Fiber Optic Termination Tools

- Tools for Installing New Fiber Optic Connectors and Building Patch Cables

T06S13

Fiber Stripping Tool

AFS900

Adjustable Fiber and Wire Stripping Tool

FSGT

Coating Stripping Tweezers

for Fluoride Fibers

T186

Kevlar Cutting

Shears

CT042

Connector Crimp Tool

FTS4

Three-Hole Fiber Stripper

TBS1400

Tight Buffer Stripper

TSK1

Fiber Stripping Kit

Please Wait

Click to Enlarge

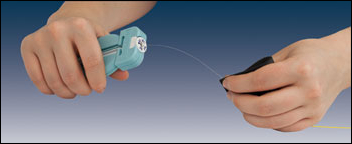

T12S16 Stripping Tool Shown with Included BFG1 Fiber Gripper

Thorlabs offers the following tools used to install connectors on single mode and multimode optical fiber.

- Fiber Buffer Stripping Tools, Stripping Kit, and Replacement Blades: Used to Remove the Buffer from an Optical Fiber, for Ø80 to Ø1550 μm Clad Fibers; Kit Also Includes Fiber Jacket Stripper

- Three-Hole Fiber Stripping Tool: Used to Strip the Fiber Jacket (Furcation Tubing), Buffer, and Coating

- Coating Stripping Tweezers: Used to Remove the Coating from Fluoride Fibers and Other Soft Fibers

- Adjustable Fiber Buffer and Jacket Stripping Tool: Used to Strip the Fiber Jacket and Buffer from an Optical Fiber, for Jackets and Buffers Down to Ø400 µm

- Vytran Tight Buffer Stripping Tool: Used to Remove Tight Buffers Without Cutting the Coating, for Ø900 µm to Ø1400 µm Buffered Fibers

- Furcation Stripping Tools and Replacement Blades: Used to Remove the Fiber Jacket from an Optical Fiber, for Ø3 mm and Ø3.8 mm Fiber Jackets

- Connector Crimp Tool: Used to Crimp SMA, FC, SC, and ST®† Connectors

- Kevlar Cutting Shears: Carbon Steel Blades Used to Cut through Kevlar Fibers

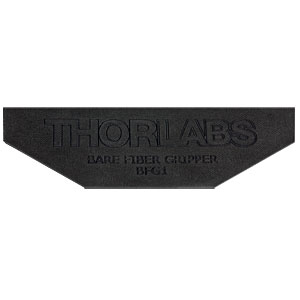

- Fiber Gripper: Provides a Secure Hold without Damaging the Fiber

- Fiber Optic Disposal Unit: Offers a Safe Solution for Disposal of Cleaved Fiber Ends, Epoxy and Syringes, and Other Sharp Objects

Click options in the guide below to quickly navigate the page.

†ST® is a registered trademark of Lucent Technologies, Inc.

| Posted Comments: | |

Ines Ruiz

(posted 2024-07-05 11:01:39.047) Does the T06S13 Fiber Buffer Stripping Tool work with polyimide coated optic fibers? If not, are there any other options to strip these fibers? Thanks! ksosnowski

(posted 2024-07-11 12:09:12.0) Hello Ines, thank you for reaching out to us. Polyimide is somewhat difficult to mechanically strip by hand though it can be done with mechanical blades. Other common removal methods include using heat to burn the buffer or chemicals to strip it. We also sell a polyimide fiber stripping station for fiber as our FWS100. I have reached out directly to discuss your application in further detail. Chang Liu

(posted 2024-01-05 18:03:54.5) Hello, may I know the diameter of the third hole of FTS4? Many thanks! jpolaris

(posted 2024-01-05 05:21:37.0) Thank you for contacting Thorlabs. The third and smallest hole of FTS4 is designed to strip the cable down to the 125 μm diameter cladding. Tzu-Hsiang Lin

(posted 2023-09-27 13:45:20.077) Hello,

This is Tzu-Hsiang Lin.

