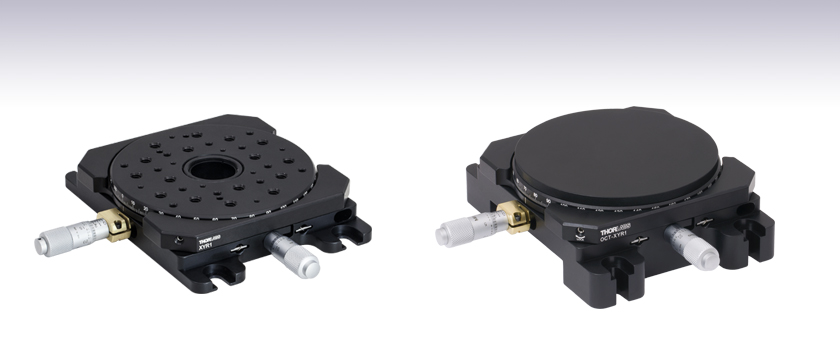

XY Translation Stages with Rotating Platform

- 1/2" (13 mm) Linear Travel Along X and Y Axes

- Central SM1-Threaded (1.035"-40) Through Hole

- 360° of Continuous Rotation

XYR1

XY Linear Translation and Rotation Stage

OCT-XYR1

XY Linear Translation and Rotation Stage with Removable Solid Top Plate

Please Wait

Click to Enlarge

XYR1 Stage with SLH1 Slide Clips in a Custom Imaging System (See Application Info Tab for Details)

Features

- XY Stage with Central SM1-Threaded Hole and 1" Stage Height

- XY Stage with Central SM1-Threaded Hole, 1.65" Stage Height, and Removable Solid Top Plate

- Ø4.18" (Ø106 mm) Rotating Platform

- Array of Mounting Options

Thorlabs' Low-Profile Translation Stages provide 1/2" (13 mm) of travel along X and Y plus 360° of continuous rotation. The micrometers incorporated into these stages have graduations at 0.001" per division (10 µm per division). On the XYR1(/M) stage, the continuously rotating platform is equipped with a central, SM1-threaded (1.035"-40) through hole, allowing it to be used in imaging applications that require illumination from underneath the sample. Translation of the stage in both X and Y will not obstruct the Ø1" through hole. In contrast, the OCT-XYR1(/M) features a removable, solid top plate that is secured to the central SM1-threaded through hole.

An engraved angular scale along the outer edge of the stage's rotating platform allows the user to set the angular orientation of the stage. Rotation of the platform can be locked using a 5/64" (2 mm) hex setscrew; when locked, translational movements are still possible.

| Item # | XYR1(/M) | OCT-XYR1(/M) |

|---|---|---|

| Horizontal Load Capacity (Max) | 10 lbs (4.5 kg) | |

| Vertical Load Capacity (Max)a | 2 lbs (0.9 kg) | |

| Mounting Platform Dimensions | Ø4.18" (Ø106 mm) | |

| Stage Height | 1.00" (25.4 mm) | 1.65" (41.8 mm) |

| Stage Footprint without Actuators | 5.50" x 4.42" (139.7 mm x 112.3 mm) |

|

| XY Micrometers | ||

| Translation Range | 1/2" (13 mm) | |

| Travel per Revolution | 0.025" (0.5 mm) | |

| Graduation | 0.001" (10 µm) per Division | |

| Linear Translation Mechanism | Bearings in V-Groove | |

In addition to the SM1-threaded through hole, the rotating platform also contains an array of 1/4"-20 (M6), 8-32 (M4), and 4-40 taps for mounting of samples and components. The eight 4-40 tapped holes are placed around the central through hole for use with our 30 mm or 60 mm cage systems, while the 8-32 (M4) tapped holes are ideal for mounting our SLH1 Microscope Slide Spring Clips (available below). On the OCT-XYR1(/M), these tapped holes can be accessed by removing the solid sample plate. The XYR1A Solid Sample Plate can be purchased separately below for users who wish to convert the tapped surface of the XYR1(/M) to a flat surface. With the adapter plate, the XYR1(/M) stage height is 1.20".

