Adjustable SM1 Lens Tubes

- Translate Ø1/2" Optics, Ø1" Optics, or Ø1" Lens Tubes Along the Optical Axis

- Rotating or Non-Rotating Adjustment

- Compatible with SM-Threaded Components

- Create Variable-Length Lens Tube Assemblies

SM1V15

Ø1" Adjustable Lens Tube, 1.31" Travel Range

SM1U

Adjustable Collimation Adapter

SM1ZM

High-Precision Zoom Housing

SM1NR1

Non-Rotating Zoom Housing

SM1V10V

Ø1" Vacuum-Compatible Adjustable Lens Tube,

0.31" Travel Range

Please Wait

Additional Vacuum-Compatible Components

Many of our other optomechanical components can be special ordered for vacuum use. Contact techsupport@thorlabs.com for details.

Features

- Allow Precise Positioning of an Optic within SM1 Lens Tube Systems

- Compatible with SM-Threaded Components

- Mount SM1-Threaded Lens Tubes, Ø1" (25.4 mm) Optics, Ø25 mm Optics, or Ø1/2" (12.7 mm) Optics

- Vacuum-Compatible Rotating Optic Adjustment Versions Available

Adjustable lens tubes allow for the adjustment of an optic's position within an SM lens tube system. The SM1V05, SM1V10, SM1V10V, and SM1V15 provide rotating adjustment, while the SM1ZM, SM1NR1, and SM1NR05 zoom housings use helical drive mechanisms to provide linear travel of the internal cell without rotation.

Unlike the other items on this page, the SM1V05, SM1V10, and SM1V15 must be combined with another SM1-threaded lens tube in order to provide adjustment. The SM1V10V adjustable lens tube is a vacuum-compatible version of the SM1V10 that features vented channels along its threading and at the ends the tube.

The SM1ZM and SM1NR1 can be combined with a standard SM1 lens tube to construct a non-rotating telescoping lens tube system. Finally, the SM1U adjustable collimation adapter provides 11 mm of non-telescoping, rotating adjustment of a Ø1" (Ø25 mm) collimation optic.