I have already purchased the T06S13 fiber stripper. However, I would like to replace the fiber guide and the replacement blade with what the T28S46 and M44S63 models use.

Do you have these replacement parts available for sale?

Thank you

Best regards,

Tzu-Hsiang Lin cdolbashian

(posted 2023-10-03 01:27:04.0) Thank you for reaching out to us with this inquiry. I have contacted you directly with some details regarding the acquisition of such replacement blades. 书广 马

(posted 2023-08-25 09:32:56.033) 这个工具可以用于塑料光纤剥皮吗?

塑料光纤规格:光纤有2层,纤芯层,纤芯直径0.265mm,一共8根纤芯,外面一个包层,包层直径:1.3mm.光纤在包层内呈现不规则排布。 cdolbashian

(posted 2023-10-02 04:29:04.0) The question asked:

Can this tool be used for plastic optical fiber cleaving? Plastic optical fiber specifications: optical fiber has 2 layers, core layer, core diameter 0.265mm, a total of 8 cores, the outside of a cladding, cladding diameter: 1.3mm. optical fiber in the cladding presents an irregular arrangement.

------------------------

I have contacted you directly with some more inquiries, but based on your description and the images shared with me, this does seem feasible. KiSik Kim

(posted 2023-04-17 14:15:45.313) Dear Thorlabs.

Hi, I'm a graduate student in Korea.

I have a question about Fiber and Fiber Stripper.

I have 'FG365LEC' multimode optical fiber and i want to guide pulse laser using it. When I used it, my PI recommended stripping the fiber.

But I'm not sure stripping is right. If okay, which stripper should I use? In the datasheet, I can't find a suitable model(fiber buffer stripping tool).

Could you advise me?

Sincerely.

Kim. jgreschler

(posted 2023-04-17 09:18:51.0) Thank you for reaching out to Thorlabs. The stripping tool we recommend for FG365LEC is the part number T21S31, which is effective for removing the coating over short lengths. user

(posted 2023-03-08 13:06:20.317) Can your recommend a T06S13-style tool to remove the 900um tight buffer jacket from SMF-28-100 fiber ? jgreschler

(posted 2023-03-08 08:56:41.0) Thank you for reaching out to Thorlabs. The product number FTS4 on the same product page has a function suitable for stripping 900um buffer off of SMF28. Amit Pascal

(posted 2022-03-31 18:13:55.987) Dear madam/Sir

Please recommend on the required stripping tools in order to perform the following:

Stripping a loose tube 900um , of a 250um fiber.

we need to expose a predefine sector of the fiber , so we need a tool to "separate" the jacket of eth fiber in two end , and then cut vertically the jacket to expose the fiber.

Thanks

Amit jgreschler

(posted 2022-04-06 10:46:24.0) Thank you for reaching out to Thorlabs. Unfortunately we do not carry a device that is capable of cutting vertically along a 900um fiber tube, either for loose or tight fiber optic cables. You may look into using an AFS900 to make the horizontal cuts you have described on either end of your area of interest. Swagatha Ghosh

(posted 2020-03-12 05:59:53.27) Hello,

We want to fit 'FG400UEP - 0.22 NA, Ø400 µm Core Multimode Fiber, High OH with Polyimide Coating, for 250 - 1200 nm ' into '10440A - Standard SMA905 Multimode Connector, Ø440 µm Bore, SS Ferrule'.

Could you please suggest which Fiber Stripping Tool is suitable to remove the coating?

Regards. YLohia

(posted 2020-03-12 10:38:48.0) Hello, thank you for contacting Thorlabs. We recommend the FWS100 Vytran Polyimide Fiber Stripper (https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=13473&pn=FWS100). Alternately, you may use the 10490V connector without stripping the coating of this fiber: https://www.thorlabs.com/thorproduct.cfm?partnumber=10490V user

(posted 2019-10-09 12:36:38.583) If my fiber is FG105UCA (125um cladding/250 um coating), and I use fiber buffer stripping tools(T06S13).

