Spatial Light Modulators

- Reflective 2D Phase Only Spatial Light Modulators (SLMs)

- 400 - 850 nm, 650 - 1100 nm, or 1550 nm Operating Wavelengths

- 1920 x 1200 (WUXGA) Resolution

- Highly Stable Phase Control with Minimal Flickering

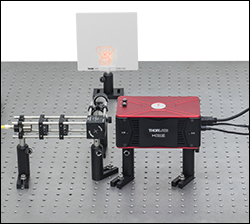

EXULUS-HD3HP

Removable SLM Head,

1920 x 1200 (WUXGA),

650 - 1100 nm

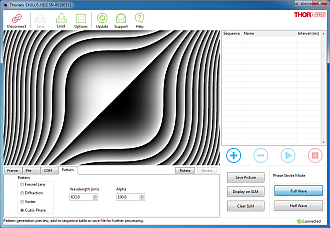

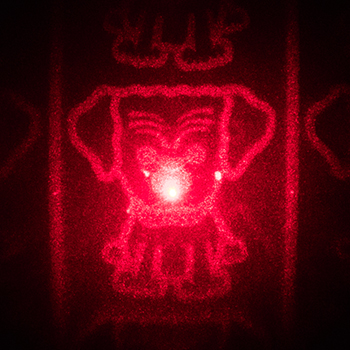

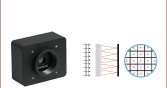

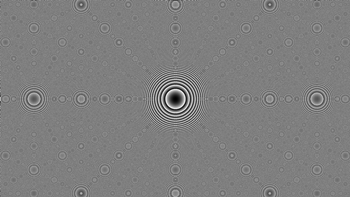

Image Generated by SLM Using Computer-Generated Hologram Projection. For Details, See the App Note Tab

EXULUS-HD4

1920 x 1200 (WUXGA),

1550 nm

Please Wait

Applications

- Wavefront Correction

- Optical Trapping

- Beam Steering

- Adaptive Optics

- Holography

- Pulse Shapinga

- Laser Processinga

- Lithographya

- Interferometrya

- Quantum Orbital Angular Momentuma

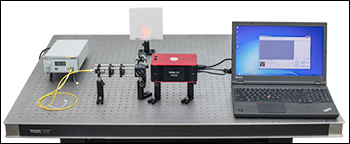

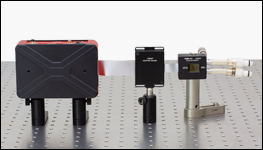

Click to Enlarge

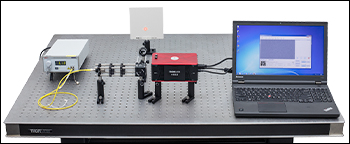

Each Exulus SLM features multiple 8-32 (M4) taps for post mounting. For a list of items used in this setup, see the App Note tab.

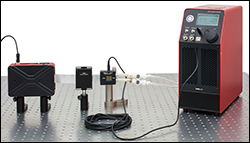

Click to Enlarge

The Exulus SLMs (excluding the high-power SLMs) are provided with a magnetic cover; when the SLM is in use, the cover can be attached to the back of the housing.

Watch a demonstration of an interferometric method for calibrating the phase delay of reflective SLMs.

Features

- Liquid Crystal on Silicon (LCoS) with Reflective Coating

- Panel Resolution: 1920 x 1200 (WUXGA)

- Operating Wavelengths: 400 - 850 nm, 650 - 1100 nm, or 1550 nm

- High-Power Models Available for 400 - 850 nm or 650 - 1100 nm Operating Ranges

- All-in-One and Separate-Panel Mounting Configurations

- Liquid Cooling Module Included on SLM Head

- Fill Factor: >90% (Varies by Model)

- Independent Horizontal and Vertical SLM Panel Tilt Adjustments (Standard SLM

Models Only) - Trigger Output for Timing Control of Other Devices

- Fast Frame/Refresh Rates

- Customizations Available:

- Panel and Controller in Separate Units (Standard SLM Models Only)

- Other Retardance Ranges (Contact Tech Support for Details)

Thorlabs' Exulus® Spatial Light Modulators (SLMs) employ Liquid Crystal on Silicon (LCoS) technology to produce high-resolution, high-speed reflective phase modulation with individually addressable pixels. This phase control is highly stable with minimal fluctuations and minimal crosstalk with adjacent pixels. For maximum phase shift values, refer to the table below. These spatial light modulators provide far more pixels than lower-order phase modulators such as segmented or deformable mirrors. For applications requiring improved thermal stability and high-power handling (≤200 W/cm) in the 400 nm to 850 nm or 650 nm to 1100 nm wavelength ranges, high-power SLMs are available.

Exulus spatial light modulators are driven by an input video signal and operate as a general WUXGA. They are bundled with a software GUI that provides complete control over the device. Different driving modes are supported by the software, including full frame, image input, video input, Fresnel lens, diffraction, and computer-generated holography (CGH). The CGH mode also allows tilting and focusing effects to be overlaid onto a pattern. The GUI enables quick switching between operating modes, as well as allowing images, videos, and patterns to be uploaded to the panel. For more details on the operating modes, please see the Software and App Note tabs.

Standard Models

Each standard spatial light modulator (-HD2, -HD3, and -HD4) includes a built-in SLM panel with independent horizontal and vertical tilt adjustment of ±3.2°. Locking rings are installed to fix the adjustment settings, as well as provide extra stability. Customized versions are also available with the panel separated from the control unit; contact Tech Support for details.

These Exulus spatial light modulators have input ports compatible with HDMI* connectors and ship with two corresponding cables: one for connecting to an HDMI-compatible output, and one for connecting to a DisplayPort*-compatible output. Also included are a mini-USB cable for connecting to a PC, a power supply with a location-specific power cord and a HKTS-5/64 hex key thumbscrew for adjusting the horizontal and vertical tilt adjusters.

High-Power Models

Our high-power SLMs (EXULUS-HD2HP and EXULUS-HD3HP) are designed for applications requiring highly stable phase operation, which include interferometry, quantum orbital angular momentum, and laser processing. To improve thermal stability and allow for high-power handling (≤200 W/cm), they feature a liquid-cooled SLM head and adapter board, which can be mounted directly on the controller or positioned separately from the main housing. The SLM head includes two preinstalled 1/4" hoses with CPC®† valved quick-connect coupling inserts for easy connection to a chiller, and the adapter board houses the FPC connectors and a circuit boards that connects the controller and SLM head. We recommend using Thorlabs' LK220 chiller (sold below) for full compatibility with the Thorlabs EXULUS software package.

These high-power spatial light modulators have input ports compatible with HDMI* connectors and ship with two corresponding cables: one for connecting to an HDMI-compatible output, and one for connecting to a DisplayPort*-compatible output. A mini-USB cable is also included for connecting to a PC. To aid in connecting to a liquid chiller, two CPC valved quick-connection fittings for both 4.3 mm (0.17") and 6.0 mm (0.24") inner diameter hoses are included with the unit, as well a 2.5 mm stereo cable for thermistor compatibility. A power supply with a location-specific power cord, a USB drive with the software and manual, and a BD-2M 2 mm balldriver for removing the adapter board and SLM head from the main unit are also shipped with these Exulus models.

*HDMI is a trademark or registered trademark of HDMI Licensing Administrator, Inc. DisplayPort is a trademark owned by the Video Electronics Standards Association (VESA) in the United States and other countries. The use of such trademarks by Thorlabs does not constitute or imply any affiliation with or endorsement or sponsorship by their respective trademark owners.

