Low-Profile Motorized XY Scanning Stages

- Precise XY Scanning with <5.0 µm Position Accuracy

- Low-Profile, Compact Footprint

- Compatible with Thorlabs' Cerna®, Nikon, and Olympus Microscopes

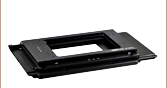

LPXY1

Stage Shown with MLS203P10 Slide Holder

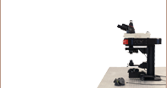

LPXY1 Stage with MLS203P10 Slide Holder Shown Mounted to an Olympus IX71 Inverted Microscope

Please Wait

Click to Enlarge

LPXY1 Scanning Stage with MLS203P5 Breadboard Adapter

Attached to an Optical Table with our MLSA01 Bracket Set

(Stage Shown With Finger Guard Removed)

Features

- Integrates with Nikon, Olympus, and Thorlabs' Cerna® Upright and Inverted Microscopes

- Compact Design with Easy Sample Access

- Stepper Motor Control for High Position Stability

- High-Quality, Precision-Engineered Linear Bearings

- Range of Sample Holders Available

- Compatible with Thorlabs' Kinesis® Software

Thorlabs' Low-Profile Motorized XY Microscopy Stage has been designed as a drop-in replacement for the manual stages found on select Nikon, Olympus, and Cerna® microscopes to provide motorized XY positioning of microscopy samples. A complete stage package consists of the stage itself, a controller, mounting brackets, and optional accessories; all of these items need to be purchased separately. The table below outlines the items that should be purchased to form a stage package compatible with a particular microscope. Alternatively, optional mounting adapters enable a stage to be bolted to an optical table or breadboard as part of a custom-built microscope setup or for use in typical photonics applications.

The LPXY1 microscopy stage uses stepper motors with open-loop control to provide a compact, durable, and cost-effective scanning stage for microscopy. The stage is constructed without the external motor housings to allow for easy sample access, and uses stepper motors to provide optimal low-speed performance with high positioning stability. With no moving electronics, the LPXY1 stage is designed to ensure maximum lifetime and durability, making the stage a reliable and cost-effective option for routine positioning in microscopy. The stage can also be combined with our

Z-Axis Piezo Stage to form an XYZ stage ideally suited for laser scanning microscopy. For applications requiring high-speed, Thorlabs offers

High-Speed Motorized XY Scanning Stages, with Item # MLS203-1 having identical microscope compatibility as the LPXY1 scanning stage (see table below).

Calibration Files

Each LPXY1 scanning stage is calibrated during manufacturing. Calibration enables the controller to correct for any mechanical errors present in the system. Mechanical components, such as the lead screw and linkages, can be machined only within a certain tolerance. These mechanical errors result in deviations of the actual position from the commanded position. However, the deviations are repeatable and can be compensated for using the Kinesis software and included calibration files. These files are used by the software to convert the position entered by the user into the required mechanical motion. The calibration files can be downloaded by clicking on the red Docs icon ![]() )

)

The use of calibration files is optional. Without them, the repeatability and resolution of the stage are unaffected, but no compensations are made to enhance the accuracy. Each stage is calibrated at the factory, giving a typical on-axis accuracy of <5 µm without the use of the calibration files.

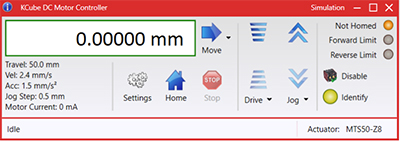

Controller Option

The LPXY1 scanning stage is compatible with any of the BSC200 series Benchtop Stepper Motor Controllers. For dual-axis control, Thorlabs recommends the BSC202 two-channel controller. See below for a brief overview, or click here to view the full presentation for this controller. Please note that while the BSC202 controller is compatible with both Thorlabs' Kinesis and APT™ software suites, the LPXY1 stage should only be driven with the Kinesis software to provide the correct current level in the motors. Use of the APT software may cause mechanical failure.

Specimen Holders and Accessories

We offer a range of adapters to allow the positioning of standard microscope slides, multiwell plates, petri dishes, and mounted metallurgical specimens. Please see below for details.

