Discrete Piezoelectric Stacks, 5.2 µm to 100.0 µm Travel

- Low Voltage Piezo Stacks with 75 V, 100 V, 120 V, or 150 V Max Voltage

- Sub-Millisecond Response Time with No Load

- Free Stroke Displacement Options from 5.2 µm to 100.0 µm

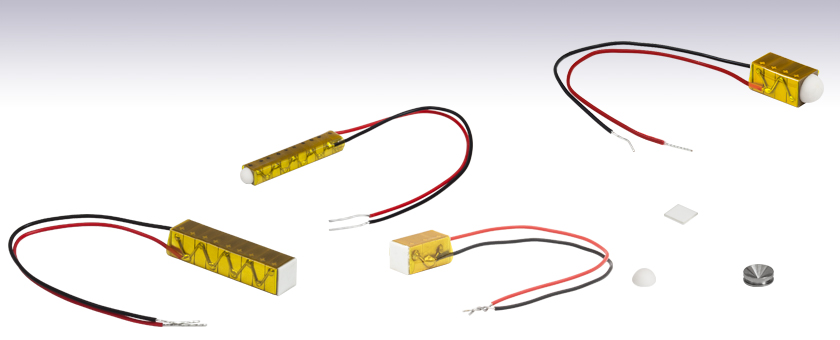

PK3JRP1

100 V PZT with One Hemispherical and One Flat Ceramic Plate

PK2FSP2

75 V PZT with Two Flat Ceramic Plates

PK4FMYP2

150 V BSPT with

Two Flat Ceramic Plates

PK2FMP1

75 V PZT with

One Hemispherical and

One Flat Ceramic Plate

PKFCUP

Conical End Cup

PKFEP4

Flat End Plate

PKFESP

End Hemisphere

Please Wait

| Piezo Selection Guide |

|---|

| Piezoelectric Ceramic Stacks |

| Discrete, Square |

| Discrete, Square with Through Hole |

| Discrete, Round |

| Discrete, Ring |

| Discrete, Hermetically Sealed |

| Discrete, Shear (1D to 3D Positioners) |

| Co-Fired: Square, Square with Through Hole, Round, & Ring |

| Co-Fired or Discrete: Square with Strain Gauges |

| Piezoelectric Crystal Stacks |

| Square |

| Piezoelectric Chips |

| Mounted Piezoelectric Actuators |

| Ultrasonic Piezo Chips & Transducers |

| Vibrating Piezo Actuator |

Click to Enlarge

Correct and Incorrect Methods for Interfacing an

Off-Axis Load with a Piezo Stack (For More

Examples, See Operation Tab)

| Webpage Features | |

|---|---|

| Clicking this icon below will open a window that contains specifications, mechanical drawings, and graphs. | |

Features

- Drive Voltage Ranges: 0 to 75 V, 0 to 100 V, 0 to 120 V, or 0 to 150 V

- Free Stroke Displacement Options from 5.2 µm to 100.0 µm

- Each Stack Contains Multiple 75 V, 100 V, 120 V, or 150 V Piezoelectric Chips

- Operating Temperature Up to 130 °C or 150 °C for Lead Zirconate Titanate (PZT) Stacks

- BiScO3-PbTiO3 (BSPT) Stack Offered for Temperatures Up to 250 °C

- For Use in Open-Loop Setups

- Pre-Attached Wires (~75 mm Long) for Ease of Integration

- Ideal for OEM Applications

- Conical End Cups, Hemispheric End Pieces, and Flat End Plates Also Available Separately

- Custom Options Available, Please Contact Tech Support

Thorlabs' Discrete Piezoelectric Stacks consist of multiple piezoelectric chips stacked face-to-face and bonded via epoxy and glass beads. By combining many chips, a stack is able to achieve a free stroke displacement that is significantly larger than that of its single chip counterpart while maintaining sub-millisecond response times and a low drive voltage range. The piezo stacks available below are made from Lead Zirconate Titanate (PZT), low-dielectric PZT (Item # PK3GYXP2), or BiScO3-PbTiO3 (BSPT) (Item # PK4FMP2) ceramics. Using low-dielectric PZT ceramic allows for a higher displacement at a lower driving voltage, while BSPT ceramics offer higher operating temperatures (up to 250 °C).