After stripping,how large is the diameter of my fiber?(125 um or 135 um)

How is the accuracy of the fiber diameter?(+/-1 um or other)

If I want my fiber be +/- 1 um, can I use this stripping tool or I need to use Fiber Preparation Station?

thank you. asundararaj

(posted 2019-10-09 04:33:29.0) Thank you for contacting Thorlabs. The cladding size range for the T06S13 is 125 µm to 135 µm. The stripping tool should remove all the coating so you can expect the diameter of your fiber to be 125 µm ± 1 µm. alex.maclean

(posted 2017-10-12 15:18:48.233) The description of this tool says to use the small brush to clean it, but the brush is not sold separately, only in the stripping tool range. It would make more sense to me to include the brush with the gripping mat or have it available on its own. nbayconich

(posted 2017-11-17 04:24:00.0) Thank you for contacting Thorlabs. The FTS4 is not intended to be cleaned with a fine plastic bristled brush just with compressed air. Thank you for bringing this to our attention we will correct the product description on our website.

We can provide you with a free FTS4 and CA4 compressed air as a courtesy service. I will contact you directly with more information. |

Click to Enlarge

Stripping Tool Components

- Self-Aligning Blade Set Assures Concentric Scoring of Buffer or Coating

- Color-Coded Blades are Long-Lasting and Replaceable

- Each Stripping Tool Includes a BFG1 Bare Fiber Gripper

- Foolproof, No-Nick Design

- Fast, Reliable Fiber Stripping

These fiber buffer stripping tools provide a quick, easy, and reliable way to remove the buffer from an optical fiber in preparation for connectorization. A fiber guide and matched blades ensure that the optical fiber is correctly positioned and stripped each time. The blades are color coded to allow for fast identification of the proper fiber stripping tool. Replacement blade sets are available separately (see below) for stripping tools with Item # Prefix T06, T12, T18, T21, or T28. The blades and fiber guide lock are removed using the included assembly tool as illustrated in the diagram to the right. We also offer the TSK1 fiber stripping kit below, which includes a variety of blade sets and fiber guides, as well a fiber jacket stripper, in a compact case.

The BFG1 Bare Fiber Gripper is included with each fiber buffer stripping tool. When removing the buffer from an optical fiber, the textured rubber material of this gripper provides a secure hold without damaging the fiber. This method of gripping is recommended over wrapping or clamping the loose end of the fiber, as these techniques can create microfractures in the fiber. The BFG1 gripper is also sold separately below.

To select the correct fiber stripping tool for your cladding and coating diameter, please expand the Stripping Tool Selection Guide table below.

| Stripping Tool Selection Guide |

|---|

|

Step 1: Note your cladding and coating diameters along with their respective ± tolerances. Note: For Thorlabs fibers, the proper stripping tool can be found on the product page of the fiber in question. |

