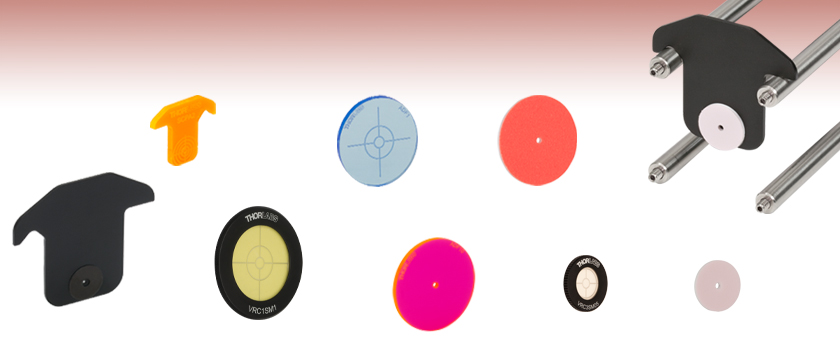

Fluorescing and Liquid Crystal Alignment Targets

- Fluorescing and Liquid Crystal Targets for Wavelengths from UV to MIR

- Central Hole or Target Aids Alignment

- Available Unmounted, in RMS- or SM-Threaded Housing, or as Cage-Compatible Plates

VRC6SCPT

MIR Alignment Plate

VRC1SM1

SM1 UV/Visible Alignment Disk

VRC4D05

Ø1/2" IR

Alignment Disk

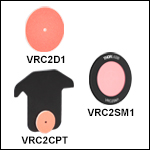

VRC2D1

Ø1" Visible/IR

Alignment Disk

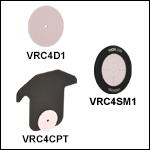

VRC4CPT

Placed in a 30 mm

Cage System

ADF1

Ø1" Visible Blue

Alignment Disk

ADF10

Ø1" Visible Red

Alignment Disk

SCPA2

Orange 16 mm Cage Alignment Plate

VRC3SM05

SM05 UV/Visible

Alignment Disk

Please Wait

| Alignment Target Selection Guide | |||

|---|---|---|---|

| Spectral Region | Absorption Band | Emission Band | Material |

| UV/Visible | 250 - 540 nm | 450 - 750 nm | Fluorescing Slow-Fading Phosphor |

| UV/Visible | 300 - 540 nm | 520 - 700 nm | Fluorescing Slow-Fading Phosphor |

| UV/Visible/NIR | - | Orange | Fluorescing Cast Acrylic (Cage-Mountable Plates) |

| UV/Visible/NIR | - | Blue, Green, Yellow, Orange, and Red | Fluorescing Cast Acrylic (Unmounted or Threaded Disks) |

| Visible/IR | 400 - 640 nm and 800 - 1700 nm |

~580 - 750 nm | Fluorescing Slow-Fading Phosphor |

| IR | 790 - 840 nm, 870 - 1070 nm, and 1500 - 1590 nm |

~520 - 580 nm | Fluorescing Slow-Fading Phosphor |

| Mid-IR | 1500 - 13 200 nm | N/A | Thermochromic Liquid Crystal |

Features

- Fluorescing Slow-Fading-Phosphor Disks for UV to IR Alignment

- Unmounted in Ø1/2" and Ø1" Sizes

- Mounted in Externally Threaded Housings or on Drop-In Alignment Plates for 30 mm Cage Systems

- 16 mm, 30 mm, and 60 mm Fluorescing, Acrylic Cage Alignment Plates

- Ø1" Fluorescing, Acrylic Disks for UV to IR Alignment

- SM1-Threaded and Cage-Plate-Mounted Liquid Crystal Disks for MIR Alignment

Our alignment disks and plates are made from either fluorescing or liquid crystal material to aid with the alignment of ultraviolet (UV) to mid-infrared (MIR) beams.

We offer fluorescing, slow-fading phosphor disks, which are either unmounted; SM05- (0.535"-40), SM1- (1.035"-40), RMS- (0.800"-36), or SM2- (2.035"-40) threaded; or mounted to a drop-in cage plate. The unmounted and cage-plate-mounted disks feature a centered Ø1.5 mm through hole, while the threaded disks have an alignment target. The graphs below detail the absorption and emission bands of these fluorescing, slow-fading phosphor disks.

Our Ø1" fluorescing cast acrylic disks are available in five colors: blue, green, yellow, orange, and red. They feature target guide lines or center holes. We also offer orange fluorescing cage alignment plates for 16 mm, 30 mm, and 60 mm cage systems. These disks and plates have fluorescence spectra similar to various fluorophores, making them ideal for use with a variety of lasers used in fluorescence imaging.

Our MIR liquid crystal alignment disks are available mounted to a drop-in cage plate with a Ø10.0 mm active region or a SM1-threaded disk with a Ø20.0 mm active region.

Other Alignment Options

Our fluorescing and liquid crystal alignment targets are based on our alignment targets meant for aligning visibile light.

Insights into Aligning a Laser Beam

When installing a laser in an optical setup, it is good practice to start by leveling and orienting its beam so that it travels along a well-defined path. When the beam is prepared this way, not only is it easier to then divert the beam and route it through the optical elements in the system, but the results provided by tuning the system's alignment are more predictable and repeatable. The following sections describe how to:

- Level and Align the Laser Beam's Pointing Angle

- Divert the Beam and Align it to Follow a Desired Path

Click here for more Insights about lab practices and equipment.

