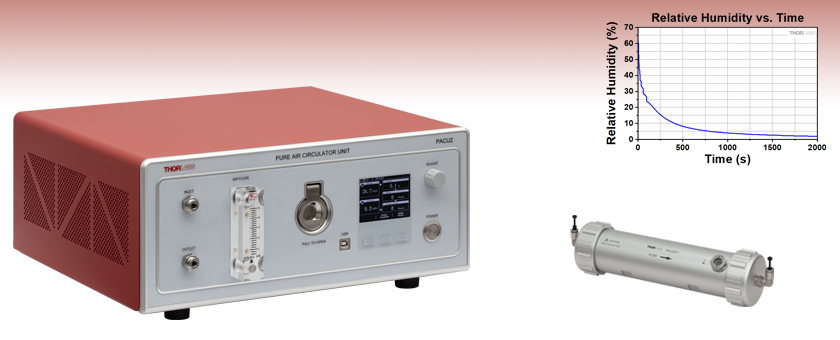

Pure Air Circulator Unit

- Filters Out Particulates, Volatile Organic Compounds, and Moisture

- Continuously Variable Flow Rate

- On-Unit LCD or PC Control

PACU2F1

Desiccant Filter Replacement for the PACU2 System

PACU2

Pure Air Circulator Unit

3.0 L Chamber Being Purged

at Flow Rate of 3.0 L/min

Please Wait

Click to Enlarge

Inlet, Outlet, and Air Flow Meter on the PACU2 Air Purifier

Click to Enlarge

LCD Screen, Control Buttons, and Flow Rate Knob on the PACU2 Air Purifier

Features

- Three-Stage Filtration System Removes Moisture, Particulates, and Volatile Organic Compounds (VOC)

- Ideally Suited for Closed-Loop Systems

- Flow Rate Continuously Adjustable

- On-Unit Button-Controlled Display (LCD) Shows Settings and Diagnostics

- PC Control with Software GUI or Command Line Interface

- Rack Mount Version of the PACU2 Unit Available upon Request by Contacting Tech Sales

- Replacement Filters and Tubing Also Available

Thorlabs' PACU2 Pure Air Circulator Unit excels at providing an extremely clean, dry atmosphere for closed-loop experimental setups. Consisting of desiccant and particulate filters in series, it can quickly and reliably purge contaminants from inside sealed experimental volumes, generating very high-purity environmental conditions. This closed-loop laboratory air circulator is an ideal choice for use in infrared spectroscopy measurements, which can be extremely sensitive to water vapor. It is also useful in applications that benefit from a pure and clean atmosphere like the cavity of our Long-Wave Infrared Supercontinuum Laser. For enclosed SM1 lens tube systems, Thorlabs offers the CPPC(/M) Purge Connector, shown below.

Click to Enlarge CPPC Purge Connectors make the PACU2 Pure Air Circulator Unit compatible with enclosed SM1 Lens Tube systems.

By simply connecting two hoses (one supply and one return) to the 1/4" push-to-connect fittings on the front of the unit, the user gains a turnkey air filtration system, capable of providing a cleanroom-grade environment for several months without service. For external connections, Thorlabs recommends a low-outgassing tubing (0.18" ID x 1/4" OD), 13.1' (4 m) of which is included with the PACU2 air circulation system. Additional tubing can be purchased below in 13.1' (4 m) and 26.2' (8 m) lengths.

This air circulation unit purifies air in three separate stages. First, air is passed through the PACU2F1 Desiccant Filter and 4A Molecular Sieve designed to trap airborne water molecules. Next, air is passed through the PACU2F2 Sintered Pore Element Filter which removes particulates larger than 15 µm. The final filter is the PACU2F3 13X Molecular Sieve and Desiccant Filter, which traps volatile organic compounds. Replacement filters can also be purchased separately below.

The flow rate of the micro-diaphragm in-line pump is continuously adjustable by a knob on the front panel and is measured by an in-line flow meter after the first of the three filters. A locking handle on the front of the unit pulls open a drawer to access the filters and internal components. The desiccant of the PACU2F1 and PACU2F3 filters can be assessed for saturation once the drawer is open by checking the viewing window on the filter housing. Pink desiccant indicates that the desiccant is saturated and should be replaced. The LCD screen (shown above) shows the elapsed time each filter has been in operation, with a counter for the PACU2F1 filter and a separate counter that times both PACU2F2 and PACU2F3 filter use. When the PACU2F1 filter is replaced, its counter should be reset. If the PACU2F3 filter needs to be replaced, we recommend replacing the PACU2F2 filter at the same time, resetting their counter upon replacement. However, if the maximum flow of the unit is < 3 liters per minute (when the inlet and outlet are directly connected) and the PACU2F3 filter is not saturated (and there are no tubing or pump obstructions), then only the PACU2F2 filter needs replacement. The counter does not need resetting in this case until the PACU2F3 filter is saturated and replaced. For instructions on how to replace the desiccant filters, please see the circulator's manual.

In addition to on-unit controls, the PACU2 unit can be connected to a PC via the USB port on the front panel for either GUI or command line interface control. Software for GUI control can be downloaded by going to the Software tab. Details on using the command line interface can be found in the manual.

