Fixed Mounts for Multi-Axis Flexure Stages

- Designed for Use with Our Multi-Axis Flexure Stages

- Compact Design with Excellent Stability

- Flexible Mount and Adapter Configurations

Application Idea

Output from a Fiber Being Collimated by an Asphere Mounted in an HCS209 Fixed Mount

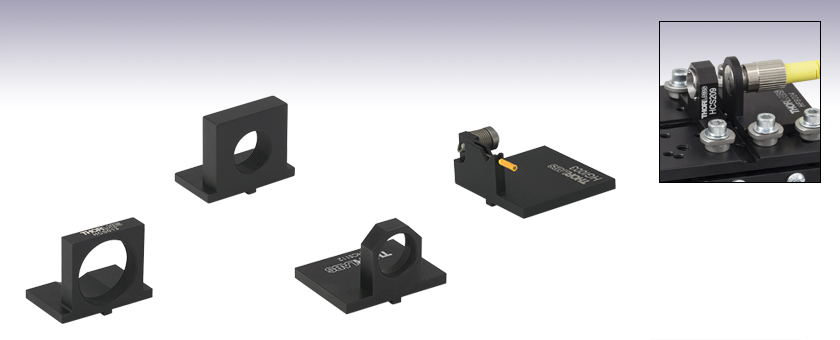

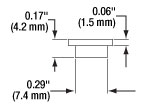

HCS020

SM05-Threaded Mount

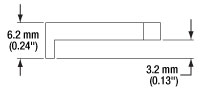

HCS013

RMS-Threaded Mount

HCS112

M12-Threaded Aspheric Lens Mount

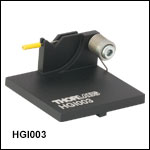

HGI003

GRIN Lens Mount

Please Wait

Click for Details

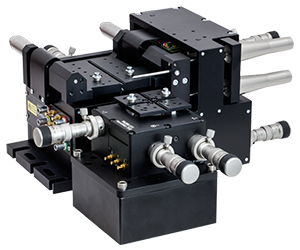

HCS013 Objective Mount and HFF001 Quick-Release Fiber Clamp Accessories Attached to the Top Plate Using Mounting Cleats for

Fiber Launch Applications

These Fixed Mounts are designed for use on our extensive line of multi-axis flexure stages. The central key-way that extends across the top mounting surface of the stage is designed to allow rapid reconfiguration of mounted optics and accessories while maintaining system alignment. For a complete overview of compatible stages, please see the Multi-Axis Stages tab.

Flexure stage mounts can be fixed in position using AMA010(/M) mounting cleats, which are sold below. Each cleat is designed with one edge milled flat, making it possible to insert or remove a flexure stage mount without removing the clamp.

The image to the right shows multiple flexure stage accessories, including the HCS013 RMS Objective Mount, available below, mounted onto a 3-axis flexure stage using multiple mounting cleats.

| Multi-Axis Stage Accessories | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Fiber Mounts |

Fiber Rotators |

Waveguide Mounts |

Diode Mounts |

Fixed Mounts |

Kinematic Mounts |

Top Plates |

Extension Platforms |

Fiber Chucks |

Slide Holders |

Kinematic Platforms |

Adapter Plates |

Multi-Axis Stage Selection Guide

Click to Enlarge

In the above application, a 3-Axis NanoMax flexure stage is aligned in front of a 6-axis stage at the proper 112.5 mm deck height using an AMA554 Height Adapter.

3-Axis Stages

Thorlabs offers three different 3-Axis Stage variations: NanoMax flexure stages, MicroBlock compact flexure stages, and RollerBlock long-travel stages. Each stage features a 62.5 mm nominal deck height. Our NanoMax line of 3-axis stages offers built-in closed- and open-loop piezos as well as modular drive options that include stepper motors, differential drives, or additional piezos. The MicroBlock stages are available with differential micrometer drives or fine thread thumbscrews; these drives are not removable. Finally, our RollerBlock stage drivers can be switched out for any actuator that has a Ø3/8" (9.5 mm) mounting barrel.