Level and Align the Laser Beam's Pointing Angle

0:00 - Introduction

1:25 - Level and Align the Laser Beam's Pointing Angle

4:09 - Divert the Beam and Align it to Follow a Desired Path

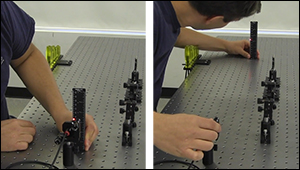

Click to Enlarge

Figure 2: The beam can be aligned to travel parallel to a line of tapped holes in the optical table. The yaw adjustment on the kinematic mount adjusts the beam angle, so that the beam remains incident on the ruler's vertical reference line as the ruler slides along the line of tapped holes.

Click to Enlarge

Figure 1: Leveling the beam path with respect to the surface of an optical table requires using the pitch adjustment on the kinematic laser mount (Figure 2). The beam is parallel to the table's surface when measurements of the beam height near to (left) and far from (right) the laser's front face are equal.

Pitch (tip) and yaw (tilt) adjustments provided by a kinematic mount can be used to make fine corrections to a laser beam's angular orientation or pointing angle. This angular tuning capability is convenient when aligning a collimated laser beam to be level with respect to a reference plane, such as the surface of an optical table, and when aligning with respect to a particular direction in that plane, such as along a line of tapped holes in the table.

Before Using the Mount's Adjusters

First, rotate each adjuster on the kinematic mount to the middle of its travel range. This reduces the risk of running out of adjustment range, and the positioning stability is frequently better when at the center of an adjuster's travel range.

Then, make coarse corrections to the laser's height, position, and orientation. This can be done by adjusting the optomechanical components, such as a post and post holder, supporting the laser. Ensure all locking screws are tightened after the adjustments are complete.

Level the Beam Parallel to the Table's Surface

Leveling the laser beam is an iterative process that requires an alignment tool and the fine control provided by the mount's pitch adjuster.

Begin each iteration by measuring the height of the beam close to and far from the laser (Figure 1). A larger distance between the two measurements increases accuracy. If the beam height at the two locations differs, place the ruler in the more distant position. Adjust the pitch on the kinematic mount until the beam height at that location matches the height measured close to the laser. Iterate until the beam height at both positions is the same.

More than one iteration is necessary, because adjusting the pitch of the laser mount adjusts the height of the laser emitter. In the video for example, the beam height close to the laser was initially 82 mm, but it increased to 83 mm after the pitch was adjusted during the first iteration.

If the leveled beam is at an inconvenient height, the optomechanical components supporting the laser can be adjusted to change its height. Alternatively, two steering mirrors can be placed after the laser and aligned using a different procedure, which is detailed in the section. Steering mirrors are particularly useful for adjusting beam height and orientation of a fixed laser.

Orient the Beam Along a Row of Tapped Holes

Aligning the beam parallel to a row of tapped holes in the table is another iterative process, which requires an alignment tool and tuning of the mount's yaw adjuster.

The alignment tool is needed to translate the reference line provided by the tapped holes into the plane of the laser beam. The ruler can serve as this tool, when an edge on the ruler's base is aligned with the edges of the tapped holes that define the line (Figure 2).

The relative position of the beam with respect to the reference line on the table can be evaluated by judging the distance between the laser spot and vertical reference feature on the ruler. Vertical features on this ruler include its edges, as well as the columns formed by different-length rulings. If these features are not sufficient and rulings are required, a horizontally oriented ruler can be attached using a BHMA1 mounting bracket.

In the video, when the ruler was aligned to the tapped holes and positioned close to the laser, the beam's edge and the ends of the 1 mm rulings coincided. When the ruler was moved to a farther point on the reference line, the beam's position on the ruler was horizontally shifted. With the ruler at that distant position, the yaw adjustment on the mount was tuned until the beam's edge again coincided with the 1 mm rulings. The ruler was then moved closer to the laser to observe the effect of adjusting the mount on the beam's position. This was iterated as necessary.

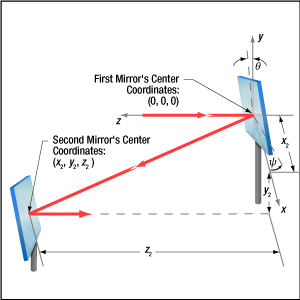

Divert the Beam and Align it to Follow a Desired Path

The first steering mirror reflects the beam along a line that crosses the new beam path. A second steering mirror is needed to level the beam and align it along the new path. The procedure of aligning a laser beam with two steering mirrors is sometimes described as walking the beam, and the result can be referred to as a folded beam path. In the example shown in the video above, two irises are used to align the beam to the new path, which is parallel to the surface of the optical table and follows a row of tapped holes.

Click to Enlarge

Figure 3: The beam reflected from Mirror 1 will be incident on Mirror 2, if Mirror 1 is rotated around the x- and y-axes by angles θ and ψ, respectively. Both angles affect each coordinate (x2 , y2 , z2 ) of Mirror 2's center. Mirror 1's rotation around the x-axis is limited by the travel range of the mount's pitch (tip) adjuster, which limits Mirror 2's position and height options.

