Optical Enclosure Accessories

- Anodized Aluminum and High-Strength Plastic Cubes for Corners

- Black Hardboard and Aluminum Enclosure Panels

- Hardware and Kits for Adding Enclosure Lids

- Cover Plate Protects Rail End

XE25H

Hinge for Lids or

Other Openings

XE25W3

Quick-Install Corner

XE25LS

Backstop

XE25C

Cover Plate

TB4

Black Hardboard

XE25GSK

Door Opener Kit

(Not to Scale;

Screws, Brackets, and Gas Springs Included)

XE25DK1

Sliding Door Kit

(Not to Scale)

LPCE9

Laser Safety Fabric Panel

(Not to Scale)

Please Wait

| XE25 25 mm Construction Rail Accessories | ||||

|---|---|---|---|---|

|

|

|

|

|

| Rails | Cubes and Brackets |

Breadboard Mounting |

Rail Joiners | Channel Insert |

|

|

|

|

|

| Construction Tools |

T-Nuts and Screws |

Enclosures | Enclosure Accessories |

|

Click for Details

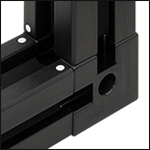

Side view of XE25C11 and AEPU1 enclosure utility panel.

Features

- Construction Cubes for Rigid Corners and Joints

- Right-Angle Brackets and Gusset Plates Reinforce Corners

- Enclosure Panels

- Lightweight Black Hardboard Panels Block Unwanted Light

- Durable Aluminum Panels with Blank Connection Panels

- Laser Safety Fabric Panels Certified to EN Specifications

- Transparent Certified Laser Safety Panels Also Available

- Kit for Assembly of Sliding Doors for Existing Enclosures

- Hinge for Constructing Lids that Smoothly Open and Close

- Backstops, Door Opener Kit, and Lockable Bracket to Hold Enclosure Lids Open

- Attachable Handles Allow Easy Movement

- Cover Plate Hides Exposed Rail Ends

Thorlabs' add-ons for 25 mm rail optical enclosures aid in building complex structures that are sturdy and easy to use. We offer construction cubes of either high-strength plastic or anodized aluminum for forming corners of up to three rails, as well as brackets and gusset plates that reinforce right-angle connections. Our black hardboard and posterboard panels block stray light and can easily be cut to size. We also offer a kit for the addition of sliding doors to an existing optical enclosure such as the XE25C9(/M). Additionally, our hinges, backstops, door opener kit, and locking bracket help construct convenient enclosure openings. Our non-flammable, black-anodized aluminum enclosure utility panels offer superior durability to our black hardboard panels, while our flame-retardant laser safety fabric panels provide a flexible alternative. Transparent laser safety panels allow for visibility into enclosures without compromising safety. Thorlabs also manufactures a cover plate designed to shield a rail end.

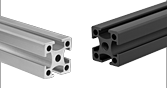

Thorlabs' accessories for assemblies made of 25 mm rails include corner cubes and brackets, T-Nuts, low-profile channel screws, breadboard mounting accessories, rail joiners, and a channel insert. In addition, we offer optical enclosures and do-it-yourself tools like taps, tap guides, and drill guides for home-built XE25-based constructions.

Click to Enlarge

Click to EnlargeHome-Built 90° Corner

XE25 Construction Techniques

Thorlabs' XE25 rails and components are the building blocks for many types of modular systems, including custom enclosures. For the most demanding applications, Thorlabs recommends the "direct connection" technique for forming right angles with rails, detailed here. All the construction parts shown in this tutorial are available on our XE25 Construction Tools page.

Step 1: Drill Side Holes

A Ø4.6 mm hole in the end of one rail, as shown in the picture to the right, is needed to provide access for a 1/8" (4 mm) balldriver.

For this step, you will need the T119873 Ø4.6 mm Drill Bit, the XE25DG Drill Guide, a hand drill or drill press, and a vise.

The XE25DG drill guide is secured to the rail using the locking screw on top. A guide hole for the drill bit will be located 12.5 mm from the end of the rail. Now a hole can be drilled into the rail as shown in the figure to the left.

If your application requires a "three-way corner," such as that shown at the top of the page, you will have to drill a second hole in the rail at a 90° angle relative to the first hole.

