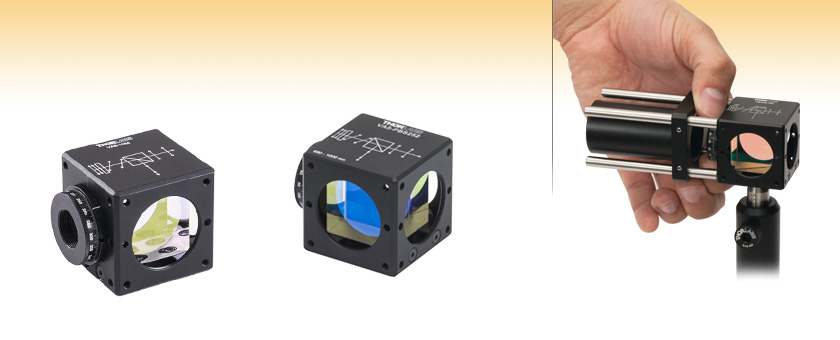

Mounted Variable Beamsplitters

- Continuously Adjust Transmitted Polarized Light

- Available for Laser-Line or Broadband Operation

- SM1 and 30 mm Cage System Compatible

VA5-1064

Laser-Line Variable Beamsplitter for 1064 nm

VA5-PBS252

Broadband Variable Beamsplitter for 690 nm to 1000 nm

Application Idea

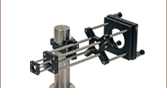

Variable Beamsplitter with Ø6 mm Cage Rods and Ø1" Lens Tube

Please Wait

Click to Enlarge ERSCB Rod Adapters are Used to Connect the C4W Cage Cube to the VA5-780 Variable Beamsplitter Cube

Features

- Constructed Using Half-Wave Plates and Beamsplitter Cubes

- Optimized for Either Specific Laser Lines or Broadband Use

- Compatible with Ø1" Lens Tubes and 30 mm Cage System

- Ø1/2" Post Mountable

- Connect Two Cage Cubes Side by Side with the CM1-CC Cage Cube Connector

Thorlabs' Variable Beamsplitters allow the user to continuously vary the transmitted intensity of a linearly polarized beam of light. This is accomplished by first rotating an incoming, linearly polarized beam using a half-wave plate in a rotation mount. The light is then split into its s- and p-polarized components by a polarizing beamsplitter cube allowing the user to achieve continuously variable split ratios. This effect is often used in holography and interferometry. Items are offered that allow for the continuous adjustement of either laser-line wavelengths or broadband wavelength ranges.

These beamsplitters are aligned to integrate easily into systems using Thorlabs' Ø1" lens tubes and 30 mm cage systems. The mounted half-wave plate is in a compact rotation mount designed to not interfere with the use of cage rods on the same side as the rotation mount. Using this mount to rotate the waveplate allows for continuous adjustment of the splitting ratio of the system. Additional wave plates can be used to isolate the input beam port from back reflections or to rotate the output polarization, as shown in the Applications tab.

Cage System Compatibility

Each beamsplitter cube is epoxied within the cage cube mount and cannot be removed from the mount. The cage cube can be mounted onto an optical post using a bottom-located 8-32 or M4 tap. Each of the four through ports includes SM1 (1.035"-40) threading for compatibility with SM1-enabled components, such as lens tubes or additional CRM05 rotation mounts. The CM1-CC connector is available to connect multiple cubes side-by-side using the two smooth-bore holes surrounding each through-port; the coupler cannot be used on the sides utilizing the SM1-threaded port. Additionally, these mounted variable beamsplitters can be connected to other cage cubes through the use of our cage rods and ERSCB adapters, as shown in the image to the right.

Other Cage Cube Options

If you require an attenuator for higher power applications, consider constructing your own using our mounted high-power polarizing beamsplitter cubes, Ø1/2" zero-order half-wave plates, and an SM1-threaded 1/2" rotation mount, such as the CRM05 continuous rotation mount. Attenuators with different wavelengths can also be built in the same way. Thorlabs also offers empty compact 30 mm cage cubes for mounting a variety of different cube optics or prisms. For a complete selection of our cube-mounted optics please see the Mounted Optics Guide tab.

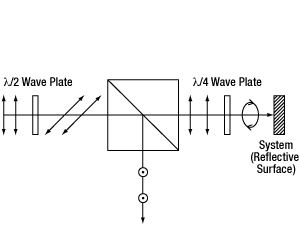

Isolation of the Input Port

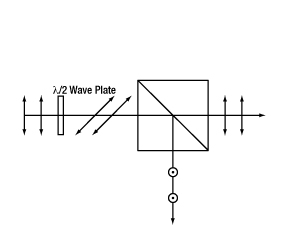

In normal operation, the variable beamsplitters utilize a half-wave plate to rotate the polarization of a previously linearly polarized beam of light. At the beamsplitter interface, P-polarized light will be transmitted, while S-polarized light will be reflected. By choosing the correct orientation with the half-wave plate, one can determine the amount of P-polarized and S-polarized light incident upon the interface (as shown in Figure 1).

Once through the beamsplitter, light may be reflected back from various optical elements in the system. To protect your light source from these reflections, a simple isolator may be created by the addition of a quarter-wave plate. This isolation will utilize the transmission/reflection properties of polarized light at the beamsplitter interface. In order to isolate the input port, the polarization of the exit beams must be rotated 90 degrees.

