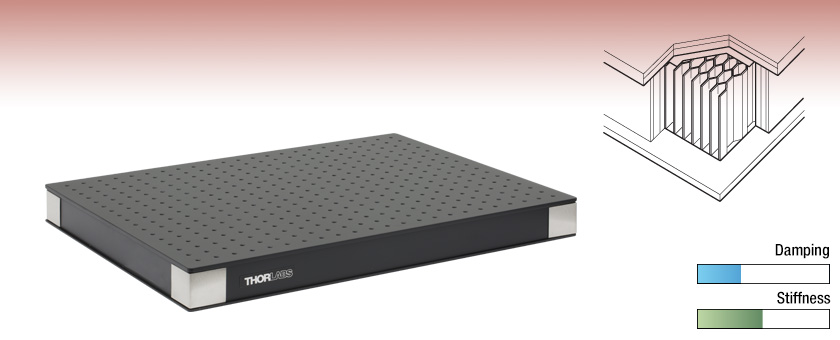

Aluminum Breadboards: Enhanced Stiffness, 55 mm (2.2") Thick

- All-Aluminum Construction Minimizes Thermal Instabilities

- High Strength-to-Weight Ratio

- Useful for Applications Demanding a

Totally Nonmagnetic Structure

PBG12118

18" x 24" UltraLight™

Optical Breadboard

Cutaway Showing the Internal Honeycomb Structure

Please Wait

| Key Specificationsa | ||

|---|---|---|

| Construction | ||

| Breadboard Thickness | 55 mm (2.2") | |

| Top Skin Flatness | ±0.15 mm (±0.006") Over Any 0.3 m2 | |

| Construction | Double-Plate, Single-Honeycomb Core, Athermalized Aluminum Design |

|

| Mounting Holes | Imperial | Metric |

| Threads and Spacing | 1/4"-20 Tapped Holes on 1" Centers |

M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Holes |

1.0" from Table Edge on all Sides |

25.0 mm from Table Edge on all Sides |

| Maximum Screw Depth | 6 mm (0.24") from Top Surface | |

Features

- Thickness: 55 mm (2.2")

- All-Aluminum Construction for Matching CTE to Reduce Thermal Effects

- Large Range of Sizes (W x L):

- Imperial: 1' x 2' to 3' x 5'

- Metric: 300 mm x 600 mm to 900 mm x 1500 mm

- Higher Rigidity than 0.5" Thick Solid Aluminum Breadboards (See Construction Tab for Details)

- Black Matte Painted Surface Reduces Reflectivity and Backscatter

- High-Density Honeycomb Core Provides Static and Dynamic Rigidity

- Custom Sizes Available; Contact Tech Support for Details

UltraLight™ Honeycomb Breadboards offer a high strength-to-weight ratio and an all-aluminum construction. Using aluminum throughout means that the breadboard will have similar coefficients of thermal expansion (CTE), which will minimize thermal instabilities. These breadboards are ideal for optical setups where portability and dynamic rigidity are important. They are typically used as replacements for aluminum, steel, or granite surface plates, as well as for applications demanding a totally nonmagnetic surface.

Choosing an Optical Breadboard

When choosing an aluminum optical breadboard, stiffness is a major consideration. For aluminum optical breadboards, Thorlabs offers two levels of stiffness: high and enhanced. Although most people associate deflection under load with thickness, it is actually the stiffness of a board that determines the deflection.

The higher the stiffness, the better the breadboard's ability to resist bending when a load or force is applied to it. Therefore, when a heavy load is placed in the center of a breadboard with high stiffness, the board will deflect more than it would if the same load were placed on an enhanced stiffness breadboard. This deflection can create misalignment between two components on opposite ends of the breadboard. This is especially important, for example, when conducting experiments that require sliding optical setups across the breadboard while maintaining a straight optical axis.

We also offer a broad selection of Nexus® Steel Honeycomb Breadboards, which provide greater stiffness and vibration damping. For a quick comparison of our different breadboard options, please see the BB Selection Guide tab.

