Pellicle Beamsplitters

- Eliminates Ghosting

- No Chromatic Aberration with Uncollimated Beams

- Uncoated for Beam Sampling or Coated for Beamsplitting

- Versions Available for Wavelengths from 300 nm to 5 µm

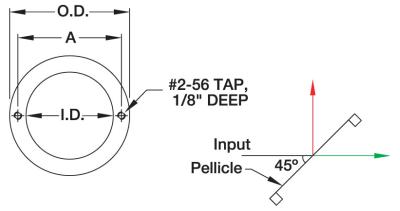

2-56 Tap

(2 Places)

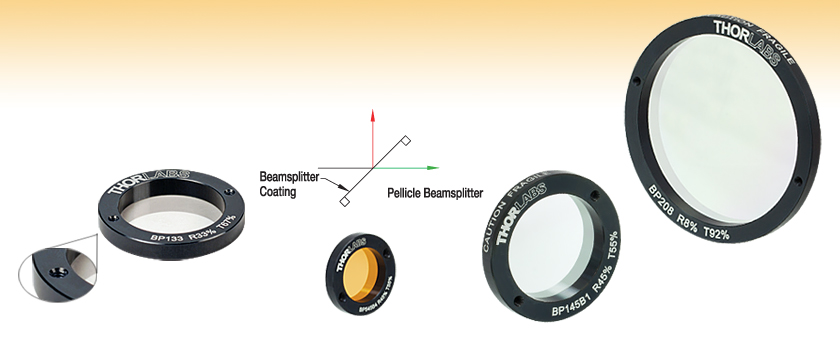

BP133

(Ø1")

BP545B4

(Ø1/2")

BP145B1

(Ø1")

BP208

(Ø2")

Please Wait

Features

- Eliminates Ghosting

- No Chromatic Aberration with Focused Beams

- Minimal Change in Optical Path Length

- Choose from Uncoated Versions for Beam Sampling or Coated Versions for Beamsplitting

- Ø1/2", Ø1", and Ø2" Versions Available

- Surface Quality: 40-20 (Scratch-Dig)

Thorlabs' Ø1/2", Ø1", and Ø2" Pellicle Beamsplitters, which are available with models covering wavelengths from 300 nm - 5 µm, are ideal for use in applications where chromatic dispersion must be minimized (i.e., cases where focused beams are necessary). Pellicle beamsplitters virtually eliminate ghosting since the second surface reflection is superimposed on the first one. However, they are extremely fragile due to the nitrocellulose membrane being only a few microns thick. For each size, Thorlabs offers both coated and uncoated versions. When using a coated optic, light should be incident upon the coated surface first (Note: the coated side of these beamsplitters is the side without the engraving). When using an uncoated optic, light can be incident on either surface.

The curves pictured below show each of the different coating types as well as the uncoated beamsplitting ratios over a variety of wavelengths. Data was obtained for unpolarized, S-polarized, and P-polarized light incident at 45°. In general, P-polarized light will be transmitted more than S-polarized light, and sinusoidal oscillation is present, resulting from thin film interference effects. See the Tutorial tab for more information about interference effects.

| Available Models (Click to View) | |

|---|---|

| Wavelength Range | Splitting Ratio (R:T) |

| Uncoated, 400 nm - 2.4 µm |

8:92 |

| 300 - 400 nm | 45:55 |

| 400 - 700 nm | 45:55 |

| 635 nm | 33:67 |

| 635 nm | 50:50 |

| 700 - 900 nm | 45:55 |

| 1 - 2 µm | 45:55 |

| 3 - 5 µm | 45:55 |

Mounting Options

Each pellicle is mounted in a black anodized frame that has two 2-56 tapped mounting holes on the engraved side for mounting them in either our Fixed or Kinematic Pellicle Mounts. Both the fixed and kinematic pellicle mounts are available in versions that accommodate our Ø1/2", Ø1", or Ø2" pellicles. We also offer cage-cube-mounted pellicle beamsplitters, which are pre-mounted in cage cubes, offer protection to the delicate pellicle surface, and are compatible with our 30 mm cage systems. For a direct comparison of the performance of our non-polarizing beamsplitting cube, plate, and pellicle at 633 nm, see the Lab Facts tab.

Please note that the size of the pellicle beamsplitter (e.g., Ø1") refers to the inner diameter of the aluminum frame, not the outer diameter. Hence, these beamsplitters are not compatible with our standard Ø1/2", Ø1", and Ø2" optic mounts. Refer to the Specs tab for a complete table of dimensions.