Click to Enlarge

Figure 5: The adjusters on the second kinematic mirror are used to align the beam on the second iris.

Click to Enlarge

Figure 4: The adjusters on the first kinematic mirror mount are tuned to position the laser spot on the aperture of the first iris.

Setting the Heights of the Mirrors

The center of the first mirror should match the height of the input beam path, since the first mirror diverts the beam from this path and relays it to a point on the second mirror. The center of the second mirror should be set at the height of the new beam path.

Iris Setup

The new beam path is defined by the irises, which in the video have matching heights to ensure the path is level with respect to the surface of the table. A ruler or calipers can be used to set the height of the irises in their mounts with modest precision.

When an iris is closed, its aperture may not be perfectly centered. Because of this, switching the side of the iris that faces the beam can cause the position of the aperture to shift. It is good practice to choose one side of the iris to face the beam and then maintain that orientation during setup and use.

Component Placement and Coarse Alignment

Start by rotating the adjusters on both mirrors to the middle of their travel ranges. Place the first mirror in the input beam path, and determine a position for the second mirror in the new beam path (Figure 3). The options are notably restricted by the travel range of the first mirror mount's pitch (tip) actuator, since it limits the mirror's rotation (θ ) around its x-axis. In addition to the pitch, the yaw (tilt) of the first mirror must also be considered when choosing a position

After placing the second mirror on the new beam path, position both irises after the second mirror on the desired beam path. Locate the first iris near the second mirror and the second iris as far away as possible.

While maintaining the two mirrors' heights and without touching the yaw adjusters, rotate the first mirror to direct the beam towards the second mirror. Adjust the pitch adjuster on the first mirror to place the laser spot near the center of the second mirror. Then, rotate the second mirror to direct the beam roughly along the new beam path.

First Hit a Point on the Path, then Orient

The first mirror is used to steer the beam to the point on the second mirror that is in line with the new beam path. To do this, tune the first mirror's adjusters while watching the position of the laser spot on the first iris (Figure 4). The first step is complete when the laser spot is centered on the iris' aperture.

The second mirror is used to steer the beam into alignment with the new beam path. Tune the adjusters on the second mirror to move the laser spot over the second iris' aperture (Figure 5). The pitch adjuster levels the beam, and the yaw adjuster shifts it laterally. If the laser spot disappears from the second iris, it is because the laser spot on the second mirror has moved away from the new beam path.

Tune the first mirror's adjusters to reposition the beam on the second mirror so that the laser spot is centered on the first iris' aperture. Resume tuning the adjusters on the second mirror to direct the laser spot over the aperture on the second iris. Iterate until the laser beam passes directly through the center of both irises, as shown in the video. If any adjuster reaches, or approaches, a limit of its travel range, one or both mirrors should be repositioned and the alignment process repeated.

If a yaw axis adjuster has approached a limit, note the required direction of the reflected beam and then rotate the yaw adjuster to the center of its travel range. Turn the mirror in its mount until the direction of the reflected beam is approximately correct. If the mirror cannot be rotated, reposition one or both mirrors to direct the beam roughly along the desired path. Repeat the alignment procedure to finely tune the beam's orientation.

If a pitch axis adjuster has approached a limit, either increase the two mirrors' separation or reduce the height difference between the new and incident beam paths. Both options will result in the pitch adjuster being positioned closer to the center of its travel range after the alignment procedure is repeated.

| Alignment Disks, Laser Viewing Cards, and IR Viewers Selection Guide | ||||||

|---|---|---|---|---|---|---|

| (Click Representative Drawing for Details; Not to Scale) |

|

|

|

|

|

|

| Wavelengths | Ø1/2" Unmounted Disk | Ø1" Unmounted Disk | Threaded Disk | Alignment Plate with Disk for 30 mm Cage System | Viewing Cards | IR Viewers |

| 250 - 540 nm | VRC1D05 | VRC1D1 | VRC1SM05 (SM05 Threading) |

VRC1CPT | VRC1 | - |

| VRC1SM1 (SM1 Threading) |

||||||

| VRC1SM2 (SM2 Threading) |

||||||

| 300 - 540 nm | VRC3D05 | VRC3D1 | VRC3SM05 (SM05 Threading) |

VRC3CPT | - | - |

| VRC3SM1 (SM1 Threading) |

||||||

| VRC3SM2 (SM2 Threading) |

||||||

| 350 - 1300 nm | - | - | - | - | - | VWR1B |

| 350 - 1700 nm | - | - | - | - | - | VWR2B |

| 400 - 640 nm 800 - 1700 nm |

VRC2D05 | VRC2D1 | VRC2SM05 (SM05 Threading) |

VRC2CPT | VRC2 | - |

| VRC2RMS (RMS Threading) |

||||||

| VRC2SM1 (SM1 Threading) |

||||||

| VRC2SM2 (SM2 Threading) |

||||||

| 700 - 1400 nm | - | - | - | - | VRC5 | - |

| 790 - 840 nm, 870 - 1070 nm, 1500 - 1590 nm |

VRC4D05 | VRC4D1 | VRC4SM05 (SM05 Threading) |

VRC4CPT | VRC4 | - |

| VRC4SM1 (SM1 Threading) |

||||||

| VRC4SM2 (SM2 Threading) |

||||||

| 1500 - >13 200 nm | - | - | VRC6SM1 (SM1 Threading) |

VRC6SCPT | VRC6S VRC6H |

- |

| Posted Comments: | |

user

(posted 2024-02-16 18:18:02.44) VRC4SM1- this product does not work well.