Step 2: Tap the Center Hole, If Necessary

All stock and custom-length anodized XE25 rails have a 1/4"-20 (M6) tapped hole in the end of the rail. If you have cut a standard XE25 rail, or are using the XE25RL2 Raw Extrusion, you will need to tap a hole into the end of the rail.

For this step, you will need the 71598 1/4"-20 Tap (or the 71498 M6 Tap), the XE25TG Tap Guide, and the TW25 Hand Tap Wrench.

Fix the tap inside the tap wrench. Place the tap guide block over the end of the rail. The hole in the top of the guide will keep the tap square with the hole and minimize the chance of misthreading. Turn the tap to thread the hole.

Step 3: Attach Low-Profile Channel Screw

For this step, you will need a SH25LP38 1/4"-20-threaded (SH6M10LP M6-threaded) Low-Profile Channel Screw and a 1/8" (4 mm) balldriver.

Insert the screw into the threaded hole in the end of the rail, and tighten down partway with the balldriver. If you are making a three-way connection, you will need to thread another channel screw into the end of a second rail.

Step 4: Join the Rails

Slide the head of the channel screw into the channel of the rail with the drilled holes, so that the hex head lines up with the hole. Insert the balldriver into the hole, and tighten the channel screw. If making a three-way connection, repeat this process with the third rail, as shown in the figure to the right.

For increased stability, the corners may be reinforced with the XE25A90 Right-Angle Bracket.

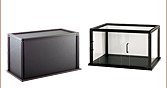

525 mm (L x W x H) enclosure with black hardboard panels. The parts needed for this custom enclosure are provided in the tables below.

Design a Custom Enclosure Using Thorlabs Components

With our vast selection of enclosure components, building your own DIY optical enclosure is simple. All our optical enclosure components, from panels to optical rails and corner cubes, can be purchased separately and customized to a size suitable for your application. For example, simple enclosures can be constructed to be as small as 1' x 1' x 1' (300 mm x 300 mm x 300 mm), whereas much larger enclosures are possible and might include hinged doors for easy access to an experiment. Enclosure components are designed to work together seamlessly, reducing the amount of time required during assembly.

Any side or dimension of the enclosure can be modified to suit the requirements of your application. The black hardboard enclosure panels can be cut to the appropriate size or drilled to accommodate integrating optomechanical components, like lens tubes. Alternatively, black-anodized aluminum panels are available with pre-drilled slots, for fiber and electrical panels, and an SM1-threaded (1.035"-40) through hole.

Should you choose not to build your own DIY enclosure, we welcome the opportunity to work with you to provide a custom enclosure that meets your specific requirements. Customizable options include enclosure dimensions, like panel sizes and optical rails; panel material, like black hardboard or black-anodized aluminum; and number and configuration of doors. We will ensure the proper fit and function of the customized components. Once the custom enclosure meets specification, we will ship the components for customer assembly. Please note that aluminum breadboards are not included with our custom enclosures and that enclosures will need to be assembled by the customer.

If you would like consultation regarding whether to place a custom order or which components you need to purchase in order to assemble your own DIY optical enclosure, please contact Tech Sales.

Custom Enclosure Example

This section details how to construct a two-door enclosure with black hardboard panels, which is shown completely assembled in the bottom-right image. Watch the video above for step-by-step instructions on how to assemble this particular enclosure. The size of this enclosure is 1200 mm x 600 mm x 525 mm (L x W x H). Refer to the tables below for a complete parts list. The enclosure was constructed from metric components, but it can also be constructed using the imperial equivalent components.

Click for Details

Custom enclosures can be built using our 25 mm rails and accessories. This two-door enclosure was constructed entirely from stock items. The video above provides step-by-step instructions on how to assemble this enclosure.

Click to Enlarge

Two TB4 hardboards (cut to the required height) can be taped together using T743-2.0 Black Masking Tape to form the back panel of the enclosure.

This enclosure was assembled on a 600 mm x 1200 mm aluminum breadboard (24" x 48" for imperial components), though other breadboard sizes are possible. The left and right doors are 500 mm and 600 mm (20" and 24") wide, respectively. Each door can be opened separately, allowing access to the breadboard inside the enclosure. We recommend building the doors and frame of the enclosure separately and then assembling them to complete the enclosure. The rails used in the doors and frame are connected via construction cubes with slotted corners, which help to prevent light leakage at the corners of the enclosure, and are secured using low-profile channel screws. Alternatively, for a faster solution, our quick corner cubes can be used. Our TB4 hardboard, which constitute the panels of the enclosure, can be cut to size using a utility knife; these pieces fit directly into the slots of the 25 mm rails and the counterbores of the cubes. The back panel is formed using two pieces of hardboard cut to the desired length and height and taped together using T743-2.0 Black Masking Tape (see the image to the right). Note that, for the imperial enclosure, black masking tape will also be needed to connect the 24" x 24" panels together along the sides and back of the enclosure.