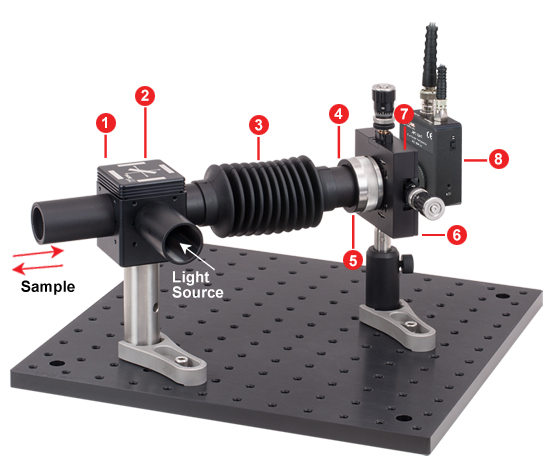

| # | Product Description | Qty. | Photo (Click to Enlarge) |

|---|---|---|---|

| 1 | DFM1 - Kinematic Dichroic Filter Cube |

1 |  |

| 2 | Microscopy Filters | 1 Set |  |

| 3 | SM1B3 - Lens Tube Bellows | 1 |  |

| 4 | SM1ZM - Non-Rotating SM1 Zoom Housing |

1 |  |

| 5 | Focusing Lens Inside Zoom Housing |

1 |  |

| 6 | ST1XY-D - XY Translator with Differential Drives |

1 |  |

| 7 | Precision Pinhole Between XY Translator and Photodetector |

1 |  |

| 8 | Photodetector SM1-Compatible Photodetector |

1 |  |

SM1ZM Zoom Housing - Optic Alignment in a Confocal Microscope

Thorlabs' SM1ZM High-Precision Zoom Housing (denoted by 4 in the image below) is useful when precise Z-positioning of optics is necessary. In the following example of a partial confocal microscope, a light-tight connection can be created between a DFM1 Dichroic Filter Cube (1) containing a Microscopy Filter Set (2), and an APD130A(/M) Photodetector (8). A lens (5) located inside the SM1ZM Zoom Housing (4) focuses the beam onto a precision pinhole (7) located just before the avalanche photodetector's sensor. The SM1ZM zoom housing is mounted directly onto the ST1XY-D XY Translation Mount with Differential Adjusters (6), creating a compact XYZ mount. SM1 Lens Tubes and the SM1B3 Lens Tube Bellows (3) allow for a light-tight connection without inhibiting the free movement of the XYZ mount.

Components used in the configuration pictured below are listed in the table to the right. These parts, along with SM1 Lens Tubes and 1" Post Assemblies, are sold separately.

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

Clemens Spinnler

(posted 2024-06-17 08:42:07.013) We are interested in the torque needed to rotate the outer ring. We currently posess two of these and for one we measured 0.022 Nm and for the other 0.066 Nm, which is quite a difference. Do you have data about what range the torque should be in? And how much does it varry from part to part?

Many thanks,

Clemens Spinnler cdolbashian

(posted 2024-06-21 04:35:08.0) Thank you for reaching out to us with this inquiry! As of now, we do not quantify the required torque required to adjust one of these components as part of our manufacturing process. If this is something you need for your experimentation, perhaps we can standardize the required torque for you as a custom. I have reached out to you directly to discuss this. user

(posted 2024-04-09 13:44:54.197) This is in regards to the SM1U and maybe the SM1NR1 (I didn't look at that one closely.)

Can you measure and publish some pointing and centering specs for optics mounted in the moving portions with respect to the fixed portions? (Something like "better than ___") I think this will add significant value for a great many customers. jpolaris

(posted 2024-05-02 03:16:37.0) Thank you for your suggestion about how we could improve our website. At this moment, we have not empirically measured pointing or centering of optics retained in these cells over their translations for either SM1U or SM1NR1. However, for SM1NR1, we can make worst-case scenario projections based on manufacturing tolerances. The optic centering could be off by up to 0.005" over the lens cell's translation. Further, lens cell tilt could be ± 0.11° along the translation. user

(posted 2024-03-11 14:14:16.247) Hello,

we are currently using the SM1ZM to hold a lense focusing a beam on a pinhole. We are trying to investigate the worst case drift of the optical axis or what the lense cann tilt and drop so that we can elimnate the risk of moving out ot the pinhole with the beam. It strongly depens on the guide length and the tolerance of the guide. Could you provide this data to investigate the cases? If you also have some data on how the SM1ZM is performing under enviromental conditions would be great. Thanks in Advance! cdolbashian

(posted 2024-03-15 04:45:55.0) Thank you for reaching out to us with this inquiry! Unfortunately we do not have this type of stability data measured for this component. These are used for fine adjustment of lenses with respect to a camera surface, rather than spatial filtering or other tightly toleranced motion. Perhaps something like a fine-Z translator in a cage system would be more appropriate, as this is what we use for our spatial filtering system. I have contacted you directly to discuss this alternative. Aaron Mueninghoff

(posted 2024-03-08 11:27:24.697) It seems that the locking screw only engages with threading in the plastic housing. The plastic threading has been stripped quite easily, making the locking screw non-functional. If a small metal insert were included in the housing so that the locking screw engaged with metal threads, it would be an improvement to the product. jdelia

(posted 2024-03-11 10:27:30.0) Thank you for contacting Thorlabs and for providing this valuable feedback. I have forwarded this along to our design engineers via our internal suggestion forum. 靖家 顏

