Translating Cage Segment Plates

- Laterally Offset Two Cage Segments

- Internally SM-Threaded Moving World

- Post Mountable via a 4-40 (M3) or 8-32 (M4) Tapped Hole

CPX1

30 mm Translating Cage Segment Plate

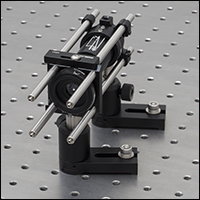

Application Idea

LCPX1 Post-Mounted via 8-32 (M4) Tap on Bottom with Moving World Offset by 8 mm

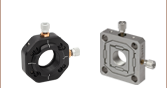

LCPX1

60 mm Translating Cage Segment Plate

SPX1

16 mm Translating Cage Segment Plate

Please Wait

Click to Enlarge

Iris Mounted in CPX1 Translated 4 mm to Select Output from Beam Displacer

Features

- Translates a 16 mm, 30 mm or 60 mm Cage System Subassembly Along X or Y Axis

- Position-Locking Screw with 5/64" (2.0 mm) Hex

- Post Mountable via Tapped Hole

- SM05, SM1, or SM2 Internally Threaded Moving World

- Precision Machined Dovetail Enables Quick, Repeatable Adjustment

- Laser Engraved Scale and Witness Line on Front

Thorlabs' 16 mm, 30 mm, and 60 mm Translating Cage Segment Plates allow an entire cage subsystem to be laterally offset. Each consists of two plates: the fixed world plate is attached to a fixed cage segment, while the moving world plate translates all attached cage elements. This makes the translating cage segment plate ideal for compensating for the beam displacement caused by optics such as plate beamsplitters, anamorphic prism pairs, and beam displacers (shown to the right).

To translate the moving world, first loosen the position-locking cap screw located on the top of the part with a 0.05" (1.3 mm) hex key for the 16 mm segment plate or 5/64" (2.0 mm) hex key for the 30 mm and 60 mm segment plates (hex keys not included). Then, slide the moving world plate along the dovetail until the desired displacement is achieved. Tighten the position locking screw and then attach any additional components to the moving world plate. Alternatively, these translating cage plates can be installed at 90° for vertical translation (shown below) to correct for beam displacement in the Y axis, but they cannot be post-mounted in this orientation.

The 16 mm translating cage plate can be mounted on Mini-Series Posts via a 4-40 (M3) mounting hole on the bottom of its fixed world plate. The 30 mm and 60 mm translating cage plates are equipped with an 8-32 (M4) tapped hole on the bottom of their fixed world plates for mounting onto Ø1/2" posts.

The fixed world plates have four blind holes for attaching cage rods. Each rod is held in place by a side-located M4 x 0.7 locking setscrew, which can be secured using a 5/64" (2.0 mm) hex key. The moving world plates have four 4-40 tapped holes to attach SR series cage rods (16 mm plate) or ER series cage rods (30 mm and 60 mm plates). To aid in alignment, the fixed world plates are laser engraved with a 1 mm graduated scale, while the moving world plates are engraved with a witness line.

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see image below). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

| Posted Comments: | |

cbrideau

(posted 2018-04-02 10:57:46.533) This would be great for incorporating anamorphic prism pairs into the cage system. The beam offset of these prisms prevented me from doing this in the past. Will definitely keep these in mind for future builds. YLohia

(posted 2018-04-03 05:04:45.0) Hello, thank you for your feedback. We are always happy to hear of potential new applications of our products. I have posted your feedback on our internal engineering forum to keep your application in mind when adding features/modifications to the current version of the CPX1 mount. |

Click to Enlarge

SPX1 Rotated 90° to Correct for Vertical Beam Displacement within a 16 mm Cage System

- Translates 16 mm Cage System Subassembly Along X or Y Axis

- Internal SM05 (0.535"-40) Thread on Moving World

- Post Mountable via a 4-40 (M3) Tapped Hole

- Laser Engraved ±6 mm Scale and Witness Line on Front

The SPX1(/M) Translating Cage Segment Plate allows a 16 mm cage system to be laterally offset. The moving world plate has a 5.3 mm deep, SM05-threaded (0.535"-40) central bore for attaching lens tubes or SM05-threaded mounted optics, such as lenses or irises. A single SM05RR retaining ring (included) can be used for securing an unmounted optic up to 3.7 mm thick against the retaining lip of the moving world plate. The aperture on the fixed world plate is 0.74" wide, so that even at the maximum offset of 6 mm, the moving world will still have a minimum clear aperture of 0.35" (8.9 mm) with the retaining ring installed. The maximum clear aperture is 0.44", which is the inner diameter of the retaining lip on the moving world plate.

Click to Enlarge

CPX1 Rotated 90° to Correct for Vertical Beam Displacement within a 30 mm Cage System

- Translates 30 mm Cage System Subassembly Along X or Y Axis

- Internal SM1 (1.035"-40) Thread on Moving World

- Post Mountable via an 8-32 (M4) Tapped Hole

- Laser Engraved ±6 mm Scale and Witness Line on Front

The CPX1(/M) Translating Cage Segment Plate allows a 30 mm cage system to be laterally offset. The moving world plate has a 5.3 mm deep, SM1-threaded (1.035"-40) central bore for attaching lens tubes or SM1-threaded mounted optics, such as filters or irises. A single SM1RR retaining ring, sold separately, can be used for securing an unmounted optic up to 3.3 mm thick against the retaining lip of the moving world plate. The aperture on the fixed world plate is 1.30" wide, so that even a maximum offset of 6 mm will still have a minimum clear aperture of 0.89". The maximum clear aperture is 0.94", which is the inner diameter of the retaining lip on the moving world plate.

Click to Enlarge

LCPX1 Rotated 90° to Correct for Vertical Beam Displacement within a 60 mm Cage System

- Translates 60 mm Cage System Subassembly Along X or Y Axis

- Internal SM2 (2.035"-40) Thread on Moving World

- Post Mountable via an 8-32 (M4) Tapped Hole

- Laser Engraved ±12 mm Scale and Witness Line on Front

The LCPX1(/M) Translating Cage Segment Plate allows a 60 mm cage system to be laterally offset. The moving world plate has a 5.84 mm deep, SM2-threaded (2.035"-40) central bore for attaching lens tubes or SM2-threaded mounted optics, such as lenses or irises. A single SM2RR retaining ring, sold separately, can be used for securing an unmounted optic up to 3.2 mm thick against the retaining lip of the moving world plate. If the moving world is offset at the maximum of 12 mm, the moving world will still have a minimum clear aperture of 1.73" (43.9 mm). The maximum clear aperture is 1.90", which is the inner diameter of the retaining lip on the moving world plate.

Products Home

Products Home

Zoom

Zoom

Translating Cage Segment Plates

Translating Cage Segment Plates