†CPC® is a registered trademark of Colder Products Company.

| Key Specificationsa | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # Suffix |

Operating Wavelength |

Panel Resolution |

Fill Factor |

Phase / Retardance Rangeb |

Frame Rate |

Output Trigger |

Liquid Cooling Module |

Separable SLM Panel |

| HD2 | 400 - 850 nm | 1920 x 1200 (WUXGA) |

>92% | π or 2π at 633 nmc | 60 Hz | Yes (SMA) |

- | - |

| HD3 | 650 - 1100 nm | 1920 x 1200 (WUXGA) |

>92% | π or 2π at 1064 nmc | 60 Hz | - | - | |

| HD4 | 1550 nm | 1920 x 1200 (WUXGA) |

>92% | π or 2π at 1550 nmc | 60 Hz | - | - | |

| HD2HP | 400 - 850 nm | 1920 x 1200 (WUXGA) |

>92% | π or 2π at 633 nmc,d | 60 Hz |  |

|

|

| HD3HP | 650 - 1100 nm | 1920 x 1200 (WUXGA) |

>92% | π or 2π at 1064 nmc,d | 60 Hz |  |

|

|

| Item # | EXULUS-HD2 | EXULUS-HD3 | EXULUS-HD4 | |

|---|---|---|---|---|

| Panel Resolution | 1920 x 1200 (WUXGA) | |||

| Type | Liquid Crystal on Silicon (LCoS) with Reflective Coating | |||

| Operating Wavelength | 400 - 850 nm | 650 - 1100 nm | 1550 nm | |

| Panel Active Area | 15.42 mm x 9.66 mm | |||

| Pixel Pitch | 8 µm | |||

| Fill Factor | >92% | |||

| Reflective Coating | Aluminum | Dielectric | ||

| Average Reflectance | 80% (Typical) | 82% (Typical) | ||

| Phase / Retardance Range | 2π at 633 nm (Full Wave Mode) π at 633 nm (Half Wave Mode) |

2π at 1064 nm (Full Wave Mode) π at 1064 nm (Half Wave Mode) |

2π at 1550 nm (Full Wave Mode) π at 1550 nm (Half Wave Mode) |

|

| Angle of Incidencea | 0° | |||

| Optic Axis | 0° | |||

| Reflected Wavefront Distortion | <λ/2 @ 633 nm | <0.4λ @ 633 nm | ||

| Damage Threshold | Pulsed (ns) | 0.22 J/cm2 (532 nm, 6.8 ns, 10 Hz, Ø200.5 µm) |

0.15 J/cm2 (1064 nm, 10 ns, 100 Hz, Ø235 µm) |

0.187 J/cm2 (1550 nm, 6.0 ns, 10 Hz, Ø230.6 µm) |

| Pulsed (fs) | 0.0935 J/cm2 (515 nm, 203.3 fs, 100 Hz, Ø108.2 µm) |

0.03 J/cm2 (1030 nm, 200 fs, 100 Hz, Ø135 µm) |

0.076 J/cm2 (1550 nm, 55.6 fs, 100 Hz, Ø143.1 µm) |

|

| Frame Rate | 60 Hz | |||

| Fluctuation / Flickering (RMS)b | <0.01% | <0.05% | <0.15% | |

| Beam Deviation Using Panel Tip / Tilt | ±3.2° | |||

| Trigger Outputc | SMA Female | |||

| Trigger Output High Voltage Level | 5 V (TTL) | |||

| Trigger Output Pulse Width | 54 µs | |||

| Dimensions (L x W x H)d | 155.9 mm x 104.3 mm x 42.0 mm (6.14" x 4.11" x 1.65") | |||

| Weight | 0.76 kg (1.68 lbs) | |||

| Storage Temperature | 0 °C to 60 °C (32 °F to 140 °F) | |||

| Operating Temperaturee | 10 °C to 40 °C (50 °F to 104 °F) | |||

| PC Connection | HDMI-Compatible Connector USB 2.0 Connector |

|||

| Bit Depth | 8 Bit, 0 - 255 Gray Level | |||

| Item # | EXULUS-HD2HP | EXULUS-HD3HP | |

|---|---|---|---|

| Panel Resolution | 1920 x 1200 (WUXGA) | ||

| Type | Liquid Crystal on Silicon (LCoS) with Reflective Coating | ||

| Operating Wavelength | 400 - 850 nm | 650 - 1100 nm | |

| Panel Active Area | 15.42 mm x 9.66 mm | ||

| Pixel Pitch | 8 µm | ||

| Fill Factor | >92% | ||

| Reflective Coating | Aluminum | ||

| Average Reflectance | 80% (Typical) | ||

| Phase / Retardance Rangea | 2π at 633 nm (Full Wave Mode) π at 633 nm (Half Wave Mode) |

2π at 1064 nm (Full Wave Mode) π at 1064 nm (Half Wave Mode) |

|

| Angle of Incidenceb | 0° | ||

| Optic Axis | 0° | ||

| Reflected Wavefront Distortion | <λ/2 @ 633 nm | <0.4λ @ 633 nm | |

| Frame Rate | 60 Hz | ||

| Optical Power Handlingc | ≤200 W/cm | ||

| Damage Threshold | Pulsed (ns) | 0.22 J/cm2 (532 nm, 6.8 ns, 10 Hz, Ø200.5 µm) |

0.15 J/cm2 (1064 nm, 10 ns, 100 Hz, Ø235 µm) |

| Pulsed (fs) | 0.0935 J/cm2 (515 nm, 203.3 ns, 100 Hz, Ø108.2 µm) |

0.03 J/cm2 (1030 nm, 200 fs, 100 Hz, Ø135 µm) |

|

| Fluctuation / Flickering (RMS)d | <0.01% | <0.15% | |

| Beam Deviation Using Panel Tip / Tilt | N/A | ||

| Trigger Outpute | SMA Female | ||

| Trigger Output High Voltage Level | 5 V (TTL) | ||

| Trigger Output Pulse Width | 54 µs | ||

| Connector Type (for Tubing) | CPC® Valved Thumb Latch Quick-Disconnect Fitting | ||

| Tubing Dimensions | 0.17" (4.3 mm) Inner Diameter (Pre-Installed) 0.24" (6 mm) Inner Diameter (Optional) |

||

| Dimensions (L x W x H) | 220.0 mm x 104.0 mm x 68.0 mm (8.66" x 4.09" x 2.68") All-in-One Mode 420.0 mm x 104.0 mm x 42.0 mm (16.54" x 4.09" x 1.65") Separate-Panel Mode |

||

| Weight | 0.7 kg (1.54 lbs) | ||

| Storage Temperature | 0 °C to 60 °C (32 °F to 140 °F) | ||

| Operating Temperaturee | 10 °C to 40 °C (50 °F to 104 °F) | ||

| PC Connection | HDMI-Compatible Connector USB 2.0 Connector |

||

| Bit Depth | 8 Bit, 0 - 255 Gray Level | ||

| SLM Head Thermistor | |||

| Type | VISHAY NTC LE413 (R0 = 10 kΩ @ T0 = 25 °C, B = 3435 K) | ||

| Accuracy | ±0.5 °C (@ 25 °C) | ||

Diffraction Efficiency

When a repeating, linear phase pattern is displayed on the SLM, it will function similarly to a blazed diffraction grating. The diffraction efficiency is the power in the first-order of the diffraction pattern divided by the zero-order when the phase of the SLM is set to zero across the panel. These measurements were made at 633 nm, 1064 nm, or 1550 nm for several test patterns with varying phase steps, effectively creating gratings with varying line spacing (denoted as line pair / mm). The measured results and patterns used are plotted below.

Phase Patterns Used to Measure Diffraction Efficiency

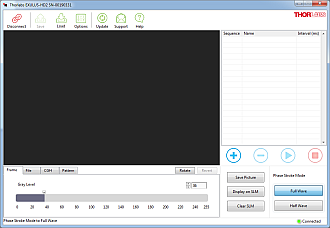

Software

Thorlabs EXULUS Version 2.5.4

The software page provides the Thorlabs EXULUS software package for our current and previous generations of SLMs.

Click the button below to visit the software page.

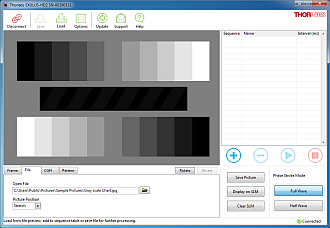

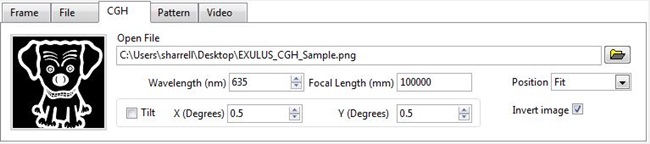

Each Exulus® SLM comes with a software interface that provides complete control of the SLM panel as well as device settings. Users can input a specific phase level (gray level) over the entire panel, import a custom image, produce a computer generated holography (CGH) pattern, and other patterns such as Fresnel lenses and diffraction gratings. All the patterns can be saved into a sequence list and played with a predefined interval of 16.7 ms (60 Hz frame rate, EXULUS-HD2, EXULUS-HD3, EXULUS-HD4, EXULUS-HD2HP, and EXULUS-HD3HP). The software also supports video input at 1080p or 4K resolution with the H.264 video codec (supported file formats: MP4, M4V, and MOV).

