Hermetically Sealed Piezo Actuators

- Hermetically Sealed Housing for Harsh Environments

- Option for High-Temperature Operation Up to 210 °C

- Sub-Millisecond Response Time with No Load

- Free Stroke Displacements of 12.0 µm or 17.0 µm

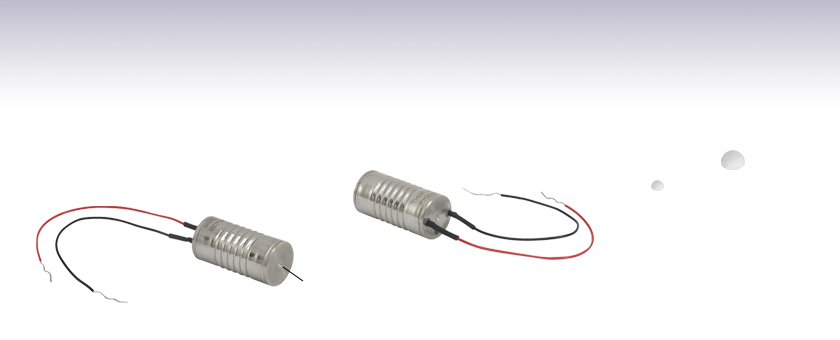

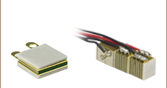

PH24SRW

150 V PZT, 17.0 µm,

Hermetically Sealed

Top

Bottom

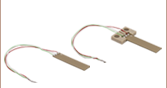

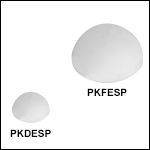

PKFESP

Ø5.0 mm

Hemisphere

PKDESP

Ø2.5 mm

Hemisphere

Mounting Divot

(Each End)

Please Wait

| Piezo Selection Guide |

|---|

| Piezoelectric Ceramic Stacks |

| Discrete, Square |

| Discrete, Square with Through Hole |

| Discrete, Round |

| Discrete, Ring |

| Discrete, Hermetically Sealed |

| Discrete, Shear (1D to 3D Positioners) |

| Co-Fired: Square, Square with Through Hole, Round, & Ring |

| Co-Fired or Discrete: Square with Strain Gauges |

| Piezoelectric Crystal Stacks |

| Square |

| Piezoelectric Chips |

| Mounted Piezoelectric Actuators |

| Ultrasonic Piezo Chips & Transducers |

| Vibrating Piezo Actuator |

Proper Mounting Method

Using Hemispheres

(Sold Separately Below)

Features

- 0 to 150 V Drive Voltage Range

- Free Stroke Displacements of 12.0 µm or 17.0 µm

- Hermetically Sealed, Laser Welded Metal Packages for Harsh Environments

- PH24SRZW: Can Operature at Temperatures Up to 210 ºC

- For Use in Open-Loop Setups

- Pre-Attached Wires (~75 mm Long) for Ease of Integration

- Vacuum Compatibility: 10-8 Torr

- Ideal for OEM Applications

- Hemispheric Mating Pieces Available Separately

- Custom Options Available, Please Contact Tech Support

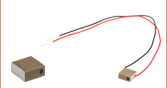

Thorlabs' Hermetically Sealed Piezoelectric Actuators each consist of a piezoelectric stack mounted inside a metal bellows and sealed with end caps under N2. The bellows and end caps are laser welded to create a hermetic seal, resulting in longer service life and higher reliability, even under vacuum or in environments with high humidity, water, or oil exposure.

The PH24SRW actuator uses a PK4FQP1 Discrete Piezoelectric Stack inside the metal bellows to provide a 17 μm free stroke displacement. The PH24SRZW actuator has a shorter, 12 μm free stroke displacement, and is designed for higher temperature applications, up to 210 °C, with a discrete stack of hard Lead Zirconate Titanate (PZT) inside the metal bellows. Full specifications, drawings, and performance plots can be accessed by clicking the Info icons ![]() in the table below.

in the table below.

