S-Polarized | Linear, S-Polarized |

| Beam Height | 75 mm | 102 mm |

| RRE-SYNCRO Specifications | |

|---|---|

| RMS Timing Jitter | <200 fs (0.1 Hz - 500 kHz) or Same as Reference, Whichever Applies First |

| Input Signals | |

| External Reference | 10 MHz (Provided by Customer) Signal Level: 5 to 10 dBm |

| Repetition Rate | Signal Level: -20 to -10 dBm |

| Output Signals | |

| Stepper Motor | Stepper Motor Control, Sub-D, 9 Pin |

| Piezo | Piezo Control BNO |

| Error | Error Signal for Monitoring, BNC |

| Timing Jitter | |

|---|---|

| Configuration | Relative Phase Noise |

| RF Reference (10 MHz) to Laser | <200 fs (0.1 Hz - 500 kHz) or Same as Reference, Whichever Applies First |

| Laser to Laser | <20 fs (0.1 Hz - 500 kHz) for Menlo fs Lasers as Master/Slave with Small Locking Bandwidth |

Complete Synchronization Solution

- Laser and Synchronization Electronics

- All Components from One Supplier

- Full Automation for Hands-Off Operation

- Integrated and Tested for Immediate, Out-of-the-Box Operation

Synchronize your pulsed laser sources with high accuracy using Menlo Systems' RRE-SYNCRO. This unit provides state-of-the art phase lock electronics in a user-friendly, plug-and-play system. Menlo Systems has developed the Repetition Rate Synchronization for the patented, Nobel Prize awarded Optical Frequency Synthesizer technology. The RRE has been field-tested in this highly demanding environment enabling measurements with precision never reached before.

The main application is the synchronization of a pulsed laser to a radio frequency reference, derived from a radio frequency clock or an optical reference clock. An embedded microcontroller for the stepper motor and Piezo control in laser cavity ensures long-term stability.

Laser to Reference

Click to Enlarge

Laser to Laser

Click to Enlarge

Click to Enlarge

Integrated Timing Jitter of Free Running Laser: <2 fs (rms, 10 kHz - 10 MHz)

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

Pulsed Laser Emission: Power and Energy Calculations

Determining whether emission from a pulsed laser is compatible with a device or application can require referencing parameters that are not supplied by the laser's manufacturer. When this is the case, the necessary parameters can typically be calculated from the available information. Calculating peak pulse power, average power, pulse energy, and related parameters can be necessary to achieve desired outcomes including:

- Protecting biological samples from harm.

- Measuring the pulsed laser emission without damaging photodetectors and other sensors.

- Exciting fluorescence and non-linear effects in materials.

Pulsed laser radiation parameters are illustrated in Figure 1 and described in the table. For quick reference, a list of equations is provided below. The document available for download provides this information, as well as an introduction to pulsed laser emission, an overview of relationships among the different parameters, and guidance for applying the calculations.

|

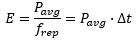

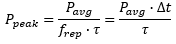

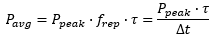

Equations: |

||||

|

and |  |

||

|

||||

|

||||

|

||||

Peak power and average power calculated from each other: |

||||

|

and |  |

||

| Peak power calculated from average power and duty cycle*: | ||||

|

*Duty cycle ( ) is the fraction of time during which there is laser pulse emission. ) is the fraction of time during which there is laser pulse emission. |

|||

Click to Enlarge

Figure 1: Parameters used to describe pulsed laser emission are indicated in the plot (above) and described in the table (below). Pulse energy (E) is the shaded area under the pulse curve. Pulse energy is, equivalently, the area of the diagonally hashed region.

| Parameter | Symbol | Units | Description | ||

|---|---|---|---|---|---|

| Pulse Energy | E | Joules [J] | A measure of one pulse's total emission, which is the only light emitted by the laser over the entire period. The pulse energy equals the shaded area, which is equivalent to the area covered by diagonal hash marks. | ||

| Period | Δt | Seconds [s] | The amount of time between the start of one pulse and the start of the next. | ||

| Average Power | Pavg | Watts [W] | The height on the optical power axis, if the energy emitted by the pulse were uniformly spread over the entire period. | ||

| Instantaneous Power | P | Watts [W] | The optical power at a single, specific point in time. | ||

| Peak Power | Ppeak | Watts [W] | The maximum instantaneous optical power output by the laser. | ||

| Pulse Width |  |

Seconds [s] | A measure of the time between the beginning and end of the pulse, typically based on the full width half maximum (FWHM) of the pulse shape. Also called pulse duration. | ||

| Repetition Rate | frep | Hertz [Hz] | The frequency with which pulses are emitted. Equal to the reciprocal of the period. | ||

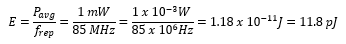

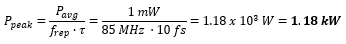

Example Calculation:

Is it safe to use a detector with a specified maximum peak optical input power of 75 mW to measure the following pulsed laser emission?

- Average Power: 1 mW

- Repetition Rate: 85 MHz

- Pulse Width: 10 fs

The energy per pulse:

seems low, but the peak pulse power is:

It is not safe to use the detector to measure this pulsed laser emission, since the peak power of the pulses is >5 orders of magnitude higher than the detector's maximum peak optical input power.

| Posted Comments: | |

Hidetoshi Nakanishi

(posted 2019-06-19 15:09:17.82) (株)SCREENホールディングスの中西英俊です。

価格などの情報も提供いただけると助かります。800nm程度の安価で高出力なfsレーザーを探しています。 YLohia

(posted 2019-06-19 08:33:10.0) Hello, thank you for contacting Thorlabs. Our Technical Support team from Japan will reach out to you directly. |

Products Home

Products Home

780/1560 nm fs Fiber Lasers

780/1560 nm fs Fiber Lasers