The air purifier is housed in a 17.02" x 15.97" x 7.65" (432.4 mm x 405.7 mm x 194.3 mm) [L x W x H] benchtop enclosure. A rack-mountable version of the unit for use in a 19" Rack Cabinet is available upon request by contacting Tech Sales.

| PACU2 Specifications | |

|---|---|

| Temperature and Relative Humidity Sensor | |

| Ambient Temperature Range (Accuracy) | -40 - 125 °C (±0.2 °C) |

| Ambient Relative Humidity Range (Accuracy) | 0 - 100% (±1.8%) |

| Inlet Relative Humidity Range (Accuracy) | 0 - 100% (±1.8%) |

| Outlet Relative Humidity Range (Accuracy) | 0 - 5 % (±0.5%) 5 - 10% (±1.0%) |

| Filters | |

| Item # PACU2F1a | Indicating DRIERITE®b Desiccant and 4 Å Molecular Sieve |

| Item # PACU2F2 | 15 µm Sintered Pore Element Filter |

| Item # PACU2F3 | Indicating DRIERITE® Dessicant and 13X Molecular Sieve |

| General | |

| Flow Ratec | 0 to 3.5 L/min. |

| Flow Meter Range | 0.6 to 5 L/min. |

| Compatible Air Temperature Range |

5 - 40 ºC |

| Air Pump | Micro-Diaphragm Pump with 3.5 L/min. Max Delivery at 1 atm Pressure, Ultimate Pressure 1.5 Bar |

| Internal Tubing | Low-Outgassing Tubing, 0.18" ID x 1/4" OD, 1 MPa @ 20 °C |

| External Tube Fittings | Type 304/316 Stainless Steel, Push-to-Connect fittings for 1/4" OD Tubing |

| Power Compatibility | 110 - 240 VAC, 50 - 60 Hz Operation, Location Specific Power Cord Included |

| Dimensions (L x W x H) | 17.02" x 15.97" x 7.65" (432.4 mm x 405.7 mm x 194.3 mm) |

| Weight | 13.9 kg |

Click to Enlarge

Click for Raw Data

An enclosure with a 3.0 L volume that contained a hygrometer probe was exposed to ambient conditions, then sealed and purged by the PACU2 unit at a flow rate of 3.0 L/min. After 33 minutes (2000 seconds), the relative humidity had dropped below the concentration measurable by the hygrometer, demonstrating near-complete removal of airborne water molecules.

Click to Enlarge

Click for Raw Data

The graph above shows the water absorption spectrum of a broadband halogen source coupled to an OSA205C Optical Spectrum Analyzer through free space. The blue trace shows the spectrum without the air purification while the red shows the spectrum with air purification used to purge the OSA205C cavity. The use of the PACU2 Pure Air Circulator Unit reduces the water absorption inside the OSA.

Software for the PACU2 Pure Air Circulator Unit

The Windows® based software package provides a GUI for remote PC control of the PACU2 unit. The GUI's controls duplicate all the front panel functions including inlet and outlet relative humidty, the service time of the individual filters, and pump power. More information on the software can be found in the manual.

| Recommended System Requirements | |

|---|---|

| Operating System | Windows® 7 (32 or 64-Bit)a, 10 (64-Bit), or 11 (64-Bit) |

| Processor (CPU) | ≥1 GHz |

| Memory (RAM) | 2 GB |

| Hard Drive | 25 MB (Min) of Available Disk Space |

| Interface | USB 2.0 |

| Posted Comments: | |

jlow

(posted 2012-10-08 14:58:00.0) Response from Jeremy at Thorlabs: The desiccant in the PACU can be recharged over and over again. It is done by removing the desiccant from the filter casing and then baking it in an oven to recharge it. The indicating desiccant can lose its indicating property after the first bake and turns white, making it a non-indicating desiccant. One would typically just replace the indicating desiccant instead. Per your suggestion, a possible future version would be incorporating a rechargeable desiccant container by adding a heater and changing the desiccant container to metal. There might also be an option to either cool or heat the filtered air using Peltier devices and a temperature controller too but that's still quite some time away. andrgrimes

(posted 2012-10-06 03:35:06.0) This looks like a great product one question I have which also might be an improvement would be why dont you use a desiccant that can be dryed from being heated and have a heater surround the desiccant. If that was part of this unit it would be perfect. |

Click to Enlarge

Easily check or replace filters by opening the drawer on the PACU2 unit.

- Three-Stage Filtration System Includes Desiccant Filter, 15 µm Particulate Filter, and 13X Molecular Sieve

- Ideal for Applications that Benefit from a Pure and Clean Atmosphere

- Optional 19" Rack Mountable Version Available by Contacting Tech Sales

- 4 m of Low-Outgassing Tubing is Included with the Device (Additional Tubing is Available Below)

The PACU2 Pure Air Circulator Unit is a closed-loop filtration unit that consists of several filters designed to remove moisture and particulates from the air. It is ideal for the continuous filtering and circulation of extremely clean, dry air in an optical cavity. The three filters included with the system are the desiccant and 4 Å molecular sieve filter, 15 µm in-line particulate filter, and a 13X molecular sieve with desiccant filter.

