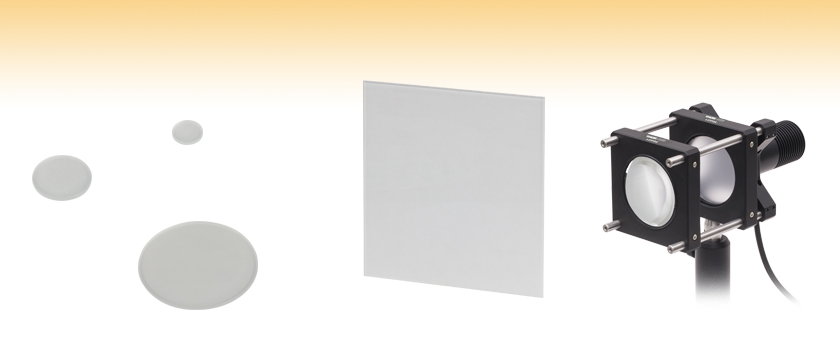

Unmounted N-BK7 Ground Glass Diffusers

- Offered in 120, 220, 600, and 1500 Grit Polishes

- Polished for Greater Uniformity than Sand Blasting

- Round and Square Diffusers

DG05-220

(Ø1/2")

DG10-120

(Ø1")

DG20-600

(Ø2")

DG100X100-120

(100 mm x 100 mm)

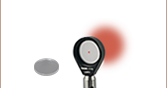

Application Idea

Diffused

LED Condenser

Please Wait

Features

- Available in Four Sizes:

- Round: Ø1/2", Ø1", and Ø2"

- Square: 100 mm x 100 mm

- Substrate Material: N-BK7 (Uncoated)

Thorlabs' Unmounted N-BK7 Ground Glass Diffusers provide a solution for a variety of applications requiring a diffuse Gaussian-like distribution. They are offered in 120, 220, 600, and 1500 grit polishes. Each grit polish is available in Ø1/2", Ø1", and Ø2" round versions as well as a 100 mm x 100 mm square.

For improved transmission, our Ø1" diffusers are also available with an AR coating for either 350 - 700 nm or 650 - 1050 nm. When positioning the diffusers, the grit-polished side should face away from the source.

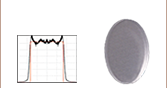

Polished diffusers are advantageous over sand blasted diffusers, as their surfaces have greater uniformity. The various grits provide a range from fine to coarse scattering. A finer grit (e.g. 1500) has a small diffusion pattern, while a coarser grit (e.g. 120) will have a larger diffuser pattern. See the plot below to compare the performance of our diffusers. See the Graphs tab to see individual graphs for each grit polish level, as well as measurement details.

Please see the Application Idea tab for a Diffused LED Condenser that uses a ground glass diffuser. For applications requiring specific divergence angles, spatial distribution of the illumination, and intensity profiles, our Engineered Diffusers®* are more suitable. Thorlabs also offers UV Fused Silica Diffusers for applications that extend into the ultraviolet portion of the spectrum.

*Engineered Diffusers® is a registered trademark of VIAVI Solutions, Inc.

| Diffuser Selection Guide | |||

|---|---|---|---|

| Ground Glass Diffusers | |||

| Standard Diffusers | N-BK7 Substrate | Unmounted, Uncoated | 350 nm - 2.0 μm |

| Unmounted, AR Coated | 350 nm - 700 nm 650 nm - 1050 nm |

||

| Mounted, Uncoated | 350 nm - 2.0 µm | ||

| UVFS Substrate | Unmounted, Uncoated | 185 nm - 2.0 µm | |

| Diffuse Reflectors | N-BK7 Substrate | Unmounted, UV-Enhanced Aluminum Coated | 250 nm - 450 nm |

| Unmounted, Protected Silver Coated | 450 nm - 20 µm | ||

| Unmounted, Protected Gold Coated | 800 nm - 20 µm | ||

| Alignment Disks | |||

| Engineered Diffusers | |||

| Glass Diffusers | UVFS Substrate | Unmounted and Mounted, Uncoated | 193 nm to 2.0 µm |

| Polymer Diffusers | ZEONOR Substrate | Unmounted and Mounted, Uncoated | 380 nm to 1.1 µm |