Click the yellow bar below for screenshots highlighting various software features and capabilities:

Thorlabs EXULUS Software Package for EXULUS-HD2, EXULUS-HD3, EXULUS-HD4, EXULUS-HD2HP, and EXULUS-HD3HP

Click to Enlarge

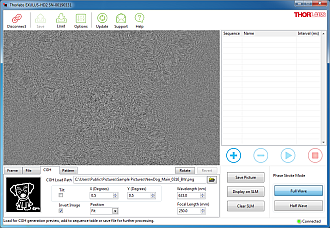

Frame Tab in Standard Frame Rate Mode: Setting a specific gray level from 0 to 255 will set the entire panel to a certain phase level.

Click to Enlarge

File Tab: Upload a user-defined pattern in PNG, JPEG, or BMP format.

Click to Enlarge

CGH Tab: Convert a user-defined image into a holographic pattern. For more details, please see the App Note tab.

Click to Enlarge

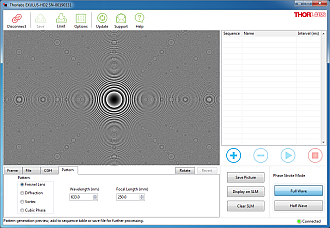

Pattern Tab for Fresnel Lens Generation: Sets the SLM panel to focus the reflected light at a user-selected wavelength and focal length.

Click to Enlarge

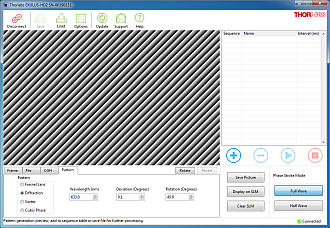

Pattern Tab for Diffraction Grating Generation: Sets the SLM panel to diffract the reflected light with user-selected wavelength, deviation angle, and grating rotation angle. For more infromation about the diffraction efficiency of different patterns, please see the Diffraction Efficiency tab.

Click to Enlarge

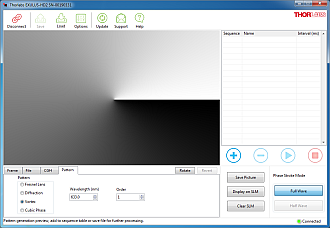

Pattern Tab for Vortex Generation: This pattern creates a helical output beam and contains a characteristic donut beam profile. The mode contains two parameters: wavelength and pattern order m.

Click to Enlarge

Pattern Tab for Cubic Phase Generation: This pattern generates a non-diffracted beam with self-recovery characteristics, commonly called an airy beam. The mode contains two parameters: wavelength and alpha.

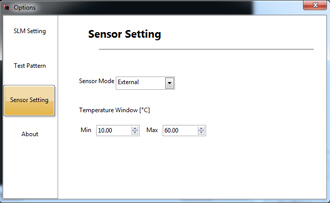

Click to Enlarge

Sensor Setting: When a high-power SLM is connected to the LK220 chiller, the temperature sensor can be set to internal or external mode. The internal sensor measures the output coolant temperature, while the external sensor gives the thermistor temperature reading from the LK220 chiller.

The optical working principles of liquid crystal on silicon SLMs that provide phase-modulated output beams are illustrated.

Click to Enlarge

Figure 1: A schematic diagram of the SLM LCoS panel.

Overview

Two-dimensional spatial light modulators (SLMs) offer individually addressable pixels of phase shift. Thorlabs' Exulus® 2D SLM is fabricated with liquid crystal on silicon (LCoS) technology, which is based on display technology. This allows it to provide far more pixels than lower-order phase modulators such as segmented or deformable mirrors. Also, the phase shift of one pixel has little crosstalk with other pixels. Therefore, the Exulus 2D SLM is perfect for many beam manipulation applications including optical trapping, beam steering and shaping, femtosecond pulse shaping, adaptive optics, imaging applications, and holography.

The main component of the Exulus® is the 2D SLM LCoS panel. Figure 1 shows a basic schematic of the LCoS panel. The liquid crystal layer is sandwiched between the top transparent and conductive ITO electrode, and the reflective electrode on the bottom. Each pixel on the SLM panel corresponds to individually addressable electrodes on the bottom. Together with the ITO layer on top, an electric field is built up by applying a voltage between the two electrodes. The liquid crystal modules line up according to the direction and strength of the electric field. Since liquid crystal is a birefringent material, the alignment of the liquid crystal molecules in turn controls the retardance or phase shift of each pixel. A wavefront that is incident on the panel reflects with its phase or wavefront being shifted according to the signal that is sent to the SLM panel. With a properly calculated pattern on the SLM panel, the reflected wavefront results in different optical effects in the far field. These effects typically include diffraction, tilt, focus, and holographic image formation.

Click to Enlarge

Figure 2: Setup for CGH using the previous-generation EXULUS-HD1 SLM. In this case, the focusing effect added to the CGH is set to a

100 000 mm focal length.

| View Metric Product List |

Holographic Projection

We show here a holographic projection as one of the applications of the Exulus SLM. Figure 2 shows a typical setup required to realize a 2D holographic projection using the previous-generation EXULUS-HD1. A collimated laser beam is incident on the SLM panel; best results for holographic projection are obtained using a beam size just smaller than Ø7 mm. The incident beam passes through a polarizer and a half-wave plate such that it is polarized at 45°, the direction of the optical axis of the panel. The target projection image is first converted into a computer generated holography (CGH) pattern that is calculated by the bundled software (accessed through the CGH tab in the software). The output beam is separated from the incident beam with a beam splitter. Within the SLM software, a focusing effect is added to the CGH pattern; if you do not desire to have the SLM provide focusing, set the focal length to an extremely long value. In this example, we have set the focal length to 100 000 mm (at the laser wavelength of 635 nm), checked the "Invert Image" box to set the image outline to be bright in the projected pattern, and set the position to "Fit" so that the entire image is visible on the preview. Since CGH relies on far-field diffraction, a set of imaging lenses is required to produce a sharp holographic image on a screen (in this example, first lens: f = 50 mm, second lens: f = 75 mm). Figure 3 shows the holographic image to be projected and the corresponding CGH pattern, which is calculated using the bundled software. The resulting holographic projection is shown in Figure 4.

Click to Enlarge

Figure 4: CGH projection of an image using the setup with the previous-generation SLM shown in Figure 2 and the image shown in Figure 3. The central bright spot is a zero-order diffraction spot due to the gaps between the SLM pixels.

c.

Figure 3: a. The image used to generate the holographic projection.

c. The CGH settings tab in the Exulus software.

Effects of Focusing and Tilt

Due to the fill factor of the SLM panel, there is a small gap between the pixels. This in turn causes higher diffraction orders and a high-energy zero-order spot which is unaffected by the SLM, but inherently exists at the output. The center bright spot often overlaps with the holographic projection on the same image plane, as is visible in Figure 4. It is highly preferable to remove this zero-order-spot in many applications.

In order to further enhance the holographic image, one can adjust the focusing effect added to the CGH pattern. This causes the CGH projection to focus itself without the requirement of imaging lenses. Since the zero-order spot is not affected by the focusing parameter, the CGH projection will form an image while the zero-order spot remains collimated at the original beam size. Figure 5 shows the focusing effect that is added to the CGH as well as the final processed CGH pattern sent to the SLM panel; in this example, the focal length was changed to 100 mm in the software; the other software settings remained unchanged.

Figure 5: a. The 100 mm Fresnel lens focusing effect added to the CGH pattern. b. The resultant CGH pattern of the image in Figure 3 a, including the 100 mm focus, generated by the EXULUS software.

Click to Enlarge

Figure 6: Setup used for removing the focused zero-order spot from the CGH projection. Note that the lenses are in different locations than in Figure 2. The setup shown utilizes a previous-generation SLM.

If the imaging lenses used in the first example above are inserted into the beam path again, then the center bright spot can be made to diverge while the holographic projection is refocused. This can be accomplished by following these steps:

- Generate a CGH pattern using a short focal length setting (here, we use 100 mm; other settings remained unchanged from the first example).