(posted 2024-01-23 17:38:50.98) 您好~我已經有購買你們的產品分別為

ACN-254-075-A、ACN-254-125-A-ML、ACY-254-100-A

由於我想要方便對心因此有找到你們的lens tube看起來是可以用的,

但是我不確定要如何使用,因為ACN-254-125-A-ML這個透鏡外圈有housing因此似乎沒辦法放置在同一個鏡筒,想請問如果欲使用你們的lens tube組裝這三個透鏡組,我可以如何選用你們的產品。

再麻煩回復~感謝 jdelia

(posted 2024-01-24 02:16:04.0) Thank you for contacting Thorlabs. Assuming you are referring to the AC254-125-A-ML, you can thread the AC254-125-A-ML onto the end of an SM1 lens tube but you cannot thread it within the lens tube since it is a pre-mounted lens. We would suggest going with the unmounted version AC254-125-A if you want it mounted inside the tube. Denis Pristinski

(posted 2023-11-17 11:34:03.86) Unfortunately the answer below does not help. I would like to know the _focus_thread pitch for SM1U, not the _mount_ thread.

Let me try it this way:

SM1NR1 - 16 mm per revolution

SM1ZM - 0.5 mm per revolution

SM1NR05 - 17 mm per revolution

SM1U - ??? dpossin

(posted 2023-11-20 07:01:01.0) Dear Denis,

Thank you for your follow up question. Well the 11mm travel range is achieved by less than one revolution. To be precise, its 120 degree. I am reaching out to you for further discussion. Denis Pristinski

(posted 2023-11-16 17:02:57.103) What is the focus thread pitch of SM1U exactly? dpossin

(posted 2023-11-17 10:24:02.0) Dear Denis,

Thank you for your feedback. The Threading Specifications for the SM1U is normed and called SM1. You can find the specs here: https://www.thorlabs.de/newgrouppage9.cfm?objectgroup_id=3307&tabname=threading%20specs. Felix Lin

(posted 2023-03-02 06:42:52.28) Would it be possible to have a version of the SM1NR1 that's 25.4mm (1in)?

Thanks jdelia

(posted 2023-03-03 02:43:12.0) Thank you for contacting Thorlabs. I have contacted you directly regarding the feasibility of an SM1NR1 with a travel range reduced from 2" to 1". Haugen Mittelstaedt

(posted 2022-09-22 07:06:12.243) Hello,

would it be possible to add a scale to the SM1NR05? If the tube system is closed you cannot see anymore where the optic inside is located.

Kind regards

Haugen Mittelstaedt

Abberior Instruments Sam Hariri

(posted 2022-09-21 07:42:35.803) These products are unfortunately not compatible with air-spaced achromatic doublets, e.g. ACA254-075-A.

It's a bit thicker (13.1 mm) than what is allowed. jdelia

(posted 2022-09-22 10:53:07.0) Thank you for contacting Thorlabs. This is correct, unfortunately none of our SM1 adjustable lens tubes are able to accommodate an optic as long as 13.1 mm like the ACA254-075-A. We apologize for the inconvenience, and can certainly pass along the idea for adjustable lens tubes optimized for thicker optics to our engineers. user

(posted 2019-06-05 21:08:43.703) 是否有小一号,可用于1/2英寸或16mm笼式的此类高精度伸缩套筒? llamb

(posted 2019-06-05 04:15:55.0) Thank you for your feedback. We do not have an SM05 zoom housing for Ø1/2" optics. I have added this to our internal product forum. Alternatively, you may consider the SM1ZM with our SM1A1 adapter, or otherwise our SM05V- series of adjustable lens tubes. Also, you may reach out to your local Thorlabs Tech Support team by emailing techsupport-cn@thorlabs.com with additional inquiries.