4- and 5-Axis Stages

Our 4- and 5-axis stages are ideal for the static positioning of waveguides or complex optical elements with respect to our 3-axis or 6-axis high-performance alignment stages. Thorlabs' 5-axis stages have nominal heights of 62.5 mm or 112.5 mm. The AMA554 Height Adapter can be used to raise the deck height of the 3-axis or 4-axis stages to 112.5 mm for compatibility with our 5-axis MicroBlock or 6-Axis NanoMax Stages.

6-Axis Stages

Thorlabs' 6-Axis NanoMax Nanopositioners are ideal for complex, multi-axis positioning and have a nominal deck height of 112.5 mm. These stages offer a common point of rotation and a patented parallel flexure design that allows all actuators to be coupled directly to the base to minimize any unwanted motion in the system. Built-in closed- and open-loop piezo options are available. A selection of modular drive options allows any axis to be manual or motorized with the option for external piezos. Our units without included actuators are also available in right- or left-handed configurations. To increase the stage height of the 3-axis stages to 112.5 mm, we recommend our AMA554 Height Adapter, shown in the image to the right.

A complete selection and comparison of our multi-axis stages is available below.

3-Axis Stages

| Item # | MAX313D | MAX312D | MAX311D | MAX383 | MAX381 | MAX303 | MAX302 | MAX301 | MBT602 | MBT616D | RB13M | RBL13D | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage Type | NanoMax Flexure Stages | MicroBlock Compact Flexure Stages |

RollerBlock Long Travel Stages | |||||||||||||||||

| Included Drives | DRV3 Differential Micrometers | DRV208 Stepper Motor Actuators | N/A | Fine Thread Thumbscrews | Differential Micrometers | 148-801ST Micrometer Drives |

DRV304 Differential Micrometers |

|||||||||||||

| Built-in Piezos | N/A | Open Loop |

Closed Loop | N/A | Closed Loop | N/A | Open Loop | Closed Loop | N/A | N/A | ||||||||||

| Travel (X, Y, Z) | 4 mm (0.16") | 13 mm (0.51") | ||||||||||||||||||

| Deck Height (Nominal) | 62.5 mm (2.46") | |||||||||||||||||||

| Optical Axis Height (Nominal) | 75 mm (2.95") | |||||||||||||||||||

| Load Capacity (Max) | 1 kg (2.2 lbs) | 4.4 kg (9.7 lbs) | ||||||||||||||||||

| Thermal Stability | 1 µm/°C | - | ||||||||||||||||||

| Weight | 1.00 kg (2.20 lbs) | 0.64 kg (1.40 lbs) | 0.59 kg (1.30 lbs) | |||||||||||||||||

4-Axis Stages

| Item # | MBT401D MBT401D/M |

MBT402D MBT402D/M |

|

|---|---|---|---|

| Stage Type | 4-Axis Thin-Profile MicroBlock Device Stage | 4-Axis Low-Profile MicroBlock Device Stage | |