Ceramic plates cap the two mounting surfaces of the piezoelectric stack, which are located at opposite ends of the stack. These piezos (except for Item #s PK3GYXP2 and PK4FMYP2) are available with one flat plate, and the other can be chosen to be flat or hemispherical. The hemispherical plate is attached so that the curved surface is exposed to the interface with the load. If your application requires the PK3GYXP2 or PK4FMYP2 stack with a hemispherical end plate, please contact Tech Support.

The ceramic plates assist in both distributing the applied force of the load over the mounting surface of the stack and in directing the force along the actuator's axis of translation. The flat and hemispherical ceramic plates offer different advantages. When the load can be directed along the translating axis of the actuator, the flat plate with its large contact area provides a better option for achieving maximum force transfer. The hemispherical ceramic plate makes it possible to interface the actuator with an off-axis load, as the curved surface routes the applied force along the actuator's translating axis.

Thorlabs' piezoelectric chips are individually inspected using a proprietary AI algorithm to ensure the highest quality of our line of piezo chips, actuators, and transducers.

The PKJCUP, PKFCUP, and PKGCUP conical end cups (sold below), which are compatible with ball contacts with diameters between 1.5 to 7.0 mm, can also be used to safely interface the load and the actuator. Please see the Operation tab for more information on interfacing piezoelectric actuators with loads, special operational considerations, and data that will allow the lifetimes of these actuators to be estimated when their operational conditions are known.

A ceramic layer covering the other four sides of the stack acts as a barrier against moisture. The ceramic layer offers better protection against moisture than an epoxy coating. For harsh environments, we also offer discrete stacks with hermetically sealed housings. For convenience, the stacks have pre-attached 75 mm long wires and are wrapped in polyimide tape. Piezo chips with custom dimensions, voltage ranges, and coatings are available. Please contact Tech Support for more information.

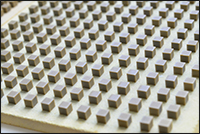

Click to Enlarge

Dicing the PZT Block into Individual Elements

Click to Enlarge

Chips After Binder Burnout and Sintering

Thorlabs' In-House Piezoelectric Manufacturing

Our piezoelectric chips are fabricated in our production facility in China, giving us full control over each step of the manufacturing process. This allows us to economically produce high-quality products, including custom and OEM devices. A glimpse into the fabrication of our piezoelectric chips follows. For more information about our manufacturing process and capabilities, please see our Piezoelectric Capabilities page.

- Build Blocks from Flexible Sheets of Lead Zirconate Titanate (PZT) or BiScO3-PbTiO3 (BSPT) Powder

- Screen Print Electrodes on Each Individual Sheet

- Layer the Printed Sheets One Top of Another

- Consolidate the Layered Sheets in an Isostatic Press

- Dice the Block into Individual Elements

- Purge Solvent and Binder Material Residues by Heat Treating the Elements

- Sinter the Elements to Fuse the Piezoelectric Pressed Powder and Grow PZT or BSPT Crystals

- Lap the Elements to Achieve Tight Dimensional Tolerances: ±5 µm for Each Element

- Screen Print the Outer Electrodes on the Elements

- Align the Individual PZT or BSPT Crystals Along the Same Axis by Poling the Elements

Click to Enlarge

Diagram of Piezo Stack Insulation Methods:

(a) In-Chip Insulation Used in Standard Chips and Discrete Stacks,

(b) On-Stack Insulation Used in Co-Fired Stacks

Click to Enlarge

Schematic of PK4DMP2 Piezo Stack

Operation Notes

Co-Fired Piezo Chips, Co-Fired Piezo Stacks, and Discrete Piezo Stacks

Generally speaking, Thorlabs' co-fired piezo chips and stacks are constructed similarly. In both cases, a structure is built up from alternating electrode layers and green-state lead zirconate titanate (PZT) piezoelectric layers. (The co-fired piezo chips are also available with BiScO3-PbTiO3 (BSPT) piezoelectric layers for higher temperature applications.) The assembled structure is then sintered into a single monolithic unit. Supply electrodes of opposite polarity are attached to opposite sides of the structure. Each internal electrode is electrically coupled to one or the other supply electrode, such that no two adjacent internal electrodes have the same polarity. The most significant differences between the co-fired chips and stacks arise from the way each internal electrode is electrically isolated from the supply electrodes of opposite polarity. The different electrical insulation approaches influence the mechanical properties of the actuators. Actuators fabricated using the two different approaches are diagrammed in Figure 1.

