Compact Quick-Connect Linear Stages, 25 mm Travel, Crossed-Roller Bearings

- 25 mm Travel Range in an Ultra-Compact Design

- Low Angular Deviation and High Load Capacity

- Integrated 2" Dovetails for Multi-Axis Construction

- Side- or End-Mounted Micrometer Options

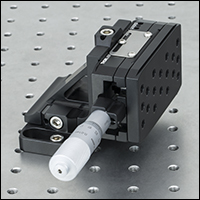

XRN25C

Compact 25 mm Stage with

End-Mounted Micrometer

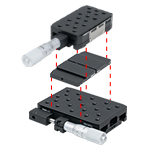

The XRN25P (left) is considerably more compact than the XR25P (right), but both provide a travel range of 25 mm.

Application Idea

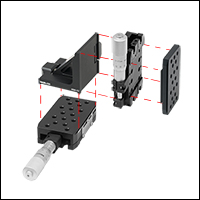

XRN25P-K2 XYZ Stage Kit

with LP126CU Low-Profile Camera

Attached Using XR25-RC1 Adapter

Please Wait

| Stage Specifications | |

|---|---|

| Travel | 25 mm |

| XY Stacked Orthogonality | <25 µrad |

| Angular Deviation | <150 µrad |

| Platform Size | 3.35" x 2.00" (85.0 mm x 50.7 mm) |

| Mounting Holes | 17 x 1/4"-20 (M6 x 1.0) Taps |

| Mating Dovetail Width | 2" |

| Horizontal Load Capacity (Max) | 170 lbs (77.1 kg) |

| Vertical Load Capacity (Max)a | 8.8 lbs (4.0 kg) |

| Bearing Type | Crossed Roller Bearings |

| Micrometer Specifications | |

| Micrometer Item # | 150-801ME-H |

| Resolution | 500 µm Per Revolution |

| Travel | 25 mm |

| Micrometer Barrel Size | Ø3/8" (Ø9.5 mm) |

Features

- Crossed-Roller Bearings for High Load Capacity and Low Angular Deviation

- Metric Micrometer in Two Different Orientations:

- Side Mounted for Compact Design

- End Mounted for Ease of Adjustment

- Preassembled XY and XYZ Stages with Side-Mounted Micrometers

- Quickly Connect Stages and Accessories Using 2" Dovetails

- See the Quick-Connect Stages Tab for Complete Line of Components

Thorlabs' XRN25 Series Compact Translation Stages provide 25 mm of linear translation with less than 150 µrad of deviation per axis in pitch and yaw over the full range of the stages. These stages use crossed-roller steel bearings to support precision motion and high load capacities. The top and bottom plates are machined from cast tool and jig aluminum for minimal internal stress and improved stability.

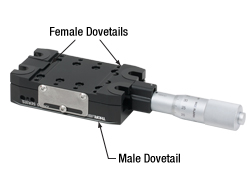

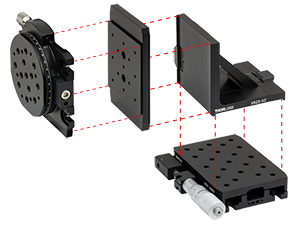

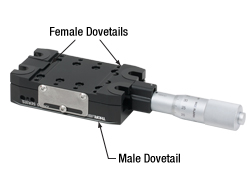

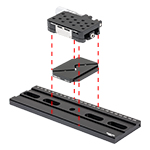

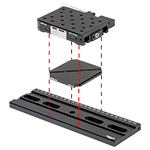

The top and bottom of each stage feature quick connect dovetails (as shown in the image below) that allow for the construction of multi-axis systems without the need for additional hardware. The stages are locked into place via a lock plate that accepts a 5/64" (2.0 mm) hex key or ball driver. See the animation to the lower right to see how multi-axis systems can be quickly built using this novel design. The 2" dovetails on our XRN25 series stages are directly compatible with the dovetails on our XRNR1 rotation stage.

Additional functionality is provided by a complete line of accessories that include multi-axis assembly kits, rail carriers, a rotation adapter, rails, and micrometer conversion kits. An adapter plate is also available for mounting these compact 25 mm stages with an integrated 2" dovetail onto 25 mm and 50 mm stages with a 3" dovetail. For more information about our quick-connect construction components, please see the Quick-Connect Stages tab.

