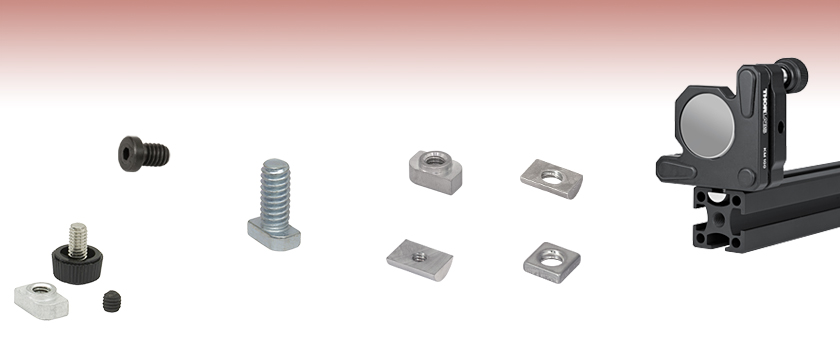

T-Nuts and Screws for 25 mm, 50 mm, & 75 mm Rails

- T-Nuts Fasten Rails to Other Mechanical Components

- Hammerhead Screws Provide Quick-Release Mounting Stud

- Low-Profile Screws Provide Added Clearance

SH25LP38

Low-Profile

Channel Screws

Quick-Release T-Nut

8-32 (M4 x 0.7)

Drop-In T-Nut

8-32 (M4 x 0.7)

Low-Profile T-Nut

1/4"-20 (M6 x 1.0)

Drop-In T-Nut

1/4"-20 (M6 x 1.0)

Four T-Nuts

Available

Application Idea

T-Nuts Securely Attach

Optomechanics

Using Rail Channels

LPCEF

Fastener Kit: Quick-Release T-Nuts, Setscrews, and Thumbscrews

XE25H025

Hammerhead

Screws

Please Wait

| Compatible Optical Rails | ||

|---|---|---|

| 25 mm Rails | ||

| 50 mm Rails | ||

| 75 mm Rails | ||

Features

- T-Nuts Fasten Rails to Other Optomechanics

- Four T-Nut Choices (See Image Above)

- Hammerhead Screws Provide Studs for Direct Mounting

- Low-Profile Channel Screws with Smaller Footprint than Standard Cap Screws

Thorlabs' T-nuts, hammerhead screws, and low-profile channel screws are designed to link 25 mm, 50 mm, and 75 mm rails to other optomechanical components.

T-Nuts

T-nuts effectively add 8-32 (M4 x 0.7) or 1/4"-20 (M6 x 1.0) tapped holes to the rail sides, permitting a wide range of standard optomechanics to be fastened to the rails. Our T-nuts are available in three styles—Quick-Release, Drop-In, and Low-Profile—which are detailed in the text below.

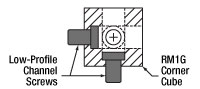

Low-Profile Channel Screws in 25 mm Corner Cube

Hammerhead Screws

These screws add 1/4"-20 (M6 x 1.0) studs to optical rails and incorporate a quick-release T-head for direct insertion into a rail slot.

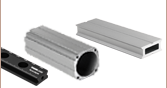

Low-Profile Channel Screws

Low-profile channel screws feature a shortened cap height and conserve space within a setup by allowing the optomechanical components that they attach to be more compact. For example, in our construction cubes, they allow several screws to be in close proximity, as shown to the left.

| Posted Comments: | |

| No Comments Posted |

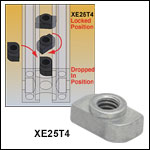

Click for Details

Drop-In T-Nut in Rail Channel

- Can Be Dropped into Any Exposed Portion of a Rail Channel Without Accessing the Ends

- Removal Requires Access to the Rail Ends

- 8-32 (M4 x 0.7) Tapped Hole or 1/4"-20 (M6 x 1.0) Tapped Hole for Mounting

Drop-in T-nuts can be dropped in along any point of an exposed rail channel, making them easy to install even if the rail ends are blocked. They are available with either an 8-32 (M4 x 0.7) tapped hole [Item # XE25T2(/M)] or 1/4"-20 (M6 x 1.0) tapped hole [Item # XE25T1(/M)].

Although these T-nuts can be easily inserted anywhere along the rail, access to the end of the rail is necessary for removal. This procedure is shown in the animation to the right. In contrast, our quick-release T-nuts, shown above, offer the added flexibility of being able to be removed when the rail ends are obstructed.

