220 mm Linear Translation Stage, Direct-Drive Servo Motor

- 220 mm Travel at Speeds Up to 300 mm/s

- Brushless DC Servo Motors

- Direct Drive - No Leadscrew

XY Configurable

DDS220

Application Example

Our ODL220 Optical Delay Line Kit

Incorporates Our DDS220 Stage

Please Wait

| Key Specificationsa | |

|---|---|

| Travel Range | 220 mm (8.6") |

| Speed (Max) | 300 mm/s |

| Acceleration (Max)b | 5000 mm/s2 |

| Bidirectional Repeatability | ±0.25 µm |

| Backlashc | NA |

| Horizontal Load Capacity (Max)d | 3.0 kg (6.6 lbs) |

| Min Achievable Incremental Movement | 100 nm |

| Absolute On-Axis Accuracy | ±2.0 µm |

| Cable Length | 2.7 m (8.9') |

| Required Controllere | Benchtop: BBD30x; Rackmount: RBD201, MBD602 |

| Stage Dimensions (L x W x H) | 370 mm x 90 mm x 44 mm (14.57" x 3.54" x 1.73") |

| Motorized Linear Long-Travel Stages | |

|---|---|

| 100 mm | Stepper |

| DC Servo | |

| 150 mm | Stepper |

| Stepper with Integrated Controller | |

| 220 mm | DC Servo |

| 300 mm | Stepper with Integrated Controller |

| DC Servo | |

| 600 mm | DC Servo |

| Optical Delay Line Kits | |

| Other Translation Stages | |

Features

- High Speeds: Up To 300 mm/s

- High Repeatability: 0.25 µm

- Positional Accuracy: <3.0 µm

- Low Profile: 44 mm (1.73")

- Integrated, Brushless DC Linear Servo Motor Actuators

- Linear Optical Encoders

- High-Quality, Precision-Engineered Linear Bearings

- 4-40, 8-32, and 1/4"-20 or M3, M4, and M6 Tapped Holes for Mounting Optomechanics

Thorlabs' DDS220(/M) low-profile, direct-drive translation stage provides 220 mm of travel with 50 nm resolution and a maximum speed of 300 mm/s. This stage is ideal for applications that require high speeds and high positioning accuracy, including automated alignment, surface inspection, mapping, and probing.

An innovative, low-profile design with integrated, brushless linear motors eliminates the external housings that create mechanical clash points and impede access to the moving platform. The direct-drive technology removes the need for a lead screw, eliminating backlash and internal flexible ducting ensures cables cannot become trapped as the mechanism moves. Twin, precision-grooved linear bearings provide superior rigidity and linearity with excellent on-axis accuracy. This backlash-free operation coupled with high-resolution, closed-loop optical feedback ensures a minimal bidirectional repeatability of ±0.25 μm. The DDS220(/M) stage is at the core of our ODL220 Optical Delay Line kit.

Dual-Axis Configuration

For dual-axis applications, two stages can be directly bolted together in an XY configuration without the need for an adapter or spacer plate, thereby keeping the vertical profile to a minimum. Furthermore, end users can choose to bolt the upper stage on centrally (as shown at the top of the page) or off center (as shown to the left).

Please note that these stages are not suitable for operation in a vertical (Z-axis) orientation.

Controller Options

We recommend the BBD30x One-, Two-, or Three-Channel Benchtop Brushless DC Motor Controllers (sold separately below) for the DDS220(/M) direct-drive linear translation stage. These controllers provide a user-configurable trapezoidal or S-curve acceleration/deceleration profile that enables fast, smooth positioning without vibration or shock. See below for a brief overview or click here to view the full presentation for these Brushless DC Motor Controllers.

We also offer the RBD201 Rackmount Controller for implementation into a 19" rack and the MBD602 Rackmount Controller Module designed for use with the MMR601 Motion Control 19" Modular Rack System. These controllers are compatible with the DDS220(/M) direct-drive, linear translation stage and allow for customizing more complex systems with multiple motor controls.

Joystick Options

Two optional joysticks are also available for remote positioning applications, the MJC2 Two-Axis Joystick and the MJC3 Three-Axis Joystick. See the presentation below for more details.

Accessory Mounting Plates

A range of mounting plates is also available. The DDSA01(/M) and DDSA02(/M) adapter plates allow accessories to be fixed to the moving platform, or either end of the stage. The DDS220P1(/M) allows a NanoMax or MicroBlock stage to be bolted to the moving platform of the DDS220(/M) stage. See the presentations below for more details.