Click to Enlarge

The 2" female dovetails on the bottom of one stage mates with the male dovetail on the other to form XY stage configurations. The left female dovetail is on a retractable clamping arm, allowing stages to be dropped into place.

Quickly Construct Multi-Axis Stages

Each stage features 2" dovetails on the top and bottom plate that allow for quick construction of multi-axis systems. There are no dowel pins to install or screws that need to be inserted through the top plate, which means that mounted components do not need to be removed from the top stage before constructing an XY configuration. In addition, the top stage can be locked at any location along the dovetail, allowing for coarse positioning.

Click to Enlarge

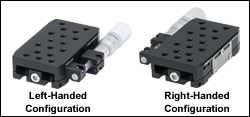

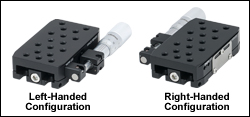

The side-mounted micrometer can be swapped with the locking plate to create both left-and right-handed stages.

Micrometer Conversion

The video to the left outlines how to convert a rear-mounted micrometer stage (XRN25C and XRN25C/M) to a side-mounted micrometer stage using the XRN-C1 conversion kit. To convert a side-mounted micrometer stage (XRN25P and XRN25P/M) to a rear-mounted micrometer stage, simply follow the directions in reverse and use the XRN-C2 conversion kit.

Note: Before removing the micrometer, lock the stage by tightening the button head cap screw in the groove in the steel locking plate using a 5/64" (2 mm) hex key.

Swapping a Side-Mounted Micrometer

If you would like to switch the location of the locking plate, as shown in the photo to the right, back out the micrometer to the 25 mm reading before removing all three button head screws from the locking plate. Failure to do this will cause the stage to quickly retract to its minimum position when the micrometer is removed, potentially damaging the mechanism.

Video Insight Clip: Replacing the Actuator on a Thorlabs XR Linear Translation Stage

This Video Insight clip demonstrates how to replace the included manual actuator on a Thorlabs XR translation stage by a motorized actuator for remote operation. When making such a replacement, be sure to verify compatibility between the travel range and mounting barrel size of the motorized actuator and the XR translation stage. For more details on installing a motorized actuator, you can find the full Insight here.

If you would like more information about tips, tricks, and other methods we often use in the lab, we recommend our other Video Insights. In addition, our webinars provide practical and theoretical introductions to our different products.

| Posted Comments: | |

Samuli Siltanen

(posted 2024-04-27 13:09:54.92) I have two of these stages in a YZ configuration. Now the Y stage is traveling only half of the range: between the center and the other extreme. It stops in the middle when I rotate the knob. Can I fix this? cdolbashian

(posted 2024-05-06 10:44:24.0) Thank you for reaching out to us with this inquiry. I would not expect the travel to become stuck halfway though the motion. I have reached out to you directly to discuss your experience with the goal of finding a solution for you. user

(posted 2019-05-13 20:16:48.25) I only have an earlier version of solidworks - would it be possible for you to share a solidworks model of XRN25P-K2 that is compatible with SW2017? llamb

(posted 2019-05-16 04:40:57.0) Since Solidworks does not offer the option to save a file as a previous version, you may download and open the Step file in a blank existence of your Solidworks 2017 instead. chris.freitag

(posted 2018-02-16 15:10:53.92) Is it possible to convert the XRN25 stages to differential micrometer screws? llamb

(posted 2018-03-01 08:24:57.0) Hello Chris, thank you for contacting Thorlabs. Yes, it is possible to convert the XRN25 stages to have differential micrometers, as long as the differential micrometers have a Ø3/8" (Ø9.5 mm) mounting barrel. Side-mounted micrometers, like on the XRN25P(/M), will have limited mounting space. I will reach out to you directly to discuss this further. |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

Build Multi-Axis Configurations

Click for Details

Z-axis assembly kits allow stages to be mounted in vertical orientations.

Quick-Connect Dovetails

Click to Enlarge

The female dovetails on the bottom of one stage mate with the male dovetails on another.

XR & XRN Dovetail Stages and Accessories

Our XR series manual stages feature quick-connect dovetails that allow for the construction of multi-axis systems without the need for additional hardware. The common dovetail feature with a single locking clamp makes it quick and simple to swap parts in and out while preserving excellent orthogonality.