As seen in Figure 2, once light exits the beamsplitter, the quarter-wave plate converts the P-polarized light into right circularly polarized light. To ensure circular polarization, the polarization axis of the output beam (the beam transmitted straight through the beamsplitter cube in Figure 2) must be incident upon the quarter-wave plate at an angle of 45° with respect to the fast and slow axis. This can be accomplished, as shown above, by using our CRM1PT Precision Cage Rotation Mount.

Upon reflection from the front surface of a lens or mirror, the polarization will be transformed from right to left handed. As seen in Figure 3, as the light passes through the quarter-wave plate, it will once again be converted to a linearly polarized beam. It is important to mention that this beam will be orthogonal to the initial polarization direction and will be reflected towards the unused port of the beamsplitter. This prevents contamination of the two linearly polarized output beams. To truly isolate the input port of the Variable Beamsplitter/Attenuator, two quarter-wave plates must be used. The polarization of each output beam must be individually rotated and accounted for. For isolation of high-power beams or greater isolation levels, please see our line of optical isolators.

Click to Enlarge

Figure 3. Reflected Beam Path

Click to Enlarge

Figure 2. Initial Pass Through System

Click to Enlarge

Figure 1. Normal Variable Beamsplitter Operation

Attenuation of Broadband Sources

Broadband variable beamsplitters are used to adjust the percentage of transmitted light through the assembly at a variety of wavelengths by rotating a linearly polarized beam with an achromatic wave plate. The resulting beam will have a mixed linear polarization state, the components of which will be separated by a polarizing beamsplitter cube. In an ideal case, this mixed linear polarization state will be identical at all wavelengths within the operating range of the assembly.

Achromatic wave plates inherently have a variance in their retardance and transmission over their operating range. This causes the mixed linear polarization state incident on the polarizing beamsplitter cube to vary by wavelength. When using a narrow section of the broadband variable beamsplitter’s operating range, the physical rotation angle of the wave plate will need to be adjusted by the user depending both on the input wavelength and desired splitting ratio.

For a broadband input beam utilizing a large part of the operating range of the assembly, the wave plate will impart a slight chromatic ellipticity to the beam, i.e. each discrete wavelength within the input beam’s spectrum will have its polarization rotated at a different angle. This causes varying intensities of the output polarization based on wavelength, resulting in an unevenly attenuated beam.

To illustrate how intrinsic chromatic ellipticity caused by an achromatic wave plates affects a broadband input beam to a broadband variable beamsplitter, each of our beamsplitters was analyzed using a linearly polarized broadband light source over their operating wavelength. The maximum transmission from the transmitting arm of the assembly was achieved by aligning the transmitted polarization axis to the input polarization axis. Then the achromatic wave plate was rotated 90° to achieve the lowest possible transmission out of the transmitting arm. The resulting plots show a variation in the transmitted light across the wavelength of the cube. Therefore, even attenuation across the entire range cannot be achieved with a broadband beam. This sample data represents one test of each beamsplitter and does not represent the performance of all of the broadband variable beamsplitters. For more even attenuation of broadband beams, consider incorporating a variable neutral density filter.

Damage Threshold Data for Thorlabs' Variable Beamsplitters

| Broadband Damage Threshold Specificationsa | ||

|---|---|---|

| Item # | Damage Threshold | |

| VA5-PBS251(/M) | CWb | 350 W/cm at 532 nm, Ø1.000 mm |

| Pulsed | 2 J/cm2 at 532 nm, 10 ns, 10 Hz | |

| VA5-PBS252(/M) | CWb | 50 W/cm at 810 nm, Ø0.019 mm |

| Pulsed | 2 J/cm2 at 810 nm, 10 ns, 10 Hz | |

| VA5-PBS253(/M) | CWb,c | 2000 W/cm at 1064 nm, Ø0.018 mm |

| Pulsed | 2 J/cm2 at 1064 nm, 10 ns, 10 Hz | |

| VA5-PBS254(/M) | CWb,c | 2000 W/cm at 1542 nm, Ø0.033 mm |

| Pulsed | 5 J/cm2 at 1542 nm, 10 ns, 10 Hz | |

| Laser-Line Damage Threshold Specificationsa | ||

|---|---|---|

| Item # | Damage Threshold | |

| VA5-532(/M) | CWb | 100 W/cm (532 nm, Ø1.000 mm) |

| Pulsed | 2 J/cm2 (532 nm, 10 ns, 10 Hz, Ø0.470 mm | |

| VA5-633(/M) | Pulsed | 2 J/cm2 @ 532 nm, 10 ns, 10 Hz, Ø0.803 mm |

| VA5-780(/M) | Pulsed | 2 J/cm2 @ 810 nm, 10 ns, 10 Hz, Ø0.166 mm |

| VA5-1064(/M) | CWb | 1.5 kW/cm (1070 nm, Ø1.012 mm) |

| Pulsed | 2 J/cm2 (1064 nm, 10 ns, 10 Hz, Ø0.517 mm) | |

| VA5-1550(/M) | CWb | 1.5 kW/cm (1540 nm, Ø0.087 mm) |

The specifications to the right are measured data for Thorlabs' variable beamsplitters.

Laser Induced Damage Threshold Tutorial

The following is a general overview of how laser induced damage thresholds are measured and how the values may be utilized in determining the appropriateness of an optic for a given application. When choosing optics, it is important to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Note that the guideline presented here assumes room temperature operation and optics in new condition (i.e., within scratch-dig spec, surface free of contamination, etc.). Because dust or other particles on the surface of an optic can cause damage at lower thresholds, we recommend keeping surfaces clean and free of debris. For more information on cleaning optics, please see our Optics Cleaning tutorial.