| Diffuser Kits | |||

| Common Specifications | |

|---|---|

| Thickness | 2.0 mm |

| Clear Aperture | >90% |

| Surface Flatness of Smooth Side (@ 633 nm) | <4λ |

| Surface Quality of Smooth Side | 80-50 Scratch-Dig |

| Parallelism | <3 arcmin |

| Item # | Size | Grit |

|---|---|---|

| DG05-120 | Ø1/2" | 120 |

| DG05-220 | Ø1/2" | 220 |

| DG05-600 | Ø1/2" | 600 |

| DG05-1500 | Ø1/2" | 1500 |

| DG10-120 | Ø1" | 120 |

| DG10-220 | Ø1" | 220 |

| DG10-600 | Ø1" | 600 |

| DG10-1500 | Ø1" | 1500 |

| DG20-120 | Ø2" | 120 |

| DG20-220 | Ø2" | 220 |

| DG20-600 | Ø2" | 600 |

| DG20-1500 | Ø2" | 1500 |

| DG100X100-120 | 100 mm x 100 mm | 120 |

| DG100X100-220 | 100 mm x 100 mm | 220 |

| DG100X100-600 | 100 mm x 100 mm | 600 |

| DG100X100-1500 | 100 mm x 100 mm | 1500 |

Please note that the transmission values are affected by the manner in which the data is collected. An integrating sphere is used along with a spectrometer, and as the grit values get smaller the light is more dispersed, making it difficult to collect all of the light into the spectrometer. Therefore, lower grit values will appear to have a lower transmission.

Bidirectional Scattering Distribution Function Graphs

This data was taken by directing a HeNe laser at a diffuser and collecting the light with a receiver that was rotated around the diffuser to measure the angle-resolved scatter (ARS). The bidirectional scattering distribution function (BSDF), which is found by dividing the ARS by the cosine of the angle between the input beam and the receiver, measures the amount of scattering that occurs after light permeates the diffuser. The X axis of these graphs is the angle at which the scatter is occurring. This is why at 0° there can be a spike; this spike is representative of the specular beam going through the diffuser.

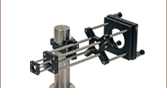

Build Your Own Collimated LED Source

The setup shown to the lower right uses a DG20-600, Ø2", 600 Grit Ground Glass Diffuser as part of a homemade Diffused LED Condenser, which collimates the light exiting the LED source. Although Thorlabs also manufactures out-of-the-box collimated LED light sources, which essentially provide the same result, the one shown here is perfect for those inclined to build their own, perhaps as part of an educational setup. In this particular case, the setup was built using a 60 mm cage system. If you are not familiar with Thorlabs' 60 mm cage assemblies, they consist of cage-compatible components that are interconnected with cage rods. Each cage component features four tapped holes with center-to-center spacings of 60 mm, and they are joined together into a cage system using Ø6 mm rigid steel cage rods; in this case, 4" long cage assembly rods were chosen. The reason for building a cage system is to ensure that the optical components housed inside the cage system have a common optical axis.

To integrate the MWWHL4 Warm White Mounted LED, which has internal SM1 (1.035"-40) threading, into the 60 mm cage system, the mounted LED was threaded into an LCP02 30 mm-to-60 mm cage plate adapter using an SM1T2 Lens Tube Coupler. Next, the light source is directed through a Ø2", 600 grit ground glass diffuser, which is held in place by two SM2RR Retaining Rings on an LCP34 60 mm Cage Plate. After exiting the diffuser, the divergent light is collimated using an LA1401 Plano Convex Lens with a focal length of 60.0 mm. The lens is also housed in an LCP34 60 mm Cage Plate.

The entire 60 mm cage assembly is mounted onto a TR3 post using the 8-32 thread on the bottom of the LCP34, placed in a PH3 post holder, and attached to the breadboard using a BA2 Mounting base.