Our selection of products with a quick-connect dovetail includes:

- Linear Translation Stages:

- Stackable 1-Axis Stages

- Pre-Assembled 2- and 3-Axis Configurations

- Rotational Stages:

- 360° Flat Rotation

- Tip/Tilt Goniometers

- Adapters:

- Z-Axis Assembly Kits

- Parallel and Perpendicular Mounting between 2" and 3" Dovetails

- Rail Accessories:

- Stationary Mounting Platforms

- Rail Component Positioners

- Base Plates and Rails

Most items are available in compact (2" dovetail) and full-size (3" dovetail) varieties. Adapters are available to interface between the two sizes. See the tables below for all available options.

| Linear Translation Stages | |||||

|---|---|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

|

|

| Items | Compact 25 mm Stages | Compact 9 mm Vertical Stage | Full-Size 25 mm Stages | Full-Size 50 mm Stages | 14 mm Vertical Stage |

| Motion | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |||

| Additional Features | |||||

| Rotation and Goniometric Stages | |||

|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

| Items | Compact Rotation Stage | Compact Goniometric Stages | Full-Size Rotation Stage |

| Motion | 360° Rotation | ±8° Tip/Tilt About Fixed Point Above Stage | 360° Rotation |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |

| Additional Features | |||

| Stage Adapters | ||

|---|---|---|

| Z-Axis Assembly Kits |  |

|

| Compact Z-Axis Assembly Kits, 2" Dovetails |

Full-Size Z-Axis Assembly Kits, 3" Dovetails |

|

| Parallel Mounting Adapters |

|

|

| Parallel Mounting Adapter, Male 2" Dovetail to Female 3" Dovetail |

Parallel Mounting Adapter, Male 3" Dovetail to Female 3" Dovetail |

|

| Perpendicular Mounting Adapter |

|

|

| Perpendicular Mounting Adapter Male 2" Dovetail to Female 3" Dovetail | ||

| Dovetail Accessories | ||

|---|---|---|

| Mounting Platforms |  |

|

| 2" Mounting Platforms | 3" Mounting Platforms | |

| Rail Positioners |  |

|

| 2" Rail Positioners | 3" Rail Positioners | |

| Dovetail Bases | |||

|---|---|---|---|

| Base Plates |  |

|

|

| 2" Dovetail Base Plate | 3" Dovetail Base Plate with Rotational Adjustment | ||

| Rails / Extended Bases |

|

|

|

| 2" Dovetail Rails | 3" Dovetail Rails | ||

Click to Enlarge

The side-mounted micrometer can be swapped with the locking plate to create both left-and right-handed stages. See the Micrometer Conversion tab for more details.

- Side- or End-Mounted Metric Micrometer

- Mounting Surface has Seventeen 1/4"-20 (M6) Tapped Blind Holes, 0.30" (7.6 mm) Deep

- Create Multi-Axis Configurations Using Dovetail Locking Screw

- Dovetail Clamp Screw has a Maximum Torque of 15 in•lbs

- Compatible with 2" Mating Dovetail Accessories

The XRN25P(/M) and XRN25C(/M) stages are compact versions of our XR25 series quick-connect stages. They provide 25 mm of travel and feature a side- or end-mounted metric micrometer, respectively, which gives a 500 µm displacement for each revolution. Stages are available with side-mounted micrometers for situations where space is a premium, and end-mounted micrometers for ease of adjustment. The stages are lockable with a plate on the side of the stage that can be locked using a 5/64" (2.0 mm) hex key. The top plate of each stage is tapped with an array of 1/4"-20 (M6) tapped blind holes.

These stages can be easily stacked and secured to one another using the integrated 2" mating dovetails. The stages are secured by a single dovetail locking mechanism with a 3/16" (5 mm) hex key. Other multi-axis configurations are also possible as illustrated in the table below. Take care during assembly to ensure no collisions occur with the Z-axis stage during full downward extension. To purchase the necessary components, simply click on the product list and add the items to your cart. They can also be mounted to our 3" mating dovetail stages (25 mm and 50 mm) using the XRN-A1 adapter plate (sold below).