Testing Method

Thorlabs' LIDT testing is done in compliance with ISO/DIS 11254 and ISO 21254 specifications.

First, a low-power/energy beam is directed to the optic under test. The optic is exposed in 10 locations to this laser beam for 30 seconds (CW) or for a number of pulses (pulse repetition frequency specified). After exposure, the optic is examined by a microscope (~100X magnification) for any visible damage. The number of locations that are damaged at a particular power/energy level is recorded. Next, the power/energy is either increased or decreased and the optic is exposed at 10 new locations. This process is repeated until damage is observed. The damage threshold is then assigned to be the highest power/energy that the optic can withstand without causing damage. A histogram such as that below represents the testing of one BB1-E02 mirror.

The photograph above is a protected aluminum-coated mirror after LIDT testing. In this particular test, it handled 0.43 J/cm2 (1064 nm, 10 ns pulse, 10 Hz, Ø1.000 mm) before damage.

| Example Test Data | |||

|---|---|---|---|

| Fluence | # of Tested Locations | Locations with Damage | Locations Without Damage |

| 1.50 J/cm2 | 10 | 0 | 10 |

| 1.75 J/cm2 | 10 | 0 | 10 |

| 2.00 J/cm2 | 10 | 0 | 10 |

| 2.25 J/cm2 | 10 | 1 | 9 |

| 3.00 J/cm2 | 10 | 1 | 9 |

| 5.00 J/cm2 | 10 | 9 | 1 |

According to the test, the damage threshold of the mirror was 2.00 J/cm2 (532 nm, 10 ns pulse, 10 Hz, Ø0.803 mm). Please keep in mind that these tests are performed on clean optics, as dirt and contamination can significantly lower the damage threshold of a component. While the test results are only representative of one coating run, Thorlabs specifies damage threshold values that account for coating variances.

Continuous Wave and Long-Pulse Lasers

When an optic is damaged by a continuous wave (CW) laser, it is usually due to the melting of the surface as a result of absorbing the laser's energy or damage to the optical coating (antireflection) [1]. Pulsed lasers with pulse lengths longer than 1 µs can be treated as CW lasers for LIDT discussions.

When pulse lengths are between 1 ns and 1 µs, laser-induced damage can occur either because of absorption or a dielectric breakdown (therefore, a user must check both CW and pulsed LIDT). Absorption is either due to an intrinsic property of the optic or due to surface irregularities; thus LIDT values are only valid for optics meeting or exceeding the surface quality specifications given by a manufacturer. While many optics can handle high power CW lasers, cemented (e.g., achromatic doublets) or highly absorptive (e.g., ND filters) optics tend to have lower CW damage thresholds. These lower thresholds are due to absorption or scattering in the cement or metal coating.

LIDT in linear power density vs. pulse length and spot size. For long pulses to CW, linear power density becomes a constant with spot size. This graph was obtained from [1].

Pulsed lasers with high pulse repetition frequencies (PRF) may behave similarly to CW beams. Unfortunately, this is highly dependent on factors such as absorption and thermal diffusivity, so there is no reliable method for determining when a high PRF laser will damage an optic due to thermal effects. For beams with a high PRF both the average and peak powers must be compared to the equivalent CW power. Additionally, for highly transparent materials, there is little to no drop in the LIDT with increasing PRF.

In order to use the specified CW damage threshold of an optic, it is necessary to know the following:

- Wavelength of your laser

- Beam diameter of your beam (1/e2)

- Approximate intensity profile of your beam (e.g., Gaussian)

- Linear power density of your beam (total power divided by 1/e2 beam diameter)

Thorlabs expresses LIDT for CW lasers as a linear power density measured in W/cm. In this regime, the LIDT given as a linear power density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size, as demonstrated by the graph to the right. Average linear power density can be calculated using the equation below.

The calculation above assumes a uniform beam intensity profile. You must now consider hotspots in the beam or other non-uniform intensity profiles and roughly calculate a maximum power density. For reference, a Gaussian beam typically has a maximum power density that is twice that of the uniform beam (see lower right).

Now compare the maximum power density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately. A good rule of thumb is that the damage threshold has a linear relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 10 W/cm at 1310 nm scales to 5 W/cm at 655 nm):

While this rule of thumb provides a general trend, it is not a quantitative analysis of LIDT vs wavelength. In CW applications, for instance, damage scales more strongly with absorption in the coating and substrate, which does not necessarily scale well with wavelength. While the above procedure provides a good rule of thumb for LIDT values, please contact Tech Support if your wavelength is different from the specified LIDT wavelength. If your power density is less than the adjusted LIDT of the optic, then the optic should work for your application.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. The damage analysis will be carried out on a similar optic (customer's optic will not be damaged). Testing may result in additional costs or lead times. Contact Tech Support for more information.

Pulsed Lasers

As previously stated, pulsed lasers typically induce a different type of damage to the optic than CW lasers. Pulsed lasers often do not heat the optic enough to damage it; instead, pulsed lasers produce strong electric fields capable of inducing dielectric breakdown in the material. Unfortunately, it can be very difficult to compare the LIDT specification of an optic to your laser. There are multiple regimes in which a pulsed laser can damage an optic and this is based on the laser's pulse length. The highlighted columns in the table below outline the relevant pulse lengths for our specified LIDT values.