The SLH1 spring clips are designed to securely hold various sizes of microscope slides and test targets, and include two 8-32 (M4) threaded shoulder screws with a 3/32" (2.5 mm) hex socket for simple attachment to a variety of stages. Each clip is 2.51" (63.7 mm) long with a 0.20" (5.1 mm) wide tip and can be rotated 360° for easy access to, or positioning of, a slide. These clips come with 3 dowel pins that can be used with the XYR1(/M) stage to center a 1" × 3" standard microscope slide over the Ø1" through hole.

The stage can also be mounted in a vertical orientation to enable XZ translation. Note that the vertical actuator should be pushing upward against gravity to support the vertical load and ensure proper translation. When mounting the stage vertically, please ensure there is a sufficient amount of clearance for the vertical actuator as well as any intended downward travel.

For applications that do not require rotation, Thorlabs also offers an XY translation stage with a non-rotating mounting surface.

The XYR1 translation stage with a rotating mounting platform is an excellent choice for use as a sample stage in a custom imaging application. The base imaging system to the right is constructed using the components listed in the table below.

| Posted Comments: | |

John Senger

(posted 2024-10-07 18:25:27.45) Could you clarify what the Load Capacity specifications refer to? I am confused what the "Vertical Load Capacity" means for this stage, and what the "vertical actuator" referred to in Footnote a is? There does not seem to be a vertical actuator.

Is is saying that if you turn this stage on its side, you should have one of the micrometers facing upward in contact with the stage, to be able to support the 2lb load? EGies

(posted 2024-10-08 05:14:51.0) Thank you for contacting Thorlabs. Your interpretation of the vertical load capacity is correct. If you have the stage mounted with the bottom base against a vertical surface, one of the micrometers should be pushing the stage upward in order for it to support 2 lbs. I have reached out to you directly regarding your specific application requirements. Sebastian Bachus

(posted 2023-06-21 15:00:33.9) Dear Thorlabs team,

is it possible to combine the XYR1/M with a Z-stage? Do you have suggestions for any other combination to achieve linear XYZ together with a rotational degree of freedom around the Z-axis?

Kind regards,

Sebastian Bachus jpolaris

(posted 2023-06-23 03:27:03.0) Thank you for contacting Thorlabs. Yes, it is possible to combine XYR1/M with other stages to allow for Z-axis translation. I have reached out to you directly to discuss some options. Michael Davis

(posted 2022-02-23 18:53:41.197) the hole in the xyr1 stage is 1" in diameter. can it be widened? ie. can i widen it in my machine shop so i can fit a microscope objective throught it? i would use it on an inverted microscope. jdelia

(posted 2022-03-04 10:41:44.0) Thank you for contacting Thorlabs. We do not suggest doing this, as it would void the warranty of the stage. The top platform would no longer be fixed to the rest of the body, you would likely cut into some sub-assemblies, and we cannot make any guarantee that the stage would still move after modifying it in this manner. I have contacted you directly to discuss alternative solutions. steve rosen

(posted 2021-05-02 17:00:04.433) This item has no means of locking in the settings to avoid movement and loss of settings. For the cost, the device should have the means to lock the settings. ridiculous design flaw., YLohia

(posted 2021-05-05 02:25:55.0) Hello, thank you for your feedback. We will consider these points while implement a redesign of this product in the future. Darvin Munoz

(posted 2021-02-15 14:01:00.22) I really like this stage but I need micrometer adjustment for rotation. If you could Add that functionality it would make this a great product. YLohia

(posted 2021-02-16 11:48:10.0) Hello, thank you for your feedback. We will consider adding such an item to our catalog in the future. devin.metante

(posted 2016-12-10 16:05:35.947) I will need accurate adjustment for the rotary stage as well. Please contact me. tfrisch

(posted 2016-12-15 10:03:57.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly. cbrideau

(posted 2016-02-08 18:16:48.0) A version of this top plate with just two SLH1 spring clips mounted would be idea. That way you have a smooth flat surface for placing your slide, while still having a couple clips to hold it down. besembeson