Handling Precautions

Our pellicle beamsplitters are manufactured from an extremely thin and fragile membrane. Please do not touch the membrane under any circumstances. Compressed or canned air can be used to clean these beamsplitters, but please exercise caution as the force of the air may be large enough to damage the membrane. Aim the stream of air such that it makes a small angle with the surface, and hold the can sufficiently far away to avoid damaging the membrane.

| Specification | Value | ||

|---|---|---|---|

| Membrane Material | Nitrocellulose | ||

| Membrane Thickness | 2 μm; 5 µm for 300-400 nm Version | ||

| Index of Refractiona (nd) | 1.5 (@ 550 nm) | ||

| Surface Quality | 40-20 Scratch-Dig | ||

| Transmitted Wavefront Errorb | λ/2 (Typical) | ||

| Reflected Wavefront Errorb | <λ (Typical) | ||

| Frame Thickness | 3/16" (4.8 mm) | ||

| Temperature Range | -40 to 70 °C | ||

| Inner Diameterc (I.D.) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50.4 mm) |

| Outer Diameter (O.D.) | 0.75" (19.1 mm) | 1.38" (34.9 mm) | 2.38" (60.3 mm) |

| Mounting Hole Spacingd | 0.63" (15.9 mm) | 1.19" (30.2 mm) | 2.19" (55.6 mm) |

Thorlabs Lab Fact: Beamsplitter Package Matters

We present laboratory measurements of the polarization angle, split ratio, and total throughput power of a beam transmitted through Thorlabs plate, cube, and pellicle beamsplitters. While all non-polarizing beamsplitters function similarly, the exact performance is different for different types of beamsplitter. Each type of beamsplitter contains its own advantages and disadvantages compared to other types of beamsplitters. Appropriate choice of beamsplitter is essential to sensitive experimental systems. We present a complete analysis and comparison of optical parameters for three common types of non-polarizing beamsplitters.

For our experiment we used the former generation HRS015 stabilized HeNe laser (replaced by the HRS015B) as the light source for our investigation. A linear polarizer is used to set the laser beam's polarization axis to 45° in order to provide equal s- and p-polarized light incident on the beamsplitter. The beamsplitter under investigation was then placed in the beampath, and its split beams directed to appropriate detectors. The total power though the optic, polarization states, split ratios, and angle of incidence effects were investigated under this configuration.

The plots below summarize the measured results for all three types of beamsplitters. From these graphs the performance of each optic can be easily compared to one another. The bottom left plot summarizes the results for the total power throughput for each optic. The total power throughput is measured as the fraction of input power. While the plate and pellicle beamsplitters perform rather similarly, the cube shows signs of absorption inside the optic. Additionally, this plot shows the relative insensitivity of throughput power to angle of incidence. The bottom middle graph summarizes the results for the output polarization angle for each optic. The cube shows the most similar polarization angles between the reflected and transmitted beams, with the plate producing the largest difference in polarization between beams. The bottom right plot summarizes the results for the split ratio, as a fraction of input power, for the beamsplitters. Here it can be shown that the plate beamsplitter demonstrates the most ideal for 50/50 power splitting. For details on the experimental setup employed and the results summarized here, please click here.

Thin-Film Interference Effect

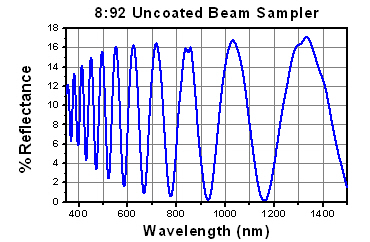

The plots below, which show transmission as a function of wavelength, depict a sinusoidal fluctuation that is caused by interference effects. These effects will occur for all pellicle beamsplitters and are sometimes averaged out when data is displayed.

The graph to the right depicts the measured reflectance of an 8:92 beam sampler without averaging the sinusoidal oscillations that result from thin film interference. The frequency and amplitude of the pattern depends several factors, such as the thickness of the film, the thickness of any coating present, the angle of incidence of the incoming light, the polarization of the incoming light, and the bandwidth of the light incident on the pellicle.

What is a Thin Film?