Pulses shorter than 10-9 s cannot be compared to our specified LIDT values with much reliability. In this ultra-short-pulse regime various mechanics, such as multiphoton-avalanche ionization, take over as the predominate damage mechanism [2]. In contrast, pulses between 10-7 s and 10-4 s may cause damage to an optic either because of dielectric breakdown or thermal effects. This means that both CW and pulsed damage thresholds must be compared to the laser beam to determine whether the optic is suitable for your application.

| Pulse Duration | t < 10-9 s | 10-9 < t < 10-7 s | 10-7 < t < 10-4 s | t > 10-4 s |

|---|---|---|---|---|

| Damage Mechanism | Avalanche Ionization | Dielectric Breakdown | Dielectric Breakdown or Thermal | Thermal |

| Relevant Damage Specification | No Comparison (See Above) | Pulsed | Pulsed and CW | CW |

When comparing an LIDT specified for a pulsed laser to your laser, it is essential to know the following:

LIDT in energy density vs. pulse length and spot size. For short pulses, energy density becomes a constant with spot size. This graph was obtained from [1].

- Wavelength of your laser

- Energy density of your beam (total energy divided by 1/e2 area)

- Pulse length of your laser

- Pulse repetition frequency (prf) of your laser

- Beam diameter of your laser (1/e2 )

- Approximate intensity profile of your beam (e.g., Gaussian)

The energy density of your beam should be calculated in terms of J/cm2. The graph to the right shows why expressing the LIDT as an energy density provides the best metric for short pulse sources. In this regime, the LIDT given as an energy density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size. This calculation assumes a uniform beam intensity profile. You must now adjust this energy density to account for hotspots or other nonuniform intensity profiles and roughly calculate a maximum energy density. For reference a Gaussian beam typically has a maximum energy density that is twice that of the 1/e2 beam.

Now compare the maximum energy density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately [3]. A good rule of thumb is that the damage threshold has an inverse square root relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 1 J/cm2 at 1064 nm scales to 0.7 J/cm2 at 532 nm):

You now have a wavelength-adjusted energy density, which you will use in the following step.

Beam diameter is also important to know when comparing damage thresholds. While the LIDT, when expressed in units of J/cm², scales independently of spot size; large beam sizes are more likely to illuminate a larger number of defects which can lead to greater variances in the LIDT [4]. For data presented here, a <1 mm beam size was used to measure the LIDT. For beams sizes greater than 5 mm, the LIDT (J/cm2) will not scale independently of beam diameter due to the larger size beam exposing more defects.

The pulse length must now be compensated for. The longer the pulse duration, the more energy the optic can handle. For pulse widths between 1 - 100 ns, an approximation is as follows:

Use this formula to calculate the Adjusted LIDT for an optic based on your pulse length. If your maximum energy density is less than this adjusted LIDT maximum energy density, then the optic should be suitable for your application. Keep in mind that this calculation is only used for pulses between 10-9 s and 10-7 s. For pulses between 10-7 s and 10-4 s, the CW LIDT must also be checked before deeming the optic appropriate for your application.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. Contact Tech Support for more information.

[1] R. M. Wood, Optics and Laser Tech. 29, 517 (1998).

[2] Roger M. Wood, Laser-Induced Damage of Optical Materials (Institute of Physics Publishing, Philadelphia, PA, 2003).

[3] C. W. Carr et al., Phys. Rev. Lett. 91, 127402 (2003).

[4] N. Bloembergen, Appl. Opt. 12, 661 (1973).

In order to illustrate the process of determining whether a given laser system will damage an optic, a number of example calculations of laser induced damage threshold are given below. For assistance with performing similar calculations, we provide a spreadsheet calculator that can be downloaded by clicking the button to the right. To use the calculator, enter the specified LIDT value of the optic under consideration and the relevant parameters of your laser system in the green boxes. The spreadsheet will then calculate a linear power density for CW and pulsed systems, as well as an energy density value for pulsed systems. These values are used to calculate adjusted, scaled LIDT values for the optics based on accepted scaling laws. This calculator assumes a Gaussian beam profile, so a correction factor must be introduced for other beam shapes (uniform, etc.). The LIDT scaling laws are determined from empirical relationships; their accuracy is not guaranteed. Remember that absorption by optics or coatings can significantly reduce LIDT in some spectral regions. These LIDT values are not valid for ultrashort pulses less than one nanosecond in duration.

A Gaussian beam profile has about twice the maximum intensity of a uniform beam profile.

CW Laser Example

Suppose that a CW laser system at 1319 nm produces a 0.5 W Gaussian beam that has a 1/e2 diameter of 10 mm. A naive calculation of the average linear power density of this beam would yield a value of 0.5 W/cm, given by the total power divided by the beam diameter:

However, the maximum power density of a Gaussian beam is about twice the maximum power density of a uniform beam, as shown in the graph to the right. Therefore, a more accurate determination of the maximum linear power density of the system is 1 W/cm.

An AC127-030-C achromatic doublet lens has a specified CW LIDT of 350 W/cm, as tested at 1550 nm. CW damage threshold values typically scale directly with the wavelength of the laser source, so this yields an adjusted LIDT value:

The adjusted LIDT value of 350 W/cm x (1319 nm / 1550 nm) = 298 W/cm is significantly higher than the calculated maximum linear power density of the laser system, so it would be safe to use this doublet lens for this application.