In the case of the chips (In-Chip Insulation), the internal electrodes of opposite polarities alternate. Each internal electrode layer is shorter than the full width of the piezo layer. All electrodes of one polarity have edges that are flush with one side of the chip, and all electrodes with the opposite polarity are flush with the opposite side of the chip. Because the electrode does not extend all the way to the opposite edge, the far end of the electrode is completely surrounded by PZT or BSPT material. The PZT or BSPT material enclosing the end of the electrode is insulating, which electrically isolates this electrode from the supply electrode of opposite polarity. This approach to electrically insulating the electrodes creates a region of stress at the edge of the electrode. The stress arises both due the abrupt change in thickness on either side of the electrode edge, as well as the tensile stress created when the PZT or BSPT material sandwiched between electrodes responds to an applied voltage drive signal, but the insulating PZT or BSPT material beyond the edge of the electrodes does not. This stress limits the maximum height of chips manufactured using this approach. The height of chips are limited to ensure internal stresses are low and do not affect lifetime or performance. Chips are sealed in a ceramic layer that offers superior resistance to humidity and heat than epoxy resin coatings.

One way of increasing the height, and therefore the maximum stroke, of piezo actuators based on these chips is to fabricate discrete piezo stacks. These are manufactured by bonding multiple chips together in series using a glass-bead epoxy. Discrete stacks can be fabricated to substantially longer lengths than co-fired chips or stacks, and this allows them to achieve higher maximum displacements while maintaining sub-millisecond response times and a low drive voltage range. As the constituent chips are sealed within a ceramic barrier layer, discrete stacks have superior resistance to humidity and heat than co-fired stacks, which are sealed in an epoxy resin coating.

In the case of co-fired stacks (On-Stack Insulation), the electrodes extend across the full width of the PZT layers. The edges of the electrodes are flush with all four sides of the stack, including the side with the supply electrode of opposite polarity. The edge of the internal electrode is insulated from that supply electrode by a layer of glass filament applied to the side of the stack. Precision localized application of the glass filament ensures that the electrode edge is electrically isolated from the supply electrode, and that the filament is applied over minimal surface area; the ability of the supply electrode to make electrical connections to the desired internal electrodes is not affected, and the small amount of applied glass filament does not affect the operation of the actuator. With their full-width electrodes, piezo actuators made using this insulating approach are characterized by homogeneous internal stress. Co-fired stacks can therefore be fabricated with greater heights than chips fabricated using the in-chip insulation approach. Co-fired stacks also have a higher percentage of active PZT material than the discrete stacks, which include inactive bonding layers of glass-bead epoxy. They are coated in an epoxy resin.

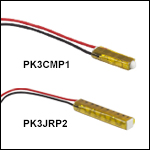

Power Connections

A positive bias should be applied across the device using the wires connected to the electrodes. The positive wire should receive positive bias, and the other wire should be connected to ground. Applying a negative bias across the device may cause mechanical failure. The positive wire may be identified in two ways: it is red, as can be seen in the product images, and it is attached to electrodes on the side of the stack indicated by the line of + marks, as is depicted in the image at right. (On some devices, the line of + marks is replaced with a line of dots.) The wire that should be grounded is black, and it is attached to the electrodes on the side of the stack opposite the side with the positive electrodes.

Caution: After driving, the piezo is fully charged. Directly connecting the positive and negative electrodes has the risk of electricity discharging, spark, and even failure. We recommend using a resistor (>1 kΩ) between the wires to release the charge.

Soldering Wire Leads to the Electrodes

If wire leads must be reattached to the electrodes, a soldering temperature no higher than 370 °C (700 °F) should be used, and heat should be applied to each electrode for a maximum of 2 seconds. Solder the lead to the middle of the electrode and keep the region over which heat is applied as small as possible.

