Concave Mirrors: Visible Dielectric Coating (400 - 750 nm), Back Side Polished

- Focal Lengths from 12 - 100 mm

- Ø1/2" or Ø1" Sizes

- Dielectric Coating for 400 - 750 nm

- Back Sides Polished to λ/4 Flatness

CM127P-012-E02

Ø1/2''

CM254P-025-E02

Ø1''

CM254P-100-E02

Ø1''

Please Wait

| Common Specifications | |

|---|---|

| Dielectric Coating Wavelength Range | 400 - 750 nm |

| Dielectric Coating Reflectance (0° to 45° AOI) |

Rs, avg, and Rp, avg, > 99% |

| Available Diameters | 1/2" and 1" |

| Clear Aperture | >90% of Diameter |

| Diameter Tolerance | +0.0 / -0.2 mm |

| Thickness Tolerance | ±0.2 mm |

| Substrate | N-BK7a |

| Front Surface Quality (Concave Side) | 20-10 Scratch-Dig |

| Front Surface Accuracy (Concave Side) | λ/4 at 633.0 nm |

| Back Surface (Plano Side) | Polished |

| Back Surface Quality (Plano Side) | 40-20 Scratch-Dig |

| Back Surface Flatness (Plano Side) | λ/4 at 633.0 nm |

| Dielectric Concave Mirrors Selection Guide | |||

|---|---|---|---|

| UV | 350 - 400 nm | ||

| Visible | 400 - 750 nm | 400 - 750 nm, Back Side Polished | |

| NIR | 750 - 1100 nm | 750 - 1100 nm, Back Side Polished | |

| Telecom | 1280 - 1600 nm | ||

See the Concave Mirror Guide tab, above, for our complete selection of concave mirrors.

Features

- High-Reflectance Dielectric Coating for 400 - 750 nm (-E02)

- >99% Average Reflectance Over Dielectric Coating Range

- Two Diameter Options: 1/2" and 1"

- Focal Lengths Range from 12 mm to 100 mm

- Polished Back Surface

- Surface Flatness: λ/4 at 633 nm

- Surface Quality: 40-20 Scratch-Dig

Thorlabs' Broadband Dielectric Concave Mirrors are designed for a wide variety of light collection, imaging, and focusing applications. These reflective optics focus light without chromatic aberration, making them especially suitable for broadband sources. With a surface accuracy of λ/4 at 633 nm, these mirrors provide excellent image quality.

Since the back sides are also polished to a λ/4 flatness at 633 nm with a surface quality of 40-20 scratch-dig, these mirrors will transmit a very small portion (<<1%) of the incident light within the coating band, thereby enabling sampling of the incident light without the need for additional optical elements.

Although the transmission properties of back side polished mirrors are desirable in certain applications, there are tradeoffs to consider. By polishing the back side of a mirror, more light will be reflected by the back surface, thereby increasing the number of stray beams present in the lab. When using back side polished mirrors, ensure that all stray beams are blocked appropriately. Thorlabs offers an extensive line of laboratory safety equipment (e.g., blackout materials, beam dumps, goggles) to facilitate safety precautions. In addition to safety concerns when using back side polished mirrors, unwanted interference effects can arise between the light reflected from the front surface and that reflected from the optically flat back surface. Finally, broadband dielectric mirrors are fabricated using a complex multilayer dielectric coating technique, which affects the transmitted light. Both the wavefront and the polarization of the transmitted beam will be altered, and these effects are temperature dependent.

All of the mirrors on this page can be mounted by our Precision Kinematic Mirror Mounts.

Thorlabs also offers Plano Back Side Polished Mirrors.

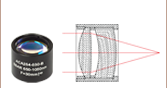

These plots show the reflectance of our -E02 dielectric coating for a typical coating run. The shaded region in each graph denotes the spectral range over which the coating is highly reflective. Due to variations in each run, this recommended spectral range is narrower than the actual range over which the optic will be highly reflective. If you have any concerns about the interpretation of this data, please contact Tech Support. For applications that require a mirror that bridges the spectral range between two dielectric coatings, please consider a metallic concave mirror.

Excel Spreadsheet with Raw Data for -E02 Coating, 8° and 45° AOI

| Posted Comments: | |

Lauren Weiss

(posted 2022-02-14 13:52:52.4) Hello, I purchased the CM127P-050_E02 to use in a cavity. It is more transmissive than the graphs on this site suggest. I found that for 852 nm light, when I send 49 mW in at 0 incidence, I get 2.85 mW out, a transmission rate of 5.81%. jgreschler

(posted 2022-02-17 04:02:42.0) Thank you for reaching out to Thorlabs. Due to variations in each run, this recommended spectral range is narrower than the actual range over which the optic will be highly reflective. For 852nm I would recommend using the NIR dielectric coated mirrors, suffix -E03. |

Click on a particular graphed line or the corresponding name in the legend to view concave mirrors with that coating option.

Metallic-Coated Concave Mirrors are available in UV Enhanced Aluminum, Aluminum, Silver, and Gold.

Concave Dielectric Coated Mirrors

Click to Enlarge

Raw Data

Reflectance of -E02 Dielectric-Coated Concave Mirrors at 8° AOI.

These mirrors are also available with a Back Side Polish.

_G1-350.gif)

Click to Enlarge

Raw Data

Reflectance of -E03 Dielectric-Coated Concave Mirrors at 6° AOI.

These mirrors are also available with a Back Side Polish.

Products Home

Products Home

VIS Dielectric Concave Mirrors, Back Side Polished

VIS Dielectric Concave Mirrors, Back Side Polished