The tables below correspond to either the imperial or metric list of components needed to build a Diffused LED Condenser.

| Posted Comments: | |

Jeffrey Carson

(posted 2024-10-10 14:49:27.877) Is is possible to have DG100x100-220 cut down into four 48mm x48mm pieces? What is the extra cost? tdevkota

(posted 2024-10-14 10:32:02.0) Thank you for reaching out to Thorlabs. Custom sizes can be requested by contacting techsales@thorlabs.com. I have contacted you directly to further discuss this possibility. Yan Shuo

(posted 2024-08-06 09:02:56.937) why dont you write the scatter angle?I need to know it。 cdolbashian

(posted 2024-08-14 10:01:22.0) Thank you for reaching out to us with this inquiry. Rather than a singular scattering angle, we have full scattering profiles within the "Graphs" tab. I have reached out to you directly to share the location of these data with you. cdolbashian

(posted 2024-08-14 10:01:22.0) Thank you for reaching out to us with this inquiry. Rather than a singular scattering angle, we have full scattering profiles within the "Graphs" tab. I have reached out to you directly to share the location of these data with you. cdolbashian

(posted 2024-08-14 10:01:22.0) Thank you for reaching out to us with this inquiry. Rather than a singular scattering angle, we have full scattering profiles within the "Graphs" tab. I have reached out to you directly to share the location of these data with you. Yicheng Lai

(posted 2023-12-13 14:51:46.757) Query on grain size of DG20-600

Dear sir

I was trying to understand better the specifications of your ground glass diffuser.

While it is clear on the grind grit used for different part numbers, I am not able to deduce the approximate/average grain size of the diffuser structure of your parts.

I would appreciate if you can update me on the approximate/average grain size for #600GRIT polished diffuser.

thx

yicheng cdolbashian

(posted 2023-12-15 04:26:12.0) Thank you for reaching out to us with this inquiry! We do not spec particle size when we characterize these diffusers, but rather the scattering performance and grit size. I have contacted you directly to discuss your application. shampy mansha

(posted 2023-10-10 12:00:35.403) Hi, I was interested in knowing the relation between the grit size and surface roughness of the glass diffuser. Say we have grit size 600, then what is the mean height and the standard deviation of height of the "rough" surface of the glass diffuser? Is there a grit conversion chart where we can have these surface roughness values? Thank you. jdelia

(posted 2023-10-13 12:23:06.0) Thank you for contacting Thorlabs. We unfortunately do not have this information as we do not measure the specific size of the particles, and the standard we use is not always the same throughout the years. We characterize them by the grit # and the performance. user

(posted 2023-04-12 14:20:14.46) Hello, I wish to transmit a range of lights from a single large panel light, aiming for transmission at points between 5-95%. How does using a diffuser will be different from using a ND filter? jgreschler

(posted 2023-04-14 03:04:19.0) Thank you for reaching out to Thorlabs. The ground glass diffusers will serve two primary functions- incoming spectral light will be transmitted as diffuse, and the beam will leave with some amount of divergence. They do not work effectively to reduce the beam power. ND filters by comparison preserve spectral qualities and collimation, but cut down on power according to their OD specification. Zihao Pang

(posted 2022-09-12 22:38:14.26) Hi Thorlabs,

I wonder if you can provide the information of the damage threshold regarding the product DG10-220 and DG10-1500?

Many thanks,

Zihao jgreschler

(posted 2022-09-21 04:07:26.0) Thank you for reaching out to Thorlabs. Additional specifications including damage threshold can be requested by contacting techsupport@thorlabs.com. In this case damage threshold is going to be highly dependent on your laser parameters. I have reached out to you directly to discuss this further. Zihao Pang

(posted 2022-06-02 18:07:53.01) Hi Thorlabs,

In your description it said when positioning the diffusers, the grit-polished side should face away from the source. We wonder how we can tell which side is the grit-polished side of a diffuser like DG10-1500?

Many thanks,

Zihao cdolbashian

(posted 2022-06-06 10:27:35.0) Thank you for reaching out to us with this inquiry. While 1500 is the finest grit diffuser we offer here, determining the specular side is fairly straightforward. I would sat the easiest way was to tilt your diffuser such that you could see the reflection of a bright source, perhaps a room overhead light. On one side, you will see a clear crisp image from the specular reflection, while on the diffuse side, even though the grit is very fine, you will see a more blurry reflection. I have reached out to you directly with an additional suggestion. Zihao Pang

(posted 2022-05-19 20:15:45.903) Hi Thorlabs,

We've recently bought the diffusers DG05-220 and DG05-1500. And we are planning to focus a laser beam onto one of the diffusers to make the scattering light field. The thing is we don't know if the laser beam after tightly focusing would burn the diffuser. Can you provide any information about that?