Complete Microscope Stage Assemblies

| Microscopea | XY Stage / Controller | Mounting Bracket | Optional Specimen Holders and Accessories |

|---|---|---|---|

| Thorlabs Cerna | LPXY1 Stageb / BSC202 Controllerc | CSA1000 | MLS203P2: Petri Dish / Slide Holder for Inverted Microscopes MLS203P10 & MLS203P13: Multiple Slide Holders for Upright and Inverted Microscopes C4SH01: Multi Slide Holder for Inverted Microscopes MLS203P1: Multiwell Plate Adapter MLS203P3: Blank Adapter Plate MLS203P5: 1/4"-20 Tapped Breadboard Plate MLS203P4: M6-Tapped Breadboard Plate MJC2: 2-Axis Microscopy Joystick |

| Nikon 50i, 80i, 90i, and Ci-L | MLSA06 | ||

| Nikon TE2000 and Eclipse Ti | MLSA03 | ||

| Nikon Eclipse FN1 | MLSA07 | ||

| Olympus BX41, BX43, BX51, BX53, and BX61 | MLSA08 | ||

| Olympus IX51, IX71, IX73, IX81, and IX83 | MLSA02 | ||

| Olympus IX70 | MLSA09 | ||

| Optical Breadboard / Custom Configuration | MLSA01 or MLSA04 |

| LPXY1 Stage | |

|---|---|

| Travel Range | 110 mm x 75 mm (4.33" x 2.95") |

| Speed (Max) | 25 mm/s |

| Velocity Stability | <1.27 mm/s |

| Acceleration (Max) | 400 mm/s2 |

| Bidirectional Repeatability | <±1.5 µm |

| Unidirectional Repeatability | <±1.5 µm |

| Minimum Repeatable Incremental Movement | 0.1 µm |

| Calibrated On-Axis Accuracy | <±5.0 µm |

| Home Location Accuracy | <±2.5 µm |

| Load Capacity (Max)a | 1 kg (2.2 lb) |

| Pitch Angular Deviation | ±150 µrad |

| Yaw Angular Deviation | ±150 µrad |

| Horizontal Straightness | ±3 µm |

| Vertical Straightness | ±3 µm |

| Limit Switches | X and Y as Standard |

| Bearing Type | High Rigidity Recirculating Precision Linear Bearing |

| Motor Type | Stepper Motor |

| Step Angle | 1.8° (200 Step Motor) |

| Step Accuracy | 5% |

| Microsteps per Full Step | 2048 |

| Microsteps per Revolution of Motor | 409 600 (For 200 Step Motor) |

| Dimensions (Mid Travel, Excluding Guards) | 310.1 mm x 255.6 mm x 32.3 mm (12.21" x 10.06" x 1.27") |

| Weight (Including Cables) | 3.0 kg (6.6 lbs) |

| Cable Length | 3 m |

| Recommended Controller | BSC202b |

| BSC202 Controller | |

|---|---|

| Input and Output | |

| Motor Drive Connector (15-Pin, D-Type Female) |

2-Phase Bipolar Motor Drive Output Differential Quadrature Encoder (QEP) Input Forward, Reverse Limit Switch Inputs Encoder 5 V (with Ground) |

| Control IO Connector (15-Pin, D-Type Female) |

Jog Forward/Back Input (TTL) User Logic Input/Output (TTL) Single-Ended Analog Input (0 - 10 V) User 5 V (with Ground) 100 mA Max Trigger Input/Output (TTL) |

| Motor Resolution | |

| Microsteps per Full Step | 2048 |

| For 200 Step Motor | 409 600 Microsteps/Rev |

| Motor Drive Voltage | 48 V |

| Motor Drive Power | Up to 50 W (Peak) / 25 W (Average) |

| Motor Speeds | Up to 3000 RPM (200 Full Step Motor) |

| Encoder Feedback Bandwidth | 500 KHz (500 000 Counts/s) |

| Input Power Requirementsa | |

| Voltage | 85-264 VAC |

| Power | 200 W (Peak) |

| Fuse | 3.15 A |

| General | |

| Housing Dimensions (W x D x H) | 240 mm x 360 mm x 133 mm (9.5" x 14.2" x 5.2") |