Pull up on the handle lock on the front of the unit and pull open the drawer to access the filters and internal components. The desiccant of the PACU2F1 and PACU2F3 filters can be assessed for saturation once the drawer is open by checking the viewing window on the filter housing. Pink desiccant indicates that it is saturated and the filter should be replaced. If the filters are saturated, the airflow will be reduced as indicated by the flow meter. Filter replacements for this unit can be purchased separately below. Alternatively, the desiccant can be regenerated by following the regeneration instructions in the manual.

Click to Enlarge

Pink, Water-Saturated Desiccant as Viewed through the PACU2F1 Filter Window

Click to Enlarge

Blue, Unused Desiccant as Viewed through the PACU2F1 Filter Window

- Direct Replacement Filters for the PACU2 System:

- PACU2F1 Desiccant and 4 Å Molecular Sieve

- PACU2F2 Sintered Pore Element Filter for >15 µm Particulates

- PACU2F3 13X Molecular Sieve with Desiccant

The PACU2F1, PACU2F2, and PACU2F3 filters are replacement filters for the PACU2 pure air circulator unit system. The PACU2F1 filter consists of indicating desiccant and 4 Å molecular sieve with 70 g moisture capacity for air- and gas-drying. The PACU2F2 filter is a sintered pore element filter that removes particulates larger than 15 µm with better than 95% efficiency. The PACU2F3 filter consists of a 13X molecular sieve and indicating desiccant, which traps volatile organic compounds. If the filters are saturated, the airflow will be reduced as indicated by the flow meter.

The indicating desiccants of the PACU2F1 and PACU2F3 filters will change color from blue to pink when saturated with water. Filter saturation can be checked by opening the drawer of the PACU2 unit and checking the viewing window on the filter housing. After several months of use the desiccant filter is likely to need replacement. Additionally, the desiccant and molecular sieve can be regenerated by heating the materials. Installation and filter regeneration instructions for the desiccant filter can be found in the PACU2 unit manual.

- Low-Outgassing Tubing for PACU2 Pure Air Circulator Unit

- 0.18" ID x 1/4" OD (4.6 mm ID x 6.4 mm OD), 1 MPa @ 20 °C Tubing

- Continuous Operation Temperature: -4 °F to 392 °F (-20 °C to 200 °C)

- Available in 13.1' (4 m) and 26.2' (8 m) Lengths

This clear low-outgassing tubing is required for supplying and returning air or inert gas (N2) to the pure air circulator unit. This tubing is resistant to abrasions and many commonly used chemicals, and can be used in any application where maintaining high purity is critical. It has a max pressure rating of 1 MPa at 20 °C and is available in both 13.1' (Item # PACU2T4) and 26.2' (Item # PACU2T8) lengths. The PACU2 system includes the PACU2T4 Tubing. Even though the tubing can handle air temperatures from -4 °F to 392 °F (-20 °C to 200 °C), the PACU2 unit is rated for air temperatures from 41 °F to 104 °F (5 °C to 40 °C).

Note: Only low-outgassing semi-flexible or rigid tubing is compatible with the PACU2 system, other tubings such as the HPU6 hose are not suitable for use with the air purifier.

Click to Enlarge

Pink, Water-Saturated Desiccant in the Former PACU System

Click to Enlarge

Blue, Unused Desiccant in the Former PACU System

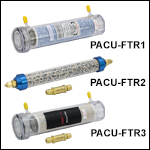

- Desiccant Air- and Gas-Drying Filter

- Filter Set Includes a 15 µm In-Line Particle Filter and a 13X Molecular Sieve

- Direct Replacement Filters for the Former PACU Pure Air Circulator Unit

The PACU-FTR1 filter is a desiccant air- and gas-drying replacement filter for the former PACU Pure Air Circulator Unit system. This filter will change color from blue to pink when saturated with water. As shown to the right, the vent holes on the top of the unit offer a convenient way to check for saturation without having to disassemble the unit. After several months of use the desiccant filter is likely to need replacement. Installation instructions for the desiccant filter can be found in the former PACU unit manual.

The PACU-FTR2 and PACU-FTR3 are fine filter replacement sets for the former PACU Pure Air Ciculator Unit. The first filter in each set is a 15 µm in-line particle filter, which removes particulates with better than 95% efficiency. The second is a 13X molecular sieve, which traps volatile organic compounds. If the filters are saturated, the airflow will be reduced as indicated by the flow meter. When replacement is needed, both filters should be replaced simultaneously. Step-by-step installation instructions for these filters can be found in the PACU manual.

The 13X molecular sieve comes in two different styles. When the filter set needs to be replaced, it should be replaced with the set that contains the same style of sieve. For PACU systems purchased before September 1, 2015, please purchase the PACU-FTR2 Replacement Filter Set. For PACU systems purchased on or after September 1, 2015, please purchase the PACU-FTR3 Replacement Filter Set.

Products Home

Products Home

Zoom

Zoom

Pure Air Circulator Unit

Pure Air Circulator Unit