Frame and Isolation Options

We offer a number of support options for breadboards. Our standard breadboard frames are available with rigid supports, or with passive or self-leveling active vibration isolation. We also offer passive and electronic isolator feet for mounting a breadboard on top of a table.

| Specifications | ||

|---|---|---|

| Construction | ||

| Breadboard Thickness | 55 mm (2.2") | |

| Top Skin Flatness | ±0.15 mm (± 0.006") Over Any 0.3 m2 | |

| Construction | Double-Plate, Single-Honeycomb Core, Athermalized Aluminum Design |

|

| Top Plate | 6 mm Thick Aluminum | |

| Bottom Plate | 3 mm Thick Aluminum | |

| Core | High-Density Plated Aluminum Honeycomb | |

| Sides | Black Laminated Aluminum Sides, Slightly Inset | |

| Finish | Matte Black | |

| Mounting Holes | Imperial | Metric |

| Threads and Spacing | 1/4"-20 Tapped Holes, Not Sealed, on 1" Centers |

M6 Tapped Holes, Not Sealed, on 25 mm Centers |

| Distance from Edge to First Holes | 1.0" on all Sides | 25.0 mm on all Sides |

| Maximum Screw Depth | 6 mm from Top Surface | |

| Imperial Breadboard Dimensions and Weights | |||||

|---|---|---|---|---|---|

| Item # | Dimensions (L x W x H) |

Unpackaged Mass |

Unpackaged Weight |

Packaged Shipping Massa |

Packaged Shipping Weighta |

| PBG12102 | 12" x 24" x 2.2" | 6.00 kg | 13.00 lbs | 12.00 kg | 26.40 lbs |

| PBG12103 | 12" x 36" x 2.2" | 8.00 kg | 18.00 lbs | 17.00 kg | 37.40 lbs |

| PBG12118 | 18" x 24" x 2.2" | 8.00 kg | 17.64 lbs | 14.32 kg | 31.50 lbs |

| PBG12105 | 24"' x 24" x 2.2" | 12.00 kg | 27.00 lbs | 20.96 kg | 51.41 lbs |

| PBG12106 | 24" x 36" x 2.2" | 16.00 kg | 35.00 lbs | 29.00 kg | 63.80 lbs |

| PBG12108 | 24" x 60" x 2.2" | 26.00 kg | 57.00 lbs | 43.00 kg | 94.60 lbs |

| PBG12110 | 30" x 36" x 2.2" | 21.00 kg | 46.30 lbs | 35.00 kg | 68.39 lbs |

| PBG12111 | 30" x 48" x 2.2" | 27.00 kg | 60.00 lbs | 46.00 kg | 96.80 lbs |

| PBG12113 | 36" x 48" x 2.2" | 32.00 kg | 71.00 lbs | 54.00 kg | 118.80 lbs |

| PBG12114 | 36" x 60" x 2.2" | 39.00 kg | 86.00 lbs | 64.00 kg | 140.80 lbs |

| Metric Breadboard Dimensions and Weights | |||||

|---|---|---|---|---|---|

| Item # | Dimensions (L x W x H) |

Unpackaged Mass |

Unpackaged Weight |

Packaged Shipping Massa |

Packaged Shipping Weighta |

| PBG52502 | 300 x 600 x 55 mm | 6.00 kg | 13.00 lbs | 12.00 kg | 26.40 lbs |

| PBG52503 | 300 x 900 x 55 mm | 8.00 kg | 18.00 lbs | 16.00 kg | 35.20 lbs |

| PBG52522 | 450 x 600 x 55 mm | 8.20 kg | 18.00 lbs | 15.34 kg | 33.75 lbs |

| PBG52505 | 600 x 600 x 55 mm | 11.00 kg | 24.00 lbs | 20.00 kg | 44.00 lbs |

| PBG52506 | 600 x 900 x 55 mm | 16.00 kg | 35.00 lbs | 28.00 kg | 60.00 lbs |

| PBG52508 | 600 x 1500 x 55 mm | 27.00 kg | 60.00 lbs | 44.00 kg | 94.60 lbs |

| PBG52510 | 750 x 900 x 55 mm | 20.00 kg | 44.00 lbs | 36.00 kg | 79.37 lbs |

| PBG52511 | 750 x 1200 x 55 mm | 26.50 kg | 58.42 lbs | 43.00 kg | 103.62 lbs |

| PBG52513 | 900 x 1200 x 55 mm | 27.00 kg | 59.00 lbs | 51.00 kg | 112.20 lbs |

| PBG52514 | 900 x 1500 x 55 mm | 39.50 kg | 87.08 lbs | 63.00 kg | 140.80 lbs |

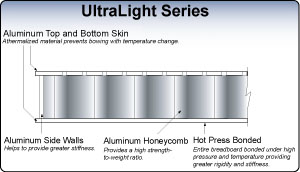

Thorlabs UltraLight™ optical breadboards offer high strength-to-weight ratio and excellent thermal stability. These breadboards are ideal for optical setups where portability and dynamic rigidity are important.