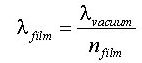

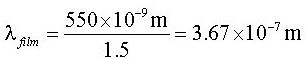

A layer of material is referred to as a thin film if the thickness of the layer is on the order of the wavelength of incident radiation in the film medium. The relationship between the wavelength of light in air and that in the film is given by

For the pellicle beamsplitters featured here, the information under the Specs tab states that nfilm = 1.5 at 550 nm. Therefore, for this incident wavelength, the wavelength in the pellicle membrane itself is

| Posted Comments: | |

user

(posted 2024-05-03 11:23:12.93) Ran into an issue where the inner part of the pellicle mount is illuminated and scatters into a detector. The system runs a beam through the 50:50 pellicle and the return beam is reflected onto a detector. Have an expanding Gaussian beam with a waist approximately 5 times smaller than the pellicle diameter. Part of the beam clips the pellicle directly, and the reflected beam also clips the mount. If practical recommend beveling the inside cylinder, 45 degrees or more, to avoid these illuminated mount problems. I had to solve the problem by a baffle which blocks portion of the source beam which illuminates the inner cylinder of the pellicle mount both directly and reflected from the pellicle. cdolbashian

(posted 2024-05-24 10:03:43.0) Thank you for reaching out to us with this suggestion. We are always happy to discuss application-specific difficulties and work with you to find direct solutions. Although you have no email provided, we would love to discuss this with you via our technical support channel. Please email us at techsupport@thorlabs.com. Hisham FORRIERE

(posted 2024-02-21 09:09:39.827) Hello

I'm using BP245B3 and BP208 on an optical bench, and i'm measuring aberation with a high speed wave front sensor. I detect a vibration of the system around 400-450 Hz. Every other part of the system is rigid, and the bench is monted on a isolation table. The room is quiet noisy and i wonder if the pellicle is not transmitting the virbration to the optical bench.

Could you please inform me about the resonance spectrum of those elements ? Is it possible that the pellicles are the source of the optical vibration ?

Thanks cdolbashian

(posted 2024-03-01 03:16:11.0) Thank you for reaching out to us with this inquiry. From our discussion and following tests, it seems as if these pellicles were indeed resonating ambient audio and causing noise in your system. We have discussed alternatives to fill the same role as these pellicles within your system. wang pl

(posted 2023-09-18 18:54:20.633) The application range of BP058 is between 400-2400nm, but we would like to use it for 3400nm laser only for spectroscopic detection. We are not sure if it can be used or how much transmittance it can achieve. cdolbashian

(posted 2023-09-25 09:08:07.0) Thank you for reaching out to us with this inquiry. While we do not have any performance data for this beamsplitter at the center wavelength of 3400nm, I have contacted you directly to share the information we do have. user

(posted 2023-07-31 18:10:19.32) Hi. For the coated Pellicle lens, it is mentioned that the light must be incident on the coated side, but if it is incident on the uncoated side, will it have a different reflectance and transmittance than the specification, or will it be misaligned? Also, I was wondering what the possibility of fragile is if I install it on top of a flip mount adapter and use it. cdolbashian

(posted 2023-08-10 02:05:30.0) Thank you for reaching out to us with this inquiry. We expect very similar performance regardless of which direction the light is incident on. Regarding the fragility of this film, this depends on how you handle it when you are flipping it. I have contacted you directly to discuss your application. Nguyễn Văn Ái

(posted 2021-07-21 19:25:05.023) Hello: I want to know how to clean dirt on the surface BP108? YLohia

(posted 2021-07-21 03:16:34.0) Thank you for contacting Thorlabs. You may use isopropanol with a lens tissue to clean it. First, blow off as much dust and loose contaminants as possible using an air duster. Then, apply a couple of drops of Isopropanol to a lens tissue. Using a continuous, slow and circular motion, gently remove fingerprints or skin oils outward from the lens surface. For detailed cleaning procedures, please refer to this link: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=9025 卢 尚

(posted 2020-11-02 17:23:11.377) hello,I want to know the parallelism of pellicle beamsplitter(such as BP108), I did not find it on your official website.Thank you so much. YLohia

(posted 2020-11-10 03:53:29.0) Hello, thank you for contacting Thorlabs. The top to bottom pellicle uniformity (parallelism of the film) is one fringe per inch measured at 633nm at normal incidence. The pellicle thickness we use for the BP108 is typically 1.80µm to 2.20µm. Encheng Sun

(posted 2020-09-07 16:30:29.687) 请问BP108的损伤阈值是多少?我们会用到1w左右的fs光,想了解一下 YLohia

(posted 2020-09-08 10:48:39.0) Thank you for contacting Thorlabs. An applications engineer from our team in China (techsupport-cn@thorlabs.com) will reach out to you directly to discuss this. 帅 张

(posted 2020-06-09 13:13:51.463) 您好,我是天津大学的学生。目前在实验中需要用到一款薄膜分束镜,所以想咨询您一下。

我们实验需要用到的是 BP145B3 - Ø1英寸薄膜分束器,已镀膜,45:55 (R:T)分光比,1-2 µm

请问这款薄膜分束器的价格就是1670.49元吗?请问可以再便宜点吗?可以开发票吗?如果购买的话,供货期是多长时间?在运输过程中薄膜会受到损伤而破裂吗?