Interfacing a Piezoelectric Stack with a Load

Piezoceramics are brittle and have low tensile strength. Avoid loading conditions that subject the actuator to lateral, transverse, or bending forces. When applied incorrectly, an external load that may appear to be compressive can, through bending moments, cause high tensile stresses within the piezoelectric device. Improperly mounting a load to the piezoelectric actuator can easily result in internal stresses that will damage the actuator. To avoid this, the piezoelectric actuator should be interfaced with an external load such that the induced force is directed along the actuator's axis of displacement. The load should be centered on and applied uniformly over as much of the actuator's mounting surface as possible. When interfacing the flat surface of a load with an actuator capped with a flat mounting surface, ensure the two surfaces are highly flat and smooth and that there is good parallelism between the two when they are mated. If the external load is directed at an angle to the actuator's axis of displacement, use an actuator fitted with a hemispherical end plate or a flexure joint to achieve safe loading of the piezoelectric stack.

To accommodate a variety of loading conditions, these discrete piezoelectric stacks may be purchased with either two flat ceramic end plates or one flat and one hemispherical end plate. In addition, Thorlabs offers Conical End Cups which feature concave surfaces that can interface with Ø1.5 mm to Ø7.0 mm hemispherical or curved contacts. To attach a load to PZT piezo stacks, we recommend using an epoxy that cures at a temperature lower than 80 °C (176 °F), such as our 353NDPK or TS10 epoxies or Loctite® Hysol® 9340. For BSPT piezo stacks, we recommend any inorganic adhesive which cures at a temperature lower than 120 °C and has a melting point higher than 250 °C; our 353NDPK epoxy is safe to use, however the strength will be reduced at 250 °C, and therefore a preload should be applied to maintain the mechanical structure. Loads should be mounted only to the faces of the piezoelectric stack that are fitted with the flat or hemispherical ceramic end plates; the other sides of the actuator do not translate, and mounting a load to a non-translating face may lead to the mechanical failure of the actuator. Some correct and incorrect approaches to interfacing loads with piezoelectric stacks capped with both kinds of end plates are discussed in the following.

Click to Enlarge

Actuation of a lever arm using stack fitted with a flat plate (A, Incorrect), and a hemispherical plate (B, Correct).

Click to Enlarge

Loads properly and improperly mounted to PZT actuators using a variety of interfacing methods.

The image at left presents incorrect (A, far-left) and correct (B, near-left) methods for using a piezoelectric stack to actuate a lever arm. The correct method uses a hemispherical end plate so that, regardless of the angle of the lever arm, the force exerted is always directed along the translational axis of the actuator. The incorrect interfacing of the stack and the lever arm, shown at far-left, endangers the stack by applying the full force of the load to one edge of the stack. This uneven loading causes dangerous stresses in the actuator, including a bending moment around the base.

The image at right shows one incorrect (near-right, A) and three correct approaches for interfacing a flat-bottomed, off-axis load with a piezoelectric stack. Approaches A and B are similar to the incorrect and correct approaches, respectively, shown in the image at left. Correct approach C shows a conical end cup, such as the PKFCUP, acting as an interface. The flat surface is affixed to the mating surface of the load, and the concave surface fits over the hemispherical dome of the end plate. In the case of correct approach D, a flexure mount acts as an interface between the off-axis flat mounting surface of the load and the flat mounting plate of the actuator. The flexure mount ensures that the load is both uniformly distributed over the surface plate of the actuator and that the loading force is directed along the translational axis of the actuator.

Operating Under High-Frequency Dynamic Conditions

It may be necessary to implement an external temperature-control system to cool the device when it is operated at high frequencies. The maximum operating temperature of PZT piezos is 130 °C (266 °F), and high-frequency operation causes the internal temperature of the piezoelectric device to rise. For higher temperature applications, BSPT piezos are available with a maximum operating temperature of 250 °C. The dependence of the device temperature on the drive voltage frequency for each product can be accessed by clicking the Info icons, ![]() , below. The temperature of the device should not be allowed to exceed its specified maximum operating temperature.