A 25 mm rail is installed along the top of the enclosure to mount the doors and door hinges. This rail is attached by drilling through the top two frame rails; see the video above for details. For details on drilling and tapping a hole into the top frame rails for precise placement of the support rail, see the Construction Methods tab above.

The height of the enclosure can easily be customized to fit any application. For best results when adding doors to your enclosure, the total door height with connection cubes should match the enclosure height minus the bottom rails; otherwise, the door will overlap with the bottom rail. We recommend using 500 mm (20") and 525 mm (21") long rails for the door and enclosure, respectively.

For applications requiring a light-tight enclosure, our BFP1 black flocked self-adhesive paper can be used to seal gaps in the hinges of the enclosure.

| Posted Comments: | |

Matthieu GRAU

(posted 2024-03-27 08:15:13.02) It would be nice to have two option with this product :

One with imperial screws and one with metric screws.

Even in my cart, there is an automatic message saying I have metric and imperial products in the same time in my cart, and when I choose, "change to metric" then the message come back.

Thanks for reading,

Have a nice day. cdolbashian

(posted 2024-03-29 02:52:14.0) Thank you for reaching out to us with this inquiry. Fortunately, since this component just adapts to the 1" extrusion via t-nuts, the threads are only interfacing with the components sold in this kit. As such there isn't really a necessity for a metric vs imperial version. That being said, perhaps we need to change the cart checkout notification to reflect that this is not an incompatibility. I have contacted you directly to discuss this further. |

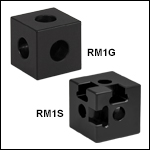

Click to Enlarge

Low-Profile Screw in RM1G Construction Cube

Click to Enlarge

Standard Cap Screw in RM1G Construction Cube

Click to Enlarge

Three-Way 25 mm Rail Junction Using an RM1G Construction Cube

Click to Enlarge

RM1S Slotted Cube Securing a Hardboard Enclosure Wall

- RM1G: Counterbored on Three Sides

- RM1S: Counterbored on Three Sides and Slotted to Accommodate Panels

- One-Piece Aluminum Construction for Excellent Rigidity

- Parallel and Perpendicular to Within 0.002" (0.05 mm)

These Construction Cubes contain three 1/4" (M6) counterbores on adjacent faces. They can be connected to up to three rails by tightening our low-profile channel screws (sold separately) through the counterbores, as shown in the first two images to the right. The third and fourth images illustrate how a low-profile screw's shortened cap height prevents neighboring screws from interfering with each other. In addition, the RM1S cube has slotted corners to accept posterboard and hardboard walls for the construction of light-tight optical enclosures. Since both these cubes are machined from a single block of aluminum, they are ideal for constructions that need to be as sturdy as possible.

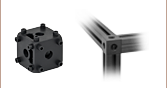

Click to Enlarge

Three-Way 25 mm Rail Junction Using an XE25W3 Quick Corner Cube

- Holds up to Three Rails at Right Angles

- Made from High-Strength Reinforced Plastic

- For Use with Low-Profile Channel Screws

The prongs on the faces of an XE25W3 Quick Corner Cube are positioned to fit into the four alignment holes on the end of a 25 mm rail. Because the prongs and the alignment holes form a tight fit, it may be difficult to insert the corner cube by hand. We therefore recommend using our low-profile channel screws (sold separately) to fasten the corner cube to the rail, as shown in the image and the animation to the right.

Although these corner cubes provide excellent results when building enclosures, they are not recommended in cases where rails are being used to support optomechanics. In these situations, please use the RM1G Construction Cube shown above, or consider the techniques shown in the Construction Methods tab.