- Find the location where the CGH pattern is in focus, which should be at the distance set in the SLM software (100 mm).

- Put the first lens a short distance after this focused spot (here, we used an f = 50 mm lens).

- Fix the location of the viewing screen at the desired location, and then insert the second lens into the beam path (here, we used an f = 75 mm lens). Adjust the position of this lens until an image begins to form on the screen.

- Once the image of the CGH projection is found, make small adjustments to the position of both lenses to optimize the size and clarity of the image.

The experimental setup is shown in Figure 6; note the lenses are in different positions than they are in Figure 2. The resulting holographic projection is shown in Figure 7.

Additionally, the Exulus software allows an X and/or Y tilt to be added to the CGH pattern; this can be used to displace the CGH projection from the central zero-order spot.

Click to Enlarge

Figure 7: CGH projection of the CGH pattern shown in Figure 5 and the setup shown in Figure 6.

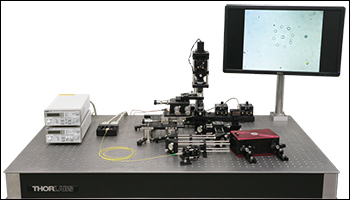

Optical Tweezers Application

In optical tweezers systems, an SLM can be used to generate several focused spots at different locations in the sample volume. By using the video or sequence features in the Exulus software package, a moving pattern of focal points can be generated to move trapped particles within a sample volume. In the video to the lower right, several trapped beads are moved continuously in a circle. The tweezers system incorporating the previous-generation EXULUS-HD1 is shown in Figure 8.

Click to Enlarge

Figure 8: An optical tweezers system incorporating the previous-generation EXULUS-HD1 SLM.

| Damage Threshold Specifications | ||

|---|---|---|

| Item # | Type |

Damage Threshold

|

| EXULUS-HD2 EXULUS-HD2HP |

Pulsed (ns) | 0.22 J/cm2 (532 nm, 6.8 ns, 10 Hz, Ø200.5 µm) |

| Pulsed (fs) | 0.0935 J/cm2 (515 nm, 203.3 fs, 100 Hz, Ø108.2 µm) | |

| EXULUS-HD3 EXULUS-HD3HP |

Pulsed (ns) | 0.15 J/cm2 (1064 nm, 10 ns, 100 Hz, Ø235 µm) |

| Pulsed (fs) | 0.03 J/cm2 (1030 nm, 200 fs, 100 Hz, Ø135 µm) | |

| EXULUS-HD4 | Pulsed (ns) | 0.187 J/cm2 (1550 nm, 6.0 ns, 10 Hz, Ø230.6 µm) |

| Pulsed (fs) | 0.076 J/cm2 (1550 nm, 55.6 fs, 100 Hz, Ø143.1 µm) | |

Damage Threshold Data for Thorlabs' Exulus Spatial Light Modulators

The damage threshold provided in the table to the right are measured data for Thorlabs' family of Exulus® Spatial Light Modulators.

Laser Induced Damage Threshold Tutorial

The following is a general overview of how laser induced damage thresholds are measured and how the values may be utilized in determining the appropriateness of an optic for a given application. When choosing optics, it is important to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Note that the guideline presented here assumes room temperature operation and optics in new condition (i.e., within scratch-dig spec, surface free of contamination, etc.). Because dust or other particles on the surface of an optic can cause damage at lower thresholds, we recommend keeping surfaces clean and free of debris. For more information on cleaning optics, please see our Optics Cleaning tutorial.

Testing Method

Thorlabs' LIDT testing is done in compliance with ISO/DIS 11254 and ISO 21254 specifications.

First, a low-power/energy beam is directed to the optic under test. The optic is exposed in 10 locations to this laser beam for 30 seconds (CW) or for a number of pulses (pulse repetition frequency specified). After exposure, the optic is examined by a microscope (~100X magnification) for any visible damage. The number of locations that are damaged at a particular power/energy level is recorded. Next, the power/energy is either increased or decreased and the optic is exposed at 10 new locations. This process is repeated until damage is observed. The damage threshold is then assigned to be the highest power/energy that the optic can withstand without causing damage. A histogram such as that below represents the testing of one BB1-E02 mirror.

The photograph above is a protected aluminum-coated mirror after LIDT testing. In this particular test, it handled 0.43 J/cm2 (1064 nm, 10 ns pulse, 10 Hz, Ø1.000 mm) before damage.

| Example Test Data | |||

|---|---|---|---|

| Fluence | # of Tested Locations | Locations with Damage | Locations Without Damage |

| 1.50 J/cm2 | 10 | 0 | 10 |

| 1.75 J/cm2 | 10 | 0 | 10 |

| 2.00 J/cm2 | 10 | 0 | 10 |

| 2.25 J/cm2 | 10 | 1 | 9 |

| 3.00 J/cm2 | 10 | 1 | 9 |

| 5.00 J/cm2 | 10 | 9 | 1 |

According to the test, the damage threshold of the mirror was 2.00 J/cm2 (532 nm, 10 ns pulse, 10 Hz, Ø0.803 mm). Please keep in mind that these tests are performed on clean optics, as dirt and contamination can significantly lower the damage threshold of a component. While the test results are only representative of one coating run, Thorlabs specifies damage threshold values that account for coating variances.

Continuous Wave and Long-Pulse Lasers

When an optic is damaged by a continuous wave (CW) laser, it is usually due to the melting of the surface as a result of absorbing the laser's energy or damage to the optical coating (antireflection) [1]. Pulsed lasers with pulse lengths longer than 1 µs can be treated as CW lasers for LIDT discussions.

When pulse lengths are between 1 ns and 1 µs, laser-induced damage can occur either because of absorption or a dielectric breakdown (therefore, a user must check both CW and pulsed LIDT). Absorption is either due to an intrinsic property of the optic or due to surface irregularities; thus LIDT values are only valid for optics meeting or exceeding the surface quality specifications given by a manufacturer. While many optics can handle high power CW lasers, cemented (e.g., achromatic doublets) or highly absorptive (e.g., ND filters) optics tend to have lower CW damage thresholds. These lower thresholds are due to absorption or scattering in the cement or metal coating.

LIDT in linear power density vs. pulse length and spot size. For long pulses to CW, linear power density becomes a constant with spot size. This graph was obtained from [1].

Pulsed lasers with high pulse repetition frequencies (PRF) may behave similarly to CW beams. Unfortunately, this is highly dependent on factors such as absorption and thermal diffusivity, so there is no reliable method for determining when a high PRF laser will damage an optic due to thermal effects. For beams with a high PRF both the average and peak powers must be compared to the equivalent CW power. Additionally, for highly transparent materials, there is little to no drop in the LIDT with increasing PRF.

In order to use the specified CW damage threshold of an optic, it is necessary to know the following:

- Wavelength of your laser

- Beam diameter of your beam (1/e2)

- Approximate intensity profile of your beam (e.g., Gaussian)

- Linear power density of your beam (total power divided by 1/e2 beam diameter)

Thorlabs expresses LIDT for CW lasers as a linear power density measured in W/cm. In this regime, the LIDT given as a linear power density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size, as demonstrated by the graph to the right. Average linear power density can be calculated using the equation below.

The calculation above assumes a uniform beam intensity profile. You must now consider hotspots in the beam or other non-uniform intensity profiles and roughly calculate a maximum power density. For reference, a Gaussian beam typically has a maximum power density that is twice that of the uniform beam (see lower right).

Now compare the maximum power density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately. A good rule of thumb is that the damage threshold has a linear relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 10 W/cm at 1310 nm scales to 5 W/cm at 655 nm):

While this rule of thumb provides a general trend, it is not a quantitative analysis of LIDT vs wavelength. In CW applications, for instance, damage scales more strongly with absorption in the coating and substrate, which does not necessarily scale well with wavelength. While the above procedure provides a good rule of thumb for LIDT values, please contact Tech Support if your wavelength is different from the specified LIDT wavelength. If your power density is less than the adjusted LIDT of the optic, then the optic should work for your application.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. The damage analysis will be carried out on a similar optic (customer's optic will not be damaged). Testing may result in additional costs or lead times. Contact Tech Support for more information.