(posted 2016-02-10 01:45:48.0) Response from Bweh at Thorlabs USA: Thanks for the suggestion. This was designed for OCT applications that mostly require a flat surface for the sample. We will review this addition. joseph.boswell

(posted 2016-01-25 09:26:06.9) I want this product with a fine vernier adjustment on the rotation stage, same as the XY. Can you accommodate? besembeson

(posted 2016-02-01 03:39:12.0) Response from Bweh at Thorlabs USA: Thanks for contacting Thorlabs. A re-design of the stage will be necessary to accomodate this vernier addition so this is not something we can provide short term at the moment unfortunately. I will contact you regarding your application requirements so we can look into this in the future. james.sweetman

(posted 2015-05-28 10:25:51.393) Looks like in 2009 someone first suggested micrometer driven z-rotation. Still nothing? In the works? mthrossell

(posted 2015-08-24 01:10:56.0) Thanks for contacting us. Our design team is reviewing such a product development. Unfortunately there is no solid time line to release yet. bdada

(posted 2011-09-22 19:52:00.0) Response from Buki at Thorlabs:

Thank you for your feedback about including a theta Z axis micrometer. We have passed the idea to our design engineers. If we move ahead with this project soon, I will contact you regarding the possibility of testing a prototype. bdada

(posted 2011-09-21 14:38:00.0) Response from Buki at Thorlabs:

Thank you for your feedback regarding this. Unfortunately we do not have a torque spec for this. It would be a good idea to use a counterbalance if you are planning on putting a lever arm on this (but make sure the max. load is not exceeded). You should be able to use this upside down.

Please contact TechSupport@thorlabs.com if you have further questions. tledwar

(posted 2011-09-20 17:30:00.0) This stage would be perfect with theta-Z micrometer control as some of the others have already mentioned. fbeunis

(posted 2011-09-07 18:51:20.0) What is the maximum torque that can be applied to the XYR1/M (around an axis in the plane of the platform)? Also, do you foresee any problems if the stage would be mounted upside-down? bdada

(posted 2011-08-26 14:02:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. The prices for most of our products, including the XYR1 translation stages you referenced, are listed on our website. It is located to the right of the item name and description.

http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=3693 sorooshsadeh

(posted 2011-08-26 12:40:50.0) Its ok but if it had price would be more useful jjurado

(posted 2011-05-27 10:58:00.0) Response from Javier at Thorlabs to nkaddy: Thank you very much for contacting us. The current design of the XYR1 does not easily allow for enlarging the diameter of the SM1 opening. I will contact you directly to help you find other alternatives that might be suitable for your application. nkaddy

(posted 2011-05-27 16:10:13.0) Great idea, but I need to have a larger hole in the middle, how large would be possible? jjurado

(posted 2011-02-28 11:03:00.0) Response from Javier at Thorlabs to rbjaculbia: Thank you for submitting your request. The current design of the XYR1 does not allow for replacing the micrometers with coarse adjustment screws. The micrometer we use is actually our 148-811ST (http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=1223&pn=148-811ST#1223). Two of these actuators are inserted into the outer body of the XYR1 and then we use screws to hold the mounting barrel in place. I will contact you for further discussuion of your application. rbjaculbia

(posted 2011-02-27 22:26:09.0) hi, can we replace the micrometer of the XYR1 with a coarse adjustment screw? Thanks Thorlabs

(posted 2010-10-08 17:29:51.0) Response from Javier at Thorlabs to rosaura.rucalvaba: We have not yet developed a version of the XYR1 with translation along the rotation axis. I will discuss this with our mechanics engineers and get back to you. rosaura.ruvalcaba

(posted 2010-10-08 16:17:49.0) Has a modified version of product XYR1 with a micrometer driven z-rotation been developed? If so, who would I contact for the specs and a quote? Javier

(posted 2010-06-18 15:48:30.0) Response from Javier at Thorlabs to daniel-d-gall: we would recommend limiting the load to 2 lbs when the XYR1 is mounted vertically, with one of the actuators pushing up. It is also recommended to keep the load close to the stage, so as to prevent excessive torque onto the rotation plate. daniel-d-gall