Click to Enlarge

Reinforced Corner

Click to Enlarge

Enclosure Bolted to Optical Table

- Brace 25 mm Rail Corners or Mount Rails Vertically

- One-Piece Aluminum Construction for Excellent Rigidity

- For Use with 1/4"-20 (M6) Cap Screws

The AB90H and XE25A90 Right-Angle Brackets can be used to fasten 25 mm rails to each other using a T-Nut (sold separately) or to an optical table. Both intended for use with 1/4"-20 (M6) cap screws and washers, the AB90H has a total of two 1/4" wide slots of lengths of 1" (25.4 mm) and 0.5" (12.7 mm), allowing for additional flexibility in positioning the rails on a breadboard, while the XE25A90 has two counterbored holes.

These brackets are ideal for fastening our optical enclosures to an optical table or breadboard.

Click to Enlarge

XE25GP Gusset Plate Connecting Two 25 mm Rails

| Item # | Rail 1 | Rail 2 | Recommended # of Nut & Screw Setsa |

|---|---|---|---|

| XE25GP | 25 mm | 25 mm | 3 |

| XE50GP2 | 50 mm | 5 | |

| XE75GP2 | 75 mm | 7 |

- Connect Two Rails at a 90° Elbow

- 1/8" (3.2 mm) Thick Anodized Aluminum

- For Use with Low-Profile 1/4"-20 (M6 x 1.0) Channel Screws and

T-Nuts (Sold Separately; See Table to the Right for Details)

These gusset plates are used to create strong 90° elbows using our 25 mm, 50 mm, and 75 mm construction rails. They provide reinforcement similar to the right-angle brackets sold above but do not block the inner channels of the elbow joint, instead leaving them open for hardboard or plexiglass panels. Each gusset plate features mounting holes designed for use with low-profile 1/4"-20 (M6 x 1.0) channel screws (10 mm max length) and matched T-nuts (both sold separately). When attaching rails of different sizes, we recommend mounting the smaller rail using multiple holes along the base of the gusset plate to provide additional rigidity, if possible.

To assemble, insert the screws into the gusset plate and loosely thread them into nuts on the back. Then slide the nuts into the rail channels and align the rail ends. With the rails aligned, tighten the channel screws.

Click to Enlarge

XE50GP4 Gusset Plate Connecting a 25 mm Rail to a 50 mm Rail

| Item # | End Rail(s) |

Center Rail |

Recommended # of Nut & Screw Setsa |

|---|---|---|---|

| XE25GP2 | 25 mm | 25 mm | 4 |

| XE50GP4 | 50 mm | 6 | |

| XE75GP5 | 75 mm | 8 |

- Connect Two or Three Rails in a Three-Way Junction

- 1/8" (3.2 mm) Thick Anodized Aluminum

- For Use with Low-Profile 1/4"-20 (M6 x 1.0) Channel Screws and

T-Nuts (Sold Separately; See Table to the Right for Details)

These gusset plates are used to create strong three-way junctions using our 25 mm, 50 mm, or 75 mm construction rails. They provide reinforcement similar to the elbow gusset plates sold above but with additional mounting holes to form a tee. Each gusset plate features mounting holes designed for use with low-profile 1/4"-20 (M6 x 1.0) channel screws (10 mm max length) and matched T-nuts (both sold separately). When attaching rails of different sizes, we recommend mounting the smaller rail using multiple holes along the base of the gusset plate to provide additional rigidity, if possible.

To assemble, insert the screws into the gusset plate and loosely thread them into nuts on the back. Then slide the nuts into the rail channels and align the rail ends. With the rails aligned, tighten the channel screws.

Click to Enlarge

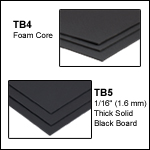

Enclosure with TB4 Panels

- Blocks Stray or Unwanted Light

- Easily Shaped with a Utility Knife

- TB5: 1/16" (1.6 mm) Thick, Solid Cardboard Panel

- TB4: 3/16" (4.76 mm) Thick, Plastic-Coated Cardboard Panel with Foam Core

Thorlabs' black panels are an essential component of light-tight enclosures. Our TB5 Black Posterboard is 1/16" (1.6 mm) thick and ships in packages of five 20" x 30" (50.8 cm x 76.2 cm) panels. Simply score the panel with a utility knife and bend to form a light-tight corner.

In contrast, our TB4 Black Hardboard is 3/16" (4.76 mm) thick and ships in packages of three 24" x 24" (61.0 cm x 61.0 cm) panels. The increased thickness provides enhanced acoustic absorption, while the foam core (pictured to the right) helps it remain lightweight. We recommend using our 2" wide black masking tape for corners and other joints to eliminate the passage of light through those areas. This is the same hardboard used in our preconfigured optical enclosures.