Micrometer conversion kits are available below that can be used to convert a side- or end-mounted stage into an end- or side-mounted stage, respectively.

| Sample Multi-Axis Configurationsa | ||||||

|---|---|---|---|---|---|---|

| XY | XZb | YZb | XYZb | Zb | ||

| Click Images to Enlarge |

|

|

|

|

|

|

| Micrometer Options |

All Side- Mounted |

View Imperial Product Listc View Metric Product Listc |

View Imperial Product List View Metric Product List |

View Imperial Product List View Metric Product List |

View Imperial Product Listc View Metric Product Listc |

View Imperial Product List View Metric Product List |

| All End- Mounted |

View Imperial Product List View Metric Product List |

View Imperial Product List View Metric Product List |

View Imperial Product List View Metric Product List |

View Imperial Product List View Metric Product List |

View Imperial Product List View Metric Product List |

|

Click to Enlarge

XRN25P-K2 Stage Kit Preassembled in XYZ Configuration

- Conveniently Preassembled XRN25P Stages in XY or XYZ Configurations

- Side-Mounted Micrometers Suitable for Adjustment in Tight Spaces

- Included Dovetail Clamp Screw has a Maximum Torque of 15 in•lbs

Thorlabs offers XRN25P(/M) stages preassembled in XY and XYZ configurations. The XRN25P-K1(/M) Preassembled XY Stage consists of two XRN25P(/M) stages preassembled in an XY configuration. The XRN25P-K2(/M) Preassembled XYZ Stage consists of three XRN25P(/M) stages preassembled in an XYZ configuration using an XRN-XZ(/M) Assembly Kit. The XRN25P-K2 eliminates the need to buy and manually assemble the multi-axis stage assembly kits, which are sold below.

Each stage features a side-mounted metric micrometer for 25 mm of travel at 500 µm translation per revolution. The XRN25P offers 1/4"-20 tapped mounting holes, while the XRN25P/M offers M6-tapped mounting holes. The micrometer can be moved to the opposite side of the stage by swapping the micrometer mounting blocks with the steel locking plate. For more information, please see the Micrometer Conversion tab above. Micrometer conversion kits are available below that can be used to convert an end- or side-mounted stage into a side- or end-mounted stage, respectively.

Click to Assemble

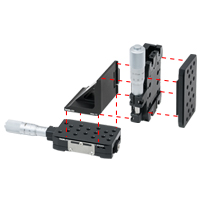

YZ Stage Assembly Constructed Using the XRN-YZ Assembly Kit

Click to Enlarge

Vertical X-Axis Stage Constructed Using the XRN-XZ Assembly Kit and

the XRN-B1 Base Plate (Sold Below)

- Kits Consist of Angle Bracket and Z-Axis Mounting Plate

- Supports X, Z, XZ, YZ, or XYZ Configurations

- Compatible with 2" Mating Dovetail Stages

- Included Dovetail Clamp Screw has a Maximum Torque of 15 in•lbs

Thorlabs offers two assembly kits used to mount two XRN25 series stages perpendicular to each other. The XRN-XZ(/M) Assembly Kit contains a mounting plate and an angle bracket that mounts the surface of the Z-axis platform in-line to the direction of travel (XZ configuration). The XRN-YZ(/M) Assembly Kit contains a mounting plate and an angle bracket that mounts the surface of the Z-axis platform perpendicular to the direction of travel (YZ configuration). Take care during assembly to ensure no collisions occur with the Z-axis stage during full downward extension.

Both configurations require purchasing two XRN25C(/M) or XRN25P(/M) stages in any combination as well as either assembly kit. The female dovetail on one arm of the angle bracket attaches to the male dovetail on the tapped platform of the X- or Y-axis stage, and then the male dovetail of the tapped platform of the Z-axis stage is mated to the other arm of the angle bracket. The tapped mounting plate provided with the XRN-XZ and the XRN-YZ is mounted to the Z-axis stage by attaching the male dovetail of the plate to the female dovetail on the stage, as shown in the image to the right. Mating the Z-axis stage this way ensures that the micrometer is countering forces from both gravity and the internal spring.

Z-Axis Stage Configuration

For situations where only a Z-axis translation stage is needed, either the XRN-XZ or the XRN-YZ angle bracket can be secured directly to the XRN-B1(/M) base plate (sold below). An image of this configuration is shown in the sample configuration table above.