Pulsed Lasers

As previously stated, pulsed lasers typically induce a different type of damage to the optic than CW lasers. Pulsed lasers often do not heat the optic enough to damage it; instead, pulsed lasers produce strong electric fields capable of inducing dielectric breakdown in the material. Unfortunately, it can be very difficult to compare the LIDT specification of an optic to your laser. There are multiple regimes in which a pulsed laser can damage an optic and this is based on the laser's pulse length. The highlighted columns in the table below outline the relevant pulse lengths for our specified LIDT values.

Pulses shorter than 10-9 s cannot be compared to our specified LIDT values with much reliability. In this ultra-short-pulse regime various mechanics, such as multiphoton-avalanche ionization, take over as the predominate damage mechanism [2]. In contrast, pulses between 10-7 s and 10-4 s may cause damage to an optic either because of dielectric breakdown or thermal effects. This means that both CW and pulsed damage thresholds must be compared to the laser beam to determine whether the optic is suitable for your application.

| Pulse Duration | t < 10-9 s | 10-9 < t < 10-7 s | 10-7 < t < 10-4 s | t > 10-4 s |

|---|---|---|---|---|

| Damage Mechanism | Avalanche Ionization | Dielectric Breakdown | Dielectric Breakdown or Thermal | Thermal |

| Relevant Damage Specification | No Comparison (See Above) | Pulsed | Pulsed and CW | CW |

When comparing an LIDT specified for a pulsed laser to your laser, it is essential to know the following:

LIDT in energy density vs. pulse length and spot size. For short pulses, energy density becomes a constant with spot size. This graph was obtained from [1].

- Wavelength of your laser

- Energy density of your beam (total energy divided by 1/e2 area)

- Pulse length of your laser

- Pulse repetition frequency (prf) of your laser

- Beam diameter of your laser (1/e2 )

- Approximate intensity profile of your beam (e.g., Gaussian)

The energy density of your beam should be calculated in terms of J/cm2. The graph to the right shows why expressing the LIDT as an energy density provides the best metric for short pulse sources. In this regime, the LIDT given as an energy density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size. This calculation assumes a uniform beam intensity profile. You must now adjust this energy density to account for hotspots or other nonuniform intensity profiles and roughly calculate a maximum energy density. For reference a Gaussian beam typically has a maximum energy density that is twice that of the 1/e2 beam.

Now compare the maximum energy density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately [3]. A good rule of thumb is that the damage threshold has an inverse square root relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 1 J/cm2 at 1064 nm scales to 0.7 J/cm2 at 532 nm):

You now have a wavelength-adjusted energy density, which you will use in the following step.

Beam diameter is also important to know when comparing damage thresholds. While the LIDT, when expressed in units of J/cm², scales independently of spot size; large beam sizes are more likely to illuminate a larger number of defects which can lead to greater variances in the LIDT [4]. For data presented here, a <1 mm beam size was used to measure the LIDT. For beams sizes greater than 5 mm, the LIDT (J/cm2) will not scale independently of beam diameter due to the larger size beam exposing more defects.

The pulse length must now be compensated for. The longer the pulse duration, the more energy the optic can handle. For pulse widths between 1 - 100 ns, an approximation is as follows:

Use this formula to calculate the Adjusted LIDT for an optic based on your pulse length. If your maximum energy density is less than this adjusted LIDT maximum energy density, then the optic should be suitable for your application. Keep in mind that this calculation is only used for pulses between 10-9 s and 10-7 s. For pulses between 10-7 s and 10-4 s, the CW LIDT must also be checked before deeming the optic appropriate for your application.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. Contact Tech Support for more information.

[1] R. M. Wood, Optics and Laser Tech. 29, 517 (1998).

[2] Roger M. Wood, Laser-Induced Damage of Optical Materials (Institute of Physics Publishing, Philadelphia, PA, 2003).

[3] C. W. Carr et al., Phys. Rev. Lett. 91, 127402 (2003).

[4] N. Bloembergen, Appl. Opt. 12, 661 (1973).

In order to illustrate the process of determining whether a given laser system will damage an optic, a number of example calculations of laser induced damage threshold are given below. For assistance with performing similar calculations, we provide a spreadsheet calculator that can be downloaded by clicking the button to the right. To use the calculator, enter the specified LIDT value of the optic under consideration and the relevant parameters of your laser system in the green boxes. The spreadsheet will then calculate a linear power density for CW and pulsed systems, as well as an energy density value for pulsed systems. These values are used to calculate adjusted, scaled LIDT values for the optics based on accepted scaling laws. This calculator assumes a Gaussian beam profile, so a correction factor must be introduced for other beam shapes (uniform, etc.). The LIDT scaling laws are determined from empirical relationships; their accuracy is not guaranteed. Remember that absorption by optics or coatings can significantly reduce LIDT in some spectral regions. These LIDT values are not valid for ultrashort pulses less than one nanosecond in duration.

A Gaussian beam profile has about twice the maximum intensity of a uniform beam profile.

CW Laser Example

Suppose that a CW laser system at 1319 nm produces a 0.5 W Gaussian beam that has a 1/e2 diameter of 10 mm. A naive calculation of the average linear power density of this beam would yield a value of 0.5 W/cm, given by the total power divided by the beam diameter:

However, the maximum power density of a Gaussian beam is about twice the maximum power density of a uniform beam, as shown in the graph to the right. Therefore, a more accurate determination of the maximum linear power density of the system is 1 W/cm.

An AC127-030-C achromatic doublet lens has a specified CW LIDT of 350 W/cm, as tested at 1550 nm. CW damage threshold values typically scale directly with the wavelength of the laser source, so this yields an adjusted LIDT value:

The adjusted LIDT value of 350 W/cm x (1319 nm / 1550 nm) = 298 W/cm is significantly higher than the calculated maximum linear power density of the laser system, so it would be safe to use this doublet lens for this application.

Pulsed Nanosecond Laser Example: Scaling for Different Pulse Durations

Suppose that a pulsed Nd:YAG laser system is frequency tripled to produce a 10 Hz output, consisting of 2 ns output pulses at 355 nm, each with 1 J of energy, in a Gaussian beam with a 1.9 cm beam diameter (1/e2). The average energy density of each pulse is found by dividing the pulse energy by the beam area:

As described above, the maximum energy density of a Gaussian beam is about twice the average energy density. So, the maximum energy density of this beam is ~0.7 J/cm2.

The energy density of the beam can be compared to the LIDT values of 1 J/cm2 and 3.5 J/cm2 for a BB1-E01 broadband dielectric mirror and an NB1-K08 Nd:YAG laser line mirror, respectively. Both of these LIDT values, while measured at 355 nm, were determined with a 10 ns pulsed laser at 10 Hz. Therefore, an adjustment must be applied for the shorter pulse duration of the system under consideration. As described on the previous tab, LIDT values in the nanosecond pulse regime scale with the square root of the laser pulse duration:

This adjustment factor results in LIDT values of 0.45 J/cm2 for the BB1-E01 broadband mirror and 1.6 J/cm2 for the Nd:YAG laser line mirror, which are to be compared with the 0.7 J/cm2 maximum energy density of the beam. While the broadband mirror would likely be damaged by the laser, the more specialized laser line mirror is appropriate for use with this system.

Pulsed Nanosecond Laser Example: Scaling for Different Wavelengths

Suppose that a pulsed laser system emits 10 ns pulses at 2.5 Hz, each with 100 mJ of energy at 1064 nm in a 16 mm diameter beam (1/e2) that must be attenuated with a neutral density filter. For a Gaussian output, these specifications result in a maximum energy density of 0.1 J/cm2. The damage threshold of an NDUV10A Ø25 mm, OD 1.0, reflective neutral density filter is 0.05 J/cm2 for 10 ns pulses at 355 nm, while the damage threshold of the similar NE10A absorptive filter is 10 J/cm2 for 10 ns pulses at 532 nm. As described on the previous tab, the LIDT value of an optic scales with the square root of the wavelength in the nanosecond pulse regime:

This scaling gives adjusted LIDT values of 0.08 J/cm2 for the reflective filter and 14 J/cm2 for the absorptive filter. In this case, the absorptive filter is the best choice in order to avoid optical damage.