感謝您的反饋意見。 我們沒有用於Ø1/ 2英寸光學元件的SM05變焦外殼。我已將其添加到我們的內部產品論壇。或者,您可以考慮SM1ZM與我們的SM1A1適配器,或我們的SM05V系列可調節鏡頭管。此外, 您可以通過發送電子郵件至techsupport-cn@thorlabs.com與其他查詢聯繫,與您當地的Thorlabs技術支持團隊聯繫。 nikita.vladimirov

(posted 2017-12-14 21:36:47.463) Hi,

I tried to use the SM1ZM high-precision zoom housing for holding microscope objectives at 45 degrees, but found a large wobbling that this mount allows. It wobbles >1-2 degrees from the optical axis because the internal lead thread is too short, only 2 mm (I disassembled the housing). This made both my SM1ZM useless for rigid mounting of microscope objectives. Can you guys possibly improve the design to reduce the wobbling? I have some ideas if you'd like to hear. Thanks! llamb

(posted 2018-03-30 10:24:41.0) Hello, thank you for your feedback. The drift/wobble of the SM1ZM will depend on your load and environmental conditions. We are always looking to improve our products, so I will reach out to you directly to discuss your ideas further. Thank you! ludoangot

(posted 2015-07-06 14:15:53.97) (addendum to my post) Or ideally you could propose a version of the SM1NR1 similar to the SM1NR05, that is with fixed internal SM1 threads on the end with the 35mm boss. That may reduce the clear aperture slightly but not dramatically and it adds a lot of convenience to your current product. besembeson

(posted 2015-09-22 09:18:51.0) Response from Bweh at Thorlabs USA: Thanks for the feedback. You will however need the clearance at the 35mm end as the lens tube translator is inside. It also gives you the flexibility of adding even a longer lens tube for a telescopic assembly. We have some further details at the following link: http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=4109 ludoangot

(posted 2015-07-06 14:09:38.943) Besides the CP03 cage plate and more required plates, could you consider an adapter that would allow to connect the unthreaded 35mm dia. end of the SM1NR1 to an SM1 tube? That would be a simple step down smooth bore 1.38" to 1.2" adapter. It would be very useful. Also, I am interested in a shorter travel version of the tube. besembeson

(posted 2015-09-22 09:03:23.0) Response from Bweh at Thorlabs USA: Thanks for the feedback. I will follow-up with you on these. peter

(posted 2013-11-21 14:41:45.103) This is a very useful part but it is easy to jam the focusing mechanism in the barrel when attaching other SM1 parts. I believe this is due to the face of the focusing barrel binding against the mount. It would be good idea to fit a stop in the mount so that the faces could not meet. pbui

(posted 2013-11-21 12:02:59.0) Response from Phong at Thorlabs: Thank you for your feedback. I will discuss your comments with our mechanics department. We are constantly looking for ways to improve our products and will consider your suggestion when designing a new version of the SM1ZM. user

(posted 2013-09-16 16:25:43.35) Love the idea of the SM1NR1, this would have been perfect for my application but it is too long. Would be great if you could offer a ~2" long version with 0.75" or more travel. jlow

(posted 2013-09-18 16:46:00.0) Response from Jeremy at Thorlabs: Thank you for your feedback. We will look into the possibility of adding a more compact version in the future. bdada

(posted 2012-01-31 01:26:00.0) Response from Buki at Thorlabs:

Thank you for using our feedback forum. We have contacted you to get more information about how you want the SM1V05 or SM1V10 rotatinglens tube customized. For an off-the-shelf solution, you could consider combining a lens tube with a rotating lens tube. amills

(posted 2012-01-26 10:13:12.0) I have need of a 1" diameter lens tube that has the external threaded range offered by the SM1V05, but has a internal threaded tube length of 1". The opposite of the SM1V10 I guess. Please let me know if such customization is possible. If so I would probably want to order at least 15-20 units. bdada

(posted 2011-12-15 17:14:00.0) Response from Buki at Thorlabs:

The SM1V10 is made from anodized aluminum and it is not recommended for vacuum applications because it could outgas quite a bit. However, we could strip the anodization off to expose the bare aluminum underneath.

We have contacted you regarding a quote for an unanodized version of the SM1V10. akorte

(posted 2011-12-14 15:30:03.0) I'm interested in using part # SM1V10 under vacuum. Can you tell what material(s) it's made of and whether it is vacuum-compatible?