| Weight | 6.7 kg (14.75 lbs) |

| Compatible Motor Specifications | |

| Peak Powers | 15 to 50 W |

| Average Power | 25 W (Max) |

| Step Angle Range | 20° to 1.8° |

| Coil Resistance (Typical) | 4 - 15 Ω |

| Coil Inductance (Typical) | 4 - 15 mH |

| Rated Phase Currents (Typical) | 0.1 - 1 A |

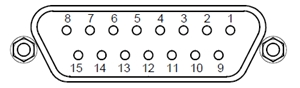

LPXY1 Motorized Scanning Stage Pin Out Descriptions

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Not Connected | 9 | CW Limit Switch |

| 2 | Not Connected | 10 | CCW Limit Switch |

| 3 | Not Connected | 11 | 0 V User |

| 4 | Not Connected | 12 | For Future Use |

| 5 | 5 V User | 13 | For Future Use |

| 6 | Identification | 14 | Motor Phase B+ |

| 7 | Motor Phase B- | 15 | Motor Phase A+ |

| 8 | Motor Phase A- | - | - |

Each axis has a 15-Pin D-type connector that is designed to connect to a BSC200 series controller.

BSC200 Series Controller Pin Out Descriptions

| Pin | Description | Return | Pin | Description | Return |

|---|---|---|---|---|---|

| 1 | User 5 V I/O | 9 | 9 | User 0 V | - |

| 2 | Jog Forwardsa | 9 | 10 | Jog Forwardsa | 9 |

| 3 | Not Used | 9 | 11 | Analog Inb | 9 |

| 4 | Trigger In | - | 12 | Trigger Out | 9 |

| 5 | User 0 V | - | 13 | Not Used | 5 |

| 6 | Not Used | - | 14 | Not Used | 6 |

| 7 | Digital (User) In | - | 15 | Digital (User) Out | 9 |

| 8 | Keyed Pin | - | - | - | - |

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Encoder A +ve | 9 | CW Limit Switch |

| 2 | Encoder A -ve | 10 | CCW Limit Switch |

| 3 | Encoder B +ve | 11 | 0 V User |

| 4 | Encoder B -ve | 12 | For Future Use |

| 5 | 5 V User | 13 | For Future Use |

| 6 | For Future Use | 14 | Motor Phase B+ |

| 7 | Motor Phase B- | 15 | Motor Phase A+ |

| 8 | Motor Phase A- | - | - |

| Pin | Description |

|---|---|

| 1 | RX (Controller Input) |

| 2 | Ground |

| 3 | Ground |

| 4 | +5V, 100 mA Power Supply |

| 5 | TX (Controller Output) |

| 6 | Ground |

Software

Kinesis Version 1.14.50

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

Legacy Software

Select products are still capable of running the legacy APT™ software package. Information on software compatibility can be found in the product documentation (![]() ), and additional details about the APT software can be found here.

), and additional details about the APT software can be found here.

Thorlabs' Kinesis® software features new .NET controls which can be used by third-party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications.

C#

This programming language is designed to allow multiple programming paradigms, or languages, to be used, thus allowing for complex problems to be solved in an easy or efficient manner. It encompasses typing, imperative, declarative, functional, generic, object-oriented, and component-oriented programming. By providing functionality with this common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from the low-powered, single-axis to the high-powered, multi-axis systems and control all from a single, PC-based unified software interface.

The Kinesis System Software allows two methods of usage: graphical user interface (GUI) utilities for direct interaction and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

For a collection of example projects that can be compiled and run to demonstrate the different ways in which developers can build on the Kinesis motion control libraries, click on the links below. Please note that a separate integrated development environment (IDE) (e.g., Microsoft Visual Studio) will be required to execute the Quick Start examples. The C# example projects can be executed using the included .NET controls in the Kinesis software package (see the Kinesis Software tab for details).

|

Click Here for the Kinesis with C# Quick Start Guide Click Here for C# Example Projects Click Here for Quick Start Device Control Examples |

|

LabVIEW

LabVIEW can be used to communicate with any Kinesis- or APT-based controller via .NET controls. In LabVIEW, you build a user interface, known as a front panel, with a set of tools and objects and then add code using graphical representations of functions to control the front panel objects. The LabVIEW tutorial, provided below, provides some information on using the .NET controls to create control GUIs for Kinesis- and APT-driven devices within LabVIEW. It includes an overview with basic information about using controllers in LabVIEW and explains the setup procedure that needs to be completed before using a LabVIEW GUI to operate a device.