期待您的回复~您方便的话,可以加我微信:zstju1994

我们可以进一步沟通交流,谢谢!

祝好!

张帅 YLohia

(posted 2020-06-09 11:13:37.0) Thank you for contacting Thorlabs. An applications engineer from our team in China (techsupport-cn@thorlabs.com) will reach out to you directly. wally 007

(posted 2020-01-31 13:36:37.427) Hello,

is there a possibility to add the wavelength dependent refractive index of nitrocellulose to the specs tab? Due to the strong interference effects in the reflectance and transmittance it might be an useful information for users, who work with a broad wavelength spectrum or at an angle of incidence which differs from 45°. I should be possible to extract this information from the data you already uploaded, but thats rather cumbersome. I could not find a source for the dielectric function of nitro cellulose online. YLohia

(posted 2020-03-11 04:36:07.0) Hello, thank you for contacting Thorlabs. I had reached out to you with the refractive index data at the time of your original post. Zachary Falgout

(posted 2019-05-15 05:50:08.267) There is a line of zero reflectance that stretches through the middle of the profile in the reflected beam. Is this normal?

-zack YLohia

(posted 2019-06-13 08:51:16.0) Hello Zack, thank you for contacting Thorlabs. We reached out to you directly at the time of your original post to gather more details such as beam profile, laser source used, setup, etc. If you still have this issue, please contact your local Thorlabs Tech Support team for further assistance (in this case, techsupport.uk@thorlabs.com). stephanie.gilbertcorder

(posted 2018-06-20 10:34:50.23) Hello,

We noticed when imaging the reflected beam with a Thorlabs camera after the BP108, the image contains a double diffraction pattern we are able to isolate as being caused by the pellicle beamsplitter. Our beam is 800 nm, 35 fs, approximately 10 mW incident on the beamsplitter.

Has anyone reported observing this before? We didn't expect to see what we believe to be thin film diffraction from both the front and back surface. Is this because the beamsplitter is uncoated?

Thanks,

Stephanie YLohia

(posted 2018-07-02 02:47:11.0) Hello Stephanie, thank you for contacting Thorlabs. This is quite normal for our pellicle beamsplitters. For more information please see the "Tutorial" tab on the same page: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=898&Tabname=Tutorial talan

(posted 2017-11-10 06:23:06.553) Hello,

I'm interested in Pellicle Beam Splitter but I'm curious about how to clean it, for example if it is contaminated by finger print or some other dirty stuff. Would you please help?

Best Regards.

Talan tfrisch

(posted 2017-11-13 04:40:39.0) Hello, Talan. Thank you for contacting Thorlabs. You may use compressed air, but only from a safe distance to keep the force low. These membranes can be damaged by contact, so I would not recommend cleaning with any solvent. Preventative care is the best practice. I will reach out to you directly to discuss handling procedures. shyamal.mondal

(posted 2017-10-20 19:15:46.42) Hi, I would like to know the damage threshold of the beam splitters (BP208 and BP245B2)? Is it possible to order a Pellicle Beamsplitter having 92:8 (R:T) ratio? Thanks. nbayconich

(posted 2017-10-27 09:41:20.0) Thank you for contacting Thorlabs. We recommend limiting the incident intensity to for the coated pellicles to <3W/cm^2. For the uncoated pellicles we recommend limiting the incident intensity to <20W/cm^2. We can offer custom split ratio pellicles. I will contact you directly with more details. e0002163

(posted 2017-10-03 13:41:43.293) hi, can i have the threshold of the BP245B2. I didn't find that on the website. thank you for your help. nbayconich

(posted 2017-10-12 09:52:09.0) Thank you for contacting Thorlabs. We do not have a damage threshold spec for the uncoated pellicles but we recommend limiting the incident intensity to <20W/cm^2. For the coated pellicle, you should keep the power density at <3 W/cm^2. nizamtm

(posted 2017-07-19 21:34:55.883) I expanded the laser beam entering of beamsplitter and captured the image. I found there are some line (maybe dust). I can send you the image if you want.

My question is, how I can clean the beamsplitter to remove the dust? tfrisch

(posted 2017-07-27 10:07:30.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly to discuss this. It would be helpful to see the images you have, and I want to discuss this before trying to clean the beam splitter as these films are rather fragile. user

(posted 2016-03-03 16:23:21.257) I ordered this product, and just received it today. No word yet on how well it functions as an optic. However, as a optical mechanic piece, it is extremely difficult to mount in your KM100BP mount, which was listed as compatible on your website. A thicker, double sided plastic ring, on both sides of the beamsplitter (not just the one where it is now) would be much more useful for mounting. besembeson

(posted 2016-03-09 04:50:26.0) Response from Bweh at Thorlabs USA: Thanks for the feedback. We will review your suggestion. sandy.sutherland

(posted 2014-07-07 10:51:56.697) Have previously used a number of the BP145B4 pellicles in varius test set-ups, but need a larger ~6" diameter device for a test set up being planned. Would a custom 3-5 micron 45/55 device at this larger diameter be a possible product?