Pulsed Microsecond Laser Example

Consider a laser system that produces 1 µs pulses, each containing 150 µJ of energy at a repetition rate of 50 kHz, resulting in a relatively high duty cycle of 5%. This system falls somewhere between the regimes of CW and pulsed laser induced damage, and could potentially damage an optic by mechanisms associated with either regime. As a result, both CW and pulsed LIDT values must be compared to the properties of the laser system to ensure safe operation.

If this relatively long-pulse laser emits a Gaussian 12.7 mm diameter beam (1/e2) at 980 nm, then the resulting output has a linear power density of 5.9 W/cm and an energy density of 1.2 x 10-4 J/cm2 per pulse. This can be compared to the LIDT values for a WPQ10E-980 polymer zero-order quarter-wave plate, which are 5 W/cm for CW radiation at 810 nm and 5 J/cm2 for a 10 ns pulse at 810 nm. As before, the CW LIDT of the optic scales linearly with the laser wavelength, resulting in an adjusted CW value of 6 W/cm at 980 nm. On the other hand, the pulsed LIDT scales with the square root of the laser wavelength and the square root of the pulse duration, resulting in an adjusted value of 55 J/cm2 for a 1 µs pulse at 980 nm. The pulsed LIDT of the optic is significantly greater than the energy density of the laser pulse, so individual pulses will not damage the wave plate. However, the large average linear power density of the laser system may cause thermal damage to the optic, much like a high-power CW beam.

| Posted Comments: | |

Alexander Brisson

(posted 2023-10-25 13:50:09.967) I would like to compare ThorLabs SLMs in terms of liquid crystal response time (in other words, response time to a changing pattern or switching frequency). I do not see this spec for the HD4 at 1550 nm operating wavelength.

Thanks cdolbashian

(posted 2023-11-08 12:23:28.0) Thank you for contacting Thorlabs with this inquiry! We have sent the response time data to you via email. Minsu Yeo

(posted 2023-09-13 20:58:11.09) I have the EXULUS-HD1 and HD2 from Thorlabs.

I am conducting optimization experiments by setting up a feedback loop with the SLM, but I am having difficulty setting up the feedback loop using your software.

I would like to know if there is another way to control the SLM without using Thorlabs software, using programming languages or tools such as MATLAB, Python, C++, etc.?

This is very important to me and I look forward to your reply.

Thank you. cdolbashian

(posted 2023-09-25 10:17:08.0) Thank you for contacting Thorlabs! Our software supports 3rd-party language to create custom applications. There are two software packages for SLM, the "Spatial Light Modulator" software is designed for HD1, we now only have the C programming examples and will send it to you via email. The "Thorlabs EXULUS" software is designed for HD2, it supports C++, LABVIEW and Python, the SDK files can be accessed by clicking the "help" on software interface. T Isayama

(posted 2023-07-03 17:05:35.027) Dear Sir or Madam,

I have a questions about EXULUS-HD2HP.

Like the previous commenters, I would like to see the code with regard to CGH. Can I ask them to share it with me?

Sincerely, Isayama cdolbashian

(posted 2023-07-14 04:45:22.0) Thank you for contacting Thorlabs! Our CGH algorithm is based on a common approach described in https://doi.org/10.1364/JOSAA.3.001897. Due to the proprietary reason, we cannot share the code, what we provide is SDK files to support 3rd language development, such as Python, C++, and LabView. The SDK files can be accessed by clicking the "help" on the software interface. Qiang Chen

(posted 2023-06-21 09:32:06.843) Dear Sir or Madam,

My name is Qiang Chen. I'm a scientist at Lawrence Berkeley National Lab. I recently purchased EXULUS-HD1 and had some questions about it. Do you have code in python or matlab for your CGH? Any additional reference papers will be appreciated. Also, to help us understand better the product, do you have more demos we can use, such as Bessel beam, ...? If so, could you share with us? Thank you very much.

Best,

Qiang jpolaris

(posted 2023-06-29 07:22:56.0) Thank you for contacting Thorlabs. We currently have a C programming example that we can share with you. I have reached out to you directly by email to send this to you. Additionally, we have published a video insight named "EXULUS® Spatial Light Modulators: Principles and Applications", which can help you better understand the product. The video can be found at the following link. https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=13891&tabname=PWest_2021 user

(posted 2023-05-29 20:50:11.863) Can the size of the beam (its diameter) be changed using an SLM? cdolbashian

(posted 2023-06-12 12:44:40.0) Thank you for contacting Thorlabs. You may try CGH Tab or Pattern Tab for Fresnel Lens Generation in software to change the diameter of reflected beam Luke Peters

(posted 2023-03-08 12:03:52.017) Do you have the damage thresholds for the SLMs at 800nm? I have two lasers I am keen on using the SLMs on

the first is a 80fs 4w average 1khz source with 9mm diameter (800nm)

the second is 140 fs 4w average 80Mhz average with 3mm diameter (800nm),

are any of the slms suitable? as the threshold is listed for 530nm JReeder

(posted 2023-03-14 07:56:23.0) Thank you for contacting Thorlabs. Your first laser has a high peak power density, about 5.5E10 W/cm, it's larger than any of our SLMs' LIDT, so it's not recommended to use the first laser with our SLMs. Your second laser has a relatively low peak power density, about 2.4E6 W/cm, but the average power density is 13.3 W/cm. Only our High Power versions SLMs (EXULUS-HD2HP and EXULUS-HD3HP) can withstand such average power densities. On the other hand, the LIDT of ultrafast lasers is not scalable, it's difficult to evaluate the LIDT of an ultrafast laser with different wavelengths, pulse widths, and repetition rates. So we would recommend to attenuate the input power to a low/safe level and then ramping up slowly until modulation is observed. Amar Deo Chandra

(posted 2022-09-01 17:47:09.203) Hello, we request the following information on EXULUS-HD2 and EXULUS-HD3 SLMs. 1. What is the CW damage threshold for these SLMs? 2. For EXULUS-HD3 SLM working in 650-1100 nm, the phase shift at 1064 nm is 2pi. What would be the phase shift around 650 nm for this SLM? 3. What is the maximum 1st order diffraction efficiency of these SLMs? cdolbashian

(posted 2022-09-07 03:13:21.0) Thank you for contacting Thorlabs. To answer each question directly:

1. We currently only have pulse damage thresholds for these SLMs (which can be found under "Damage Thresholds" tab). We would recommend to start with a low/safe enough input power and then ramp up slowly until phase fluctuations are observed.

2. The phase stroke range of EXULUS-HD3 at 650 nm can be slightly less than 3.27π while considering the impact of material dispersion. Most applications of SLM are wavelength dependent, we can provide a recalibration service prior to sale if required (calibrated at operating wavelength). To get this, you could contact your local tech support team (in your case, techsupport@thorlabs.com )

3. The diffraction efficiency of SLMs is conditionally limited, e.g. test patterns, applied wavelength... We have published some typical data for reference, and they are under "Diffraction Efficiency" tab. user

(posted 2022-04-20 12:48:21.887) Hello,

Do you have more information on damage thresholds? We want to use this with short pulses and high repetition rates (200fs to 10ps, 100kHz to 1Mhz). cdolbashian

(posted 2022-05-02 01:36:40.0) Thank you for contacting Thorlabs. For the EXULUS-4K1/M damage threshold at fs rating, we currently only have "0.138 J/cm2 (535 nm, 59.4 fs, 100 Hz, Ø188 µm)". Since LIDTs for ultra-short-pulse laser are not scalable. Therefore it's hard for us to evaluate your high repetition rate ultrafast laser is safe or not without testing. We would recommend to start with a low/safe enough input power and then ramp up slowly until phase fluctuations are observed. Jongkyu Park

(posted 2022-03-23 11:08:45.273) Hello, i purchased the Exulus-HD1/M and would like to use it by Matlab. To begin with, i would like to want to control the SLM by Matlab or other ways. If you can provide a Matlab example, please let me know it. Thank you. cdolbashian

(posted 2022-04-01 01:50:25.0) Thank you for contacting Thorlabs. The full SDK package for the HD1 is currently a work in progress. We currently only have a simple programming example file written in C, and we will send the C example to you via email. Krzysztof Tyszka

(posted 2021-12-06 15:14:15.49) Hello, we have purchased HD3HP, could you please provide information on the following topics:

1. Is there an example of integration using Python o LabView?

2. How many iterations are used to calculate the CGH pattern. Can this be changed in the provided application? Which algorithm do you use?