| Included Drives | Differential Micrometers | ||

| Built-in Piezos | N/A | ||

| Travel | Horizontal Axis (Y)a | 13 mm (0.51") | |

| Vertical Axis (Z) | 6 mm (0.24") | ||

| Pitch (θy) | ±5° | ||

| Yaw (θz) | ±5° | ||

| Deck Height (Nominal) | 62.5 mm (2.46") | ||

| Optical Axis Height (Nominal) | 75 mm (2.95") | ||

| Load Capacity (Max) | 0.5 kg (1.1 lbs) | ||

5-Axis Stages

| Item # | MBT401D (MBT401D/M) or MBT402D (MBT402D/M) with MBT501 |

PY005 | |

|---|---|---|---|

| Stage Type | 5-Axis MicroBlock Stage System | Compact 5-Axis Stage | |

| Included Drives | Differential Micrometers | 100 TPI Actuators | |

| Built-in Piezos | N/A | ||

| Travel | Optical Axis (X) | 13 mm (0.51") | 3 mm (0.12") |

| Horizontal Axis (Y) | 13 mm (0.51") | 3 mm (0.12") | |

| Vertical Axis (Z) | 6 mm (0.24") | 3 mm (0.12") | |

| Pitch (θy) | ±5° | ±3.5° | |

| Yaw (θz) | ±5° | ±5° | |

| Deck Height (Nominal) | 112.5 mm (4.43") | 62.5 mm (2.46")a | |

| Optical Axis Height (Nominal) | 125 mm (4.92") | 75 mm (2.95")a | |

| Load Capacity (Max) | 0.5 kg (1.1 lbs) | 0.23 kg (0.5 lbs) | |

6-Axis Stages

| Item # | MAX601D MAX601D/M |

MAX602D MAX602D/M |

MAX603D MAX603D/M |

MAX681 MAX681/M |

MAX682 MAX682/M |

MAX683 MAX683/M |

MAX607 MAX607/M MAX607La MAX607L/Ma |

MAX608 MAX608/M MAX608La MAX608L/Ma |

MAX609 MAX609/M MAX609La MAX609L/Ma |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Stage Type | 6-Axis NanoMax Flexure Stage | |||||||||

| Included Drives | DRV3 Differential Micrometers | DRV208 Stepper Motor Actuators | N/A | |||||||

| Built-in Piezos | N/A | Open Loop | Closed Loop | N/A | Open Loop | Closed Loop | N/A | Open Loop | Closed Loop | |

| Travel | X, Y, Z | 4 mm (0.16") | ||||||||

| θx, θy, θz | 6° | |||||||||

| Deck Height (Nominal) | 112.5 mm (4.43") | |||||||||

| Optical Axis Height (Nominal) | 125 mm (4.92") | |||||||||

| Load Capacity (Max) | 1.0 kg (2.2 lbs) | |||||||||

| Posted Comments: | |

Magnus Hald Madsen

(posted 2023-02-13 10:14:49.03) Hi.

Is it possible to get a new spring for this item HGI003?

The spring on one of ours is broken and needs replacement.

BR

Magnus do'neill

(posted 2023-02-14 06:59:59.0) Response from Daniel at Thorlabs: Thank you for your enquiry. I will reach out to you to discuss this with you. sebastien.loranger

(posted 2015-11-19 10:13:23.58) I have a little suggestion for Thorlabs. When using a 3 axis stage for injection such as the MBT612D, it is important to align the optical axis perfectly parallel and centered with the objective/lens...

A little alignement tool could be useful for this: A fixed mirror that is pre-attached to the mount (such as the HCS020) so as to be perfectly perpendicular to the optical axis with a iris in front to designate the center. This has the advantage of being low cost and simple. The back reflection of the mirror can be used for alignement.

Current mounts (such as the HCS020) are not ideal, as holding a mirror within tends to give the mirror/collimator a slight angle. When doing an alignement from back-reflection, this very small angle has an important impact. besembeson

(posted 2015-11-19 01:46:43.0) Response from Bweh at Thorlabs USA: Thanks for your feedback and this suggestion. We will look into this and will follow-up with you. Not sure what configuration you have on the MBT621D but, if you can use the HCS031 and working with collimators (since you mention this above), we have some collimator adapter mounts with kinematic adjustment that may be useful in combination with an iris such as the SM1D12D for such alignments: http://www.thorlabs.us/newgrouppage9.cfm?objectgroup_id=219 |

- Internal RMS (0.800"-36) Threading

- Compact L-Shaped Mount

- 12.5 mm Optical Axis Height

The compact HCS013 microscope objective mount features internal RMS threading (0.800"-36) and has an optical axis 12.5 mm above the flexure stage. The internal RMS threading allows microscope objectives, components, or accessories with external RMS threads, such as our IR viewing screen (VRC2RMS), to be attached to one of our multi-axis flexure stages. Thorlabs also offers a complete selection of microscope objectives that are well suited for fiber coupling applications.