(posted 2010-06-15 15:30:31.0) This would could be very useful, but the setup were looking at requires the rotational axis to be horizontal rather than vertical. Would this be possible for this stage, and if so what would the weight restrictions be? apalmentieri

(posted 2009-12-21 18:08:54.0) A response from Adam at Thorlabs: This is a great idea! I am currently in contact with our head engineer to see how easy this modification may be. How much resolution would you need? What type of precision would be necessary? If you have any more information, that would be very helpful. I will email with you with any updates we may have. davymooree

(posted 2009-12-21 11:34:24.0) Is it possible to have this stage with a micrometer driven z-rotation? This would be very useful for precision applications such as mask alignment in lithography. |

Rotation Mount and Stage Selection Guide

Thorlabs offers a wide variety of manual and motorized rotation mounts and stages. Rotation mounts are designed with an inner bore to mount a Ø1/2", Ø1", or Ø2" optic, while rotation stages are designed with mounting taps to attach a variety of components or systems. Motorized options are powered by a DC Servo motor, 2 phase stepper motor, piezo inertia motor, or an Elliptec™ resonant piezo motor. Each offers 360° of continuous rotation.

Manual Rotation Mounts

| Rotation Mounts for Ø1/2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | MRM05(/M) | RSP05(/M) | CRM05 | PRM05(/M)a | SRM05 | KS05RS | CT104 |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

| Features | Mini Series | Standard | External SM1 (1.035"-40) Threads |

Micrometer | 16 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Compatible with 30 mm Cage Translation Stages and 1/4" Translation Stagesb |

| Additional Details | |||||||

| Rotation Mounts for Ø1" Optics | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | RSP1(/M) | LRM1 | RSP1D(/M) | DLM1(/M) | CLR1(/M) | RSP1X15(/M) | RSP1X225(/M) | PRM1(/M)a |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

|

| Features | Standard | External SM1 (1.035"-40) Threads |

Adjustable Zero | Two Independently Rotating Carriages | Rotates Optic Within Fixed Lens Tube System |

Continuous 360° Rotation or 15° Increments |

Continuous 360° Rotation or 22.5° Increments |

Micrometer |

| Additional Details | ||||||||

| Rotation Mounts for Ø1" Optics | ||||||

|---|---|---|---|---|---|---|

| Item # | LM1-A & LM1-B(/M) |

CRM1T(/M) | CRM1LT(/M) | CRM1PT(/M) | KS1RS | K6XS |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Optic Carriage Rotates Within Mounting Ring | 30 mm Cage-Compatiblea | 30 mm Cage-Compatible for Thick Opticsa |

30 mm Cage-Compatible with Micrometera |

±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mounta |

| Additional Details | ||||||

| Rotation Mounts for Ø2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | RSP2(/M) | RSP2D(/M) | PRM2(/M) | LM2-A & LM2-B(/M) |

LCRM2A(/M) | KS2RS | K6X2 |

| Click Photo to Enlarge |  |

|

|

|

|

|

|

| Features | Standard | Adjustable Zero |

Micrometer | Optic Carriage Rotates Within Mounting Ring | 60 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mount |

| Additional Details | |||||||

| Rotation Drive Mechanism and Adjustment Range | Manual, 360° Continuous | Coarse: Manual, 360° Continuous; Fine: ±7° Micrometer |

Manual, 360° Continuous | ||||

| Optic Mounting | Internally SM2-Threaded Carriage | Internal SM2 Threads in LM2-A |

Internally SM2-Threaded Carriage | ||||

| Maximum Accepted Optic Thickness | 0.51" (13 mm) | 0.54" (13.7 mm) | 0.48" (12.2 mm) | 0.46" (11.7 mm) | 0.52" (13.2 mm) | 0.47" (12 mm) | 0.53" (13.4 mm) |

| Post Mounting | 8-32 (M4) Tap | 8-32 (M4) Tap in LM2-B | 8-32 (M4) Tap | Four Counterbores for 8-32 (M4) Cap Screws | Six Counterbores for 8-32 (M4) Cap Screws | ||

| Cage System Compatibility | N/A | Four 4-40 (M3) Taps on Rotation Dial with 60 mm Spacing |