U need to Use the same IR card as your VRC2

thanks ksosnowski

(posted 2024-02-28 01:51:07.0) Hello, thanks for reaching out to Thorlabs. We do offer versions of the SM1 alignment targets with VRC2 material as well. VRC2 has a broader absorption band than VRC4 however VRC4 does not require any optic charging which makes it easier to use in some setups. Typically VRC2 must be moved around to maintain an emission spot and have some visible background light to recharge the exposed areas. I have reached out directly to discuss your application in greater detail. Natalia Orlova

(posted 2023-03-16 16:57:37.43) Hello, I wonder if it is possible to get the SM2 IR disk to have a 1/16" diameter hole in the very center. This would be useful to use for retroreflection-based laser alignment, so that the incident beam can be fed through and the reflected beam visualized on the disk as it propagates backwards. i tried just punching the hole but it did not work... the IR material seems pretty brittle. ksosnowski

(posted 2023-03-17 02:59:06.0) Hello Natalia, thanks for reaching out to Thorlabs. Currently our closest option to this is the VRC4D1 viewing disk which has a 1.5mm (~1/16") aperture in the center for this purpose. This disk has an adhesive backing so can be applied directly on top of other mounting surfaces in your system. We have heard of customers using standard hole punches on the viewing cards like VRC4 to create an aperture, however a leather punch may work better, and using a soft-backed surface may allow better cut-through of the punch. The adhesive-backed disks may handle the mechanical strain better that results from this application and yield a cleaner hole without breaking the viewer. I have reached out directly to discuss this application further. Mohit Verma

(posted 2022-09-06 10:47:14.16) Hi,

VRC1SM1 has been very useful for our work with UV lasers but it is sometimes helpful to have a target with a hole in it. It would be great if thorlabs sold a UV equivalent of VRC2D1 (I suppose it would be called VRC1D1?) Likewise, a UV equivalent for VRC2D05 would be helpful. We would certainly buy some!

Best,

Mohit jdelia

(posted 2022-09-07 09:34:35.0) Thank you for contacting Thorlabs, and for providing this feedback. While we do not currently have any plans to offer this as part of our product line, I can certainly forward your request over to our design engineers through our internal suggestion forum. Anton R

(posted 2021-08-24 04:27:22.397) Hello, VRC1SM1 and VRC2SM1 are nice things but the light grey "target" is in low contrast with the background and thus hard to see. I think making it black would help a lot. YLohia

(posted 2021-08-27 02:03:15.0) Hello, thank you for your feedback. We will consider offering such parts in the future. Pawel Czuma

(posted 2020-05-01 13:55:47.847) Dear Sir/Madam,

Is it possible to make 1" and 1/2" Fluorescing Alignment Disks, also with drop-in for 16mm, 30mm, 60mm cage from VRC1 UV material. It will help me lot.

Best Regards

Pawel asundararaj

(posted 2020-05-04 11:40:21.0) Thank you for your feedback. I have posted this idea in our internal forum, where it will be considered for a future product. Josh Hay

(posted 2020-03-10 11:42:24.54) Would it be possible to produce a VRC5 based 0.5" alignment disk? asundararaj

(posted 2020-03-11 08:19:12.0) Thank you for contacting Thorlabs. I will contact you directly about our custom capabilities. h.wu

(posted 2018-06-11 15:57:49.623) Could you provide me with VRC2D1 and VRC4D1 without Ø1.5 mm hole in disk center? Thanks. llamb

(posted 2018-06-12 10:42:06.0) Hello, thank you for contacting Thorlabs. Unfortunately providing VRC2D1 or VRC4D1 without the center hole will not be cost effective for small quantities, though it may be possible. I would recommend the VRC2SM1 and VRC4SM1 instead, that feature target guide lines instead of center holes. In case a custom quote is necessary instead of these alternatives, we will reach out to you directly to discuss this further. asaumier

(posted 2017-03-28 05:11:54.72) Hi,

a VRC4RMS would be a very interesting product to add because the VRC2 material fade too much rapidly for a target use. tfrisch

(posted 2017-03-31 10:04:30.0) Hello, thank you for contacting Thorlabs. I have posted your feedback in our internal engineering forum, and I will reach out to you directly about your application and IR source. salutmoi

(posted 2016-12-26 13:56:31.94) Our laser emits pulsed radiation (pulse duration 9 nanoseconds, 1 pulse per second) at 1540 nm. We are going to concentrate the beam into a "point" (small circle) with power density of approximately 1 W/(cm^2).

How much time do these alignment discs and cards (VRC2, VRC4, VRC6) fade? (will the visualization be possible?) tfrisch

(posted 2016-12-30 01:44:34.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly about this application. user

(posted 2016-04-05 00:29:58.407) Can we please have these disks that detects UV as well? Possibly made from the same material as the VRC1 detector cards? Thanks! besembeson

(posted 2016-04-05 11:21:43.0) Response from Bweh at Thorlabs USA: Thanks for your feedback. We will look into expanding these alignment discs to include the VRC1 material. franxm

(posted 2015-06-11 11:05:26.207) Hi Thorlabs: interested in a VRC4D05 attached and precisely centered on a LMR1AP housing for alignment.