- Internal SM05 (0.535"-40) Threading

- Ideal for use with Our Ø1/2" Lens Tubes and SM05-Threaded Photodiodes

- 12.5 mm Optical Axis Height

The HCS020 mount integrates our extensive line of SM05-threaded (0.535"-40) components into our flexure stage systems. The optical axis of the SM05-threaded HCS020 mount is 0.49" (12.5 mm) above the flexure stage.

- Internal SM1 (1.035"-40) Threading

- Ideal for use with Our Ø1" Lens Tubes and SM1-Threaded Photodiodes

- 18.0 mm Optical Axis Height

The HCS031 mount integrates our extensive line of SM1-threaded (1.035"-40) components into our flexure stage systems. Due to the diameter of the SM1 threading, the optical axis of the HCS031 mount is 18.0 mm above the flexure stage.

Due to the higher optical axis, a 5.5 mm Height Adjustment Shim (AMA093) will be required for all mounts with an optical axis of 12.5 mm when used in conjunction with the HCS031.

Click to Enlarge

HCS112 and Aspheric Lens with a previous-generation HFB004 Fiber Holder on an MBT616D Stage

- Internal M8 x 0.5, M9 x 0.5, or M12 x 0.5 Threading

- Ideal for use with our Molded Aspheric Lenses

- 12.5 mm Optical Axis Height

The HCS108, HCS109, and HCS112 mounts have M8 x 0.5, M9 x 0.5, or M12 x 0.5 internal threads, allowing our line of Molded Aspheric Lenses to be used with our flexure stage systems. The optical axis of the mount is 12.5 mm above the flexure stage, giving a 75 mm optical axis height when fitted.

For applications where space is limited or when multiple lenses need to be stacked next to one another, see the range of thin-profile lens holders below.

Click to Enlarge

HCS209 and Aspheric Lens with a previous-generation HFB004 Fiber Holder on an MBT616D Stage

Click for Details

AMA110 mounting block shown with two HCS209 optic mounts in a close-coupled configuration.

- Only 6 mm Thick

- Internal M8 x 0.5, M9 x 0.5, or M12 x 0.5 Threading

- Allows Back-To-Back Lens Mounting

- Ideal for use with our Molded Aspheric Lenses

- 12.5 mm optical Axis Height

The HCS208, HCS209, and HCS212 mounts are a series of extra slim mounts for lenses and optics. They have M8 x 0.5, M9 x 0.5, or M12 x 0.5 internal threads and allow our line of Molded Aspheric Lenses to be mounted back-to-back. The optical axis of the mount is 12.5 mm above the flexure stage, giving a 75 mm optical axis height when fitted.

Standard AMA010 cleats can be used for securing (see below) but for ultra-close mounting, we also offer the AMA110 mounting blocks. These feature a line of nylon-tipped setscrews to secure the optics holders. They allow easy repositioning and very close mounting of multiple HCS2xx Optic Mounts (see image right). The blocks, which must be ordered separately from the lens mounts, are secured via two holes and are supplied with either 6-32 or M3 cap screws. Our AMA111 narrow optic clamps offer an alternative solution where devices need to be mounted close together. The AMA110 and the AMA111 are sold below.

- Holds Ø1 mm to Ø3 mm Gradient-Index (GRIN) Lenses

- Easy-to-Use, Simple Spring Clamp for Lens Retention

- 12.5 mm Optical Axis Height for Ø1.8 mm GRIN Lenses

The HGI003 gradient-index lens holder easily secures gradient-index lenses, with diameters ranging from 1 to 3 mm, in a precision V-groove with a spring clamp. This mount fits into the locating keyway of our multi-axis flexure stages. The keyway allows the GRIN lens to be slid into coarse position before securing. Final positioning is accomplished using the precision control of the stage. Gradient-index lenses are used to collect and focus light from laser diodes into optical fibers, to collect and collimate light from laser diodes, or to focus collimated beams into fibers.