|||

| Item # | Typical Fiber Cladding/Coating | Cladding Range | Coating Rangea |

|---|---|---|---|

| T04S10 | 80 µm / 170 µm | 65 - 80 µm | 150 - 250 µm |

| T06S13 | 125 µm / 250 µm | 125 - 135 µm | 250 - 343 µm |

| T06S16 | 125 µm / 400 µm | 125 - 135 µm | 343 - 407 µm |

| T08S13 | 125 µm / 250 µm | 125 - 175 µm | 250 - 343 µm |

| T08S40 | 125 µm / 900 µm | 125 - 175 µm | 889 - 1016 µm |

| T10S13 | 200 µm / 300 µm | 180 - 230 µm | 250 - 343 µm |

| T12S16 | 230 µm / 400 µm | 235 - 280 µm | 343 - 407 µm |

| T12S18 | 230 µm / 430 µm | 235 - 280 µm | 407 - 457 µm |

| T12S21 | 230 µm / 500 µm | 235 - 280 µm | 457 - 533 µm |

| T12S25 | 230 µm / 600 µm | 235 - 280 µm | 533 - 635 µm |

| T14S21 | 285 µm / 500 µm | 285 - 330 µm | 457 - 533 µm |

| T16S31 | 325 µm / 650 µm | 335 - 380 µm | 635 - 787 µm |

| T14S18 | 330 µm / 450 µm | 285 - 330 µm | 407 - 457 µm |

| T18S25 | 400 µm / 600 µm | 385 - 430 µm | 533 - 635 µm |

| T18S31 | 400 µm / 730 µm | 385 - 430 µm | 635 - 787 µm |

| T21S31 | 425 µm / 730 µm | 435 - 500 µm | 635 - 787 µm |

| T23S46 | 500 µm / 1000 µm | 505 - 550 µm | 1016 - 1168 µm |

| T28S31 | 630 µm / 780 µm | 605 - 680 µm | 635 - 787 µm |

| T28S46 | 630 µm / 1040 µm | 605 - 680 µm | 1016 - 1168 µm |

| M37S46 | 830 µm / 1040 µm | 835 - 900 µm | 1016 - 1168 µm |

| M37S63 | 830 µm / 1400 µm | 835 - 900 µm | 1397 - 1600 µm |

| M44S63 | 1035 µm / 1400 µm | 905 - 1050 µm | 1397 - 1600 µm |

| M44S67 | 1035 µm / 1600 µm | 905 - 1050 µm | 1600 - 1702 µm |

| M44S68 | 1100 µm / 1350 µm | 1085 - 1115 µm | 1315 - 1385 µm |

| M63S86 | 1550 µm / 2000 µm | 1390 - 1600 µm | 2057 - 2184 µm |

- Jacket Stripping Tool Strips Jackets up to Ø3.0 mm

- Coating/Buffer Stripping Tool Removes Ø250 µm to Ø1016 µm Coatings to Expose Cladding from Ø125 µm to Ø680 µm

- Self-Aligning Blade Set Assures Concentric Scoring of Buffer

- Color-Coded Blades are Long-Lasting and Replaceable

Jacket Stripping Tool

The jacket stripping tool (callout 1 in the contents diagram to the right) provides a quick, easy, and reliable way to remove the outer jacket from an optical fiber. The tool is preconfigured with a Ø0.054" matched blade set and a guide for fiber jackets up to Ø2.5 mm. A guide for Ø3.0 mm jackets is also included in the kit (callout 2). The jacket stripping tool is not interchangeable with the fiber stripping blades or guides designed for the coating/buffer stripping tool and should only be used with only the preinstalled Blade for ".054" guide lock, and Ø2.5 mm or Ø3.0 mm guides.

Coating/Buffer Stripping Tool

The fiber coating/buffer stripping tool (callout 3 in the contents diagram to the right) provides a quick, easy, and reliable way to remove the coating from an optical fiber in preparation for connectorization. Fiber guides for Ø250 - Ø1016 μm coatings (callout 4) and matched blade sets for Ø125 - Ø680 μm claddings (callout 5) are included to ensure that a wide range of fibers can be correctly positioned and stripped. Please refer to the diagram below for details. The blade sets and fiber guide locks are color coded, and the guide locks are stamped with the corresponding blade diameter in inches. The stripping tool comes preloaded with the Ø0.008" stripping blade/guide lock set (red) and Ø0.0135" fiber guide. This configuration exposes Ø125 - 175 µm cladding from Ø250 - 343 µm coated fiber. Blades of the same color are matched pairs that should only be used together; do not mix two halves of different blade pairs. Replacements for a subset of the included blade sets are available separately below. A wide variety of individual fiber coating stripping tools with preinstalled blades and guides are available separately above.

Please see the Tool Configuration Guide and Fiber Stripping Kit Components table below for instructions on identifying the correct blade set and fiber guide for processing your fiber.