Upon request, we can offer the TB4 hardboard in custom sizes up to 48" x 48" (121.9 cm x 121.9 cm) to customers in North America, or up to 44" x 32" (111.8 cm x 81.3 cm) elsewhere. Please contact Tech Sales for a quote. Thorlabs also offers a comprehensive selection of blackout materials.

| Damage Threshold Specificationsa | |

|---|---|

| Type | Damage Threshold |

| Pulsed | 0.50 J/cm2 (532 nm, 10 ns, 10 Hz, Ø0.504 mm, 200 shots) 0.90 J/cm2 (1064 nm, 10 ns, 10 Hz, Ø1.00 mm, 200 shots) |

| CW | 23.6 W/cm (532 nm, Ø1.00 mm, 60 s exposure) |

Click to Enlarge

AEPU1 Being Inserted in an Aluminum Enclosure

- Anodized Aluminum For Durability

- Four Blank Connection Panels and One SM1-Threaded Through Hole

- Eliminates Need to Drill Holes for Connectors

- Rubber Anti-Vibration Dampeners Increase Stability

- Available in 15" x 12" (375 mm x 300 mm) or 9" x 12" (225 mm x 300 mm) Sizes

- 0.13" (3.2 mm) Thick

These aluminum enclosure utility panels feature four RBX-BLK1F blank connection panels and one SM1-threaded (1.035"-40) through hole covered by a removable SM1CP2M end cap. The blank connection panels can be removed for easy installation of our fiber or electrical connection panels. The SM1-threaded hole allows for a range of SM1-compatible components, like our lens tubes, to be installed. Designed to be used in an optical enclosure, each utility panel includes six rubber anti-vibration dampeners to increase durability and stability, eliminating rattling when the enclosure is moved.

These enclosure panels are designed to be used in our line of optical enclosures. The AEPU2(/M) enclosure panel is compatible with our XE25C7(/M) and XE25C8(/M) black hardboard enclosures, while the AEPU1(/M) enclosure panel is compatible with the XE25C9(/M) and XE25C9D(/M) black hardboard enclosures, as well as the XE25C10(/M) and XE25C10D(/M) Plexiglass enclosures. Note the AEPU1(/M) is already included with our XE25C11(/M), XE25C11D(/M), and XE25C11T(/M) aluminum enclosures.

These aluminum enclosure panels are offered in custom sizes and designs. Please send all inquiries to Tech Sales.

| Fabric Panel Item # | Dimensions | Compatible Enclosures |

|---|---|---|

| LPCE9 | 10.96" x 12.99" | XE25C7 XE25C8 |

| LPCE15 | 16.97" x 12.99" | XE25C7 XE25C9 |

| LPCE21 | 22.97" x 12.99" | XE25C8 XE25C9 |

| LPCE225/M | 275.0 x 325.0 mm | XE25C7/M XE25C8/M |

| LPCE375/M | 425.0 x 325.0 mm | XE25C7/M XE25C9/M |

| LPCE525/M | 575.0 x 325.0 mm | XE25C8/M XE25C9/M |

Click to Enlarge

LPCE21 Panel Used to Replace One Hardboard Side of an Optical Enclosure. The thumbscrews can be easily removed in order to access the inside of the enclosure.

- Attach to 25 mm Rails for Optical Enclosures

- Flame Retardant

- Certified to EN 12254: 2010(E) (See Disclaimer Below)

- For Custom Sizes, Contact Tech Sales

- Fasteners Sold Separately Below

These laser safety fabric panels are designed for the sides of our optical enclosures. Alternatively, the panels can be attached to custom-built enclosures using 25 mm rails. The table to the right shows compatible enclosures for each fabric panel.

All imperial panels are 12.99" tall and designed for an enclosure using vertical XE25L12 rails. All metric panels are 325.0 mm tall and designed for an enclosure using vertical XE25L300/M rails.

The fabric panels can be attached to the 25 mm rails using the LPCEF(/M) fasteners sold separately below.

*DISCLAIMER

This laser safety fabric has been tested by a third party using EN specifications; see the Certifications tab of the full web presentation for details. Due to manufacturing variances, mechanical wear, and laser damage, Thorlabs assumes no responsibility for laser material failure. Please consult your local laser safety specialist before purchasing to ensure that the fabric is suitable for your application. To minimize risk, inspect the material before each use and ensure that it is in excellent condition.