- Two Setscrews and a Double-Bored Mounting Hole for Maximum Stability

- Models for Ø4 mm, Ø11 mm, Ø12 mm, and Ø15 mm Collimation Packages

- Designed for Multi-Axis Flexure Stages

- 12.5 mm Optical Axis Height

These collimation package mounts feature a 3 mm wide keyway in the base of the mount for compatibility with our line of multi-axis flexure stages. Our HCS004, HCS011, HCS012, and HCS015 Mounts are designed for Ø4 mm, Ø11 mm, Ø12 mm, and Ø15 mm collimation packages, respectively. Please see the table below for more details and for a list of compatible items.

Two setscrews with a 5/64" (2.0 mm) hex are used to press a collimator against the two lines of contact created by the double-bored mounting hole.

| Item # | Intended for Use With: | Accepted Diameter | Bore Length |

|---|---|---|---|

| HCS004 | CFS2 Pigtailed Aspheric Fiber Collimators | 4 mm | 0.40" (10.2 mm) |

| HCS011 | FC/PC, FC/APC, or SMA905 Fixed Collimators, Laser Diode Modules, Laser Line Generator | 11 mm | 0.59" (15.0 mm) |

| HCS012 | FC/PC, FC/APC, or SMA905 Fixed Collimators, TC12 and TC18 Triplet Collimators (FC/PC or FC/APC) | 12 mm | 0.59" (15.0 mm) |

| HCS015 | F810 Doublet Collimators, LT Collimation Tubes, TC18 Triplet Collimators (FC/PC or FC/APC) | 15 mm | 0.59" (15.0 mm) |

- Only Compatible with "Cross Style" Flexure Top Plates [Item # MMP1(/M)]

- 12.5 mm Optical Axis Height

- Holds Ø1" Optics

The HCS030 holds Ø1" (Ø25 mm) optics with the optical axis 12.5 mm above the flexure stage. A Delrin®* pin is used to secure, without marring, the optic.

Note: the HCS030 must be used with flexure stages that feature the "cross style" top plate [MMP1(/M)] to provide clearance for Ø1" optics. The flexure stage top plate is easily replaced and is standard on all stages and accessories shipped after February 2006.

*Delrin is a registered trademark of DuPont Polymers, Inc.

While we offer an extensive line of fiber launch and waveguide accessories, it is difficult to anticipate all of the possible requirements that may arise for customers. Hence, we have added these simple components, which ease the production of one-of-a-kind mounting accessories. As can be seen in the photograph to the left, the front surface of each blank is clearly marked with witness lines, which are centered on the 12.5 mm high optical axis of our multi-axis flexure systems.

Click for Details

Accessories mounted in close proximity using the AMA110 Mounting Block.

- Secures Components to NanoMax, MicroBlock, or RollerBlock Stages

- Cleats for Mounting Single Components

- Mounting Blocks and Clamps for Close Proximity Mounting of Multiple Components

The AMA010(/M) Cleats have a flat milled along one side. To lock an accessory along the center alignment groove, rotate the cleat so that the flat is facing the groove. Place the accessory into the groove between the cleats, rotate the cleat so that the rounded edge covers the edge of the mount, and lock down the 6-32 (M3) locking screw and washer. The cleats can be rotated without needing to remove the locking screws. See the animation to the right for details. The included screws are 5/16" (8 mm) long and are used with a 3/32" (2.5 mm) hex key.

For mounting multiple components in close proximity, we offer the AMA110 mounting blocks. These mounting blocks feature a line of nylon-tipped setscrews to secure components, and allow for easy repositioning and very close mounting. The blocks are secured via two holes and are supplied with either 6-32 or M3 cap screws.

The AMA111 Narrow Device Mounting Clamps offer an alternative solution when devices need to be mounted close together. They are secured using an M3.5 or M3 washer and a 6-32 or M3 cap screw, compatible with a 7/64" or 2.5 mm hex key, respectively.

Products Home

Products Home

Zoom

Zoom

Click to Enlarge

Click to Enlarge

Fixed Mounts and Accessories

Fixed Mounts and Accessories