Kinematic Mounts for 30 mm Cage Systems

- Precision Angular Adjustment of Optics

- Ideal for Retroreflection Mirror or Collimation Lens

- 30 mm Cage System Compatible

KC1XY

SM1 (1.035"-40) Tap in Front Slip Plate

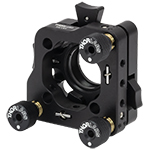

KC1T

SM1 (1.035"-40)

Tap in Front Plate

Application Idea

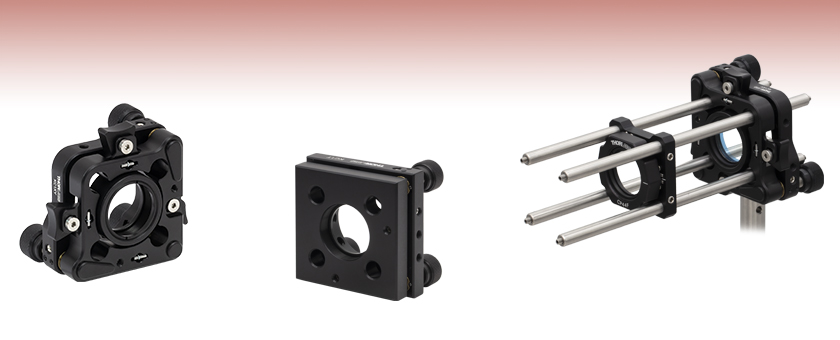

KC1XY Retroreflector Cage (Components Sold Separately)

Please Wait

Click to Enlarge

The KC1T kinematic mount can be combined with a CRM05 rotation mount to create a 30 mm-cage-compatible kinematic rotation mount.

| Alternative Size Options |

|---|

| 16 mm Kinematic Cage Mounts |

| 30 mm Kinematic Cage Mounts |

| 30 mm Right-Angle Kinematic Cage Mounts |

| 60 mm Kinematic Cage Mounts |

Features

- Ø1" (Ø25.4 mm) Optic Mount

- Compatible with 30 mm Cage System

- 8-32 (M4) Tapped Hole for Post Mounting

Thorlabs offers five 30 mm-cage-compatible kinematic mounts that are designed for easy integration into our cage assembly system. They are ideal for holding retroreflecting mirrors or collimated light sources, enabling precise angular alignment of a beam along the axis of a 30 mm cage system. In addition to mounts with manual adjusters, we also offer piezo-driven options with the same optic mounting features and cage compatibility. Accurate center axis alignment with the 30 mm cage system is made easier using one of the cage system alignment plates offered at the bottom of this page.

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment. Our mounts featured here have been designed to allow for the precise angular positioning of optics within a cage system. Thorlabs offers 16 mm, 30 mm, and 60 mm cage systems designed for Ø1/2", Ø1", and Ø2" optical components, respectively. The parts on this page are compatible with our 30 mm cage system and utilize Ø6 mm ER cage rods.

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see image below). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

| Posted Comments: | |

Yeon Hoon Kim

(posted 2021-06-14 21:00:09.75) Could you send me a Solidworks file which can open at the version of 2016?

I can't open with my Solidworks (the version of 2016), because KC1-T/M solidworks file is latest version (Maybe after 2016 version).

Best regards,

Kim. YLohia

(posted 2021-06-15 11:04:44.0) Hello Kim, unfortunately, Solidworks does not allow exporting previous versions of solidworks files. Please try using the .step file instead. Manuel De la Torre

(posted 2021-05-28 13:27:46.12) The springs of the KC1 after some use are easy to loose. Actually we have several KC1 without the springs. Is it possible to have them as spare parts? YLohia

(posted 2021-08-27 02:27:30.0) Thank you for contacting Thorlabs. Component-level parts can be requested by emailing techsupport@thorlabs.com. We will reach out directly. a.webber-date

(posted 2018-02-19 15:27:47.243) It would be nice to have one of these with an independent front plate, i.e. one that doesn't have the cage move as you do the tip/tilt.

I know you make the cage holes larger to compensate for this but the whole thing is just hard to use. llamb

(posted 2018-03-04 04:05:13.0) Thank you for contacting Thorlabs and for your feedback. I will add this idea to our internal product forum so that hopefully we can offer these with an independent front plate in the future. jlow

(posted 2012-08-13 11:37:00.0) Response from Jeremy at Thorlabs: The diameter on the back of the KC1-T/M is Ø1.32". It is designed such that a SM1 lens tube can be attached to the front plate (from the back) without the back plate interfering. kr

(posted 2012-08-13 10:37:23.0) What is the diameter of the hole in the back plate of the KC1-T/M? The front hole (threaded) is dimensioned in the drawing but not the hole in the back plate (it is actually not shown). In the step file it looks quite large.