Best,

Zihao jgreschler

(posted 2022-05-21 10:09:47.0) Thank you for reaching out to Thorlabs. Additional specifications including damage threshold can be requested by contacting techsupport@thorlabs.com. In this case damage threshold is going to be highly dependent on your laser parameters. I have reached out to you directly to discuss this further. Kwangho Lee

(posted 2021-08-26 15:37:33.96) I need a 100 mm diameter and a hole for the M6 bolt at the center. Is it possible to place a production order? Grit size is1500 Grit. Thanks. YLohia

(posted 2021-08-27 03:10:48.0) Hello, custom optics can be requested by emailing techsales@thorlabs.com. We will discuss the possibility of offering this directly. Jason Mill

(posted 2021-07-14 08:34:29.47) Hi there, if I wish to collimate an LED, to then focus it, is it necessary to have a ground glass diffuser in between the two lenses? YLohia

(posted 2021-07-15 11:03:26.0) Hello, thank you for contacting Thorlabs. It is not necessary to use a ground glass diffuser in between, but we do strongly recommend it for a more homogeneous beam and to prevent an image of the LED emitter (square) from being projected to the focused spot. Jasper Jans

(posted 2021-06-14 07:33:31.967) Dear,

Just to let you know the step file is the wrong dimension. It's 1" instead of 2".

Kind regards,

Jasper YLohia

(posted 2021-06-15 03:26:14.0) Hello Jasper, we triple checked the .step file for the DG20-1500 and we found that the diameter is 2", as specified. Patrick Lee

(posted 2021-03-09 18:42:40.64) Hi, I am interested in DG20-600.

I have a collimated light source which will cast a shadow of an object on the diffuser. A camera is placed on opposite side of diffuser to capture the shadow image. Will DG20-600 suitable for this use? YLohia

(posted 2021-04-14 02:36:52.0) Hello, thank you for contacting Thorlabs. While this is not the typical application of such products, we do expect it to work for you in the way you have described. James Griggs

(posted 2020-06-26 11:36:48.95) We are using your diffusers as the front element of a target board to measure HEL beam profiles. I note you advise to orient the diffusive slide so the diffuse surface is on the back (down-beam). Was this the orientation used to obtain your published data for radiant intensity versus scattering angle? If we flip the slide to put the diffuse surface on the front side, will the scattering pattern be the same? Thanks for any insight! nbayconich

(posted 2020-07-06 08:06:37.0) Thank you for contacting Thorlabs. We will reach out to you directly with more information regarding our ground glass diffusers. Jobert Gabriel

(posted 2020-06-15 11:37:20.793) Hi, can you provide the depolarization efficiency of those diffusers ?

Thank you in advance for your answer, Gabriel Jobert nbayconich

(posted 2020-06-17 08:28:16.0) Thank you for contacting Thorlabs, at the moment we do not characterize the depolarization efficiency of these diffusers. I will reach out to you directly to discuss your application. James Griggs

(posted 2020-05-25 12:43:44.26) Hi,

I have two questions about how the power vs angle plots were measured.

1. What was the geometry of the diffuser and detector? Was the power measured along a plane perpendicular to the diffuser surface, or on a circle at constant radius from the incident spot?

2. Are the big discontinuities near 68 and 83 degrees real, or an artifact of the measurement geometry?

Comment: Its surprising that the DG600 curve has a sharp peak, whereas the DG220 has a rounded peak. Most peaks are rounded at the maximum.

Thanks for your responses,

Jim Griggs nbayconich

(posted 2020-06-02 05:34:59.0) Thank you for your feedback, the power distribution was measured on a plane parallel to the surface of the diffuser. The discontinuities are artifacts during the measurement procedure.

The fine grit sizes will create less diffusion in the output creating more well defined peaks than the coarse grit sizes. Milan Buncick

(posted 2020-04-23 15:30:07.403) Hi. Would you please have someone contact me about the

diffuser pattern vs angle plot? I have several questions.

Thank you,

Milan YLohia

(posted 2020-04-23 04:21:34.0) Hello Milan, thank you for contacting Thorlabs. We will reach out to you. user

(posted 2020-01-23 08:49:37.613) In the plot of diffuser transmission vs output angle, why are the curves for DG-120 and DG-220 basically the same, and those for DG-600 and DG-1500 are also very similar? I would expect a more gradual transition between grit polishes. MKiess

(posted 2020-01-24 07:50:24.0) Thank you for contacting Thorlabs. The grit sizes are relatively close which can be seen from the transmission vs. wavelength graphs. We do not control the scattering profile of our diffusers, we ensure that the diffusers are ground to the particular grit size specified. rooogerlo06

(posted 2017-12-11 22:27:07.803) Dear Thorlabs pals,

Could you kindly explain how can I compare the capability of the diffuser by only transmission?