3. Why in your application there is no possibility to calculate Pattern (like Vortex) for wavelength longer than 633nm?

4. Can you provide phase calibration curves? Can this be adjusted via your software somehow?

5. The image created with our SLM has a significant speckle pattern. What can be the cause?

Best regards Chris YLohia

(posted 2021-12-10 02:16:55.0) Thank you for contacting Thorlabs. To answer each question directly:

1. The software v2.5.1 for the EXULUS contains the SDK that supports Python and LabVIEW. The SDK manual and examples can be found by clicking the "Help" button within the software application.

2. Our algorithm is proprietary and, unfortunately, we cannot share this information. CGH (computer generated holography) is common in the academic world and you are welcome to take a look at existing literature describing common approaches such as: https://doi.org/10.1364/JOSAA.3.001897.

3. The wavelength range defined in "Pattern" tab is related to the operating wavelength range of connected SLM. For example, 633 nm is not an option for the software when the EXULUS-HD3HP has been connected, since 633 nm < 650nm. We will contact you directly in order to gather more information.

4. A report containing the phase calibration curves is provided inside the packaging box. If you cannot find it, you may send the serial number of your SLM to your local tech support team for the report. Those curves are not able to be modified in software at current stage.

5. We will reach out to you directly via email to help troubleshoot. Kinam Joo

(posted 2021-11-07 21:37:31.557) Hi, I purchased the Exulus HD1 and would like to use it by Matlab. Like other customers in previous comments, I would like to know if there is a SDK or any other way to control the SLM by Matlab. If you can provide a Matlab example, please let me know it.

Thank you. YLohia

(posted 2021-11-12 02:42:43.0) Hello, thank you for contacting Thorlabs. The full SDK package for the HD1 is currently a work in progress. We currently only have a simple programming example file written in C, which I have sent you directly. longchao chen

(posted 2021-08-10 15:48:12.57) 1、Is there only the trigger output for the EXULUS-HD2, not including the function of trigger input?

2、When using the sequence output, does a trigger signal output after each frame of the SLM?

3、Does the sequence output function support user-definded pattern? And what is the shortest time interval of the sequence function?

4、Is number of pixel of the user-definded figure should be the same with the SLM?

5、What is the maximum light power that this SLM can withstand?

6、Does the SLM have SDK for secondary development? Such as matlab、labview and other grogramming software can be directly called to control the SLM?

7、Is the polarization state of linearly polarized light still linearly polarized after it is reflected by the SLM? If so, does the polarization Angle change?

8、If no images are loaded, or if white images are loaded, will the SLM still produce higher order diffraction? cdolbashian

(posted 2021-08-26 05:25:59.0) Thank you for your inquiry with us here at Thorlabs.

To answer each question directly:

1. Yes.

2. No, the sequence mode provides pattern switching with user defined interval time in software. The trigger output signal refers to the SLM panel refresh rate (i.e. 60Hz for EXULUS-HD2). They are not synchronized to each other.

3. Yes, the sequence mode in software supports the image/pattern upload from File Mode (user defined), Frame Mode, CGH Mode and Pattern Mode. Theoretically, the minimum interval time is the reciprocal value of frame rate: i.e. 1/(60Hz)=0.167s, but the actual performance may be limited by computer hardware.

4. The resolution of the user defined image/pattern is best to be consistent with the SLM panel. A scaling and/or cropping will be applied for uploaded image/pattern with resolution that is different than the panel and is selected in the “File Mode”. Please refer the details of “File Mode” to Page 34 -35 of User Manual.

5. Pulsed (ns) 0.22 J/cm2 (532 nm, 6.8 ns, 10 Hz, Ø200.5 µm) , Pulsed (fs) 0.0935 J/cm2 (515 nm, 203.3 fs, 100 Hz, Ø108.2 µm)

6. We will release the SDKs for C/C++, LabVIEW and Python in the near future, but do not have them right now.

7. The reflection will impact the polarization state of input light. However, if the AOI is defined less than 5°, the change of polarization state shall not be a critical problem for most applications.

8. Regardless of whether the image is uploaded or not, there will always be higher order diffraction.

I have also contacted you directly to continue this conversation. Davide D'Ambrosio

(posted 2021-07-26 04:41:51.907) Hi, I would like to use the Exulus HD2 in an experiment entirely controlled via MATLAB. Like other customers in previous comments, I would like to know if there is a SDK or any other way to control the SLM via MATLAB, thanks YLohia

(posted 2021-07-29 01:58:24.0) Thank you for contacting Thorlabs. The upcoming SDK for EXULUS-HD2/3/4/HP series provides easy integration with C/C++ and Python. Unfortunately, we only plan to support LabVIEW as a third-party software package for this product. We will reach out to you directly with more information on controlling EXULUS-HD2 with MATLAB. Leon S

(posted 2020-12-01 04:17:11.433) Hi, I would like to use the Exulus SLM for scientific tests in a measuring setup with a camera and piezo positioner. Currently measuring is controlled via MATLAB. Is there a way to also control the Exulus SLM via MATLAB? If not, does the Thorlabs Exulus software offer the possibility for external triggering or additional options to sync the SLM with other measuring components? YLohia

(posted 2020-12-04 10:20:11.0) Hello, thank you for contacting Thorlabs. We will reach out to you directly with a MATLAB example for controlling the EXULUS-HD2. Unfortunately, there is no software sync feature and the unit can only be triggered via the 5 V TTL port. Wei-Jen Hsiao

(posted 2020-08-17 00:22:54.11) Hello, I am interested in these SLM products, but I did not find any lifetime information about these products. Can you provide lifetime specifications and test conditions? Thank, YLohia

(posted 2020-08-21 10:28:14.0) Hello, thank you for contacting Thorlabs. Our spatial light modulators are based on liquid crystals and we have found that the lifetime of our liquid crystals is on the order of > 7 years. Our SLMs have two years warranty. Juan Ahuir-Torres

(posted 2020-08-10 13:39:03.36) Ladies and gentlemen,

I am writing about the EXULUS-HD3 device specifications. I would like to ask you if this device could need an air cooling system to operate with infrared (1064nm) nanosecond (500-3ns) pulsed fiber laser at 1 MHz, 20W and 1mJ.

Thanks for your time and if you have any question, please do not hesitate to contact me.

Best regards,

Juan. YLohia

(posted 2020-08-11 09:07:51.0) Hello Juan, thank you for contacting Thorlabs. The EXULUS-HD3 is not designed to sustain long term high-power applications. We have reached out to you directly to discuss other alternatives. user

(posted 2020-08-04 10:45:44.397) Is a SDK available for the software?

Thanks. nbayconich

(posted 2020-08-05 09:25:56.0) Thank you for contacting Thorlabs. A techsupport representative will reach out to you directly regarding your request. Seungjae Lee

(posted 2019-06-03 20:03:43.553) Hi, I am Seungjae Lee who works in Facebook Reality Labs of Redmond, WA.

I am using 4K1/M SLM purchased a couple of weeks ago. However, I recognized that there is a kind of weird artifacts at the SLM plane. I am wondering following things are normally observed or not.

1. Displayed image is unreasonably vibrated. As boundary of the image seems to be stable enough, I guess the displayed things are continuously vibrated.

2. There is a strange straight line that shows nothing within the SLM region. It looks like a seam between two different monitors.

I suspected inferior HDMI cable and changed it, but the problem was not solved.

Actually, I think an inferior SLM has been delivered.

I need to solve this problem as soon as possible. Please contact me soon.

Thanks,

Best, nbayconich

(posted 2019-06-05 02:54:03.0) Thank you for contacting Thorlabs. It is difficult to say what exactly could be the causing the issues you have seen with your EXULUS SLM without knowing more about the display mode, display settings, pattern type uploaded etc. The SLM LCoS panel should output a clear image whether using the file upload or CGH mode, a blank line through the center of the generated image could indicate a damaged display or damaged pixels but it will best for us to reach out to you first to help troubleshoot. A techsupport representative will contact you directly, for further technical inquiries please contact us directly at techsupport@thorlabs.com. Seonghoon Kim

(posted 2019-04-24 04:14:01.333) Hello,

I'm looking for very stable 4K SLM for my application. I will put this SLM on the signal detection path. So phase fluctuation is very important for us.It seems like EXULUS-4K1 has 5% phase fluctuation. I wonder if I can get a data of this fluctuation since if this fluctuation is very periodic then we can filtered it out later.