Thanks,

Fran besembeson

(posted 2015-09-21 09:55:02.0) Response from Bweh at Thorlabs USA: This can be quite useful as well for certain alignment purposes. You can do this with a suitable glue and alignment jig or we can quote this as a special item. vl

(posted 2014-11-25 17:14:29.413) VRC2D1 smells like rotten eggs, it's digusting. Anyway you can improve that? cdaly

(posted 2014-11-26 02:15:56.0) Response from Chris at Thorlabs: Thank you for your feedback. We can take this into consideration for any future versions, but at this time, there is nothing we can do about the scent of the alignment disk. cbrideau

(posted 2013-06-17 19:46:52.773) Can we get the beam pass-through holes every 1/2" instead of just 1"? cdaly

(posted 2013-06-20 14:36:00.0) Response from Chris at Thorlabs: Thank you for your feedback. I will bring up your suggestion within our forums, but in the meantime, we can likely do this as a custom if you are interested. I will contact you directly about this. tcohen

(posted 2012-05-24 11:39:00.0) Response from Tim at Thorlabs: Thank you for sharing your idea with us! I agree that putting in a through hole would be a useful feature. A 5mm diameter hole would limit the use for smaller beam diameters and therefore may limit its value for some users. We would love to hear more feedback on this and would like to encourage others to post their opinions as well. For your immediate needs, we would be happy to provide this as a custom and I will contact you to get more information. matthew.hammond

(posted 2012-05-22 20:40:37.0) I've bought the SM1A7 and have drilled a hole in the middle of it many times. Is there a way Thorlabs could provide a pre-drilled (1mm to 5mm diam) hole someday? That would save me some time on the drill press lmorgus

(posted 2011-02-05 13:06:00.0) A response from Laurie at Thorlabs to acable: Thank you for your feedback concerning our alignment tool offering and the need for having our irises more strongly linked to this page, which is devoted to items that are solely used for alignment purposes. Thorlabs does indeed manufacture a wide selection of SM1-threaded irises, which are located on three different pages of our website. To make that connection more readily visible, we have moved irises from being the 5th related items link to being second on this page. As a result of your feedback, we also discovered that we didn't have any linkage from our iris pages back to this one. Thank you for taking the time to help us improve our website, and we hope these changes make it easier for you to navigate our product portfolio. acable

(posted 2011-02-05 12:07:39.0) Iris in SM1 housing seems to be missing from this page. Thorlabs

(posted 2010-07-09 11:58:15.0) Response from Javier at Thorlabs to last poster: thank you for your feedback. We can certainly modify an SM1A7 with a 1 mm diameter through hole like the LMR1AP. We can also expand the design of the LMR1AP with a new part that is compatible with the LM1-A and LM1-B nested mounts. Please send us an e-mail at techsupport@thorlabs.com to further discuss your requirements. user

(posted 2010-07-08 16:42:44.0) You should make your threaded target (SM1A7) with a hole like your LMR1AP. Can you make a target that hangs on a LM1-A/B pair instead of threading in? apalmentieri

(posted 2010-01-28 14:45:26.0) A response from Adam at Thorlabs to Paul: I am in the process of looking into a custom option that would allow you to use our products at 780nm. If this custom option is available, we can also consider adding this to the new product line. paulwb

(posted 2010-01-28 14:39:15.0) Oops, I meant to say that we bought a VRC4CPT, the one with the IR disk. The CPA1 and CPA2 plates dont have an IR disk.

The following was done in a very dim lab.

A 35 mW, 800 um beam of 780 will produce an extremely pale green dot on the target, but the dot is only visible if I turn my head and look at it through my laser goggles at an angle. Looking at it head on, it is invisible. The goggles are Kentek KRZ-C505C. They are OD 7+ at 532 and 755-810 nm, among others.

And thats where my problem was: using other goggles, amber Thorlabs that are OD7 at 190-534 nm and I have measured to be OD 3.2 at 780 nm, I can see the green dot for about 25 mW, same waist size.

I guess Ill have to switch goggles to do the aligning.

It would be great if you could make an alignment plate like the VRC4CPT but using the material thats in the IRC3 card, now superseded by the VRC5 card. apalmentieri

(posted 2010-01-27 15:57:06.0) A response from Adam to Paul: At this time we do not have an IR alignment disk that works at 780nm. However, we would be interested in how our VRC4CPT would work at 780nm. We can provide you with a free sample if you would provide us with the test data. We are also looking into custom versions that may work for 780nm at this time. paulwb

(posted 2010-01-27 15:41:34.0) I bought a CPA1, not having noticed that it is not useful for 780 nm. Could you make one that works at 780 nm? In the meantime, I may consider sacrificing an old IR card. |

Click to Enlarge

Absorption and Emission Bands for the VRC1 Alignment Disks

Click to Enlarge

Click to EnlargeThe back of the VRC1CPT Alignment Plate features an engraved alignment target.