I bought one ground glass diffuser and the diffused phenomenon is not clear. Could you help us on this case? Thanks for your strongly support.

Best regards,

Roger Lo llamb

(posted 2018-03-02 08:19:16.0) Hello Roger, thank you for contacting Thorlabs. There will tend to be a higher transmission for the finer/higher grits, as the less diffusive surface will scatter less. I will reach out to you directly as well. dennis.gardner

(posted 2017-12-05 11:01:03.527) There are a few standards regarding grit size. Which standard is being used here? ISO/FEPA? CAMI? nbayconich

(posted 2018-05-07 03:03:57.0) While we do not specify grit standards, we use the CAMI standard when polishing diffusers in-house while inspecting diffusers received from external vendors to a similar standard. akuznetsov

(posted 2017-09-07 12:27:08.297) Would be good to have images of the diffuser showing how well different grits diffuse light for a point source for example, or an LED source preferably. The point is to figure out which grit will be suitable for application based on how well the diffuser homogenizes the light. The setup would require a camera with a lens looking directly at the diffuser with the light behind the diffuser, preferably in a coupled configuration. In fact would be good to have this type of image for all diffuser optics. tfrisch

(posted 2017-10-20 01:05:01.0) Hello, thank you for contacting Thorlabs. I agree that an application image comparing different grits could be valuable. I have passed this note on to our Marketing Team. I'll reach out to you directly as well. maudolci

(posted 2017-01-13 11:46:03.74) Hi,

I need a diffuser working at wavelengths up to 2200 nm.

The graphs onto your website are however limited to 1200 nm. Looking at them, I noticed for example that the transmission is very good and flat up to 1200 nm and it seems that the trend could be extended beyond this maximum wavelength.

Have you such data ?

Many thanks in advance,

Mauro Dolci tfrisch

(posted 2017-01-25 04:37:40.0) Hello, thank you for contacting Thorlabs. I would expect similar performance out to 2200nm. I will reach out to you directly. david.jung

(posted 2015-06-19 14:37:06.327) Hi, I am wondering at which wavelength the diffuser transmission vs. output angle (displayed in the overview) was measured. Also, how much does this graph change for different wavelength in the visible and NIR range? Thanks! besembeson

(posted 2015-09-21 01:45:15.0) Response from Bweh at Thorlabs USA. This was done using 633nm wavelength. The graph should not change significant with wavelength as the grit sizes are much larger than the wavelengths used with these diffusers. andreas.wittmann

(posted 2013-06-07 09:18:51.91) I have question concering ground diffusers:

We would like to create some diffusive feedback to the laser (to study the impact of feedback on the laser performance). In our experiment, we have the laser then comes the diffuser (tilted by 30°) and after the diffuser the photodiode (the laser points diretely (through the diffuser) into the photodiode).

Our questions:

1. We need just a bit of feedback (below 0.1%).

2. not absolute necessary, but an AR coating at 1512nm would be useful

3. Size: Could you make a window of 7.5mm diameter

4. What is the transmission of the glasses (we want to measure the laser power with a fotodiode on the other side of the diffuser. The transmission should be high (not too much disturbed by the diffuser) tcohen

(posted 2013-06-12 20:10:00.0) Response from Tim at Thorlabs: We can provide a –C AR coating if desired as well as provide custom diameters. The amount you receive at your photodiode is dependent on the geometry of your setup as they will diffuse in an intensity distribution as shown in the graph on the “Overview” tab. We also have the total transmission available on the “Graphs” tab. We will contact you to discuss your setup directly. jasper.hoogveld

(posted 2013-05-02 08:20:28.253) when i open the step file i can't see the grid(profile)

i want to put the stepfile into an optical simulation programme to trace the rays.

i would like to know if this is possible

maybe you could diliver me raydata files

i have ordered two diffusers

dg10-1500 -a

and

dg10 120 -a tcohen

(posted 2013-05-16 16:07:00.0) Response from Tim at Thorlabs: We do not currently have a surface model for ray tracing this diffuser. We will look into providing this for the future and I will contact you to keep you updated. joanna.brunker.09