Pulsed Nanosecond Laser Example: Scaling for Different Pulse Durations

Suppose that a pulsed Nd:YAG laser system is frequency tripled to produce a 10 Hz output, consisting of 2 ns output pulses at 355 nm, each with 1 J of energy, in a Gaussian beam with a 1.9 cm beam diameter (1/e2). The average energy density of each pulse is found by dividing the pulse energy by the beam area:

As described above, the maximum energy density of a Gaussian beam is about twice the average energy density. So, the maximum energy density of this beam is ~0.7 J/cm2.

The energy density of the beam can be compared to the LIDT values of 1 J/cm2 and 3.5 J/cm2 for a BB1-E01 broadband dielectric mirror and an NB1-K08 Nd:YAG laser line mirror, respectively. Both of these LIDT values, while measured at 355 nm, were determined with a 10 ns pulsed laser at 10 Hz. Therefore, an adjustment must be applied for the shorter pulse duration of the system under consideration. As described on the previous tab, LIDT values in the nanosecond pulse regime scale with the square root of the laser pulse duration:

This adjustment factor results in LIDT values of 0.45 J/cm2 for the BB1-E01 broadband mirror and 1.6 J/cm2 for the Nd:YAG laser line mirror, which are to be compared with the 0.7 J/cm2 maximum energy density of the beam. While the broadband mirror would likely be damaged by the laser, the more specialized laser line mirror is appropriate for use with this system.

Pulsed Nanosecond Laser Example: Scaling for Different Wavelengths

Suppose that a pulsed laser system emits 10 ns pulses at 2.5 Hz, each with 100 mJ of energy at 1064 nm in a 16 mm diameter beam (1/e2) that must be attenuated with a neutral density filter. For a Gaussian output, these specifications result in a maximum energy density of 0.1 J/cm2. The damage threshold of an NDUV10A Ø25 mm, OD 1.0, reflective neutral density filter is 0.05 J/cm2 for 10 ns pulses at 355 nm, while the damage threshold of the similar NE10A absorptive filter is 10 J/cm2 for 10 ns pulses at 532 nm. As described on the previous tab, the LIDT value of an optic scales with the square root of the wavelength in the nanosecond pulse regime:

This scaling gives adjusted LIDT values of 0.08 J/cm2 for the reflective filter and 14 J/cm2 for the absorptive filter. In this case, the absorptive filter is the best choice in order to avoid optical damage.

Pulsed Microsecond Laser Example

Consider a laser system that produces 1 µs pulses, each containing 150 µJ of energy at a repetition rate of 50 kHz, resulting in a relatively high duty cycle of 5%. This system falls somewhere between the regimes of CW and pulsed laser induced damage, and could potentially damage an optic by mechanisms associated with either regime. As a result, both CW and pulsed LIDT values must be compared to the properties of the laser system to ensure safe operation.

If this relatively long-pulse laser emits a Gaussian 12.7 mm diameter beam (1/e2) at 980 nm, then the resulting output has a linear power density of 5.9 W/cm and an energy density of 1.2 x 10-4 J/cm2 per pulse. This can be compared to the LIDT values for a WPQ10E-980 polymer zero-order quarter-wave plate, which are 5 W/cm for CW radiation at 810 nm and 5 J/cm2 for a 10 ns pulse at 810 nm. As before, the CW LIDT of the optic scales linearly with the laser wavelength, resulting in an adjusted CW value of 6 W/cm at 980 nm. On the other hand, the pulsed LIDT scales with the square root of the laser wavelength and the square root of the pulse duration, resulting in an adjusted value of 55 J/cm2 for a 1 µs pulse at 980 nm. The pulsed LIDT of the optic is significantly greater than the energy density of the laser pulse, so individual pulses will not damage the wave plate. However, the large average linear power density of the laser system may cause thermal damage to the optic, much like a high-power CW beam.

30 mm Cage-Cube-Mounted Optics Selection Guide

The table below provides links to all of our 30 mm Cage-Cube-Mounted optics. For our selection of 16 mm Cage-Cube-Mounted Optics, please see our 16 mm Cage Systems guide.

30 mm Cage Cube Empty Optic Mounts Selection Guide

|  |

| Rectangular Dichroic Mirrors and Filters | Empty Compact 30 mm Cage Cube |

| Posted Comments: | |

Amir Hen

(posted 2021-10-10 21:05:43.98) Following your reply to Yachel ben Shalm from the 17th of August - while it is true that you can put the beamsplitter upside-down it poses a different problem that the mounting screw hole is now facing up and there is no convenient way to mount it. YLohia

(posted 2021-10-11 02:19:23.0) There are a few different options for mounting the beamsplitter cube upside down. Please see the PJ302 Offset Mounting Post Joist. Alternately, you could also use our right angle adapter plates with the Ø1/2" to Ø1/2" Angle Post Clamps: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=223. Yachel Ben Shalom

(posted 2020-08-17 01:30:23.043) We want use this item, but in opposite direction - we need the reflected beam go to the left side, unlike in the picture. Can we flip the direction of the hairsplitter? YLohia

(posted 2020-08-24 09:55:58.0) Hello, thank you for contacting Thorlabs. You can flip the orientation of the beamsplitter cube upside-down (engraving on the bottom) to reflect the beam to the other direction. Ondrej Novak

(posted 2019-07-01 15:29:10.23) Dear colleagues,

I would like to kindly ask you whether we can use this beamsplitter to attenuate Coherent Chameleon fs laser. Its about 1.2mm beam, 140fs pulses 80MHz, max 3W on average. Alternatively, we can use the beamsplitter downstream from the beam expander so the beam diamter would be 5mm.