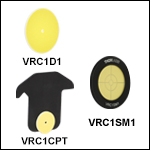

- Absorption Band: 250 - 540 nm

- Does Not Require Charging

- Disks Available:

- Unmounted

- Mounted in Externally SM-Threaded Housing

- Mounted to a Drop-In 30 mm Cage Alignment Plate

These alignment disks, made from the same slow-fading phosphor material as our VRC1 laser viewing card, are designed to simplify the alignment of UV and visible beams. They are available unmounted in Ø1/2" and Ø1" sizes, externally SM-threaded housings, or affixed to alignment plates that can be dropped into a 30 mm cage system. See the table below for a summary of the features of each alignment disk.

| Item # | Description | Alignment Features | Active Region | Absorption Band | Emission Band | Requires Charging |

|---|---|---|---|---|---|---|

| VRC1D05 | Ø1/2" Disk | Ø1.5 mm Hole in Disk Center | Ø1/2" (Ø12.7 mm) | 250 - 540 nm | 450 - 750 nm | No |

| VRC1D1 | Ø1" Disk | Ø1" (Ø25.4 mm) | ||||

| VRC1SM05 | Disk in Externally SM05-Threaded Housing |

Target Guide Lines, Ø3 mm and Ø9 mm Concentric Circles (±0.22 mm Concentricity) |

Ø0.40" (Ø10.2 mm) | |||

| VRC1SM1 | Disk in Externally SM1-Threaded Housing |

Ø0.79" (Ø20 mm) | ||||

| VRC1SM2 | Disk in Externally SM2-Threaded Housing |

Ø1.75" (Ø44.5 mm) | ||||

| VRC1CPT | Ø1/2" Disk on Drop-In Alignment Plate for 30 mm Cage Systems |

Ø0.9 mm Hole in Plate Front: Ø1.5 mm Hole in Disk Center Back: Laser-Engraved Target with Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm Concentric Circles |

Ø1/2" (Ø12.7 mm) |

Click to Enlarge

Absorption and Emission Bands for the VRC3 Alignment Disks

Click to Enlarge

Click to EnlargeThe back of the VRC3CPT Alignment Plate features an engraved alignment target.

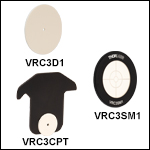

- Absorption Band: 300 - 540 nm

- Does Not Require Charging

- Disks Available:

- Unmounted

- Mounted in Externally SM-Threaded Housing

- Mounted to a Drop-In 30 mm Cage Alignment Plate

- RoHS and REACH Compliant

These alignment disks, made from a slow-fading phosphor material, are designed to simplify the alignment of UV and visible beams. They are available unmounted in Ø1/2" and Ø1" sizes, externally SM-threaded housings, or affixed to alignment plates that can be dropped into a 30 mm cage system. See the table below for a summary of the features of each alignment disk.

| Item # | Description | Alignment Features | Active Region | Absorption Band | Emission Band | Requires Charging |

|---|---|---|---|---|---|---|

| VRC3D05 | Ø1/2" Disk | Ø1.5 mm Hole in Disk Center | Ø1/2" (Ø12.7 mm) | 300 - 540 nm | 520 - 700 nm | No |

| VRC3D1 | Ø1" Disk | Ø1" (Ø25.4 mm) | ||||

| VRC3SM05 | Disk in Externally SM05-Threaded Housing |

Target Guide Lines, Ø3 mm and Ø9 mm Concentric Circles |

Ø0.40" (Ø10.2 mm) | |||

| VRC3SM1 | Disk in Externally SM1-Threaded Housing |

Ø0.79" (Ø20.1 mm) | ||||

| VRC3SM2 | Disk in Externally SM2-Threaded Housing |

Ø1.75" (Ø44.5 mm) | ||||

| VRC3CPT | Ø1/2" Disk on Drop-In Alignment Plate for 30 mm Cage Systems |

Ø0.9 mm Hole in Plate Front: Ø1.5 mm Hole in Disk Center Back: Laser-Engraved Target with Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm Concentric Circles |

Ø1/2" (Ø12.7 mm) |

- Orange Fluorescing Cast Acrylic Plates for 16 mm, 30 mm, and 60 mm Cage Systems

- Guide Lines and Ø1 mm or Ø5 mm Through Hole Aligned at Center of Compatible Cage System

- Quick, Drop-In Alignment Tools for Fluorescence Imaging Systems

These drop-in alignment plates are convenient tools for spatial calibration and alignment of cage-based fluorescence imaging systems. The cast acrylic substrate produces fluorescence spectra similar to orange fluorescing proteins and dyes. These plates provide a continuous fluorescent field so that the field of view, illumination consistency, and sample alignment may be assessed and adjusted prior to using a sample containing a fluorophore.

Each plate is cut from cast acrylic material with a thickness of 1.7 mm and has either a Ø1 mm or Ø5 mm through hole aligned at the center of the cage assembly. Each through hole is surrounded by concentric, engraved alignment rings. Options are available for compatibility with our 16 mm, 30 mm, and 60 mm cage systems. For custom colors and sizes up to 1' x 2', please contact Tech Support.

Click to Enlarge

Raw Data

Fluorescence of the 10 disks when illuminated with Thorlabs' Fiber-Coupled LEDs. Please see the raw data file for the LEDs used to obtain these fluorescence spectra. This data is typical; performance may vary from lot to lot.