, below. The temperature of the device should not be allowed to exceed its specified maximum operating temperature.

Estimating the Resonant Frequency for a Given Applied Load

A parameter of significance to many applications is the rate at which the piezoelectric actuator changes its length. This dimensional rate of change depends on a number of factors, including the actuator's resonant frequency, the absolute maximum bandwidth of the driver, the maximum current the piezoelectric device can produce, the capacitance of the piezoelectric stack, and the amplitude of the driving signal. The length of the voltage-induced extension is a function of the amplitude of the applied voltage driving the actuator and the length of the piezoelectric stack. The higher the capacitance, the slower the dimensional change of the actuator.

Quick changes in the applied voltage result in fast dimensional changes to the piezoelectric stack. The magnitude of the applied voltage determines the nominal extension of the stack. Assuming the driving voltage signal resembles a step function, the minimum time, Tmin, required for the length of the actuator to transition between its initial and final values is approximately 1/3 the period of resonant frequency. If there is no load applied to the piezoelectric stack, its resonant frequency is ƒo and its minimum response time is:

After reaching this nominal extension, there will follow a damped oscillation in the length of the actuator around this position. Controls can be implemented to mitigate this oscillation, but doing so may slow the response of the actuator.

Applying a load to the actuator will reduce the resonant frequency of the piezoelectric stack. Given the unloaded resonant frequency of the actuator, the mass of the stack, m, and the mass of the load, M, the loaded resonant frequency (ƒo') may be estimated:

Estimating Device Lifetime for DC Drive Voltage Conditions

The lifetime of a piezoelectric device is a function of the operating temperature, applied voltage, and relative humidity conditions. Lifetimes are reduced as a consequence of humidity-driven electrolytic reactions, which occur at the electrodes of the piezoelectric devices when a DC voltage is applied. These reactions both generate hydrogen and result in metal dendrites growing from the cathode towards the anode. The hydrogen liberated by the electrolytic reaction chemically reacts with and degrades the piezoelectric material. Dendrites that grow to electrically connect the cathode and anode result in increasing levels of leakage current. Failed piezoelectric devices are defined as those that exhibit leakage current levels above an established threshold.

A ceramic moisture-barrier layer that insulates Thorlabs' piezoelectric devices on four sides is effective in minimizing the effects of humidity on device lifetime. As there is interest in estimating the lifetime of piezoelectric devices, Thorlabs conducted environmental testing on our ceramic-insulated, low-voltage, piezoelectric actuators. The resulting data were used to create a simple model that estimates the mean time to failure (MTTF), in hours, when the operating conditions of humidity, temperature, and applied voltage are known. The estimated MTTF is calculated by multiplying together three factors that correspond, respectively, to the operational temperature, relative humidity, and fractional voltage of the device. The fractional voltage is calculated by dividing the operational voltage by the maximum specified drive voltage for the device. The factors for each parameter can be read from the following plots, or they may be calculated by downloading the plotted data values and interpolating as appropriate.

In the following trio of plots, the solid-line segment of each curve represents the range of conditions over which Thorlabs performed testing. These are the conditions observed to be of most relevance to our customers. The dotted-line extensions to the solid-line segments represent extrapolated data and represent a wider range of conditions that may be encountered while operating the devices.

Click to Enlarge

For an Excel file containing these fH vs. relative humidity data, please click here.

The data used to generate these temperature, voltage, and humidity factor plots resulted from the analysis of measurements obtained from testing devices under six different operational conditions. Different dedicated sets of ten devices were tested under each condition, with each condition representing a different combination of operational voltage, device temperature, and relative humidity. After devices exhibit leakage current levels above a threshold of 100 nA, they are registered as having failed. The individual contributions of temperature, humidity, and voltage to the lifetime are determined by assuming:

- MTTF = fV(V) * fT(T) * fH(H)

- A power law dependence for the voltage: fV(V) = A1Vb1

- An exponential relationship for the relative humidity: fH(T) = A2ecH

- An Arrhenius relationship for the temperature: fT(H) = A3eb2/T

where A1, A2, A3, b1, b2, and c are constants determined through analysis of the measurement data, V is the DC operational voltage, T is the device temperature, and H is the relative humidity. Because the MTTF has a different mathematical relationship with each factor, the dependence of the MTTF on each factor alone may be determined. These are the data plotted above. The regions of the above curves marked by the blue shading are derived from experimental data. The dotted regions of the curves are extrapolated.