Minimum Relative Breadboard Motion

The UltraLightTM range incorporates a double-plate, single-honeycomb design, providing excellent stiffness and dynamic rigidity. The top layer consists of a 6 mm aluminum top plate. The second layer adds the main aluminum honeycomb structure and the 3 mm aluminum bottom plate. The main honeycomb core is fabricated from strips of precision-formed plated aluminum, which is bonded together with a high-tensile-strength epoxy adhesive.

Excellent Surface Flatness

Breadboard flatness is critically important during many experimental setups. Lack of local flatness requires readjustment of components for height variations across the breadboard and can cause component “wobble”. Thorlabs breadboards offer unsurpassed flatness due to the high-precision aluminum plates, which are specially handled to maintain superior flatness throughout the manufacturing process. A unique thermal bonding process ensures that stress is not induced during manufacture, thereby retaining the flatness of the top plate.

Athermalized Design

Thorlabs breadboards have matched aluminum for both the top and bottom plates. This unique athermalized design eliminates thermal bowing effects caused by temperature variations.

| Posted Comments: | |

user

(posted 2024-07-09 10:39:46.697) For PBG 52508, the max screw depth is said to be 6mm on the top surface material. Is this 6mm the max thread engagement or the max distance the screw can go down to? The Newport IG 30x60-2 has around 19 mm hole depth and 3.4 mm thread engagement. I would like to have a clarification on this please. Thank you. cstroud

(posted 2024-07-15 11:10:48.0) Thanks for reaching out. The 6mm spec is referring to both the maximum hole depth and the thread engagement. The threads are only drilled into the top skin of the PBG breadboards, which are 6mm thick. I will contact you directly to discuss this further. user

(posted 2024-05-27 14:26:23.12) Hello,

I would like to use this breadboard to place on top of an optical table with 4 support posts. On top of the breadboard, I want to place a laser that weighs 59 kg. Do you think it can perform well for this weight?

Best regards,

Roberto do'neill

(posted 2024-06-03 08:52:58.0) Thank you for your comment. It is unlikely that you will experience any issues with ~60kg with any of these breadboards with regards to load capacity, it is likely the post will be an issue before the board. I will reach out to you directly to discuss your application in more detail. Michael Strotkamp

(posted 2024-01-11 10:22:50.0) The painting of the plates should be replaced by anodization (at least as an option) to prevent outgassing close the optics.

Especially for the customized breadboards that would be a great product enhancement. do'neill

(posted 2024-01-18 08:35:10.0) Thank you for your feedback. There is currently an active project on this and we are working on replacing this with anodised version in the near future. gking

(posted 2017-05-16 14:59:25.343) Would it be possible to get a custom 1000x1000mm breadboard?

Would the price be considerably different from say a 900x1200mm?

What would the delivery time be approximately? bwood

(posted 2017-05-18 09:40:05.0) Response from Ben at Thorlabs: Thank you for your feedback. We are able to make a wide array of custom breadboards and tables, and we will be in contact shortly with a quote for this custom breadboard. user

(posted 2015-04-09 15:50:12.95) Is there a special reason why the aluminum honeycomb breadboards are painted instead of anodized? We would prefer anodized breadboards because of the better surface axel.wiegmann

(posted 2013-12-11 10:48:55.673) Is it possible to use the breadboard upside down with the mounting holes to the floor?

We want to rest an interferometer (weight about 60kg) on the side without mounting holes and use the side with mounting holes to fix the breadboard on a translation axis. msoulby

(posted 2013-12-11 11:44:37.0) Response from Mike at Thorlabs: Yes it is entirely possible to use this breadboard upside down. However if nessary we can also provide you with a customised breadboard which will have no holes at all. I have contacted you directly to see if this might be a more suitable option. bdada

(posted 2012-03-13 11:57:00.0) Response from Buki at Thorlabs to makarov:

Thank you for using our feedback forum. Yes, the finish is black paint. It is not anodized. Please contact techsupport@thorlabs.com if you have any questions. makarov