- Attach Laser Safety Fabric Panels to 25 mm Rail Channels

- Each LPCEF(/M) Kit Includes:

- Seven 8-32 (M4 x 0.7) Thumbscrews

- Seven 8-32 (M4 x 0.7) T-Nuts

- Seven 8-32 (M4 x 0.7) Setscrews

- Replacement 8-32 (M4 x 0.7) Thumbscrews Available [Item # LPCET(/M)]

The LPCEF(/M) fastener kit contains seven sets of thumbscrews, T-nuts, and setscrews. One fastener kit is enough to affix one laser safety fabric panel to the side of a compatible enclosure. Please see the manual for instructions.

The setscrews can be tightened using a 5/64" (2.0 mm) hex key or balldriver, while the thumbscrews do not have a hex socket.

Replacement thumbscrews for the fastener kit are also available in packs of 10.

Click to Enlarge

Click to Enlarge

Back of XE25H Hinge

- Build Lids that Swing Open and Closed

- Lid Stops Allow Hands-Free Operation in Confined Spaces

- Installed Using Rail Channels

The XE25H Hinge is a high-strength, molded plastic hinge that creates a cover that smoothly opens and closes. It is held in the rail channel by four low-profile channel screws and four T-Nuts (all included) that fasten with a 3 mm balldriver. Please note that the closed hinge leaves a gap between the two rails to which it is attached, resulting in an opening that is not light tight without further modification.

The XE25LS Lid Stop is an anodized aluminum backstop that limits the travel of a lid to a 120° arc, holding the lid open and allowing hands-free operation inside the enclosure. It is ideal for setups with limited space or other situations where a fully open lid is not desirable. The XE25LS attaches to the rail channel using a T-Nut (not included) and is packaged with a 1/4"-20 cap screw, an M6 cap screw, and a washer.

Click to Enlarge

Click to EnlargeEngraved dots indicate the widened channels.

- Kit for Constructing Sliding Doors Compatible with 25 mm Rail Optical Enclosures

- 21" x 12" (525 mm x 300 mm) Rail Assembly

- Doors Made of TB4 Hardboard to Block Stray or Unwanted Light

- Some Assembly Required

- Compatible with the XE25C9(/M) Optical Enclosure

The XE25DK1(/M) Sliding Door Kit allows for the integration of sliding doors or a barrier into an existing optical enclosure. This kit uses 21" (525 mm) long and 12" (300 mm) long rails, resulting in an overall 23" x 13" (584 mm x 325 mm) frame. The frame is shipped with the rails assembled; the door panels, handles, and door guide must be added during final assembly. Holes are pre-drilled for quick installation of the handles.

Please note that the rails and cubes included in this kit are not identical to our stock items. Each rail includes a widened channel over twice the thickness of TB4 panels to allow for each panel to slide over the other. The widened rail channels are indicated with engravings, as seen in the image to the right. For a complete enclosure assembly that includes the doors from this kit, please see the XE25C9D(/M) enclosure.

Click to Enlarge

- Holds Enclosure Lid Open at 90°

- Easy Installation Using Rail Channels

- Each XE25GSK Kit Includes:

The XE25GSK Door Opener Kit for 25 mm Rail Enclosures holds the lid of an enclosure open at 90°. Each gas spring attaches to the rail channel using four XE25T1 Drop-In T-Nuts, two brackets, and four 1/4"-20 low-profile screws that fasten with a 1/8" hex key (all included). Each kit comes with two gas springs to securely hold the lid open for hands-free operation inside the enclosure and is ideal for setups where a fully open lid is not desirable or possible due to limited space. If there are additional space constraints, we recommend using the XE25LB Locking Bracket (sold below) as a lower profile option.

Installation Instructions

To create the configuration to the right, mount the body end bracket up against the front construction cube on the enclosure rail using the included hex key. Mount the rod end bracket against the rear gusset plate on the door. Press the rod end of the gas spring socket

onto the ball stud of the rod end bracket. Lift the enclosure door until the body end socket of the gas spring lines up with the

ball stud on the body end bracket. Press the body end of the gas spring socket onto the ball stud of the body end bracket, and repeat the previous steps for the second gas spring in the kit. A Quick Start Guide card with detailed installation instructions is included with each kit.