Lifetime testing of these devices continues, and additional data will be published here as they become available. To assist in temperature control, please see our selection of thermoelectric coolers. Temperature and humidity can be monitored using our USB Temperature and Humidity Logger.

| Posted Comments: | |

Ben Huang

(posted 2024-10-21 12:03:55.29) Hi, I am interested in the PK3JMP2. Is it food-safe? Thank you! jdelia

(posted 2024-10-22 03:58:36.0) Thank you for contacting Thorlabs. These piezoelectric ceramics are industrial products and not verified to be food-safe. Saptarshi BIswas

(posted 2024-10-11 10:30:02.1) Hello,

I have a question regarding PK2FMP2 model.

I see there is a voltage vs diplacement curve given in the spec sheet. However, we are using this model for building up the interferometer. So, the relation between voltage and displacement is crucial for us. Is it possible to send to data to us, so we can have a proper fit, and get requisite relation for proper callibration for our setup?

Thank you

Saptarshi

Department Physik - Fakultaet IV

Universitaet Siegen

Walter-Flex-Straße 3 END-213

57068 Siegen, Germany

Tel.: +49 (0) 271 740 5514 mgarodia

(posted 2024-10-14 12:34:10.0) Thank you for your feedback! Please refer to our response to your question in the post response below. Our team in Germany (europe@thorlabs.com) has contacted you directly via email to discuss this further. Saptarshi BIswas

(posted 2024-10-07 10:53:06.5) I bought PK2FMP2, and I am aware of the Voltage, Displacement relationship curve shown on the spec sheet.

I am building up an interferometer, and I am need a formula for proper characterization of the result to voltage displacement relationsip.

Is it possible to send the data to us? or any kind of conversion formula?

If I get the data, that would be more useful as I can fit the data for proper relation to use in my setup. mgarodia

(posted 2024-10-11 09:49:50.0) Thank you for contacting Thorlabs. The displacement tolerance of PK2FMP2 is 15%; therefore, the voltage-displacement relationship curve shown on the spec sheet is typical. The batch difference, the applied voltage difference, the load, and the temperature will affect the displacement, so we recommend measuring the displacement on your own if an accurate voltage-displacement curve is necessary. Besides, the voltage increase and decrease will be related to different displacements. If a better voltage-displacement control is needed, we recommend trying the close loop version, PK2FMC2, with strain gauge sensors attached.

The typical data of the voltage-displacement relationship curve for PK2FMP2 can be downloaded from this link: https://view.officeapps.live.com/op/view.aspx?src=https%3A%2F%2Fwww.thorlabschina.cn%2Fimages%2Ftabimages%2FPK2FMP2_data.xlsx&wdOrigin=BROWSELINK Nicolas Heinz

(posted 2023-10-27 13:43:37.943) Hi,

I have a question regarding the use of the ball ends for piezo stacks.

Is it recommended to use a piezo stack with ball ends and end cups on each end of the piezo stack or is it sufficient so only use a ball end/end cup on one end and a flat plane on the other end?

best regards

Nicolas Heinz cdolbashian

(posted 2023-11-13 04:33:36.0) Thank you for contacting Thorlabs! We usually only need the end caps or end hemispheres on the end of the piezo actuator we attached the load. These are used to avoid loading conditions that subject the actuator to lateral, transverse, or bending forces. You can find more information under the "Operation" tab. Magdoom Kulam

(posted 2022-03-31 14:43:41.38) I have question regarding the piezo (PK4GA7P2). Does this piezo contain magnetic components ? Is it MRI safe? cdolbashian

(posted 2022-04-01 03:31:51.0) Thank you for contacting Thorlabs. We have not yet thoroughly tested our piezo about the MRI safety. But we know piezo in general is MRI safe (PZT and the silver palladium electrodes are neither generating magnetic field while working, nor affected by regular magnetic field used for MRI). However, the piezo stack (PK4GA7P2) consists of not only piezo but also the tin solder, tinned copper buss wires and the Al2O3 ceramics caps. Therefore, it is hard for us to say our piezo stack (PK4GA7P2) is MRI safe or not without a professional test. gyeonuk kim

(posted 2022-02-18 18:16:25.52) If you look at the specifications of the product i inquired about, it is written as recommended load (360lbs).