Thanks

Sandy cdaly

(posted 2014-08-06 05:49:59.0) Response from Chris at Thorlabs: Thank you for your inquiry. It may be possible to offer this as a custom. I will contact your directly about this. user

(posted 2014-06-10 19:14:14.487) Hi.

I'm planning to use the pellicle beam splitter,

and I'm worryng that how fragile this thing is.

Would you give us some practical information on the fragility, like handling cautions, installation cautions, and/or vibration tolerance, etc?

Thanks. besembeson

(posted 2014-06-12 10:56:21.0) A response from Bweh at Thorlabs Newton-USA: Hello, Our pellicle beamsplitters are manufactured from an extremely thin and fragile membrane. The membrane thickness is in the order of a couple of microns. Please do not touch the membrane under any circumstances. Compressed or canned air should also not be used on these beamsplitters, as the force of the air is large enough to damage the membrane. Any vibrations of the unit should also be avoided. I hope this helps. andreas.olk

(posted 2014-05-02 15:03:11.103) Dear Tholabs Team,

is there a specification for the damage threshold of the Pellicle Beam Splitters?

Best Regards,

Andreas Olk

--

-------------------------------------------------

Andreas Olk

Optische Systeme

Optical Systems

Fraunhofer-Institut für Lasertechnik ILT

Steinbachstr. 15, 52074 Aachen, Germany

Tel +49 241 8906-614

Fax +49 241 8906-121

andreas.olk@ilt.fraunhofer.de

http://www.ilt.fraunhofer.de

-------------------------------------------------

Besuchen Sie uns/Visit us:

AKL'14 - International Laser Technology Congress

07.-09. Mai 2014, Aachen

Eurogress Conference Center

www.lasercongress.org

Control

06.-09. Mai 2014, Stuttgart

Fraunhofer-Gemeinschaftsstand, Halle 1/1502

ILA Berlin Air Show

20.- 25. Mai 2014, Berlin

Fraunhofer-Gemeinschaftsstand Luft- und Raumfahrt

Halle 6/6212 | Halle 4/4202

LASYS

24. - 26. Juni 2014, Stuttgart

Themenpark "Laser additive manufacturing", Stand 4D77.1

Solution Center „meet the Experts“ jlow

(posted 2014-05-02 09:46:02.0) Response from Jeremy at Thorlabs: For the uncoated pellicle beamsplitter, we recommend keeping the power density to be <20 W/cm^2 for CW. For the coated pellicle, you should keep the power density to be <3 W/cm^2. htu

(posted 2014-01-16 12:01:27.18) I am interested in pellicle BP145B3. It seems to display an unusual effect in my experiments. If it has a uniform dielectric (not metal) coating, as shown in some answers of this feedback section, can I find the same coating in your plate or cube beamsplitters? How thick is the coating on top of the substrate? Georgy.Onishchukov

(posted 2013-10-08 18:44:37.8) what is the CW damage power for uncoated pellicles? jlow

(posted 2013-10-10 16:00:00.0) Response from Jeremy at Thorlabs: We do not have a CW damage threshold spec for the uncoated pellicles but we recommend limiting the incident intensity to <20W/cm^2. cumaisse

(posted 2013-08-20 10:15:46.407) I'm using a 100 fs laser at 800 nm and was wondering what's the fluence or power or intensity this pellicle beam splitter are made for. I didn't find any information thereabout on the specs.

Thank you in advance for your answer tcohen

(posted 2013-08-22 14:54:00.0) Response from Tim at Thorlabs: Thank you for contacting us. We have used only low fs pulse energies for these and do not yet have a maximum empirical value for fs damage threshold. However, we have had customers successfully use the BP145B2 with no damage and the following beam properties: Beam radius: 3 mm; Repetition rate: 1 kHz; Wavelength: 775 nm; Pulse width: about 250 fs; Pulse energy: 0.8 mJ. jiri.vodak

(posted 2013-06-20 11:05:56.087) Few comments below someone asked if pellicles can be used down to 350 nm, I would ask further if they can be used down to 200, 250 nm (also the possibility of 50/50 coating). As we plan to make comparative measurements fluctuations in transmittance shouldn't be of much concern for us. The questions is if we would get any intensity through at all.