Click to Enlarge

Stripping Tool Components

Kit Accessories

The TSK1 kit also includes an assembly tool, instructions, cleaning brush, and BFG1 fiber gripper (callouts 6, 7, 8, and 9, respectively). The textured rubber material of the fiber gripper provides a secure hold without damaging the fiber when stripping fiber coating. This method of gripping is recommended over wrapping or clamping the loose end of the fiber, as these techniques can create microfractures in the fiber. The BFG1 gripper is also sold separately below.

Tool Configuration Guide

Step 1: Note the jacket, coating, and cladding diameters of the fiber to be stripped, along with their respective ± tolerances.

Step 2: Expand the component guide below, then identify the correct fiber guide and blade/guide lock set to strip the fiber jacket or coating. The jacket stripper only includes one blade/guide lock set, which is preinstalled in the tool. When stripping coating, ensure that the coating and cladding dimensions and tolerances fall within the range listed the table below for the selected components.

Step 3: Use the included assembly tool to reconfigure the stripper tools as necessary and follow the instructions in the included pamphlet to strip the fiber.

| Fiber Stripping Kit Components |

|---|

| Callout | Category | Description | Notes/Component Identifier |

| 1 | Jacket Stripper & Accessories |

Jacket Stripper Tool | Preinstalled: Fiber Guide for ≤Ø2.5 mm Jackets & Ø0.054" Blade & Guide Lock Set |

| Ø0.054" (Ø1.37 mm) Blade & Guide Lock | ".054", White | ||

| Fiber Guide for ≤Ø2.5 mm Jackets | "MAX INSL D1 DIA" | ||

| 2 | Fiber Guide for ≤Ø3.0 mm Jackets | "MAX INSL 3.0mm DIA" | |

| 3 | Coating/Buffer Stripper | Coating/Buffer Stripper Tool | Preinstalled: Fiber Guide for Ø250-343 µm Coating & Ø0.008" Blade for Ø125-175 µm Cladding |

| 4 | Fiber Guides for Coating Stripper |

Fiber Guide for Ø250-343 µm Coating | "MAX INSL .0135 DIA" |

| Fiber Guide for Ø343-407 µm Coating | "MAX INSL .016 DIA" | ||

| Fiber Guide for Ø407-457 µm Coating | "MAX INSL .018 DIA" | ||

| Fiber Guide for Ø457-533 µm Coating | "MAX INSL .021 DIA" | ||

| Fiber Guide for Ø533-635 µm Coating | "MAX INSL .025 DIA" | ||

| Fiber Guide for Ø635-787 µm Coating | "MAX INSL .031 DIA" | ||

| Fiber Guide for Ø787-889 µm Coating | "MAX INSL .035 DIA" | ||

| Fiber Guide for Ø889-1016 µm Coating | "MAX INSL .040 DIA" | ||

| 5 | Stripping Blade & Guide Lock Sets for Coating Stripper |

Ø0.0063" (Ø160 µm) Blade for Ø125-135 µm Claddinga | ".006", Purple Set |

| Ø0.008" (Ø200 µm) Blade for Ø125-175 µm Claddingb | ".008", Red Set | ||

| Ø0.012" (Ø300 µm) Blade for Ø235-280 µm Cladding | ".012", White Set | ||

| Ø0.014" (Ø350 µm) Blade for Ø285-330 µm Cladding | ".014", Dark Green Set | ||

| Ø0.016" (Ø400 µm) Blade for Ø335-380 µm Cladding | ".016", Orange Set | ||

| Ø0.018" (Ø450 µm) Blade for Ø385-430 µm Cladding | ".018", Yellow Set | ||

| Ø0.021" (Ø530 µm) Blade for Ø435-500 µm Claddingc | ".021", Blue Set | ||

| Ø0.025" (Ø630 µm) Blade for Ø555-600 µm Cladding | ".025", Light Green Set | ||