Thanks,

Andy jjurado

(posted 2011-06-21 09:24:00.0) Response from Javier at Thorlabs to johannes.piel: Thank you very much for contacting us. The required hex key size for the locking set screw used in the SM1ZM is 0.035". We offer this hex key as part of our TC2 ball driver and hex key kit and the HK2A98 hex key kit:

http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=1407 johannes.piel

(posted 2011-06-20 10:35:23.0) SM1ZM has a "nylon tipped set screw"

What size is the matching hexagon key and do you offer it? Best Regards, Johannes Customer Email: johannes.piel@mlase.com Greg

(posted 2011-01-14 15:33:51.0) A response from Greg at Thorlabs to lucia.hackermuller: Thank you for leaving feedback! We actually do offer the locking ring, but it looks like we did not do a good job of populating it in all appropriate places of our website. I have added the SM1NT to this web page based on your feedback. lucia.hackermuller

(posted 2011-01-14 21:15:12.0) I very much like the SM1V10 system, but wanted to buy an additional locking ring. I realise it does not existed. Maybe you could add it to your product line!

Cheers,

Lucia |

Adjustable Lens Tube Usage

Click for Details

Amin and Amax are the minimum and maximum distances another lens tube can be positioned from the back of the lens cell when using the locking ring.

- Long Externally Threaded Section for Adjustable Positioning of Mounted Optics

- Adjustment Range up to 1.31" (33.3 mm)

- Maximum Optic Thickness 0.42" (10.7 mm)

These SM1-threaded (1.035"-40) adjustable lens tubes have an extra-long externally threaded section, allowing Ø1" optics to be precisely positioned along the optical axis of a lens tube system.

To operate, mount the optic in the internally threaded section using the included SM1RR retaining ring. Then thread the adjustable lens tube into a compatible SM1-threaded lens tube until the optic is at the desired position. Use the included SM1NT locking ring to fix the position of the lens tube. See the video to the right for a demonstration.

For applications where it is difficult to reach the locking ring by hand, we offer the SM1NT1 Slotted Locking Ring and SPW502 Spanner Wrench. This locking ring contains slots for the 1¼" end of the spanner wrench.

These adjustable lens tubes are an ideal solution for fine tuning of the first and last lenses in a lens tube system. Although a lens tube can be attached to the front of the adjustable lens tube, it should only be done after the position has been fixed, since this lens tube will need to be free to rotate and translate if the position is changed. Like our standard lens tubes, these adjustable lens tubes are made of black anodized aluminum.

| Item # | External Thread Length (L) | Adjustment Range (Amin to Amax)a |

|---|---|---|

| SM1V05 | 0.5" (12.7 mm) | 0.11" - 0.42" (2.8 mm - 10.7 mm) |

| SM1V10 | 1.0" (25.4 mm) | 0.11" - 0.92" (2.8 mm - 23.4 mm) |

| SM1V15 | 1.5" (38.1 mm) | 0.11" - 1.42" (2.8 mm - 36.1 mm) |

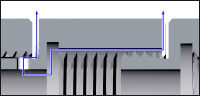

Click to Enlarge

Vents along the threading and at the ends of our vacuum-compatible lens tubes provide a free path for air to escape when under vacuum.

- Vacuum-Compatible: >10-6 Torr

- Long Externally Threaded Section for Adjustable Positioning of Mounted Optics

- 0.81" (20.6 mm) Adjustment Range

- Maximum Optic Thickness 0.42" (10.7 mm)

This Ø1" vacuum-compatible adjustable lens tube allows optics to be precisely positioned along the optical axis of a vacuum-compatible lens tube system. Made from 6061-T6 aluminum, this vented lens tube is vacuum compatible down to 10-6 Torr.