|

Click Here to View the LabVIEW Guide Click Here to View the Kinesis with LabVIEW Overview Page |

|

| Posted Comments: | |

SMR Taheri

(posted 2024-07-19 14:05:57.72) How long is the cables between the stage and controller? spolineni

(posted 2024-07-24 06:49:15.0) Thank you for reaching out to us. The total length of the cable, including the 15-pin D-type connector, is 2994mm . user

(posted 2024-05-27 11:48:22.603) Can this product be used in nitrogen atmosphere at temperatures ranging from -40°C to +40°C? cstroud

(posted 2024-06-04 07:02:39.0) Thanks for reaching out. Our stages are usually rated for operational temperature ranges of +5 degrees to +40 degrees (non-condensing), along with the controllers. The storage temperature would also have a similar range. Anything outside of this could cause a failure due to expansion/contraction of the stage, and changes in viscosity of the grease used. We will contact you directly to discuss this further. |

| Key Specificationsa | |

|---|---|

| Travel Range | 110 mm x 75 mm (4.33" x 2.95") |

| Velocity (Max) | 25 mm/s |

| Acceleration (Max) | 400 mm/s2 |

| Bidirectional Repeatability | <±1.5 µm |

| Unidirectional Repeatability | <±1.5 µm |

| Horizontal Load Capacity (Max)b | 1 kg (2.2 lb) |

| Min Achievable Incremental Movement | 0.1 µm |

| Home Location Accuracy | <±2.5 µm |

| Calibrated On-Axis Accuracy | <±5.0 µm |

The LPXY1 scanning stage is a drop-in replacement for the manual stages found on select microscopes. It uses stepper motors with open-loop control to provide a compact, reliable, and cost-effective solution for low-speed XY positioning applications. This stage is compatible with Thorlabs' Cerna® microscopes, as well as inverted and upright microscopes from Nikon and Olympus. Adapter brackets can be purchased separately that enable the stage to be fitted to a particular microscope. Tabletop mounting adapters are also available that enable the stage to be bolted to an optical table or breadboard as part of a custom built microscope setup or for use in typical photonics applications (see below for more details).

- High-Resolution Microstepping Control for Very Fine Positioning Applications

- Full Software Control Suite Supplied

- Intuitive Software Graphical Control Panels

- Extensive ActiveX® Programming Interfaces

The LPXY1 scanning stage is compatible with any of the BSC200 Series Benchtop Stepper Motor Controllers. For controlling two axes, Thorlabs recommends the BSC202 two-channel controller. This controller features Thorlabs' Kinesis® control and programming interface, enabling easy integration into automated microscopy applications. Stepper motors provide better low-speed performance and positioning stability than their DC servo motor counterparts. This controller features USB connectivity, a fully featured Graphical User Interface (GUI) panel, and an extensive software support suite that includes a number of out-of-the-box user utilities, allowing for immediate operation of the unit without any detailed pre-configuration. A fully featured ActiveX® programming environment is also included to facilitate custom application development in a wide range of programming environments, such as LabVIEW, C++, and MATLAB.

Multiple units can be connected to a single PC via standard USB hub technology; for example, both the BSC202 controller for the LPXY1 stage and the controller with our MZS500-E Z-axis piezo stage kit can be operated simultaneously with a single PC. Combining this feature with the user-friendly Kinesis software allows the user to program and carry out complex move sequences quickly. For more details on the BSC202 controller, please see the Specs tab above or the full presentation for our benchtop stepper motor controllers.