| Ø0.028" (Ø710 µm) Blade for Ø605-680 µm Claddingd | ".028", Black Set | ||

| 6 | Other Accessories | Assembly Tool | For Removing Blades & Guide Locks |

| 7 | Micro-Strip Instructions | - | |

| 8 | Cleaning Brush | - | |

| 9 | Rubber Gripper For Bare Fiber | Replacement Item # BFG1 | |

| Item # | Fiber Cladding Range | Compatible Fiber Buffer Stripping Tools |

|---|---|---|

| T06SB | 125 - 135 µm | T06S13, T06S16 |

| T12SB | 235 - 280 µm | T12S16, T12S18, T12S21, T12S25 |

| T18SB | 385 - 430 µm | T18S25, T18S31 |

| T21SB | 435 - 500 µm | T21S31 |

| T28SB | 605 - 680 µm | T28S31, T28S46 |

- Replacement Blades for Fiber Buffer Stripping Tools with Item # Prefix T06, T12, T18, T21, or T28

- Two Pre-Attached, Matched Blade Pairs Per Package

These blades replace used blade sets for select fiber buffer stripping tools sold above; see the table to the right for the compatible stripping tool models. Each package contains two blade sets and a fiber guide lock, which are color-coded to allow for easy identification of the compatible size and tool. The blades are packaged in pre-attached, matched pairs that should only be used together; do not mix two halves of different blade pairs.

Instructions for replacing the blades of the fiber stripping tool are included with the stripping tool itself. To replace blades for a stripping tool not listed in the table to the right, please contact Tech Sales.

Click to Enlarge

The FTS4 three-hole fiber stripping tool can be used to strip off (1) the jacket, (2) the buffer, and (3) the coating of an optical fiber.

The FTS4 Fiber Stripping Tool is capable of stripping the fiber jacket (furcation tubing), fiber buffer, and fiber coating. The first hole, indicated by the 1 in the photo to the right, strips the Ø1.6 mm - Ø3 mm fiber jacket down to the Ø600 µm - Ø900 µm buffer coating. The second hole strips the Ø600 µm - Ø900 µm buffer down to the Ø250 µm coating. The third hole is used to strip the Ø250 µm cable down to the glass fiber without nicks or scratches.

The handle is made of thermoplastic rubber and the tool is 6" (15 cm) long from the tip of the blade to the end of the handle. This fiber stripper is preset at the factory and cannot be adjusted or calibrated. The stripping tool should be periodically checked for proper operation and can be cleaned with dry compressed air to remove debris from the openings.

Click to Enlarge

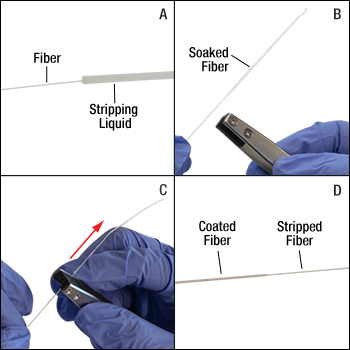

These images depict the recommended stripping procedure. A: Immerse the target fiber section in stripping liquid.

B-C: Gently pinch the base of the soaked section with FSGT tweezers and pull toward the end of the fiber.

D: The coating should slide off, leaving a stripped section.

- Coating Stripping Tweezers for Fluoride and Other Soft Glass Fibers

- Non-Marring Stripping when Used with Chemical Stripping Agent

- Acid-Resistant Stainless Steel Body and PA66/GF30 Tips

Our FSGT Coating Stripping Tweezers can be used along with a solvent to chemically strip the coating from fibers. Fibers made from soft glasses, such as our fluoride fibers, are susceptible to damage when conventional mechanical stripping methods are used. For such fibers, using these tweezers with a chemical stripping agent provides effective stripping without scratching or nicking the bare fiber.