Click for Enlarge

Click to Enlarge

The two pieces of the bracket interlock to hold open the enclosure lid.

Click to Enlarge

Engravings on the bracket pieces provide a guide for alignment during installation.

- Holds Enclosure Lid Open

- Compact Footprint

- Engraved Lines to Assist with Alignment During Installation

The XE25LB Locking Bracket for 25 mm Rail Enclosures holds the lid of an enclosure open in a set position. The bracket is composed of two interlocking pieces, one of which should be mounted to the hinged edge of the door frame and the other to the rail of the enclosure frame immediately behind. Each piece is engraved with a white line to assist with alignment, as shown in the image to the lower left. The bracket can be secured to the 25 mm rails via four SH25LP38 (SH6M8LP) cap screws and four drop-in T-Nuts (screws and T-nuts not included).

To install, secure the half of the bracket with the silver knob to the outer rail of the enclosure frame, behind the door frame. Install the second half of the bracket to the rail that forms the edge of the door frame, positioning it so that the engraved lines on the two halves of the bracket are aligned as seen in the image to the lower left. The bracket can be installed close to the gusset plate at the edge of the door for easy access (see photo to the right).

The bracket uses a spring-loaded plunger to lock the lid into place. Once installed, open the lid of the enclosure until the two pieces of the bracket snap together. This indicates that the pin on the end of the plunger has engaged with the hole in the other half of the bracket to hold the door open. To unlock the bracket so that the enclosure can be closed, keep one hand on the lid to support it and pull the spring plunger knob. Please note that once the knob is pulled, there is nothing holding the door open; a hand should be kept on the lid to prevent it from slamming down and causing damage to the enclosure.

Note that the spring-loaded plunger knob is designed to be pulled away from the bracket to disengage the pin and should not be rotated; forcing the knob to rotate may cause damage to the bracket.

Click for Details

Breadboard Handle Mounted onto a 25 mm Rail at the Base of a Custom Optical Enclosure

- Attach Handles to Rails

- Easily Open and Close Optical Enclosures

BBH1 Handles can be attached to optical enclosure rails for simplified transport and movement. As shown to the right, handles can be placed on an enclosure door, allowing easy opening and closing. These polymer handles are reinforced with glass fiber and are rated up to 250 kg (550 lbs) when properly installed. The two through holes allow the handles to be attached to rails using T-Nuts and standard 1/4"-20 or M6 cap screws (each sold separately). These handles can also be directly attached to breadboards, simplifying their removal from frames and ScienceDesks.

Click to Enlarge

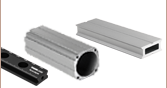

- Hide Exposed Rail Ends

- Beveled Corners Match Beveled Edges of 25 mm Rail

These 1 mm thick cover plates are designed to hide an exposed extrusion end. To maintain a minimal physical profile, we recommend the use of Low-Profile Channel Screws to hold the cover plate in place. These screws are sold below.

| Item # | Threading | Thread Length | Hex | Head Height | Quantity | Material |

|---|---|---|---|---|---|---|

| SH25LP38 | 1/4"-20 | 0.38" (9.7 mm) | 1/8" | 0.13" (3.2 mm) | 100 | Steel, Black Oxide Finish |

| SH25LP63 | 0.63" (15.9 mm) | 50 | ||||

| SH6M8LP | M6 x 1.0 | 8 mm (0.31") | 4 mm | 4 mm (0.16") | 50 | |

| SH6M10LP | 10 mm (0.39") | 100 | ||||

| SH6M16LP | 16 mm (0.63") | 50 |

Click to Enlarge

Low-Profile Screw in RM1G Construction Cube

Click to Enlarge

Standard Cap Screw in RM1G Construction Cube

Our Low-Profile Channel Screws have a reduced cap head height relative to standard screws, permitting them to be used in tight spaces. In particular, they are recommended when neighboring screws are at a right angle and in close proximity, as in our XE25W3 Corner Cube or RM1G and RM1S Construction Cubes.

Shown to the right are a standard cap screw and a low-profile channel screw installed in an RM1G cube. The low-profile screw's shortened cap height prevents neighboring screws from interfering with each other.

The head of each screw also fits into XE rail channels for alternate construction methods, as outlined here.

Products Home

Products Home

Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge

Zoom

Zoom

Optical Enclosure Components

Optical Enclosure Components