Thanks.

Keith tcohen

(posted 2012-03-07 14:24:00.0) Response from Tim at Thorlabs: Thank you for your feedback. To adjust your spacing, the KC1-T is able to slide along cage rods to a desired position. It can then be fixed into place with setscrews and the three adjusters will allow another 3mm of linear translation. ZWJIORO

(posted 2012-03-07 03:26:45.0) Dear Thorlabs, I would like to mount a collimating lens in the KC1-T.I want to konw ,Is it possible to use the KC1-T to adjust the spacing between the LD and the collimating lens to collimate the light from the LD in the cage system? jjurado

(posted 2011-06-20 19:50:00.0) Response from Javier at Thorlabs to zsolt.kis1: Thank you very much for contacting us. You can certainly mount your 6 mm thick mirror onto the KC1.The nylon-tipped setscrew will provide sufficient support for mounting this optic. zsolt.kis1

(posted 2011-06-20 11:16:47.0) Dear Thorlabs,

I would like to mount a 6mm thick mirror in the KC1 mount. Is it possible to do it with the nylon-tipped locking screw?

Best regards,

Zsolt Kis Customer Email: zsolt.kis1@gmail.com This customer would like to be contacted. jens

(posted 2010-03-29 17:41:04.0) A reply from Jens at Thorlabs: the spring stiffness is optimized in order to allow a stable mounting of the plate while still providing the possibility for smooth manual adjustment which does not require too much force. Nevertheless we can certainly offer a custom version with stiffer springs for your particular application. We would be happy to discuss the specific requirements with you. user

(posted 2010-03-29 09:10:41.0) Received a KC1-T recently. Ill have to rebuild the unit with springs that are strong enough to hold the faceplate on. As it stands, it is simply too easy to deflect the faceplate. |

Click to Enlarge

KC1L Back View

- ±5º Tip / Tilt, ±3 mm Linear Translation Along the Optical Axis

- Accepts Ø1" (25.4 mm) Optics

- Minimum Optic Thickness: 0.12" (3 mm)

- Compatible with 30 mm Cage System

- 8-32 (M4 x 0.7) Holes for Post Mounting on Three Sides

The KC1L(/M) Kinematic Mount is designed with a smooth, double-bored mounting hole that can accommodate a Ø1" optic that is at least 0.12" (3 mm) thick; the optic is held in place with a top-located, nylon-tipped locking screw. These kinematic mounts come with three 1/4"-80 adjusters that provide 0.4° (7 mrad) adjustment per revolution and up to ±5° of tip and tilt without cage rods inserted through the mount. Each of the mount's three adjusters can be independently locked using a side-located 5/64" (2.0 mm) hex setscrew.

Both the front and rear plates have been machined with four clearance holes designed for direct compatibility with our 30 mm cage system standard. The cage rod holes in the front plate are sufficiently oversized to allow ±4° tip and tilt adjustment without cage rod interference. Once the mount has been slid along the cage rods to the desired position, tighten the 2.0 mm (5/64") locking setscrews on the back plate to secure it in place. The back plate of each mount also has 8-32 (M4 x 0.7) mounting holes on three of the four sides, providing compatibility with Thorlabs' Ø1" mounting posts.

Click to Enlarge

KC1T Back View

- ±5º Tip / Tilt, ±3 mm Linear Translation Along the Optical Axis

- Accepts Ø1" (25.4 mm) Optics

- Maximum Optic Thickness: 0.23" (5.8 mm)

- Compatible with 30 mm Cage System

- 8-32 (M4 x 0.7) Holes for Post Mounting on Three Sides

The KC1T(/M) Kinematic Mount is designed with an SM1-threaded (1.035"-40) mounting hole that can directly hold optics up to 5.8 mm (0.23") thick using the two included SM1RR Retaining Rings. Thicker optics can be accommodated by housing the optic in one of our SM1-Series Lens Tubes and then threading the lens tube into the front plate of the mount. Alternatively, since the back plate features an oversized Ø1.32" bore, SM1 lens tubes can also be attached to the front plate from the rear of the mount without sacrificing angular adjustment. This kinematic mount comes with three 1/4"-80 adjusters that provide 0.4° (7 mrad) adjustment per revolution and up to ±5° of tip and tilt without cage rods inserted through the mount. Each of the mount's three adjusters can be independently locked using a side-located 5/64" (2.0 mm) hex setscrew.