(posted 2012-03-12 17:18:04.0) What is the surface finish? Is it painted black, not anodized? |

| Breadboards |  Nexus, Optimized Damping |

Intrinsically Damped |

Aluminum Honeycomb |

Stainless Steel |

Solid Aluminum |

|---|---|---|---|---|---|

| Construction | |||||

| Breadboard Thickness | 60 mm (2.4") 110 mm (4.3") |

58 mm (2.28") | 25 mm (0.98") 55 mm (2.2") |

12.7 mm (0.5") | 7.0 mm (0.28") 9.5 mm (0.375") 12.7 mm (0.5") 19.05 mm (0.75") |

| Working Surface | 4003 Grade Stainless Steel or 304L Grade Nonmagnetic Steel Top Plate |

4003 Grade Stainless Steel Top Plate | Aluminum | 416 Grade Stainless Steel | Solid Aluminum Anodized or Unanodized |

| Top Skin | 5 mm (0.20") | 5 mm (0.20") | 6 mm (0.24") | N/A | N/A |

| Bottom Skin | 5 mm (0.20") | 3 mm (0.12") | 3 mm (0.12") | N/A | N/A |

| Core Design | High-Density Plated Steel Honeycomb, 0.26 mm Thick | High-Density Plated Aluminum Honeycomb | N/A | N/A | |

| Side Panels | Rigid Steel Box Section | Unplasticized Polyvinyl Chloride (uPVC) | Black Laminated Aluminum Sides |

N/A | N/A |

| Ferromagnetism | Magnetic or Non-Magnetic Options | Magnetic | Non-Magnetic | Magnetic | Non-Magnetic |

| Sealed Holes | Sealed (25 mm Depth) or Non-Sealed Options | Non-Sealed | N/A | N/A | |

| Thread Options | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6), 4-40 (M3), or 8-32 (M3) and 1/4"-20 (M6) Tapped Holes |

|

| Spacing | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers or 0.5" (12.7 mm) Centers |

|

| Distance from Edge to First Holes |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) or 1.0" (25 mm) on all Sides |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) on all Sides | |

| Performancea | |||||

| Damping |  |

|

|

N/A | N/A |

| Stiffness |  60 mm (2.4") Thick |

58 mm (2.28") Thick |

25 mm (0.98") Thick |

12.7 mm (0.5") Thick |

7.0 mm (0.28") Thick |

110 mm (4.3") Thick |

55 mm (2.2") Thick |

19.05 mm (0.75") Thick |

|||

Optical Breadboard Selection Guides

The selection guides below list every size offered for our honeycomb, solid aluminum, and acrylic breadboards. Simply locate the specific width and length needed and then select the type of breadboard. Expand each table by clicking the More [+] button within the header.

Thorlabs also offers several unique breadboard solutions. For applications requiring temperature control, we offer anodized aluminum water cooled breadboards in several sizes, in addition to a temperature-controlled mini-series breadboard for small-scale operations. Our anodized aluminum large-area translation stages and rotating breadboards offer hand-operated positioning control, while our manual and motorized translating mounting platforms are ideal for use in microscopy applications.

| Imperial Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| Metric Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| 50 mm | 75 mm | - | - | - | - | - | - | - | - | MSB5075/M |