N/A | Four Bores for Ø6 mm Cage Rods with 60 mm Spacing |

N/A | N/A | |

Manual Rotation Stages

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | RP005(/M) | PR005(/M) | MSRP01(/M) | RP01(/M) | RP03(/M) | QRP02(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Standard | Two Hard Stops | ||||

| Additional Details | ||||||

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | XRNR1(/M) | XRR1(/M) | PR01(/M) | CR1(/M) | XYR1(/M) | OCT-XYR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Fine Rotation Adjuster and 2" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and 3" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and SM1-Threaded Central Aperture |

Fine Pitch Worm Gear | Rotation and 1/2" Linear XY Translation | |

| Additional Details | ||||||

Motorized Rotation Mounts and Stages

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | DDR25(/M) | PDR1C(/M) | PDR1(/M) | PDR1V(/M) | PDXR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM05 Lens Tubes, 16 mm Cage System, & 30 mm Cage System |

Compatible with 16 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

Vacuum-Compatible; Also Compatible with SM05 Lens Tubes & 30 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | K10CR1(/M) | PRM1Z8(/M)a | DDR100(/M) | ELL14 | HDR50(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM1 Lens Tubes & 30 mm Cage System | Compatible with SM1 Lens Tubes, 16 mm Cage System, 30 mm Cage System |

Compatible with SM1 Lens Tubes, Open Frame Design for OEM Applications |

Compatible with SM2 Lens Tubes |

|

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Tapped Platforms | ||

|---|---|---|

| Item # | PRMTZ8(/M)a | ELL18(/M)b |

| Click Photo to Enlarge |

|

|

| Features | Tapped Mounting Platform for Mounting Prisms or Other Optics | Tapped Mounting Platform, Open Frame Design for OEM Applications |

| Additional Details | ||

Click to Enlarge

XYR1 used with SLH1 Spring Clips and a test target. Dowel pins in the stage align the center of the slide to the optical center of the Ø1" hole.

- Two-Axis Translation Stage with Rotating Platform

- 360° of Continuous Rotation

- 1/2" (13 mm) Linear Travel Along X and Y Axes

- 1.00" (25.4 mm) Height from Base to Mounting Platform

Thorlabs' XYR1(/M) is a 1.00" (25.4 mm) tall, low-profile, two-axis linear translation stage with a rotating platform. The central internally SM1-threaded (1.035"-40) through hole is ideal for imaging applications that require illumination from the underneath of the sample. Both X and Y micrometers offer 1/2" (13 mm) of travel with graduations every 0.001" (10 µm). These stages are held in position by a spring force on the actuator, and thus, a locking screw is not necessary. The stage surface features an array of 1/4"-20 (M6), 8-32 (M4), and 4-40 tapped holes. The XYR1A Flat Adapter Plate can be purchased separately below to convert the tapped hole surface to a flat one.

An engraved angular scale along the outer edge of the stage's rotating platform allows the user to set the angular orientation of the stage, which can then be fixed using the 5/64" (2 mm) hex locking setscrew. Locking the rotation axis does not prevent translation along the X and Y axes. The stage's rotation and translation can be freely changed without compromising the stability of attached components.

As shown in the photo above, this stage is also compatible with the SLH1 Microscope Slide Spring Clips, which are sold below. The XYR1(/M) has 3 alignment holes for the Ø1/8" × 1/4" dowel pins included with the SLH1. These dowel pins center the middle of a 1" × 3" microscope slide over the through hole, allowing the user to repeatably and accurately position the slides on the stage. The spring clips include two 8-32 (M4) threaded shoulder screws with a 3/32" (2.5 mm) hex socket for simple attachment to the stage.