Please reply to me.

Thanks,

Sean YLohia

(posted 2019-04-24 09:36:34.0) Hello Sean, thank you for contacting Thorlabs. We will reach out to you directly regarding this. daw

(posted 2017-10-31 10:32:44.233) Would it be possible to create a version of the Exulus that would work in NIR? I am mostly interested in wavelengths between 900 and 1100 nm.

Thanks! tfrisch

(posted 2017-12-13 11:20:30.0) Hello, thank you for contacting Thorlabs. I have logged your request in our internal engineering forum. While we do not currently offer an SLM into the NIR, I will reach out to you about your application and potential solutions. h.aguiar

(posted 2017-04-21 14:06:15.003) Dear Sir/Madam,

What is the response time of the liquid crystal? (not the connection bandwidth/refresh rate)

Thanks nbayconich

(posted 2017-05-22 10:18:01.0) Thank you for contacting Thorlabs. The EXULUS-HD1 has been tested to show a 0 – 2π phase rise and fall time of 61.2ms(rise) and 17.4ms(fall) and a 0 – π phase rise and fall time of 7.4ms and 11.5ms both at 633nm.

The EXULUS-4K1 has shown a 0 – 2π phase rise and fall time of 9.4ms(rise) and 34.9ms(fall) both at 633nm. A Techsupport representative will reach out to you directly. |

Click to Enlarge

The top panels of the EXULUS-HD2, EXULUS-HD3 (shown), and EXULUS-HD4 provide HDMI-compatible and USB 2.0 ports for connecting the SLM to a PC, SMA trigger output, power supply input, and an on/off switch.

- Liquid Crystal on Silicon (LCoS) with One of Two Coatings:

- Aluminum Coating for 400 - 850 nm (EXULUS-HD2)

- Aluminum Coating for 650 - 1100 nm (EXULUS-HD3)

- Dielectric Coating for 1550 nm (EXULUS-HD4)

- 1920 x 1200 (WUXGA) Resolution

- HDMI*-Compatible and USB 2.0 Input Connectors

- SMA Trigger Output

- Optic Axis: 0°

- Housing Dimensions: 155.9 mm x 104.3 mm x 42.0 mm

The EXULUS-HD2, EXULUS-HD3, and EXULUS-HD4 Spatial Light Modulators (SLMs) are designed to operate at 400 - 850 nm, 650 - 1100 nm, and 1550 nm, respectively. Each SLM has an LCoS panel with a resolution of 1920 x 1200 in a compact housing. They also feature high phase stability and SMA trigger outputs for synchronized applications. Two sides of the housing each offer two universal mounting holes that accept both 8-32 and M4 threads; please note that these threads are separated by 50 mm. The front panel includes four 4-40 taps for 30 mm cage system compatibility; we do not recommend connecting these spatial light modulators to a cage system for applications that require precise alignment.

*HDMI is a trademark or registered trademark of HDMI Licensing Administrator, Inc. The use of such trademark by Thorlabs does not constitute or imply any affiliation with or endorsement or sponsorship by such trademark owner.

| Key Specificationsa | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Operating Wavelength |

Panel Resolution |

Fill Factor | Panel Active Area | Pixel Pitch | Phase / Retardance Rangeb |

Frame Rate | Fluctuation/ Flickering (RMS)c |

Output Trigger |

| EXULUS-HD2 | 400 - 850 nm | 1920 x 1200 (WUXGA) |

>92% | 15.42 mm x 9.66 mm | 8 µm | 2π at 633 nm | 60 Hz | <0.01% | Yes (SMA) |

| EXULUS-HD3 | 650 - 1100 nm | 2π at 1064 nm | <0.05% | ||||||

| EXULUS-HD4 | 1550 nm | 2π at 1550 nm | <0.15% | ||||||

Click to Enlarge

The adapter board and SLM head include 8-32

(M4 x 0.7) threads for mounting in the separate-panel configuration. Mounting the SLM head in a kinematic mirror mount provides tip and tilt adjustments.

Click to Enlarge

The High-Power SLM housing features two 8-32 (M4 x 0.7) taps for mounting in the all-in-one configuration.

Click to Enlarge

The LK220 liquid chiller can be easily connected to a High-Power SLM using the valved CPC quick-disconnect fittings and a 2.5 mm stereo jack.

- Liquid Crystal on Silicon (LCoS) with an Aluminum Coating for

400 - 850 nm or 650 - 1100 nm - 1920 x 1200 (WUXGA) Resolution

- High Power Handing: ≤200 W/cm

- Liquid Cooling Module Included on SLM Head Compatible with LK220 Thermoelectric Liquid Chiller

- HDMI*-Compatible and USB 2.0 Input Connectors

- SMA Trigger Output

- Optic Axis: 0°

- Housing Dimensions:

- All-in-One: 220.0 mm x 104.0 mm x 68.0 mm

- Separate-Panel: 420.0 mm x 104.0 mm x 42.0 mm

Thorlabs' High-Power Spatial Light Modulators (SLMs) are designed for applications requiring highly stable phase operation, which include interferometry, quantum orbital angular momentum, and laser processing. To improve thermal stability and allow for high-power handling (≤200 W/cm), these SLM units feature liquid cooling modules, which are compatible with the Thorlabs LK220 Thermoelectric Liquid Chiller (sold below) or an equivalent chiller.

These Exulus models consist of three main parts: the main unit, an adapter board, and the SLM head. Each SLM head contains a liquid cooling module and an integrated NTC thermistor, as well as two pre-installed 1/4" hoses with CPC®† valved quick-connect coupling inserts for connecting to the LK220 chiller. If additional coupling inserts are needed, Thorlabs offers replacement items that are compatible with the high-power SLMs. The FPC connectors and a circuit board that connects the main unit to the SLM head are housed in the adapter board.

As shown in the images above, these SLM devices can be mounted in either the All-in-One or Separate-Panel configuration. A Quick Start Guide with detailed instructions on switching between the two modes is included with each unit. For mounting the Exulus in the All-in-One configuration, two sides of the housing each offer two universal mounting holes that accept both 8-32 and M4 x 0.7 threads; please note that these mounting holes are separated by 75 mm. The adapter board and SLM head each feature one universal mounting hole that accepts both 8-32 and M4 x 0.7 threads to accommodate mounting in the Separate-Panel configuration. For tip and tilt adjustments of the SLM panel, the head can be mounted in a kinematic mount with a flat face plate, such as the POLARIS-K1E Ø1" Mirror Mount, using the Ø1.00" (Ø25.4 mm) smooth mounting surface of the housing.

The SLM software (Thorlabs EXULUS software package) features temperature read out options when the Thorlabs LK220 chiller is connected. The sensor setting can be set to internal or external, which reads the temperature of the output coolant or the thermistor in the SLM head, respectively. A status bar at the bottom of the main software GUI displays the actual temperature reading from the chiller. Note that these functions are not available for third-party chillers, but the thermistor can be read out by the TSP01 temperature logger or a third-party temperature reader with a compatible 2.5 mm stereo connector. If additional remote controls are needed for operating the chiller, the LK220 Thermoelectric Liquid Chiller software should be used. Detailed performance specifications for the LK220 thermoelectric liquid chiller can be found in the full web presentation.

*HDMI is a trademark or registered trademark of HDMI Licensing Administrator, Inc. The use of such trademark by Thorlabs does not constitute or imply any affiliation with or endorsement or sponsorship by such trademark owner.

†CPC® is a registered trademark of Colder Products Company.

| Key Specificationsa | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Operating Wavelength |

Panel Resolution |

Fill Factor | Panel Active Area | Pixel Pitch | Phase / Retardance Rangeb,c |

Frame Rate | Fluctuation/ Flickering (RMS)d |

Output Trigger |

| EXULUS-HD2HP | 400 - 850 nm | 1920 x 1200 (WUXGA) |

>92% | 15.42 mm x 9.66 mm | 8 µm | 2π at 633 nm | 60 Hz | <0.01% | Yes (SMA) |

| EXULUS-HD3HP | 650 - 1100 nm | 2π at 1064 nm | <0.15% | ||||||

Products Home

Products Home

Zoom

Zoom

Exulus® Spatial Light Modulators

Exulus® Spatial Light Modulators