Usage of pellicle would simplify our apparatus significantly. pbui

(posted 2013-06-21 14:41:00.0) Response from Phong at Thorlabs: Nitrocellulose is not transmissive at 200 nm, but it should work for 250 nm. Depending on the thickness of the layer, you can expect anywhere from 55-70% Transmission with an average Reflection of 8% at 45° for unpolarized light. If you are interested in operating at 200 nm, then we may be able to offer a custom pellicle. We will contact you directly to discuss this. user

(posted 2013-06-01 10:50:34.983) It would be great if you could make pellicles that are HR coated (R~100%). When dealing with terahertz light, a common task is to superimpose a near-infrared optical pulse onto a terahertz one. Normally this is done using mirrors with holes in them or ITO (both of which reflect terahertz and transmit near-infrared).

Alternatively, you can use pellicles to transmit terahertz and reflect infrared (as the pellicles are too thin to be seen by the terahertz). Unfortunately, if you use a 50:50 beamsplitter, you've lost half your light, not to mention the thin film effects of the beamsplitter on your spectrum. An HR-coated pellicle would be perfect for this sort of situation. tcohen

(posted 2013-06-06 12:17:00.0) Response from Tim at Thorlabs: Thank you for your feedback. Although this may not be useful as a catalog product for the majority of our users we can offer a lot of custom optics. I don’t see that you left any contact information but if you would like to pursue this product further please contact us at techsupport@thorlabs.com. klaus.albers

(posted 2013-02-19 10:22:12.03) Hello,

is there any reason not to use the BP108 at 350 nm? Spec starts at 400 nm.

Thank you and best regards

Klaus Albers tcohen

(posted 2013-02-21 15:04:00.0) Response from Tim at Thorlabs to Klaus: Nitrocellulose does display stronger absorption as we go farther into the UV. You will find that the oscillations occur more rapidly and that you will have some increased absorption but you will certainly be able to use this at 350nm. If you aren’t working with higher powers, this will be fine. tcohen

(posted 2012-09-20 12:09:00.0) Response from Tim at Thorlabs: We currently don’t have tested data for fs pulses on this optic. Because the damage mechanism for fs pulses will be different than when working with ns pulses or CW, these values cannot be directly translated. I will contact you directly to discuss your equipment and to coordinate an effort to get more data. phyvjc

(posted 2012-09-17 05:35:45.0) Hello,

can you tell me the damage threshold for this BS if used with a pulsed laser (100fs; 780nm)?

Thank you very much,

Jose Viana-Gomes

Dep. of Physics - NUS, Singapore tcohen

(posted 2012-09-05 13:44:00.0) Response from Tim at Thorlabs: Our Pellicles utilize dielectric coatings. We may be able to offer this as a special. Please contact us at techsupport@thorlabs.com to discuss your requirements. user

(posted 2012-09-05 16:24:40.0) Has any of your Pellicle Beamsplitters a metal coating? tcohen

(posted 2012-07-17 13:50:00.0) Response from Tim at Thorlabs: Thank you for your feedback. I see you have also sent an email further detailing this request. I will contact you directly to discuss your application. jinwang

(posted 2012-07-14 21:44:38.0) Can you coat the pellicle beam splitters to get a 92:8 split ratio to match the 8:92 normal ratio? tcohen

(posted 2012-06-28 11:13:00.0) Response from Tim at Thorlabs: Pellicle beamsplitters are extremely fragile due to the thickness of the membrane. They should not be touched to clean and they should be kept from high humidity. Forceful compressed air should also be avoided as this can rupture the membrane. They must be very gently blown to clean. The light force of a small hand pumped air blower will work. We will add a cleaning tab to explain their fragility. Pellicles display an etalon effect as shown in the “Tutorial” tab. As we change the AOI, we are altering this etalon and the interference rolls off with respect to the wavelength. As such, we can effectively tune the R/T ratio within the amplitude of the interference effect by altering the AOI. joekkrause

(posted 2012-06-27 21:32:11.0) How sensitive to humidity are these beam splitters? What would you recommend them to be cleaned with? Can the transmission:reflection ratio be changed by rotating it off of the exact 45 degree angle? bdada

(posted 2012-02-10 19:41:00.0) Response from Buki at Thorlabs to Pkhulbe:

Thank you for participating in our feedback forum. We will look into your request further and contact you directly. Pkhulbe

(posted 2012-02-08 16:12:51.0) Is it possible for Thorlabs to coat a pellicle that has both p-polarization and s-polarization reflectivity between 5-10% at 45 degree angle of incidence angle for 1200 nm?