(posted 2012-04-04 06:42:52.0) This is probably a silly question, but which way round should I use the diffuser? i.e. Should my laser beam be hitting the shiny surface or the "frosted" surface first? I have already destroyed two holographic diffusers so I don't want to make another mistake... tcohen

(posted 2012-04-03 10:23:00.0) Response from Tim at Thorlabs: The setup in the “Application Idea” will produce a uniform but collimated beam from your LED. If uniformity is more of a concern than transmittance, using a lower grit diffuser will allow for more diffusion. Also, as an alternative we offer Engineered Diffusers at http://thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=1660 which will greatly homogenize the input illumination. I have contacted you to further discuss the use of these diffusers in your application. zach.yang

(posted 2012-04-02 10:59:24.0) Dear Sir,

I am looking for a solution which can produce a very uniform but still collimated White LED beam, at ~5cm distance from the lens output surface.

Is the Application Idea in the Ground Glass Diffuser suitable for my application? I'm afraid this would also make a non-uniform distribution, which is similar to my previous many experiments.

Or do you have any ideas? Thank you very much! tcohen

(posted 2012-03-08 15:20:00.0) Response from Tim at Thorlabs: Thank you for your feedback. The finest custom grind we are currently able to provide is 3 micron. This would translate to about 1800 in grit size. Currently we are able to provide the ½" and 1” diameter sizes with this 3 micron polish. shorvath

(posted 2012-03-06 15:22:55.0) I was wondering if Thorlabs would be able to offer custom made higher grit diffusers, and if so, what is the highest grit? jjurado

(posted 2011-03-28 18:12:00.0) Response from Javier at Thorlabs to jyyu: Thank you very much for contacting us. We can certainly offer ground glass diffusers in UV Fused Silica. I will contact you directly to get more details about your requirements. Also, we will emphasize the advantage of UV Fused Silica over BK7 with respect to light-induced fluorescence (LIF) throughout our optics pages. jyyu

(posted 2011-03-25 18:29:59.0) Can you fabricate these diffuser using UV fused silica substrate? We had some problem with the fluorescence of BK7. klee

(posted 2009-11-12 11:20:15.0) A response from Ken at Thorlabs to giovanni.miotto: We have tested the transmission at 0° for all 4 different grits and the results are in line with the graph on this page. The 1500 grit has >80% transmission over the 350 to 700 nm range, while the 600 grit has >72% over the same range. If you are interested, we will be happy to take back the ones you have and evaluate them. giovanni.miotto

(posted 2009-11-08 20:01:07.0) I have tested your dg20-600 and 1500 grit following your graph on trasmission. Surprisingly I have found no difference in trasmission between them (measured with a spectrofotometer), moreover the trasmission is very poor (about 40%). For comparison another glass diffuser that I have (but I do not know the grit) perform 80% trasmission and looks more coarse. I am wondering if your graph is correct, my suspect is that the scale is inverted and the 120 grit is the more trasmissive. Please let me know if this is the case klee

(posted 2009-07-28 17:44:46.0) Response from Ken at Thorlabs to wouter.oepts: We do produce these diffusers. We have been selling them for 5 years and they sell well. So you should feel confident that you can get a constant flow of them from us. wouter.oepts

(posted 2009-07-28 08:38:15.0) Hi,

I am looking for glass diffusers for a lighting application.

As a starting point I believe your glass plates can fullfill the product requirements. However, when taking this to production we would be in need of acquiring a constant flow of these plates.

Are you producing these plates yourselves? Or are these commercially available elsewher?

Thank you,

Wouter Oepts. Tyler

(posted 2008-04-15 15:27:11.0) A response from Tyler at Thorlabs to pascal.mauron: Thank you for contacting us with your component needs. An application engineer will contact you with information about our current products and the feasibility of providing you with a custom solution for your application. pascal.mauron

(posted 2008-04-14 07:02:54.0) Dear Sir,

Dear Madam,

Im interested in this product and have two questions about it:

- is it available with a thickness of 1 mm?

- how are its properties affected when not used in air?

Alternatively, do you know of any commercially available diffusers that get their properties from bulk and not from surface treatment?

With my best regards,

Pascal Mauron |

Products Home

Products Home

Click to Enlarge

Click to Enlarge

Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge

N-BK7, Unmounted Ground Glass Diffusers

N-BK7, Unmounted Ground Glass Diffusers