Divots in the metal end caps are intended for use with ceramic mounting hemispheres, as illustrated in the diagram above. This configuration assists in directing the force along the actuator's axis of translation, while making it possible to interface the actuator with an off-axis load, as the hemisphere's curved surface routes the applied force along the actuator's translating axis. The hemispheres should be epoxied to the user assembly while the actuator is held in place by the hemispheres alone. If attaching the actuator directly to the user assembly, we recommend using 353NDPK, TS10, or Loctite Hysol 9340 epoxies.

For use in high vacuum enivronments, we recommend cleaning the part with isopropyl alcohol (IPA) in an ultrasonic immersion tank and then baking it at 60 °C for two hours. If using a custom baking process, the maximum baking temperature should be less than 150 °C for the PH24SRW, less than 210 °C for the PH24SRZW, and the baking time should be less than 2 hours.

Thorlabs' piezoelectric chips are individually inspected using a proprietary AI algorithm to ensure the highest quality of our line of piezo chips, actuators, and transducers.

Caution: After driving, the piezo is fully charged. Directly connecting the red and black wires has the risk of electricity discharging, spark, and even failure. We recommend using a resistor (>1 kΩ) between the wires to release the charge.

Click to Enlarge

Dicing the PZT Block into Individual Elements

Thorlabs' In-House Piezoelectric Manufacturing

Our piezoelectric chips are fabricated in our production facility in China, giving us full control over each step of the manufacturing process. This allows us to economically produce high-quality products, including custom and OEM devices. A glimpse into the fabrication of our piezoelectric chips follows. For more information about our manufacturing process and capabilities, please see our Piezoelectric Capabilities page.

- Build Blocks from Flexible Sheets of Lead Zirconate Titanate (PZT) or BiScO3-PbTiO3 (BSPT) Powder

- Screen Print Electrodes on Each Individual Sheet

- Layer the Printed Sheets One Top of Another

- Consolidate the Layered Sheets in an Isostatic Press

- Dice the Block into Individual Elements

- Purge Solvent and Binder Material Residues by Heat Treating the Elements

- Sinter the Elements to Fuse the Piezoelectric Pressed Powder and Grow PZT or BSPT Crystals

- Lap the Elements to Achieve Tight Dimensional Tolerances: ±5 µm for Each Element

- Screen Print the Outer Electrodes on the Elements

- Align the Individual PZT or BSPT Crystals Along the Same Axis by Poling the Elements

| Webpage Features | |

|---|---|

| Clicking this icon below will open a window that contains specifications, mechanical drawings, and graphs. | |

| Posted Comments: | |

| No Comments Posted |

Hermetically sealed piezoelectric actuators are ideal for harsh environments. Customers looking for a higher stroke should choose the PH24SRW with the 17 μm free stroke displacement, while those who need a higher temperature operation, up to 210 °C, should choose the PH24SRZW.

| Sizes | |

|---|---|

| Item # | Diameter |

| PKCESP | 2.0 mm |

| PKDESP | 2.5 mm |

| PKJESP | 3.0 mm |

| PKFESP | 5.0 mm |

- Hemispheres Provide Stable Contact for Actuation

- Sold in Packs of 25

These alumina hemispheres are compatible with the end plates of the hermetically sealed piezoelectric stacks sold above. They can be used to provide stable contact between the stack housing and a lever arm. We do not recommend using hemispheres with diameters greater than 6 mm with the actuators sold above due to low divot penetration depth. These hemispheres have a diameter tolerance of ±0.1 mm. Thorlabs also offers other sizes of hemispheres as well as end plates and end cups for use with other piezoelectric stacks.

Products Home

Products Home

Zoom

Zoom

Hermetically Sealed Discrete Piezo Stack

Hermetically Sealed Discrete Piezo Stack