To operate, mount the optic in the internally threaded section using the included SM1RRV retaining ring. Then thread the adjustable lens tube into a compatible SM1-threaded lens tube until the optic is at the desired position. At this point, the included SM1NT1V Slotted Locking Ring can be used to fix the position of the lens tube. See the video above for a demonstration. This locking ring contains slots for the 1¼" end of the SPW502 Spanner Wrench.

This rotating adjustable lens tube is an ideal solution for fine tuning of the first and last lenses in a lens tube system. Although a lens tube can be attached to the front of the adjustable lens tube, it should only be done after the position of the optic has been fixed, since this lens tube will need to be free to rotate and translate if the position of the optic is changed.

| Item # | External Thread Length (L) | Adjustment Range (Amin to Amax)a |

|---|---|---|

| SM1V10V | 1.0" (25.4 mm) | 0.11" - 0.92" (2.8 mm - 23.4 mm) |

| Vacuum Specifications | |

|---|---|

| Vacuum Compatibility as Packageda | >10-6 Torr |

| Materials | 6061-T6 Aluminum |

| Preparation and Packaging | Chemically Cleaned and Double Vacuum-Bagged |

Click for Details

Amin and Amax are the minimum and maximum distances another lens tube can be positioned from the back of the lens cell when using the locking ring.

| Alternatives | Ø1/2" Vacuum-Compatible Adjustable Lens Tubes | |

|---|---|---|

Click to Enlarge

Each Tick on the Engraved Scale Indicates 0.25 mm of Internal Translation

Click to Enlarge The SM1NR1 Features a Ø35 mm Boss for 30 mm Cage System Mounting using the CP37 Cage Plate.

SM1NR1 Zoom Housing Usage

Click to Enlarge

A Standard SM1 Lens Tube can be Threaded to the Internal Translating Cell to Create a Telescoping Lens Tube Assembly

- Non-Rotating Translation of SM1 Lens Tubes and Ø1" Optics up to 0.3" (7.6 mm) Thick

- Fixed External and Translating Internal SM1 (1.035"-40) Mounting Threads

- Create a Light-Tight Telescoping Lens Tube Assembly

- 2" (50.8 mm) of Travel at 0.63" (16 mm) per Revolution

The SM1NR1 is an SM1-threaded, non-rotating zoom housing. It features an internal SM1-threaded (1.035"-40) translating cell for mounting Ø1" optics using the included SM1RR retaining ring, or for connecting SM1 lens tubes. A double-helical mechanism allows this cell to be translated along the optical axis without rotation (see video to the lower left). Each engraved tick mark on the rotating adjustment collar indicates 0.25 mm of linear travel of the inner cell (see photo to the far right). An 0.050" hex setscrew located by the Thorlabs engraving locks the movement, and tungsten disulfide dry film lubricant on the exposed internal surfaces ensures smooth translation.

The back of the housing includes an external SM1 thread for integration into lens tube systems. Additionally, the front of the housing includes a Ø1.38" (Ø35 mm) boss for 30 mm cage system integration using our CP37 cage plate (see photo above, to the immediate right).

Telescoping Lens Tube

A smooth Ø1.2" bore on one end of the housing allows standard SM1 lens tubes to be connected to the internal translating cell. This creates a light-tight adjustable-length lens tube assembly (see photo to the right).

- Non-Rotating Translation of Ø1" Optics up to 0.42" (10.7 mm) Thick

- 0.14" (3.5 mm) of Travel at 0.5 mm Per Revolution

- Fixed External SM1 and Translating Internal SM1 Mounting Threads

The SM1ZM non-rotating zoom housing provides 0.14" (3.5 mm) of linear travel without rotating the optical element mounted in it. A fine helical mechanism moves the front barrel back and forth while restricting any rotational movement, preventing any rotation of the attached lens tubes or optics. This high-precision (0.5 mm per revolution) zoom housing provides the ability to accurately control the exact working distance of an optical element within a system. Once the desired position is achieved, it can be locked by tightening the setscrew on the outside of the tube with a 0.035" hex key.