Both the front and rear plate have been machined with four clearance holes designed for direct compatibility with our 30 mm cage system standard. The cage rod holes in the front plate are sufficiently oversized to allow ±4° tip and tilt adjustment without cage rod interference. Once the mount has been slid along the cage rods to the desired position, tighten the 5/64" (2.0 mm) locking setscrews on the back plate to secure it in place. The back plate also has 8-32 (M4 x 0.7) mounting holes on three of the four sides, providing compatibility with Thorlabs' Ø1" mounting posts.

Click to Enlarge

Click to EnlargeKC1-P Optic Mount

- Smooth Bore or SM1-Threaded Versions Available

- Manual and Piezo Adjusters in Series

- Accepts Ø1" (Ø25.4 mm) Optics

- Compatible with 30 mm Cage Systems

- 8-32 (M4) Taps for Post Mounting

These kinematic mirror mounts provide pizeo-driven alternatives to the KC1L(/M) and KC1T(/M) optic mounts above. Each of the three adjustable axes consists of a manual and piezo adjuster in series. The smooth bore versions secure the mirror with a nylon-tipped 8-32 (M4) setscrew, while the SM1-threaded versions secure the mirror with two included SM1RR Retaining Rings. The KC1-PZ(/M) and KC1-T-PZ(/M) offer a piezo linear travel of ±4 µm and minimum step size of 0.3 µrad, while the KC1-P(/M) and KC1T-P(/M) Mounts offer a piezo linear travel of ±9.7 µm with minimum step size of 0.37 µrad per 0.1 V step.

The piezo adjusters connect to a controller using the included 3' (91.4 cm) cables, and the maximum control voltage is 150 V. The KC1-PZ(/M) and KC1-T-PZ(/M) Mounts include permanently attached BNC cables, while the KC1-P(/M) and KC1T-P(/M) Mounts include detachable cables. The KC1-PZ(/M) and KC1-T-PZ(/M) Mounts are also sold bundled with the MDT693B Three-Channel Piezo Controller, providing all the components needed for open-loop control of the mount.

These mounts are 30 mm cage system compatible; the cage rods can be locked into place using their locking screws. They are also post mountable using one of the three 8-32 (M4) mounting taps.

| Item # | KC1-PZ(/M) | KC1-P(/M) | KC1-T-PZ(/M) | KC1T-P(/M) |

|---|---|---|---|---|

| Mechanical Specifications | ||||

| Optic Size | Ø1" (Ø25.4 mm) | |||

| Acceptable Optic Thickness | Min: 0.12" (3.0 mm) | Max: 0.12" (3.0 mm) | ||

| Clear Aperture | Ø0.94" | Ø0.90" | ||

| Mounting Hole | Smooth Bore | SM1 (1.035"-40) Threaded | ||

| Mechanical Angular Range | ±5° (±87 mrad) | |||

| Mechanical Linear Travel | ±3 mm | |||

| Adjusters | 80 TPI Screws w/ Piezos | 100 TPI Screws w/ Piezos | 80 TPI Screws w/ Piezos | 100 TPI Screws w/ Piezos |

| Post Mounting Features | 8-32 (M4) Mounting Taps | |||

| Cage System Compatablity | Bores for 30 mm Cage Rods 0.05" (1.3 mm) Hex Locking Screws |

Bores for 30 mm Cage Rods 5/64" (2 mm) Hex Locking Screws |

Bores for 30 mm Cage Rods 0.05" (1.3 mm) Hex Locking Screws |

Bores for 30 mm Cage Rods 5/64" (2 mm) Hex Locking Screws |

| Piezo Specifications | ||||

| Integrated Piezo Item # | AE0505D08Fa | POLARIS-P20 | AE0505D08Fa | POLARIS-P20 |

| Resonant Frequency | 138 kHz | 69 kHz | 138 kHz | 69 kHz |

| Piezo Angular Range | ±73 µrad | ±275 µrad | ±73 µrad | ±275 µrad |

| Piezo Linear Travel | ±4 µm | ±9.7 µm | ±4 µm | ±9.7 µm |

| Minimum Step Size | 0.3 µrad | 0.37 µrad per 0.1 V Step | 0.3 µrad | 0.37 µrad per 0.1 V Step |