Click for Details

Quick-Release T-Nut in Rail Channel

- Can Be Inserted and Removed from Any Exposed Rail Channel Without Accessing the Ends (See Animation to the Right)

- Drops into Position and Locks by Rotating

- More Surface Engagement than Drop-In and Low-Profile T-Nuts

- 8-32 (M4 x 0.7) Tapped Hole for Mounting

The XE25T4(/M) Quick-Release T-Nut is our most versatile option for mounting mechanics to rail channels. Its thin width profile allows it to be inserted into an exposed rail channel. After being inserted, a clockwise rotation by 90° prevents it from being removed again. Once rotated, screwing in a mechanical part draws the T-nut towards the part, eventually forcing the T-nut and rail channel to engage. The protruding edge of the 8-32 (M4 x 0.7) tapped hole centers the T-nut within the rail channel, ensuring even engagement on both sides.

To remove the quick-release T-nut, simply remove any attached mechanical parts and rotate the T-nut counterclockwise.

Click for Details

Low-Profile T-Nut in Rail Channel

- Can Only Be Inserted and Removed from the End of a Rail

- 1/4"-20 (M6 x 1.0) Tapped Hole for Mounting

- Economical Alternative to Drop-In and Quick-Release T-Nuts

The XE25T3(/M) Low-Profile T-Nut can be used when there is access to an XE Series rail end, which allows the T-nut to slip into place. Since installation (and removal) requires the rail end to be unobstructed, as shown in the animation to the right, this T-nut usually needs to be positioned before a mechanical construction is completed. Our quick-release and drop-in T-nuts, shown above, can be inserted even if the rail ends are blocked; the former can also be removed without access to the ends.

This T-nut is also compatible with our XT66 Series rail system mounting platforms.

- Can Be Inserted and Removed from Any Exposed Rail Channel Without Accessing the Ends

- Drops into Position and Locks by Rotating

- 1/2" (12.7 mm) Long, 1/4"-20 (M6 x 1.0) Threaded Stud for Mounting

These quick-release hammerhead screws are versatile options for mounting mechanics to rail channels. Their thin width profile allows them to be inserted into an exposed rail channel. After being inserted, rotating the screw clockwise by 90° prevents it from being removed again. Once rotated, screwing on a mechanical part draws the hammerhead screw towards the part, eventually forcing the screw and rail channel to engage.

To remove the hammerhead screw, simply remove any attached mechanical parts and rotate the screw counterclockwise.

| Item # | Threading | Thread Length | Hex | Head Height | Quantity | Material |

|---|---|---|---|---|---|---|

| SH25LP38 | 1/4"-20 | 0.38" (9.7 mm) | 1/8" | 0.13" (3.2 mm) | 100 | Steel, Black Oxide Finish |

| SH25LP63 | 0.63" (15.9 mm) | 50 | ||||

| SH6M8LP | M6 x 1.0 | 8 mm (0.31") | 4 mm | 4 mm (0.16") | 50 | |

| SH6M10LP | 10 mm (0.39") | 100 | ||||

| SH6M16LP | 16 mm (0.63") | 50 |

Click to Enlarge

Low-Profile Screw in RM1G Construction Cube

Click to Enlarge

Standard Cap Screw in RM1G Construction Cube

Our Low-Profile Channel Screws have a reduced cap head height relative to standard screws, permitting them to be used in tight spaces. In particular, they are recommended when neighboring screws are at a right angle and in close proximity, as in our XE25W3 Corner Cube or RM1G and RM1S Construction Cubes.

Shown to the right are a standard cap screw and a low-profile channel screw installed in an RM1G cube. The low-profile screw's shortened cap height prevents neighboring screws from interfering with each other.

The head of each screw also fits into XE rail channels for alternate construction methods, as outlined here.

Click to Enlarge

Click for Assembly Demonstration

LPCE21 Panel Attached to Optical Enclosure using LCPEF Fastener Kit. The thumbscrews can be easily removed in order to access the inside of the enclosure.

- Attach Laser Safety Fabric Panels to 25 mm Rail Channels

- Each LPCEF(/M) Kit Includes:

- Seven 8-32 (M4 x 0.7) Thumbscrews

- Seven 8-32 (M4 x 0.7) T-Nuts

- Seven 8-32 (M4 x 0.7) Setscrews

- Replacement 8-32 (M4 x 0.7) Thumbscrews Available [Item # LPCET(/M)]

The LPCEF(/M) fastener kit contains seven sets of thumbscrews, T-nuts, and setscrews. One fastener kit is enough to affix one laser safety fabric panel to the side of a compatible enclosure. Please see the manual for instructions.

The setscrews can be tightened using a 5/64" (2.0 mm) hex key or balldriver, while the thumbscrews do not have a hex socket.

Replacement thumbscrews for the fastener kit are also available in packs of 10.

Products Home

Products Home

Zoom

Zoom

T-Nuts and Screws for 25 mm Rails

T-Nuts and Screws for 25 mm Rails