We offer a choice of brackets to facilitate mounting the LPXY1 stage to a range of upright and inverted microscopes from Thorlabs, Nikon, and Olympus. Please see the table below for specific compatibility. Each bracket (with the exception of the CSA1000) comes with instructions describing how to attach the stage to the microscope.

| Click Image to Enlarge |

|

|

|

|

|

|

|

|

|

| Item # | CSA1000 | MLSA06 | MLSA03 | MLSA07 | MLSA08 | MLSA02 | MLSA09 | MLSA01 | MLSA04 |

| Microscope Brand | Thorlabs | Nikon | Olympus | Optical Breadboard, Custom Configurationa |

|||||

| Microscope Model | Cerna® |

50i, 80i, 90i, Ci-L |

TE2000, Eclipse Ti |

Eclipse FN1 | BX41, BX43, BX51, BX53, BX61 |

IX51, IX71, IX73, IX81, IX83 |

IX70 | N/A | |

| Microscope Type | Upright | Upright | Inverted | Upright | Upright | Inverted | Inverted | N/A | |

|

We support microscopes from Olympus, Nikon, Zeiss and Leica. Please contact Technical Support to inquire about bracket availability if your microscope model is not listed above. |

| Item # | Features | Photo |

|---|---|---|

| MLS203P2 |

|

|

| MLS203P10 |

|

|

| MLS203P13 |

|

|

| C4SH01 |

|

|

| MLS203P1 |

|

|

| MLS203P3 |

|

|

| MLS203P5 |

|

|

| MLS203P4 |

|

- Compatible with LPXY1 Scanning Stage

- Options Include Microscope Slide Holders, Petri Dish Holder, Breadboard Adapter Plates, and Blank Adapter Plate

- Ideal for Use in Standard Microscopy and Non-Standard, Custom Applications

Thorlabs offers several adapter plates and slide holders for the LPXY1 scanning stage. The MLS203P2 microscope slide/petri dish holder and the MLS203P10, MLS203P13, and C4SH01 microscope slide holders can be used with inverted and upright microscopes for standard microscopy applications. The MLS203P10 and MLS203P13 multi-slide holders feature precise spring-loaded slide retention mechanisms, unobstructed bidirectional objective access to the slides and a high degree of parallelism in the XY translation plane. The MLS203P3 blank adapter plate and the MLS203P5 and MLS203P4 tapped breadboard plates are ideal for use in non-standard and custom applications of the LPXY1 stage. These adapter plates and slide holders are also compatible with the MLS203-1 High-Speed Motorized XY Scanning Stage.

Click to Enlarge

LPXY1 Stage with MLS203P1 Multiwell Plate Adapter and C4SH01 Microscope Slide Holder (Each Sold Separately,

Stage Shown With Finger Guard Removed)

- Ideal for use with LPXY1 Scanning Stage

- High-Reliability Joysticks Utilizing USB HID Protocol

- 2-Axis Control Via a Joystick Knob

- Two Different Modes for Fast or High Precision Moves

- Speed Dial for Sensitivity Adjustment

- Allows Remote Manual Control

- Can be Reprogrammed using a PC

- Ergonomic Design

The MJC2 Joystick Console has been designed for microscope users and provides intuitive, tactile, manual positioning of the LPXY1 stage and other XY translation stages. The console features a two-axis joystick for XY control. In most applications, the default parameter settings saved within the controller allow the joystick to be used out-of-the-box, with no need for further setup, thereby negating the requirement to be connected to a host PC and allowing true remote operation. Parameter settings can also be reprogrammed and saved to a paired controller using a PC, allowing the controller to be disconnected from the computer and remote operation continued.

The MJC2 Joystick is compatible with our Stepper Motor Controllers, Benchtop Brushless DC Servo Controllers, and Rack-Mounted Brushless DC Servo Controller. The joystick has both a Mini-DIN and a USB Type-C port and is shipped complete with two cables, a 6-pin Mini-DIN plug to plug cable and a USB 3.1 Type-A to Type-C cable, for use with these controllers as well as setups utilizing the USB HID class. For more information about configuring and setting up the joystick over USB HID, please see the manual by clicking on the red Docs icon (![]() ) below. If you intend to use the joystick with a legacy BSC10x series unit, please contact Tech Support for a compatible cable.

) below. If you intend to use the joystick with a legacy BSC10x series unit, please contact Tech Support for a compatible cable.

Products Home

Products Home

Zoom

Zoom

Low-Profile XY Scanning Stage

Low-Profile XY Scanning Stage