| Piezo Control Voltage | 0 to 150 V | |||

| Piezo Connectors | Integrated BNC Cables (Click for Cable Diagram) |

Male SMB (Three Detachable PAA236R SMB-to-BNC Cables Included) |

Integrated BNC Cables (Click for Cable Diagram) |

Male SMB (Three Detachable PAA236R SMB-to-BNC Cables Included) |

| Specifications | ||

|---|---|---|

| Item # | KC1XY | KC1XY/M |

| Post Mounting | 2 8-32 Tapped Holes | 2 M4 Tapped Holes |

| Angular Drivers | 1/4"-80 TPI Adjustersa | |

| Locking Screw Hex | 5/64" (2.0 mm) (4 Places) |

|

| XY Travel | ±1.0 mm (±0.04") per Axis with Lockable Slip Plate |

|

| Angular Resolution | 0.4°/rev | |

| Angular Displacement | ±4° | |

| Z Travel | ±3.0 mm (±0.12") | |

| Inner Slip Plate XY Travel |

±0.04" (1 mm) per Axis | |

| Optic Thickness (Max) | 0.23" (5.8 mm) | |

| Optic Mounting | Internal SM1 (1.035"-40) Thread 2 SM1RR Retaining Rings |

|

Click to Enlarge

KC1XY Back View

- Slip Plate Provides ±1 mm of Coarse

X and Y Adjustment - ±4º Tip / Tilt, ±3 mm Linear Translation

Along the Optical Axis - Accepts Ø1" Optics

- Maximum Optic Thickness: 0.23" (5.8 mm)

- Compatible with Our 30 mm Cage Systems

- 8-32 (M4) Tapped Holes for Post Mounting

The KC1XY(/M) Kinematic Mount is designed with an SM1 (1.035"-40) threaded mounting hole in a front slip plate that enables direct mounting of optics up to 5.8 mm (0.23") thick using the included SM1RR Retaining Rings. Thicker optics can be accommodated by housing the optic in one of our SM1 Series Lens Tubes and then threading the lens tube into the front plate of the mount. Alternatively, since the back plate of the KC1XY(/M) Kinematic Mount features an oversized bore, SM1 lens tubes can also be attached to the front plate from the rear of the mount without sacrificing angular adjustment. This threaded, kinematic mount comes with three adjusters that can be independently locked.

Both the front and rear plates have been machined with four clearance holes designed for direct compatibility with our 30 mm cage system standard. The cage rod holes in the front plate are sufficiently oversized to allow ±4° tip and tilt adjustment without cage rod interference. Once the desired position is achieved, locking setscrews on the rear plate can be used to secure the rods in place. These setscrews have a hex of 5/64" (2.0 mm). In addition to 30 mm cage compatibility, the KC1XY(/M) has an 8-32 (M4) hole on each side of the back plate for post mounting.

The slip plate feature incorporated into these mounts provides ±1 mm of coarse travel in X and Y with respect to the front plate, which enables additional freedom when setting an optic's position within a cage system. Three locking screws allow the user to lock the slip plate down once the desired location has been reached. The user should note, however, that loosening the locking screws may result in excessive coarse movement (slop) in the slip plate. For best performance, tighten the locking screws, and then release them only enough to allow for smooth operation of the slip plate.

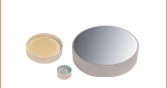

Click to Enlarge

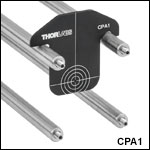

Front View of VRC1CPT Drop-In Alignment Plate

- Drop-In Beam Alignment Tools

- Small Through Hole Aligned at Center of 30 mm Cage Assembly

The CPA1 and CPA2 Alignment Plates are convenient tools for aligning cage-based optical systems. These drop-in plates feature a small through hole at the exact center of the 30 mm cage assembly that is used for aligning visible beams. For easy alignment, the through hole is surrounded by engraved rings, which indicate Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm. The CPA1 provides a Ø0.9 mm through hole, while the CPA2 provides a Ø5 mm through hole.

The VRC1CPT, VRC2CPT, VRC4CPT, and VRC6SCPT Alignment Plates are specifically designed to align UV to MIR beams in a cage-based optical assembly. These plates have concentric alignment ring engravings identical to the CPA1 (shown to the left) plate on the back. The fronts of the VRC1CPT, VRC2CPT, and VRC4CPT plates each include a Ø1/2" (Ø12.7 mm), non-rotating fluorescing alignment disk made of the same material used in our VRC1, VRC2, and VRC4 Viewing Cards, respectively. Alternatively, the front of the VRC6SCPT plate includes a Ø0.39" (Ø10.0 mm), non-rotating MIR alignment disk made of the same thermochromic liquid crystal material used in our VRC6S Viewing Card. The disk on the VRC1CPT, VRC2CPT, or VRC4CPT plate has a Ø1.5 mm hole centered on the plate's Ø0.9 mm hole, and the disk on the VRC6SCPT plate has a Ø2.0 mm hole centered on the plate's Ø0.9 mm hole.

Products Home

Products Home

Zoom

Zoom

30 mm Cage Kinematic Mounts

30 mm Cage Kinematic Mounts