High-Reflectance PTFE Sheets

- Omnidirectional, Diffusely Reflective PTFE Ideal for UV Sterilization

- >93% Average Reflectance from 250 to 400 nm

- Usable at Temperatures up to 260 °C

- Hydrophobic and Chemically Inert

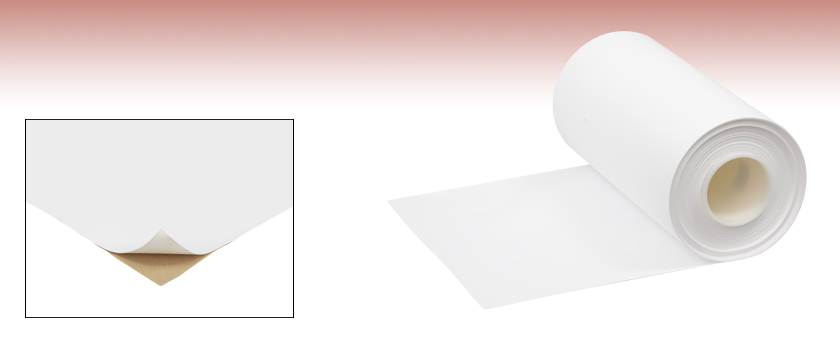

PMR10P1

33 cm x 33 cm Sheet with

Adhesive Backing

PMR10R4

34 cm x 21 m Sheet

Please Wait

| Specifications | |||||

|---|---|---|---|---|---|

| Item # | PMR10P1 | PMR10R3 | PMR10P2 | PMR10R4 | |

| PTFE Dimensions |

Thickness | 0.75 mm | |||

| Width | 33 cm | 33 cm | 34 cm | 34 cm | |

| Length | 33 cm | 21 ± 1.5 m | 34 cm | 21 ± 1.5 m | |

| Adhesive Backing | 3M 93020 Tape w/ 300LSE Adhesive, 0.20 mm Thicka | None | |||

| Average Reflectance (Click for Graph; Raw Data) |

>93% (250 - 400 nm) >92% (400 - 800 nm) |

||||

| Dielectric Constant | 1.7 | ||||

| Operating Temperature | -40 to 260 °C | ||||

| UL Rating | 5VA V-0 (UL 94), f1 (UL 746C) | ||||

Click to Enlarge

PMR10 Series PTFE Sheet Reflectance Compared to Common Metals

Features

- Porous, Sintered PTFE for High Omnidirectional Tensile Strength

- Nearly Lambertian Reflectance

- Ravg > 93% (250 - 400 nm)

- Skived (Shaved) for Precise Thickness Control

- Naturally Hydrophobic Material (IP-Rated)

- Contact Tech Sales for Custom Requests of Different Lengths

These polytetrafluoroethylene (PTFE) sheets provide highly efficient and uniform diffuse reflection of UV light, making them ideal for applications such as UV irradiation and sterilization of objects. Their average reflectance of >93% from 250 to 400 nm provides better performance than polished aluminum or stainless steel (see the graph to the right). PTFE is also chemically inert and UV resistant, traits not found in common polymers such as polyethylene, polycarbonate, and nylon.

Sintering & Skiving

These sheets are produced by first sintering PTFE particles, where the particles are fused together using heat and pressure to produce a cohesive porous solid. This technique allows for precise control of the output material properties, including pore size and pore volume. The material is then skived, a process in which thin layers of material are cut from the bulk, to produce precisely 0.75 mm thick sheets.

Comparison with Molded PTFE and Extended PTFE (ePTFE)

Sintered and skived PTFE material offers many benefits, such as low flex fatigue, omnidirectional diffuse reflectance, and compatibility with heat and vibrational welding. Testing† also shows that PTFE samples that have been sintered and then skived exhibited a lower and more consistent median pore diameter (roughly 1 to 7 µm) than those that were sintered and then molded (roughly 7 to 27 µm). The robust pore structure also makes it safe to handle during assembly and it can be easily mounted inside or outside of an enclosure. This is in contrast with ePTFE, made by heating and stretching extruded PTFE, which is fragile and requires a supporting layer due to the low strength of the nodes and fibrils that comprise it; ePTFE membranes are also sensitive to temperature and pressure.

† Testing was performed by Porex Corporation. Please see the Ultraviolet Reflectance of Microporous PTFE White Paper for more information.

| Posted Comments: | |

Dave Hommes

(posted 2024-04-01 11:04:21.957) Do you have data detailing degradation to UV wavelengths in the 254nm range, over set periods of time? jdelia

(posted 2024-04-05 09:57:20.0) Thank you for contacting Thorlabs. Unfortunately, at this time, we do not have data on UV degradation over time for our PMR10P1. However, in page 10 of the "Ultraviolet Reflectance of Microporous PTFE" white paper we offer, it states "Pure PTFE, unlike many other polymers, shows little degradation under UV exposure above 240 nm", which is shorter than your 254 nm source. EBERECHI ICHI

(posted 2023-01-18 08:31:05.803) Please, what is the reflectance up to the range of 1700um (NIR-band)? you only gave information upto 400um jdelia

(posted 2023-01-19 12:55:23.0) Thank you for contacting Thorlabs. Assuming you meant "1700 nm," then we do already have this data available on the website. You would just need to go to the "Average Reflectance" row of the "Specifications" table on the product family page. There we offer a reflectance graph that goes up to 2450 nm as well as downloadable raw data. user

(posted 2022-05-05 15:00:51.79) To follow the discussion of Joao Lopes, which type of product would fit better for a specular reflection in the UV range? cdolbashian

(posted 2022-05-10 04:12:42.0) Thank you for reaching out to us Jan. You are seeking to create a large asymmetric parabolic surface. Unfortunately, we do not have the capability to create such a surface with the methods which we have access to. We do not have a suggestion for a solution to such an application unfortunately. For future application-based discussions, please feel free to email techsupport@thorlabs.com. João Lopes

(posted 2022-04-07 10:08:40.573) Hi,

Will this sheet be of a good use for a solar reflector?

The range of interest being UV radiation. cdolbashian

(posted 2022-04-13 11:17:31.0) Thank you for reaching out to us João. The PMR10P1 does indeed have a high reflectivity for UV spectra (easily over 90%), however, the reflection is an incoherent diffuse reflection. Based on what we discussed via email, it seems like you are more interested in a specularly reflective surface, rather than a diffuse one. user

(posted 2021-08-19 05:18:06.637) Hello, I would like to ask if these sheets are fluorescent, i.e., if UV illumination causes reemission at different wavelengths. If yes, are there any additional measured data available that would show the Stokes shift, etc.? Thank you very much! cdolbashian

(posted 2021-09-10 11:06:25.0) Thank you for contacting us here at Thorlabs! There is no evidence that these PTFE sheets are fluorescent, they are simply highly reflective within the UV spectra. |

Products Home

Products Home

High-Reflectance PTFE Sheets

High-Reflectance PTFE Sheets