Thanks

Pramod K. Khulbe jvigroux

(posted 2011-11-15 10:57:00.0) A response from Julien at Thorlabs: Dear Ernst, thank you for your inquiry! We unfortunately do not have this data at hand. We will contact you directly in order to see what is the most efficient way to obtain the data you need. ernst.fill

(posted 2011-11-15 12:39:47.0) Do you have any data on the absorptivity of the material the pellicle is made of (I suppose nitrocellulose). Our problem is that we have high average power. From the absorption we could calculate the temperature increase upon irradiation. Wavelengths are 1040 nm and 520 nm.

Thanks, Ernst jjurado

(posted 2011-06-15 12:05:00.0) Response from Javier at Thorlabs to y_karp: Thank you very much for contacting us. Although we have not determined the laser induce damage threshold experimentally for our coated and uncoated pellicle beamsplitters; however, as a guideline, we recommend limiting the incident power density to 2 W/cm^2 for the coated pellicles, and 20 W/cm^2 for the uncoated ones. We currently do not have a pulsed LIDT spec. I will contact you directly for further support. y_karp

(posted 2011-06-10 09:00:05.0) Hi, I would like to use the pellicle beam splitter (BP245B1) with two Laser beams at 532 (Laser Pointer <14mw) and at 355 short laser pulses (6ns,500Hz,0.5 mJ). I would like to know what the damage threshold is.

Thanks, Yahel Karpol. Thorlabs

(posted 2010-11-29 18:36:24.0) Response from Javier at Thorlabs to dheeruchief: The main soecifications that you want to take into account when choosing a beamsplitter are the desired operating wavelength, reflection/transmission split ratio, size, substrate, and thickness. Some applications are sensitive to ghosting effects, so this also needs to be considered. Also, damage threshold may become a concern when using sources with high power outputs. dheeruchief

(posted 2010-11-29 05:18:43.0) I am an engineer of Supplier company of optical instruments in India, but I want to read about beam Splitter and wants to know the importance of Specifications for collecting a complete Inquiry.

Thanks & Regards

Dhirendra Nath

Macwin India

Kanpur Thorlabs

(posted 2010-07-06 10:31:20.0) Response from Javier at Thorlabs to r.j.collins: thank you for your feedback. None of the different coatings of our pellicle beamsplitters is designed to perform in this manner. For example, the coating of the BP150, 50:50 split ratio (@ 635nm) yields, on average, about 70% transmission at 900 nm, and 38% reflection at 800 nm, which does not comply with your requirements. I would suggest considering our DMLP900 dichroic mirror/beamsplitter. It is designed for 90% reflection from 400-872nm and 90% transmission from 932-1300nm (http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=3313). r.j.collins

(posted 2010-07-05 11:29:49.0) We are looking to use a pellicle beamsplitter at 45 degrees incidnece in an application whcih requires high transmission (>80%) of light with a wavelength of approximatly 900 nm to 1 um and high reflectivity (again >80%) of wavelengths below approximatly 800 nm.

Are any of your pellicle beamsplitters suitable for this application? apalmentieri

(posted 2009-12-07 19:37:44.0) A response from Adam at Thorlabs: As an optical coating is shifted from an angle of incidence of 45 degrees to 0 degrees, the specified wavelength range is increased by ~10%. For instance, the 400-700nm range at 45 degrees would become ~440-770 at 0 degrees. Please note the uncoated pellicle should still exhibt 8/92 %R/%T performance at 0 degrees. We can also supply curves, but I will have to contact you for more information about the exact pellicles you were considering. mwagnerikp.tu-darmstadt.de

(posted 2009-12-03 10:33:57.0) I want to use a pellice beam splitter inside a TiSa Cavity to produce higher repetition rate. Therefore I need a incedent angle of zero degree. What are the reflection spezification of coated and uncoated splitter? thanks a lot klee

(posted 2009-11-11 17:07:51.0) A response from Ken at Thorlabs to marcoc:

1) Customer feedback has shown that an Uncoated Pellicle (BP108, BP208) can withstand pulsed power of at least 25 MW/cm2.

2) When using broadband light without a line spectrum the interference effects should "wash" out to the Average R/T as advertised. For a 20nm to 30nm bandwidth, we can specially select Pellicles by thickness and coating to meet most specifications at a specific angle, wavelength, and incoming state of polarization (or unpolarized). We would provide a transmission scan with the part to show the results. The wider the bandwidth, the thinner the pellicle has to be to try to cover the full range. Please let us know if you would like a quotation for this. marcoc

(posted 2009-11-10 16:50:24.0) Hi,

I would like to use the pellice beamsplitter with short laser pulses (coming out of a 50fs amplifier). I have 2 questions:

1. damage threshold

2. is there any problem in using it with "broad band" light ? Im afraid that when having 20-30nm bandwidth I might have strange interference between the different components.