The FSGT tweezers consist of an antimagnetic, acid-resistant stainless steel body with two angled PA66/GF30 tips. The tweezers are resistant to paint strippers and other common solvents, making them ideal for use with chemical agents used to strip fibers.

Stripping Procedure

To strip a fiber, the coating should first be exposed to a stripping liquid such as a paint stripper for three to five minutes. Placing the stripping liquid in a long vessel such as a syringe with a long tip is recommended to increase ease of application. If using a gel-type stripper, it can be applied manually to the exterior of the fiber. Note that the required soaking time will depend on the particular stripping agent being used as well as the chemical composition of the coating. For example, if a dichloromethane (DCM) based stripping liquid is used, the required time may be shorter.

The coating on the section of the fiber soaked in stripping liquid will visibly swell, as seen in section B of the image to the right. A pair of FSGT tweezers can then be used to gently pinch the fiber in the soaked section, and pull toward the end of the fiber. Care should be taken to ensure that only moderate pressure is applied, or else the fiber may break. The soaked coating should slide off the end of the fiber, leaving the cladding exposed.

If additional cleaning of the stripped section is needed, a solvent such as methanol can be used with our TCW604 Lint-Free Wipes to remove any remaining debris.

When dealing with chemical stripping agents and bare fluoride fibers, chemically resistant gloves such as our nitrile gloves should always be worn. Refer to any safety documentation for the chemical stripping agent before use.

The AFS900 Adjustable Stripping Tool is capable of stripping the fiber jacket (furcation tubing) and fiber buffer. The blades have a V-groove slot to precisely hold the fiber in the proper position as the stripping tool is closed. The AFS900 has an adjustable blade stop that can be used to ensure that the optical fiber is not cut when stripping the jacket or buffer. This tool is often used when stripping Ø900 µm fiber jacket (tight or loose), and can remove jackets and buffers down to Ø400 µm. Because of the delicate nature of fiber, we recommend that when the AFS900 is used to strip fiber buffer that the stop be properly set and then to dedicate the tool for that purpose. Also available are fiber buffer stripping tools with blades that are dedicated for use with specific fiber cladding and buffer diameters (see above).

Click to Enlarge

Fiber can be fed through the TBS1400 by pressing down on the two rounded tabs.

Click to Enlarge

The TBS1400 Tight Buffer Stripper shears off a portion of the buffer, allowing the user to peel the buffer back by hand.

| Slot Label | Cut Deptha |

|---|---|

| 1 | 190 µm - 210 µm |

| 5 | 290 µm - 310 µm |

| 9 | 390 µm - 410 µm |

Thorlabs' Vytran® TBS1400 Tight Buffer Stripping Tool is used to remove tight buffer from Ø900 µm to Ø1400 µm buffered fiber without cutting the coating. It is designed for fibers with coating diameters from 250 µm to 500 µm. The tool consists of eleven slots, each of which is 4" (101.6 mm) long, and a holding plate with an installed blade. Each tool is factory-aligned and tested for cut depth at the slots listed in the lower right table.

To use, place the tool on a flat, clean surface, then push down the two rounded tabs next to the holding plate to raise the holding plate. While holding down the tabs, insert the buffered fiber into the desired slot in the direction marked "Feed", as shown in the image to the far right. Release the tabs to lower the holding plate and pick up the part with one hand. Using your other hand, pull the buffered fiber in the direction marked "Strip". This removes a portion of the buffer, as shown by the drawing directly to the right, and provides a starting point for peeling back the rest of the buffer by hand.

We recommend starting with a slot that will remove less material, then increasing the amount removed until the ideal slot is determined. Our JEL10 and EYL10X Eye Loupes are useful for inspecting the stripped fiber to ensure the coating has not been compromised.

Each TBS1400 stripping tool ships with one single-sided blade pre-installed, as well as ten extra replacement blades. Additional replacement blades are available for purchase in a pack of 100. Instructions for replacing or adjusting the blades are provided in the manual. Replacement requires only a 0.050" balldriver or hex key (not included), while adjustments additionally require a 5/64" balldriver or hex key as well as a flathead screwdriver of appropriate size (neither included).