- Fluorescing Cast Acrylic Disks Available in Five Colors: Blue, Green, Yellow, Orange, and Red

- Each Disk Sold Individually or in Packs of Five

- Ø1" and 1.7 mm Thick

- Feature Target Guide Lines or Center Holes

- Compatible with Our Ø1" Fixed Optic Mounts, Lens Tubes, or 30 mm Cage Plates

These disks are designed to aid in the alignment of widefield, confocal, or multiphoton fluorescence imaging systems. The cast acrylic substrates provide fluorescence spectra similar to various fluorophores, making the disks ideal for use with a variety of lasers used in fluorescence imaging. These disks provide a continuous fluorescent field so that the field of view, illumination consistency, and sample alignment may be assessed and adjusted prior to using a sample containing a fluorophore.

Each disk is 1" in diameter and is cut from cast acrylic material with a thickness of 1.7 ± 0.5 mm. Each disk features an engraved target with two concentric circles or a Ø1.5 mm center hole. For custom colors, sizes, and shapes up to 1' x 2', please contact Tech Support. For more details, please see the full web presentation.

These disks can be mounted with our Ø1" fixed optic mounts, lens tubes, or 30 mm cage plates.

| Item # | Color | Alignment Feature | Dimensions | Thickness | Transmission (Click for Graph) |

Requires Charging |

|---|---|---|---|---|---|---|

| ADF1(-P5) | Blue | Target Guide Lines, Ø3.4 mm and Ø9.4 mm Concentric Circles | Ø1" (Ø25.4 mm), Unmounted |

1.7 mm ± 0.5 mm | Raw Data |

No |

| ADF6 (-P5) | Ø1.5 mm ± 0.1 mm Hole in Disk Center | |||||

| ADF2(-P5) | Green | Target Guide Lines, Ø3.4 mm and Ø9.4 mm Concentric Circles | ||||

| ADF7(-P5) | Ø1.5 mm ± 0.1 mm Hole in Disk Center | |||||

| ADF3(-P5) | Yellow | Target Guide Lines, Ø3.4 mm and Ø9.4 mm Concentric Circles | ||||

| ADF8(-P5) | Ø1.5 mm ± 0.1 mm Hole in Disk Center | |||||

| ADF4(-P5) | Orange | Target Guide Lines, Ø3.4 mm and Ø9.4 mm Concentric Circles | ||||

| ADF9(-P5) | Ø1.5 mm ± 0.1 mm Hole in Disk Center | |||||

| ADF5(-P5) | Red | Target Guide Lines, Ø3.4 mm and Ø9.4 mm Concentric Circles | ||||

| ADF10(-P5) | Ø1.5 mm ± 0.1 mm Hole in Disk Center |

Click to Enlarge

Absorption and Emission Bands for the VRC2 Alignment Disks

Click to Enlarge

Click to EnlargeThe back of the VRC2CPT Alignment Plate features an engraved alignment target.

- Absorption Bands: 400 - 640 nm and 800 - 1700 nm

- Requires Charging by Visible Light

- Disks Available:

- Unmounted

- Mounted in Externally RMS- or SM-Threaded Housing

- Mounted to a Drop-In 30 mm Cage Alignment Plate

These alignment disks, made from the same slow-fading phosphor material as our VRC2 laser viewing card, are designed to simplify the alignment of visible and IR beams. They are available unmounted in Ø1/2" and Ø1" sizes, externally RMS- or SM-threaded housings, or affixed to alignment plates that can be dropped into a 30 mm cage system. See the table below for a summary of the features of each alignment disk.

| Item # | Description | Alignment Features | Active Region | Absorption Bands | Emission Band | Requires Charging |

|---|---|---|---|---|---|---|

| VRC2D05 | Ø1/2" Disk | Ø1.5 mm Hole in Disk Center | Ø1/2" (Ø12.7 mm) | 400 - 640 nm, 800 - 1700 nm |

~580 to 750 nm | Yes |

| VRC2D1 | Ø1" Disk | Ø1" (Ø25.4 mm) | ||||

| VRC2SM05 | Disk in Externally SM05-Threaded Housing |

Target Guide Lines, Ø3 mm and Ø9 mm Concentric Circles (±0.22 mm Concentricity) |

Ø0.40" (Ø10.2 mm) | |||

| VRC2RMS | Disk in Externally RMS-Threaded Housing |

Ø0.7" (Ø18 mm) | ||||

| VRC2SM1 | Disk in Externally SM1-Threaded Housing |

Ø0.79" (Ø20 mm) | ||||

| VRC2SM2 | Disk in Externally SM2-Threaded Housing |

Ø1.75" (Ø44.5 mm) | ||||

| VRC2CPT | Ø1/2" Disk on Drop-In Alignment Plate for 30 mm Cage System |

0.9 mm Hole in Plate Front: Ø1.5 mm Hole in Disk Center Back: Laser Engraved Target with Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm Concentric Circles |

Ø1/2" (Ø12.7 mm) |

Click to Enlarge

Absorption and Emission Bands for VRC4 Alignment Disks

Click to Enlarge

Click to EnlargeThe back of the VRC4CPT Alignment Plate features an engraved alignment target.