I wonder if the meaning of the sentence guarantees a displacement of 20 um even if I attach a mirror with a weight of 136 kg to the PZT.

According to past laboratory experiments, when the frequency of the PZT increases, the amplitude may decrease due to the inertia of the measurement target.

I am looking for a PZT that can guarantee a certain displacement at high frequencies even when the weight of the object to be measured increases.

Therefore, a product called APFH720f is also being considered.

As a conclusion, I am curious what is the maximum weight and frequency of an object that can give a displacement of 20 um using the PZT. cdolbashian

(posted 2022-02-22 09:21:11.0) Thank you for contacting Thorlabs. Our displacement is specced for a quasi-static driving voltage. For high frequency, you are right that the inertia of the mirror will influence the response. We would recommend to use a spring to push the mirror back to the piezo as preloading. We have published piezoelectric tutorial on our website for reference, which can be found here: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=5030. The equation (13) shows how to calculate the adjusted resonant frequency with the addition of a load, which could be a reference of maximum response frequency. We will reach out to you directly to see if we can provide further assistance. Alex Fellows

(posted 2020-08-17 09:33:17.813) I recently set-up one of these piezo stacks, connecting it to one of the connections of an open-loop 3-axis controller through a BNC cable. All was working well and I was getting full range out of the stack for a few cycles up to 100V). However, now, it won't go much over ~4V (the controller is working fine when the BNC is unplugged). Is there something I can do to fix this? YLohia

(posted 2020-08-21 10:26:04.0) Thank you for contacting Thorlabs. It appears that there may be a leakage current failure of the piezo. We have reached out to you directly to troubleshoot this further. tsubasa takanami

(posted 2020-04-23 11:10:19.517) 多段チップ型ピエゾアクチュエータPK2FVP1について2点質問があります。

1.仕様の推奨荷重(Load(Recommended))の注記で、推奨荷重で使用した場合に最大変位が発生する(the maximum displacement occurs when used with the recommended load.)と記載がありましたが、最大変位が発生するのは無負荷のFree Strokeの時ではないでしょうか。

2.全長が41.9mmとありますが、ピエゾブロック(16列×2.4mm)及びエンドプレート(2.5mm+0.4mm)を足すと41.3mmとなります。接着層などの影響でこのような誤差が発生しているのでしょうか。

以上、よろしくお願いいたします。 YLohia

(posted 2020-04-23 09:42:11.0) Thank you for contacting Thorlabs. An Applications Engineer from our team in Japan will reach out to you directly. Julien Renard

(posted 2019-11-13 15:12:34.283) Hello,

we are using the PK4GA3P2 stacks in a practical with students at the university. They use the stack to move the mirror of an interferometer and their goal is to measure the stacks characteristics. In order to extract the piezoelectric coefficient of individual layers we would need to know the total number of ceramic layers. Is this an information you could provide? This would be highly appreciated.

Regards nbayconich

(posted 2019-11-15 09:30:00.0) Thank you for contacting Thorlabs. We cannot publish this information on our webpage. Our Tech Support representatives will reach to you via email regarding these details. user

(posted 2019-05-10 12:15:38.45) Hello,I was wondering if the piezoelectric stack produces electric power when force is applied to it? nbayconich

(posted 2019-05-13 01:32:32.0) Thank you for contacting Thorlabs. Yes a piezo can be used to generate and electric field when a force is applied to the the device. The strength of the electric field generated by the actuator will be dependent on the piezo's d33 charge constant and the stress applied to the actuator. I will reach out to you directly to discuss your application. tfrisch

(posted 2016-08-25 09:06:25.563) Hello Felix, thank you for contacting Thorlabs. We can offer these, but there will be a greater risk of short circuit. I have emailed you directly about your application. -Tyler at Thorlabs USA felix.jaeckel

(posted 2016-08-05 08:49:41.103) Hi!