| 75 mm | 100 mm | - | - | - | - | - | - | - | - | MSB7510/M |

| 75 mm | 150 mm | - | - | - | - | - | - | - | - | MSB7515/M |

| 100 mm | 100 mm | - | - | - | - | - | MB10S/M | - | - | - |

| 100 mm | 150 mm | - | - | - | - | - | MB1015S/M | MB1015/M MB1015U/M |

M45B1015/Mc | MSB1015/M |

| 100 mm | 300 mm | - | - | - | - | - | - | MB1030/M | - | - |

| 100 mm | 600 mm | - | - | - | - | - | - | - | MB1060/M | - |

| 100 mm | 900 mm | - | - | - | - | - | - | - | MB1090/M | - |

| Ø149 mm | - | - | - | - | - | - | - | MBR150U/M | - | |

| Ø150 mm | - | - | - | - | - | - | - | MBR150/M | - | |

| 150 mm | 150 mm | - | - | - | - | - | MB15S/M | MB1515/M MB1515U/M |

M45B1515/Mc | MSB15/M |

| 150 mm | 300 mm | - | - | - | - | - | - | MB1530F/M | MB1530/M M45B1530/Mc |

- |

| 150 mm | 450 mm | - | - | - | - | - | - | MB1545/M | - | - |

| 150 mm | 600 mm | - | - | - | - | - | - | MB1560/M | - | - |

| 150 mm | 900 mm | - | - | - | - | - | - | MB1590/M | - | - |

| 150 mm | 1200 mm | - | - | - | - | - | - | MB15120/M | - | - |

| 180 mm | 230 mm | - | - | - | - | - | - | - | - | MSB1823/M MSBU1823/M |

| 200 mm | 200 mm | - | - | - | - | - | - | MB2020/M MB2020U/M |

- | - |

| 200 mm | 250 mm | - | - | - | - | - | - | MB2025/M | - | - |

| 200 mm | 600 mm | - | - | - | - | - | - | - | MB2060/M | - |

| 200 mm | 900 mm | - | - | - | - | - | - | - | MB2090/M | - |

| 250 mm | 300 mm | - | - | - | - | - | - | MB2530/M MB2530U/M |

- | - |

| Ø300 mm | - | - | - | - | - | - | - | MBR300/M MBR300U/M |

- | |

| 300 mm | 300 mm | B3030Ad B3030Ld |

- | - | PBG3030Ae | - | - | MB3030/M MB3030U/M |

MB3030D/M | MS12B/M MSB30/M |

| 300 mm | 450 mm | B3045Ad B3045Ld |

- | B3045AX | PBG3045Ae | - | - | MB3045/M MB3045A/Mf MB3045U/M |

- | MSB3045/M |

| 300 mm | 600 mm | B3060Ad B3060L |

- | B3060AXd | PBG3060A | PBG52502d | - | MB3060/M MB3060U/M |

- | - |

| 300 mm | 900 mm | B3090Ad B3090Ld |

- | - | PBG3090Ae | PBG52503d | - | MB3090/M | - | - |

| 300 mm | 1200 mm | - | - | - | - | - | - | MB30120/M | - | - |

| 350 mm | 1150 mm | - | - | - | - | - | - | MB35115/M | - | - |

| 350 mm | 1425 mm | - | - | - | - | - | - | MB35142/M | - | - |

| 450 mm | 450 mm | B4545Ad B4545Ld |

- | - | PBG4545A | - | - | MB4545/M | - | - |

| 450 mm | 600 mm | B4560Ad B4560Ld |

- | B4560AXd | PBG4560Ae | PBG52522d | - | MB4560/M MB4560A/Mf MB4560U/M |

- | - |

| 450 mm | 750 mm | - | - | - | - | - | - | MB4575/M | - | - |

| 450 mm | 900 mm | - | - | - | - | - | - | MB4590/M | - | - |

| 600 mm | 600 mm | B6060Ad B6060L |

- | B6060AXd | PBG6060Ae | PBG52505d | - | MB6060/M | - | |

| 600 mm | 900 mm | B6090A B6090L B6090ANd B6090Z |

B6090Bd B6090Nd |

B6090AX | PBG6090Ae | PBG52506d | - | MB6090/M | - | - |

| 600 mm | 1200 mm | B60120A B60120L |

B60120Bd B60120Nd |

B60120AX | PBG60120Ae | - | - | MB60120/M | - | - |

| 600 mm | 1500 mm | - | B60150Bd B60150Nd |

- | - | PBG52508d | - | - | - | - |

| 750 mm | 750 mm | B7575A B7575L |

- | - | - | - | - | MB7575/M | - | - |

| 750 mm | 900 mm | B7590A B7590L B7590ANd B7590Z |

B7590Bd B7590Nd |

B7590AX | PBG7590Ae | PBG52510d | - | - | - | - |

| 750 mm | 1200 mm | B75120A B75120L B75120ANd B75120Z |

B75120B B75120Nd |

B75120AX | PBG75120Ae | PBG52511 | - | - | - | - |

| 750 mm | 1500 mm | - | B75150B B75150N |

B75150AX | - | - | - | - | - | - |

| 900 mm | 900 mm | B9090A B9090L |

B9090Bd B9090Nd |

- | - | - | - | - | - | - |

| 900 mm | 1200 mm | B90120A B90120L B90120AN B90120Z |

B90120B B90120N |

B90120AX | PBG90120Ae | PBG52513 | - | - | - | - |

| 900 mm | 1500 mm | - | B90150B B90150N |

B90150AX | - | PBG52514 | - | - | - | - |

| 900 mm | 1800 mm | - | B90180B B90180N |

B90180AX | - | - | - | - | - | - |

| 1200 mm | 1500 mm | - | B120150Bd B120150Nd |

- | - | - | - | - | - | - |

| 1200 mm | 1800 mm | - | B120180B B120180Nd |

- | - | - | - | - | - | - |

Products Home

Products Home

Aluminum Breadboards, 55 mm Thick

Aluminum Breadboards, 55 mm Thick