X-Axis Stage Configuration

In addition to a Z-axis stage configuration, the XRN-XZ can be used for situations where the X-axis translation stage needs to be mounted vertically. As shown in the figure to the right, the X-axis stage needs to be secured to the XRN-XZ angle bracket, and the angle bracket secured directly to the XRN-B1 base plate (sold below).

XYZ Configurations

In order to construct an XYZ configuration, first construct an XY stage as pictured in the sample configuration table above. Then, the XRN-XZ assembly kit can be used to add the Z-axis. An XYZ configuration can also be constructed using the XRN-YZ assembly kit, which functions the same as an XYZ configuration constructed using the XRN-XZ, with only the X-axis and Y-axis stages switched. An XYZ configuration using the XRN-YZ assembly kit is shown to the right.

- XRN-A1 Adapter Enables Perpendicular Mounting of 2" Dovetail Components onto 3" Dovetail Components

- XRN-A2 Adapter Enables Parallel Mounting of 2" Dovetail Components onto 3" Dovetail Components

- Adapters Add 0.275" (7.0 mm) to the Overall Stacked Height of Components

These adapters enable mounting of quick-connect, crossed-roller bearing stages or accessories with a female 2" dovetail to components with a male 3" dovetail, as illustrated in the photos below. The XRN-A1 adapter enables perpendicular mounting while the XRN-A2 enable parallel mounting. The mounting configuration in the second photo below allows translation along the extended dovetail to be parallel to the direction of translation of a mounted stage.

To assemble, first loosen the dovetail locking screw on the end of the top stage or accessory. Position the adapter on the bottom stage or rail, as illustrated in the photos below, then align the top component on the adapter. Lastly, tighten the dovetail locking screw (maximum torque: 15 in•lbs) on the end of the top component until the entire assembly is secure. Please note that the deep-set screws in the sides of the adapter are not user adjustable.

| Mounting Adapter Compatibility | |||

|---|---|---|---|

| Item # | Orientation | Top Component | Bottom Component |

| XRN-A1 | Perpendicular | XRN25 Series XRNR1 Stages XRNV1(/M) Stage |

XR25 Series XR50 Stages XRR1 Stages XRV1(/M) Stage |

| XRN-A2 | Parallel | ||

Click to Enlarge

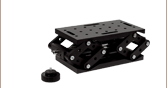

The orthogonal dovetails on the top of the XRN-B1 allow the stage to be mounted in two orientations.

- 1.26" Long, 1/4" (M6) Counterbored Slots for Additional Mounting Flexibility

- Orthogonal Male Dovetails for Two Stage Mounting Orientations

- Compatible with 2" Mating Dovetail Stages

The XRN-B1(/M) base plate offers additional mounting flexibility for coarse positioning of a translation stage within a setup. Three 1.26" long, 1/4" (M6) counterbored slots allow for coarse translation adjustment of the stage. The orthogonal dovetails on the top of the XRN-B1 allow the stage to be mounted in two orientations. The middle slot is designed to be secured by two 1/4"-20 (M6) cap screws onto an optical table or breadboard, which allows the stage to be aligned with the table's or breadboard's hole pattern.

Z-Axis Stage Configuration

For situations where only a Z-axis translation stage is needed, either the XRN-XZ or the XRN-YZ angle bracket (sold above) can be secured directly to the base plate.

X-Axis Stage Configuration

In addition to a Z-axis stage configuration, the XRN-XZ angle bracket (sold above) can be used for situations where the X-axis translation stage needs to be mounted vertically. The XRN-XZ angle bracket can be secured directly to the XRN-B1(/M) base plate.

Click to Enlarge

XRN-C2 Converts a Side-Mounted Micrometer Stage to an End-Mounted Micrometer Stage

- Compatible with XRN25 Series Stages

- Kits to Switch Between Side- and End-Mounted Micrometer Designs

- XRN-C1: End-Mounted to Side-Mounted

- XRN-C2: Side-Mounted to End-Mounted

The XRN-C1 and XRN-C2 are conversion kits that allow the micrometer head to be removed and refitted onto the side or end of the stage, respectively. More details on the conversion process can be found on the Micrometer Conversion tab above.

Products Home

Products Home

Zoom

Zoom

Compact Crossed Roller Bearing, w/ Quick Connect

Compact Crossed Roller Bearing, w/ Quick Connect