Thanks,

marco cammarata apalmentieri

(posted 2009-07-01 20:09:19.0) A response from Adam at Thorlabs: Most of the pellicles we provide have a dielectric coating that provides the beamsplitting properties. We have done custom metal coating on these beamsplitters in the past. I will contact you via email to get more information about your specific coating needs. tesar

(posted 2009-07-01 18:01:54.0) Specification of coating material would be useful. I need a pellicle with a metal coating. apalmentieri

(posted 2009-06-25 16:46:30.0) A response from Adam at Thorlabs to G.moss1: We currently do not specify an exact tolerance on the thickness. A nominal tolerance would be +/- 2um, so 1.76um is very close to being within specification. It would be great if we could get some more information about the mathematic code. I will send you an email shortly. g.moss1

(posted 2009-06-25 10:33:44.0) I have worked through the maths regarding the thin film effects on reflection and can reproduce the oscillatory plot shown in the tutorial. (I dont reproduce the smaller amplitude of oscillations at low wavelength as I did the ideal case.)

The plot matches with the one in the tutorial for a pellicle thickness of 1.76 microns. Is this within spec? Do you have an error on the thickness? (i.e. is the thickness 2+-0.5 or 1.75+-0.01?)

Im happy to share the mathematica code or its output with you if you are interested.

Gregory Moss alexey.chugreev

(posted 2009-04-18 08:03:09.0) Dear Sir or Madam,

I just sending you some my notes about pellicle beamsplitters.

Alexey

--------------------------

Dear ******,

In some experiments I used pellicle uncoated (8/92%) beamsplitters from Thorlabs. Placed at some angle (it should be the Brewster angle for nitrocellulose I guess), it is sensitive to the light polarization.

The contrast of such polarizer (for the reflected light only!) is not very good. Let us say, in the reflected light you could obtain 7% of p-polarization and 1% of s-polarization.

Transmitted light will be slightly polarized (93% and 99%). But may be better if adjusted more carefully.

Funny, no information on polarization properties exists at Thorlabs, Newport, Melles Griot etc web-sites. Greg

(posted 2009-04-13 15:00:41.0) A response from Greg at Thorlabs to diana.tsou: Thank you for your interest in our Pellicle Beamsplitters. We do not currently have data on the BP245B1 at 325 nm, but our Optics department will run a scan for you. Once I have this data I will e-mail you and update the graphs on this webpage. diana.tsou

(posted 2009-04-13 13:32:08.0) Do you have T/R data near 325 nm? Is nitrocellulose absorbing at 325 nm? sbarry

(posted 2008-12-15 15:11:52.0) I think we need to include a specification for damage threshold here. Newport, for example, shows a spec of 2W/cm^2.

Another spec Newport has that we dont is thickness uniformity. Theirs is specd as +/-0.06 fringes/mm at 550nm. |

Beamsplitter Selection Guide

Thorlabs' portfolio contains many different kinds of beamsplitters, which can split beams by intensity or by polarization. We offer plate and cube beamsplitters, though other form factors exist, including pellicle and birefringent crystal. For an overview of the different types and a comparison of their features and applications, please see our overview. Many of our beamsplitters come in premounted or unmounted variants. Below is a complete listing of our beamsplitter offerings. To explore the available types, wavelength ranges, splitting/extinction ratios, transmission, and available sizes for each beamsplitter category, click More [+] in the appropriate row below.Plate Beamsplitters

| Non-Polarizing Plate Beamsplitters |

|---|

| Polarizing Plate Beamsplitters |

|---|

Cube Beamsplitters

| Non-Polarizing Cube Beamsplitters |

|---|

| Polarizing Cube and Polyhedron Beamsplitters |

|---|

Pellicle Beamsplitters

| Non-Polarizing Pellicle Beamsplitters |

|---|

Crystal Beamsplitters

| Polarizing Crystal Beamsplitters |

|---|

Other

| Other Beamsplitters |

|---|

Thorlabs offers both fixed and kinematic mounting options for our Ø1/2", Ø1", and Ø2" pellicle beamsplitters. Two 2-56 capscrews included with the mount are used to attach the pellicle. Pellicle mounts are post-mountable via 8-32 or M4 x 0.7 tapped mounting holes (KM05BP and KM05BP/M), or #8 (M4) counterbores (all other pellicle mounts).

Click here for more information about our fixed pellicle mounts.

Click here for more information about our kinematic pellicle mounts.

Products Home

Products Home

Zoom

Zoom

Pellicle Beamsplitters

Pellicle Beamsplitters