Thank you,

Ondrej YLohia

(posted 2019-07-02 08:53:07.0) Hello Ondrej, thank you for contacting Thorlabs. Unfortunately, we have not performed damage threshold testing with fs lasers on these optics. Femtosecond sources will have a different damage mechanism than the ns pulses used in our specification, so it’s not straight forward to scale this (2 J/cm^2) number. That being said, we do strongly recommend setting up this attenuator further downstream in your setup at a point when the beam diameter is 5mm to reduce the power density incident on the optic. chenav

(posted 2018-04-29 23:37:14.533) We would like to install an additional wave plate on the variable beamsplitter, having half-wave plates on two entry ports and using it as a polarization combiner. Can you please confirm that this is doable by purchasing a CRM05 mount and a WPH05ME-780 wave plate? Is there a better approach? Thanks. nbayconich

(posted 2018-05-01 08:43:38.0) Thank you for contacting Thorlabs. Yes you can attach the CRM05 mount with a WPH05ME-780 wave plate to the SM1 threaded ports of these variable beamsplitters. You could also place an un-mounted half wave plate in the additional CRM05 mount just like the one that is already included with these beamsplitter cubes. I will contact you directly about your application. tanmaybhwmk3

(posted 2017-08-03 21:29:26.71) Can I use this attenuator to vary the power levels for our high power 532 nm CW laser? The output power is approximately 1.7 Watt and the beam diameter is 2 mm approx. Please verify with the damage threshold. tfrisch

(posted 2017-08-16 12:41:40.0) Hello, thank you for contacting Thorlabs. While we do not have CW damage threshold testing for this part, we can reach out to you to discuss your application, and if necessary, stock items can be used to make a version with a high power beam splitting cube. chenav

(posted 2016-12-18 18:03:37.38) These variable beamsplitters are extremely useful and handy. Unfortunately, they have one major design bug: the locking setscrew on the half-wave plate finds itself, more often than not, at the bottom of the cube, making access to it really hard in almost any application (and especially in space-tight setups). tfrisch

(posted 2016-12-22 05:56:28.0) Hello, thank you for bringing this concern to our attention. I have posted this in our internal engineering forum and will reach out to you directly. umzzangu

(posted 2016-06-29 10:37:55.75) I puschased 'VA5-1064'model to attenuate CW laser. I wonder damage threshold for CW type for this model. There is a only pulse type damage threshold in webpage.

Is there any calculation that convert pulse type to CW type damage threshold ??

Thanks g.ceglia

(posted 2014-07-09 17:35:45.883) About VBA05-#####, the wavelengths [nm] are available at 532,633,780,1064,1550. Is it possible to achieve the range of wavelength between 220-230nm?

Thanks jlow

(posted 2014-08-07 10:41:38.0) Response from Jeremy at Thorlabs: For UV wavelength, we do not have a beamsplitter readily available to make this. Depending on what you require, you should be able to make a similar product from other components. I will contact you directly to discuss about this. liruohong

(posted 2014-05-12 11:28:59.317) hi, If I used the this Variable Beamsplitter to beamsplit a ~50W 10ns pulsed laser (Nd:Yag 532nm, 10KHz). The diammeter of the beam is about 0.8-1cm. After one hour, I noticed the output beam diameter became smaller and smaller. there is a serious a thermal lens effect mostlikely(With the adaptor your company provide this the beamsplitter cube, the thermal contact of PBS to the post and the metal base is not good). So I took the beamspliiter out of the beamline, and found a ~0.6-0.8 damage spot on splitting surface inside the PBS. Is this normal? besembeson

(posted 2014-05-15 02:51:49.0) Response from Bweh E at Thorlabs: Thanks for the feedback. That hole is not normal. We would like you to send this back to us for evaluation because it seems very likely the high power has caused some damage to the optic. I will follow up with you via email. sfeldman

(posted 2014-02-26 09:59:13.4) I am interested in the Variable Beamsplitter/Attenuator. What is the reflectivity vs wavelength for the 780 nm coating? We have a broadband pulse with 50 nm of bandwidth (FWHM) centered at 800 nm, and I was wondering if this product could work for us. jlow

(posted 2014-02-27 02:55:18.0) Response from Jeremy at Thorlabs: The beamsplitter reflectance should be <0.5% per surface from 620nm to 1000nm. For the wave plate, the reflectance would be <1% from 780nm - 830nm. Please note that the retardance will not be exactly 0.5 wave outside of 780nm. I will send you a graph showing the expected retardance around 780nm. benjamin.r.anderson

(posted 2013-12-16 13:20:14.313) I am looking into a variably attenuated beam splitter for femtosecond interferometry using a Ti:Sapphire fs laser. Would this product for the 780nm wavelength work? tcohen

(posted 2014-01-02 04:01:50.0) Response from Tim at Thorlabs: Thanks for contacting us. The first thing to consider is that as the wavelength moves away from 780nm, the retardation will move off of a half wave and so the total control from max/min you have will decrease as you shift off this wavelength. A nominal plot for your reference would be that of the WPH05M-780. The second is the damage threshold. As we work towards adding more damage threshold specifications to our catalog we are starting with the most common parameters, which typically mean a 10ns pulse. fs sources will have a different damage mechanism than the ns pulses used in our specification, so it’s not straight forward to scale this (2J/cm^2) number. I’ve emailed you to discuss your working power, as a calcite polarizer might be more suitable from a damage threshold standpoint. sebastian.kruber