The central internally SM1-threaded hole is compatible with externally SM1-threaded components. The photo to the right uses an SM1A64 externally SM1-threaded adapter to allow a cube beamsplitter to be rotated and translated with respect to an incoming beam.

Click to Enlarge

The solid top plate of the OCT-XYR1 can be removed to access the tapped holes and SM1-threaded bore underneath.

- Two-Axis Translation Stage with Rotating Platform and Removable Solid Top Plate

- 360° of Continuous Rotation

- 1/2" (13 mm) Linear Travel Along X and Y Axes

- 1.65" (41.8 mm) Height from Base to Mounting Platform

Originally designed for Thorlabs' OCT systems, the OCT-XYR1(/M) is similar to the XYR1(/M) translation stage sold above. This stage features a removable solid top plate for holding samples and taller legs for a total height of 1.65" (41.8 mm). As seen in the photo to the right, the top plate can be removed and is secured to the stage via the central SM1-threaded (1.035"-40) through hole. The OCT-XYR1 has imperial tapped holes while the OCT-XYR1/M features metric taps. These holes can be used to mount optomechanics and are also compatible with the SLH1 Microscope Slide Spring Clips sold below.

The X and Y micrometers offer 1/2" (13 mm) of travel with graduations every 0.001" (10 µm). The stage is held in position by a spring force on the actuator, and thus, a locking screw is not necessary. An engraved angular scale along the outer edge of the stage's rotating platform allows the user to set the angular orientation of the stage, which can then be fixed using the 5/64" (2 mm) hex locking setscrew. Locking the rotation axis does not prevent translation along the X and Y axes. The stage's rotation and translation can be freely changed without compromising the stability of attached components.

- Solid Sample Plate for the XYR1(/M) Translation Stage

- Ø4.08" (Ø103.5 mm), 0.20" (5.1 mm) Thick Plate

- Screw into SM1-Threaded (1.035"-40) Hole

The XYR1A Solid Sample Plate allows a user to convert the tapped hole surface of the XYR1(/M) Translation Stage to a flat surface. This anodized aluminum plate can be purchased as a direct replacement for the sample plate included with the OCT-XYR1(/M) stage. It features a externally SM1-threaded (1.035"-40) plug that screws in the SM1-threaded hole in the center of the stage. The edge of the adapter plate is knurled for additional grip for installation or removal.

Click to Enlarge

SLH1 Spring Clips attached to the XYT1 Translation Stage, holding a test target that is aligned over central aperture using the provided dowel pins

- Pair of Spring Clips Hold Sample Firmly in Place

- Accommodates Microscope Slides and Test Targets of Various Sizes

- Attaches Directly to Any Stage with 8-32 (M4) Tapped Holes

- Dowel Pins Included for Aligning Standard Slides Over the Through Hole in Our XYR1(/M) or XYT1(/M) Translation Stages (See Photo to the Right)

These steel spring clips, ideal for securely holding various sizes of microscope slides and test targets, include two 8-32 (M4) threaded shoulder screws with a 3/32" (2.5 mm) hex socket for simple attachment to a variety of stages. Each clip is 2.51" (63.7 mm) long with a 0.20" (5.1 mm) wide tip and can be rotated 360° for easy access to, or positioning of, a slide. The tip of the clip is curved upwards to help prevent damage and facilitate the mounting of slides, while providing enough holding force to secure them in place.

The inclusion of three Ø1/8" x 1/4" dowel pins make these spring clips an excellent choice for use with our XYR1(/M) (sold above) and XYT1(/M) Translation Stages (see image to the right). These stages have a central Ø1" hole that is SM1 threaded (1.035"-40), and the top plate contains three alignment holes that are used with the Ø1/8" dowel pins. The dowel pins are positioned on the stage so that standard 1" x 3" (25.4 mm x 76.2 mm) slides are centered over the aperture, allowing for repeatable and accurate positioning of the slides.

Please note that any XYR1(/M) stage purchased before June 4, 2014 does not have dowel pin holes in the top mounting plate.

Products Home

Products Home

Zoom

Zoom

2-Axis Linear Plus Rotation

2-Axis Linear Plus Rotation