Is it possible to get PK4FA2P2 without any ceramic endplates?

Thanks!

Felix |

Piezo Stacks with End Hemisphere and Flat End Plate

Piezo Stacks with Two Flat End Plates

Piezo Stacks with End Hemisphere and Flat End Plate

Piezo Stacks with Two Flat End Plates

Note: This piezo stack is made using a low-dielectric lead zirconate titanate (PZT) ceramic, which results in a lower capacitance when compared to a piezo stack made from our standard PZT ceramic with identical physical dimensions and voltage rating.

Note: The rows shaded green below denote piezo chips made using BiScO3-PbTiO3 (BSPT) ceramics, which offer a higher operating temperature up to 250 °C. The other piezo chips, made using lead zirconate titanate (PZT) ceramics, have a maximum operating temperature of 130 °C.

Piezo Stacks with End Hemisphere and Flat End Plate

Piezo Stacks with Two Flat End Plates

- Compatible with Our Piezoelectric Stacks (Sold Above)

- Conical End Cups Accept Ball Contacts:

- From Ø1.5 mm to Ø3.0 mm (PKJCUP)

- From Ø2.6 mm to Ø5.0 mm (PKFCUP)

- From Ø3.6 mm to Ø7.0 mm (PKGCUP)

- Restricts Applied Stress to the Axial Direction

- Sold in Packs of 10

The PKJCUP, PKFCUP, and PKGCUP are 416 stainless steel conical end cups designed to be used with our PZT stacks. The conical cup can accept a ball contact, such as one of the end hemispheres available below, with a diameter from 1.5 to 3.0 mm (PKJCUP), 2.6 to 5.0 mm (PKFCUP), or 3.6 to 7.0 mm (PKGCUP). Using a ball contact with a PZT actuator ensures that the applied stress is restricted to the axial direction, limiting the probability of stress-induced failure. They can be affixed either to a flat face of a PZT stack or to the mechanical device that is being actuated. If affixing a cup to the PZT stack itself, we recommend using an epoxy that cures at a temperature lower than 80 °C (176 °F), such as 353NDPK or TS10 epoxies or Loctite® Hysol® 9340.

| End Hemispheres | Flat End Plates | ||

|---|---|---|---|

| Item # | Diameter | Item # | Dimensions |

| PKCESP | 2.0 mm | PKCEP4 | 2.0 mm x 2.0 mm x 0.4 mm |

| PKDESP | 2.5 mm | PKDEP4 | 2.5 mm x 2.5 mm x 0.4 mm |

| PKJESP | 3.0 mm | PKJEP4 | 3.0 mm x 3.0 mm x 0.4 mm |

| PKFESP | 5.0 mm | PKFEP4 | 5.0 mm x 5.0 mm x 0.4 mm |

| PKGESP | 7.0 mm | PKGEP4 | 7.0 mm x 7.0 mm x 0.4 mm |

| PKHESP | 10.0 mm | PKHEP4 | 10.0 mm x 10.0 mm x 0.4 mm |

- Hemispheres and Flat End Plates in Five Sizes

- Hemispheres Provide a Single Point of Contact for Actuation

- Flat Plates Spread Force Across Piezo Face at Contact Point

- Sold in Packs of 16 or 25

The alumina end hemispheres and flat plates used in the piezo stacks featured above are also available separately in five sizes (see the table to the right). The hemispheres can be used to create a single contact point between a PZT stack and a lever arm. Alternatively, a hemisphere can be used with a compatible conical end cup (sold above). Flat end plates are used to spread the force at the contact point over the entire end surface of a piezo stack or chip. When selecting a hemisphere or flat end plate to adhere to a piezo stack end face, it is important to match the bottom surface area of the hemisphere or plate to the cross section of the piezo stack in order to ensure that forces are spread evenly over the surface. The end hemispheres have a diameter tolerance of ±0.1 mm, and the flat end plates have a dimensional tolerance of ±0.04 mm.

Products Home

Products Home

Zoom

Zoom

Discrete Piezo Stacks, >5.2 µm Travel

Discrete Piezo Stacks, >5.2 µm Travel