- Absorption Bands: 790 - 840 nm, 870 - 1070 nm, and 1500 - 1590 nm

- Does Not Require Charging

- Disks Available:

- Unmounted

- Mounted in Externally SM-Threaded Housing

- Mounted to a Drop-In 30 mm Cage Alignment Plate

These alignment disks, made from the same slow-fading phosphor material as our VRC4 laser viewing card, are designed to simplify the alignment of IR beams. They are available unmounted in Ø1/2" and Ø1" sizes, externally SM-threaded housings, or affixed to alignment plates that can be dropped into a 30 mm cage system. See the table below for a summary of the features of each alignment disk.

| Item # | Description | Alignment Features | Active Region | Absorption Band | Emission Band | Requires Charging |

|---|---|---|---|---|---|---|

| VRC4D05 | Ø1/2" Disk | Ø1.5 mm Hole in Disk Center | Ø1/2" (Ø12.7 mm) | 790 - 840 nm, 870 - 1070 nm, 1500 - 1590 nm |

~520 to 580 nm | No |

| VRC4D1 | Ø1" Disk | Ø1" (Ø25.4 mm) | ||||

| VRC4SM05 | Disk in Externally SM05-Threaded Housing |

Target Guide Lines, Ø3 mm and Ø9 mm Concentric Circles (±0.22 mm Concentricity) |

Ø0.40" (Ø10.2 mm) | |||

| VRC4SM1 | Disk in Externally SM1-Threaded Housing |

Ø0.79" (Ø20 mm) | ||||

| VRC4SM2 | Disk in Externally SM2-Threaded Housing |

Ø1.75" (Ø44.5 mm) | ||||

| VRC4CPT | Ø1/2" Disk on Drop-In Alignment Plate for 30 mm Cage System |

0.9 mm Hole in Plate Front: Ø1.5 mm Hole in Disk Center Back: Laser Engraved Target with Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm Concentric Circles |

Ø1/2" (Ø12.7 mm) |

Click to Enlarge

Back View of VRC6SCPT in a 30 mm Cage System

- Liquid Crystal Film Changes Color When Exposed to Mid-Infrared (MIR) Light

- Does Not Require Charging

- Minimum Detectable Power Density: 0.05 mW/mm2 @ 1550 nm (22 °C)

- Ambient Operating Temperature: 20 to 24 °C

- Ambient Temperature for Peak Sensitivity and Visibility: 22 °C

- Use with Our 30 mm Cage Components or SM1 Lens Tube System

Click to Enlarge

The active areas of the VRC6SM1 and VRC6SCPT alignment disks change color above 23° C.

The VRC6SCPT Cage-Plate-Mounted Alignment Disk and VRC6SM1 SM1-Threaded MIR Alignment Disk are made of the same thermochromic liquid crystal material as our VRC6S Detector Card and have been tested with laser sources of wavelengths ranging from 1.5 µm to 13.2 µm.

Item # VRC6SCPT is composed of an alignment disk adhered to an anodized aluminum cage alignment plate. The disk is positioned such that its Ø2.0 mm central hole is concentric with the plate's Ø0.9 mm through hole and aligned with the exact center of a 30 mm cage system. The back side of the plate features a laser-engraved alignment target with Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm concentric circles (see photo to the right).

In comparison, Item # VRC6SM1 consists of an alignment disk encased within an externally SM1-threaded (1.035"-40) housing and is designed to simplify the alignment of MIR beams when used with an SM1 lens tube system. Its external SM1 threads are 2.3 mm deep. The active region of the VRC6SM1's disk is Ø0.79" with Ø3 mm and Ø9 mm concentric circular target guide lines (see photo to the left).

The recommended ambient temperature range for these alignment disks is 20 to 24 °C, with peak sensitivity and responsivity at an ambient temperature of 22 °C. The detector area is black below approximately 23 °C. Above this temperature the detector will turn red, then yellow, then green and finally blue/violet around 28 °C (see photo to the left). This color change occurs whether heated by laser exposure or increased ambient temperature. The responsivity will be reduced when used at an ambient temperature below 20 °C since the material will require more time for the area exposed to the laser to reach a temperature above 23 °C, and the alignment disks will exhibit lower sensitivity above 24 °C since the color contrast between the laser-exposed region and the rest of the active region will be reduced.

To restore the VRCS6M1 alignment disk after beam exposure, blow air on the active area with a duster such as the CA4-US or CA6-EU. The active area of the VRC6SCPT cage-plate-mounted alignment disk can be restored by resting the plate face down on a table top (i.e. an optical table with stainless steel surface) for a few minutes. These disks may take longer to recover after exposure to higher laser energy, and sometimes the color change may look permanent at room temperature. If this occurs, place the affected alignment disk in a refrigerator at 0 to 4 °C for a few minutes to accelerate the recovery.

Please Note: The spot size on the disks will vary depending on power density. See the Laser Viewing Cards presentation for more information.

| Item # | Absorption Band | Minimum Detectable Power Density | Active Region | Alignment Feature | Requires Charging |

|---|---|---|---|---|---|

| VRC6SM1 | 1.5 to >13.2 µm | 0.05 mW/mm2 @ 1550 nm (22 °C) | Ø0.79" (Ø20.0 mm) | Target Guide Lines, Ø3 mm and Ø9 mm Concentric Circles, (±0.3 mm Concentricity) |

No |

| VRC6SCPT | Ø0.39" (Ø10.0 mm) | Ø0.9 mm Hole in Plate Ø2.0 mm Hole in Disk Center |

Products Home

Products Home

Zoom

Zoom

Fluorescing and Liquid Crystal Alignment Disks

Fluorescing and Liquid Crystal Alignment Disks