Click to Enlarge

FTS3B Replacement Blade Set

The FTS3 Stripping Tool will provide precise cuts through Ø3 mm and Ø3.8 mm furcation tubing. Simply set the depth of the dual cutting blades before placing the cutting tool around the fiber. Then spin the tool around the fiber several times. This results in two precise cuts through the tubing. The furcation tubing between the two cuts can then be removed by using the blade at the end of the FTS3 to make a precise cut through the tubing along the length of the fiber. Each FTS3 also comes with a blade that has a rounded tip. Long cuts along the length of the fiber can be made through the furcation tubing by swapping the blade at the end of the FTS3 with the rounded blade. Simply place the fiber in the end V-groove, press the blade through the furcation tubing, and then draw the fiber through the tool.

Replacement blades (Item # FTS3B) are available for the FTS3 stripping tool. Each FTS3B set contains three straight blades plus the round tipped blade.

This fiber connector crimp tool can be used to crimp SMA, FC, SC, and ST®* connectors. It has hex crimp sizes of 0.128", 0.151", 0.178", 0.197", and 0.215". Crimping is only required for connectors attached to furcation tubing that is Ø2 mm or greater; Ø900 µm or smaller tubing does not need to be crimped. The color of the handle may vary.

Please note that, when using this tool with our Ø2 mm tubing, epoxy must be used after crimping a sleeve from the 190066CP or 190088CP packs to ensure that it is properly secured to the tubing. For information, please contact Tech Support.

*ST® is a registered trademark of Lucent Technologies, Inc.

The T186 Kevlar Cutting Shears (Mfg. Item # JIC-186) have carbon steel blades that are specifically designed to cut through Kevlar fibers. One blade is serrated to keep the Kevlar fibers from sliding along the blades as the shears are being closed, which allows the Kevlar fibers to be cut easily. These shears feature an ergonomic loop handle made from dual component nylon and Santoprene™. The tool is 6" (15 cm) long from the tip of the blade to the end of the handle and features an adjustable joint screw for tension adjustments.

It is important to use the T186 cutting scissors only for cutting Kevlar. Any other material, including the silica fiber itself, can potentially damage the precision edge of the blades and make them less effective in cutting Kevlar.

The BFG1 Bare Fiber Gripper is an ideal aid when removing buffer from an optical fiber. The textured rubber material of this gripper provides a secure hold without damaging the fiber. This method of gripping is recommended over wrapping or clamping the loose end of the fiber, as these techniques can create microfractures in the fiber.

- Safe Solution for Disposing of Cleaved Fiber Ends

- One Circular and One Rectangular Covered Hole in Lid

- Dimensions (L x W x H): 2.75" x 2.75" x 6" (6.99 cm x 6.99 cm x 15.24 cm)

- Disposable: Do Not Reuse

The FTDU offers a safe solution for disposal of cleaved fiber ends, epoxy and syringes, and other sharp objects. This high-density polyethylene (HDPE) bottle features a translucent lid with one circular and one rectangular hole in it (see the photo to the right). Both of these holes have individual covers that snap closed to keep the contents inside the unit. Tabs on the side of the lid hold the covers open for hands-free use. The two hole covers are connected by a plastic tab. Cut, or pull, the covers apart to use the holes separately.

To use, insert sharps into one of the holes in the lid. Do not remove the lid itself from the unit. Use the "Contents" space on the label to clearly indicate what is inside. To protect against spills, keep the holes covered when not inserting sharps. When it is full, securely cover both holes in the lid by inserting the tab on the cover into the slot in the lid and dispose of the canister according to the contents. Do not fill the sharps container past the indicated "Full" line on the label. Do not reuse this unit; it is a one-time-use container only.

Products Home

Products Home

Zoom

Zoom

Termination Tools

Termination Tools