To operate, mount a Ø1" optic in the zoom housing and secure it using the included SM1RR retaining ring. Then attach the SM1ZM to an internally threaded SM1 lens tube or mount. Once secure, the outer ring of the SM1ZM can be used to precisely position the optic. This simple setup is shown to the right. For a more involved application within a confocal microscope setup, please see the Application tab.

Note that mounting a lens tube to the zoom housing may result in misalignments due to excessive torque being applied to the translation mechanism. If a lens tube or similar item must be mounted to the zoom housing, verify that downstream optical elements do not require realignment.

SM1NR05 Zoom Housing Usage

- Non-Rotating Translation of Ø1/2" Optics up to 0.25" (6.4 mm) Thick

- 18 mm of Travel at 17 mm Per Revolution

- Internal and External SM1 Threading for Attachment Between Two Fixed SM1 Lens Tubes

The SM1NR05 non-rotating zoom housing provides 18 mm of linear travel without rotating the optical element mounted in it. A double helical mechanism moves the interior SM05 barrel back and forth while restricting any rotational movement. This 17 mm per revolution zoom housing provides the ability to accurately control the exact working distance of an optical element within a system. To operate, mount a Ø1/2" optic in the zoom housing and secure it using the included SM05RR retaining ring. Then the SM1NR05 can be mounted on any SM1 threaded lens tube or mount. Once secure, the outer ring of the SM1NR05 can be used to precisely position the optic.

Unlike the other lens tubes and housing on this page, the SM1NR05 offers fixed SM1 threading on both ends, allowing it to be attached between two fixed Ø1" lens tubes while still retaining the ability to adjust the position of the optic (see the video to the right).

- Translation of Ø1" or Ø25 mm Collimation Optic with 11 mm of Travel

- External SM1 Threading (1.035"-40) at Input and Internal SM2 Threading (2.035"-40) at Output

- Remove Threading Adapter at Output to Reveal Internal M34 x 0.5 Threading

- 6.0 mm (0.24") Thick Retaining Ring Ideal for Aspheric Lenses

- Recommended for Collimating Mounted LEDs Using Condenser Lenses

This Adjustable Collimation Adapter provides 11 mm of non-telescoping, rotating translation for a Ø1" (Ø25 mm) optic with a clear aperture of Ø24.0 mm. Versions with pre-mounted aspheric condenser lenses are also available here. As seen in the drawing to the right, the output aperture of the collimation adapter is equipped with a removable, external M34 x 0.5 to internal SM2 thread adapter. For SM1 thread compatibility, the SM1A38 external M34 x 0.5 to internal SM1 thread adapter is available separately. The SM1U collimation adapter should be used at temperatures from 15 to 60 °C (non-condensing).

The inner carriage can be translated along the Z-axis by turning the adjustment ring (engraved with the Item # in the photo above) and locked into position by turning the locking screw on the side of the adjustment ring with a 2 mm (5/64") hex key. While the lens cell will rotate within the adapter housing when translated, the mounting threads on the housing remain fixed, allowing the SM1U to be mounted between fixed lens tubes. Lines with a 2 mm spacing are engraved on the housing as a rough guide for how far the carriage has been translated. The collimation adapter also includes a 6 mm thick, SM1-threaded retaining ring that allows an aspheric condenser lens to be mounted with our SPW602 Spanner Wrench.

Inserting or Removing Optics

To insert or remove an optic, use the adjustment ring on the collimation adapter to translate the inner carriage to the output end of the housing. Remove the included retaining ring using the SPW602 spanner wrench. If there is a lens installed already, remove it from the carriage. Insert another Ø1" or Ø25 mm optic into the carriage, and use the retaining ring to secure it.

Products Home

Products Home

Zoom

Zoom

Adjustable SM1 Lens Tubes

Adjustable SM1 Lens Tubes