(posted 2013-10-28 09:35:45.79) Can you offer the VBA05 attenuator for 3µm wavelength? tcohen

(posted 2013-10-29 13:12:00.0) Response from Tim at Thorlabs: Thank you for your feedback. We’re looking into the development of more IR components but at the moment we don’t have an equivalent to offer. I’ll contact you to discuss your requirements and possible alternatives. user

(posted 2013-09-11 16:00:39.203) It would be awesome if you sold the parts to this separately, i.e. adapters for cage-mounted polarizing beamsplitters that allow to add a rotation stages to any of the sides as you wish. Many times I have optical setups where I want several waveplates around a PBS. sharrell

(posted 2013-09-12 09:16:00.0) Response from Sean at Thorlabs: Thank you for your suggestion. We have received other requests for these products to be sold individually, and had added these products to our catalog: http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=6202. We offer empty cage cubes with rotation mounts in a variety of configurations, as well as the rotation mounts with external SM1 threading that can be attached to any cage cube or lens tube. We will add links between these two webpages today. sharrell

(posted 2012-11-08 08:23:00.0) Response from Sean at Thorlabs: Thank you for letting us know about the broken links. All of the correct files are now available on the Graphs tab. user

(posted 2012-11-07 19:46:16.283) FYI: For the variable beamsplitter/attenuator, the excell files for the raw data are all the same (VBA05-532) tcohen

(posted 2012-04-19 09:37:00.0) Response from Tim at Thorlabs: Thank you for your feedback! This product utilizes a Zero Order Waveplate. We are able to provide customs with different Waveplates including Achromatic Waveplates. I will contact you with more details. emilio.gualda

(posted 2012-04-19 08:54:53.0) Which kind of wave plates uses this product: zero-order or multiorder?

Could be possible to get it with zero-order waveplate?

Which is then the cost?

I need something like this for a multiphoton microscope working on the 750-900 nm range.

Thank you

Dr. Emilio J. Gualda

Instituto Gulbenkian de Ciencias

Lisboa-Portugal |

Beamsplitter Selection Guide

Thorlabs' portfolio contains many different kinds of beamsplitters, which can split beams by intensity or by polarization. We offer plate and cube beamsplitters, though other form factors exist, including pellicle and birefringent crystal. For an overview of the different types and a comparison of their features and applications, please see our overview. Many of our beamsplitters come in premounted or unmounted variants. Below is a complete listing of our beamsplitter offerings. To explore the available types, wavelength ranges, splitting/extinction ratios, transmission, and available sizes for each beamsplitter category, click More [+] in the appropriate row below.Plate Beamsplitters

| Non-Polarizing Plate Beamsplitters |

|---|

| Polarizing Plate Beamsplitters |

|---|

Cube Beamsplitters

| Non-Polarizing Cube Beamsplitters |

|---|

| Polarizing Cube and Polyhedron Beamsplitters |

|---|

Pellicle Beamsplitters

| Non-Polarizing Pellicle Beamsplitters |

|---|

Crystal Beamsplitters

| Polarizing Crystal Beamsplitters |

|---|

Other

| Other Beamsplitters |

|---|

| Specifications | |||||

|---|---|---|---|---|---|

| Beamsplitter | |||||

| Extinction Ratioa | Tp/Ts > 3000:1 | ||||

| Transmitted Wavefront Error | <λ/4 @ 633 nm (rms) | ||||

| Surface Quality | 40-20 Scratch-Dig | ||||

| Reflectanceb | <0.25% per Surface | ||||

| Wave Plate | |||||

| Retardance Accuracy | See Table Below | ||||

| Transmitted Wavefront Error | <λ/8 @ 633 nm (rms) | ||||

| Surface Quality | 20-10 Scratch-Dig | ||||

| Reflectanceb | <2.00% | ||||

| Assembly | |||||

| Transmitted Beam Deviationc | ±10 arcmin | ||||

| Reflected Beam Deviationc | 90° ± 20 arcmin | ||||

| Clear Aperture | Ø10.0 mm | ||||

| Wave Plate Specifications by Assembly Item # | ||||

|---|---|---|---|---|

| VA5-1550(/M) | ||||

- Design Wavelengths: 532, 633, 780, 1064, or 1550 nm

- Beamsplitter Extinction Ratio of > 3000:1

- Antireflective (AR) Coated for Rabs < 0.25% @ 0° AOI

- Integrated Zero-Order Half-Wave Plates

Thorlabs' Laser-Line Variable Beamsplitters are constructed with a zero-order half-wave plate in a rotation mount and a 1" laser-line polarizing beamsplitter cube in a

Each beamsplitter cube is coated on its hypotenuse with a laser-line beamspitting coating which achieves a >3000:1 extinction ratio. Its faces are coated with an AR coating giving Rabs < 0.25% per surface at the design wavelength. The mechanical housing for these optics limits the clear aperture to Ø10.0 mm.

| Damage Thresholds | ||||

|---|---|---|---|---|

| Item # | Design Wavelength |

Unmounted |

Damage Thresholda | |

| 532 nm | PBS25-532 | CWb | 100 W/cm at 532 nm, Ø1.000 mm | |

| Pulsed | 2 J/cm2 at 532 nm, 10 ns, 10 Hz, Ø0.470 mm | |||

| 633 nm | PBS25-633 | Pulsed | 2 J/cm2 at 532 nm, 10 ns, 10 Hz, Ø0.803 mm | |

| 780 nm | PBS25-780 | Pulsed | 2 J/cm2 at 810 nm, 10 ns, 10 Hz, Ø0.166 mm | |

| 1064 nm | PBS25-1064 | CWb | 1.5 kW/cm at 1070 nm, Ø1.012 mm | |

| Pulsed | 2 J/cm2 at 1064 nm, 10 ns,10 Hz, Ø0.517 mm | |||

| 1550 nm | PBS25-1550 | CWb | 1.5 kW/cm at 1540 nm, Ø0.087 mm | |

| Specifications | |||||

|---|---|---|---|---|---|

| Beamsplitter | |||||

| Extinction Ratioa | Tp/Ts > 1000:1 | ||||

| Transmitted Wavefront Error | <λ/4 @ 633 nm (rms) | ||||

| Surface Quality | 40-20 Scratch-Dig | ||||

| Reflectanceb | <0.5% per Surface | ||||

| Wave Plate | |||||

| Retardance | See Table Below | ||||

| Transmitted Wavefront Error | <λ/8 @ 633 nm (rms) | ||||

| Surface Quality | 20-10 Scratch-Dig | ||||

| Reflectanceb | <2.00% | ||||

| Assembly | |||||

| Transmitted Beam Deviationc | ±10 arcmin | ||||

| Reflected Beam Deviationc | 90° ± 20 arcmin | ||||

| Clear Aperture | Ø10.0 mm | ||||

| Wave Plate Specifications by Assembly Item # | |||

|---|---|---|---|

- Optimized for Broadband Use in Four Bands: 420 - 680 nm, 690 - 1000 nm,

900 - 1200 nm, or 1200 - 1600 nm - Beamsplitter Extinction Ratio of > 1000:1

- Antireflective (AR) Coated for Ravg < 0.5% @ 0° AOI

- Integrated Achromatic Half-Wave Plates

Thorlabs' Broadband Variable Beamsplitters are constructed with an achromatic wave plate in a rotation mount and a 1" standard polarizing beamsplitter cube in a 30 mm cage cube. Each beamsplitter cube is coated on its hypotenuse with a broadband beamspitting coating which achieves a >1000:1 extinction ratio. Its faces are coated with an AR coating giving Ravg < 0.5% per surface over the design wavelength range. The mechanical housing for these optics limits the clear aperture to Ø10.0 mm. It should be noted that a broadband source transmitting light through the assembly will not be evenly attenuated across its entire bandwidth due to the performance of the achromatic wave plate. For more on how and why these uneven attenuations occur, see the Applications tab.

| Damage Thresholds | ||||

|---|---|---|---|---|

| Item # | Design Wavelength |

Unmounted |

Damage Thresholda | |

| 532 nm | PBS251 | CWb | 350 W/cm at 532 nm, Ø1.000 mm | |

| Pulsed | 2 J/cm2 at 532 nm, 10 ns, 10 Hz | |||

| 633 nm | PBS252 | CWb | 50 W/cm at 810 nm, Ø0.019 mm | |

| Pulsed | 2 J/cm2 at 810 nm, 10 ns, 10 Hz | |||

| 780 nm | PBS253 | CWb | 2000 W/cm at 1064 nm, >Ø0.018 mmc | |

| Pulsed | 2 J/cm2 at 1064 nm,10 ns, 10 Hz | |||

| 1064 nm | PBS254 | CWb | 2000 W/cm at 1542 nm, Ø0.033 mmc | |

| Pulsed | 5 J/cm2 at 1542 nm, 10 ns, 10 Hz | |||

Click to Enlarge

A C4W and C6W Cage Cube connected to a 1.5" wide CCM1-4ER Compact Cage Cube using the C4W-CC and CM1-CC Cube Connectors, respectively.

Click to Enlarge

CM1-CC Connecting Multiple 1.5" Wide Cage Cubes

- Connect Two 1.5" Wide Cage Cubes Side by Side

- Connect a 1.5" Wide Cage Cube to a 2" Wide Cage Cube

- Compatible with CM1 or CCM1 Series Cage Cubes

The CM1-CC cage cube connector allows two or more CM1 or CCM1 style cubes to be connected as shown in the image to the right. The CM1 and CCM1 series of cage cubes, which are all compatible with this connector, include empty cubes, empty dichroic cubes, mounted beamsplitters, mounted penta prisms, and mounted turning mirrors. The CM1-CC cage cube connector includes four 4-40 button-head screws, two 4-40 flat-head screws, four washers, and a 1/16" hex key.

Two cage cube-mounted turning mirrors cannot be connected using the CM1-CC due to a lack of Ø6 mm cage rod holes on two sides of the cube.

We also offer the C4W-CC to connect two 2" wide 30 mm cage cubes. Both C4W-CC and CM1-CC cage cube connectors can be used to connect one 1.5" wide 30 mm cage cube, such as our CCM1-4ER(/M), with a 2" wide 30 mm cage cube.

Alignment Pins

Please note that because dowel alignment pins are used, the connector requires drilled holes on the cube face between the SM1-threaded (1.035"-40) ports. If you have an older cube and would like it updated to have alignment holes for free, please contact Technical Support. Alternatively, the alignment pins are press-fit inside their mounting holes, and can be pressed out for use with cubes that do not have these alignment holes.

Products Home

Products Home

Zoom

Zoom

Variable Beamsplitters

Variable Beamsplitters