| Item # | DDS200(/M) |

|---|---|

| Travel Range | 220 mm (8.6") |

| Speed (Max) | 300 mm/s |

| Acceleration (Max) | 5000 mm/s2 |

| Bidirectional Repeatabilitya | ±0.25 µm |

| Backlashb | N/A |

| Load Capacityc | 3.0 kg (6.6 lb) |

| Incremental Movement (Min)d | 0.1 µm |

| Absolute On-Axis Accuracy | ±2.0 µm |

| Home Location Accuracy (Unidirectional) |

±0.25 µm |

| Straightness/Flatness | ± 5.0 µm |

| Pitche | ±175 µrad |

| Yawe | ±175 µrad |

| Continuous Motor Force | 7.0 N |

| Peak Motor Force (2 sec) | 15 N |

| Weight (Including Cables) | 2.4 kg (5.3 lbs) |

| Limit Switches | Yes |

| Operating Temperature Range | 5 to 40 °C (41 to 104 °F) |

| Bearing Type | Precision Linear Bearing |

| Motor Type | Brushless DC Linear Motor |

| Dimensions | 370.0 mm x 90.0 mm x 44.0 mm (14.57" x 3.54" x 1.73") |

| Weight | 2.4 kg (5.3 lbs) |

| Item # | BBD301 | BBD302 | BBD303 |

|---|---|---|---|

| Number of Channels | 1 | 2 | 3 |

| Drive Connector | 8 Pin DIN, Round, Female | ||

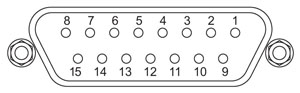

| Feedback Connector | 15-Pin D-Type, Female | ||

| Brushless Continuous Output | 2.5 A per Channel, 5 A Max All-Channel Total Output | ||

| Brushless Peak Output | 4.0 A per Channel, 5 A Max All-Channel Total Output | ||

| PWM Frequency | 40 kHz | ||

| Operating Modes | Position and Velocity | ||

| Control Algorithm | 16-Bit Digital PID Servo Loop with Velocity and Acceleration Feedforward |

||

| Velocity Profile | Trapezoidal/S-Curve | ||

| Position Count | 32 Bit | ||

| Position Feedback | Incremental Encoder | ||

| Encoder Bandwidth | 2.5 MHz (10 M Counts/sec) | ||

| Encoder Supply | 5 V | ||

| AUX Control Connector | 37-Pin D-Type Female (User Digital IO, 5 V O/P) | ||

| Front Panel Display | 4.3" Full-Color LCD, 480 x 272 Pixels | ||

| Input Power Requirements |

250 VA Voltage: 100 to 240 VAC Frequency: 47 to 63 Hz Fuse: 3.15 A |

||

| Dimensions (W x D x H) | 199.8 mm x 229.1 mm x 108.8 mm (7.87" x 9.02" x 4.28") |

250.0 mm x 279.1 mm x 108.8 mm (9.84" x 10.99" x 4.28") |

350.0 mm x 279.1 mm x 108.8 mm (13.78" x 10.99" x 4.28") |

| Mass (Weight) | 1.20 kg (2.65 lbs) | 1.70 kg (3.75 lbs) | 2.20 kg (4.85 lbs) |

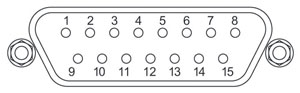

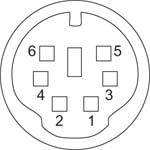

DDS220(/M) Stage Pin Out Descriptions

The flying leads are terminated in a male 15-pin D-Type and male 8-pin round DIN connector. Pin details are given below.

Feedback Connector

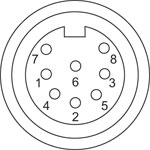

Motor Drive Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Not Used | 9 | Ground |

| 2 | Ground | 10 | Limit Switch + |

| 3 | Not Used | 11 | Limit Switch - |

| 4 | Enc Index - | 12 | Enc Index + |

| 5 | QB - | 13 | QB + |

| 6 | QA - | 14 | QA + |

| 7a | 5 V | 15 | Not Used |

| 8a | 5 V |

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Motor Phase B | 5 | Stage ID |

| 2 | GND | 6 | Enable |

| 3a | Unused (Motor Phase D) | 7 | Motor Phase C |

| 4 | Motor Phase A | 8a | +5 V |

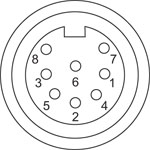

BBD30x Controller Pin Out Descriptions

MOTOR DRIVE

Female DIN Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Motor Phase B | 5 | Stage ID |

| 2 | GND | 6 | Enable |

| 3a | Unused (Motor Phase D) | 7 | Motor Phase C |

| 4 | Motor Phase A | 8a | +5 V |

FEEDBACK

Female D-Type Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Not Connected | 9 | GND |

| 2 | GND | 10 | Limit Switch + |

| 3 | Not Connected | 11 | Limit Switch - |

| 4 | Index - | 12 | Index + |

| 5 | QB - | 13 | QB + |

| 6 | QA - | 14 | QA + |

| 7a | 5 V | 15 | Not Connected |

| 8a | 5 V |

HANDSET

Female Mini DIN Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | RX (Controller Input) |

4 | Supply Voltage for Handset 5 V |

| 2 | Ground | 5 | TX (Controller Output) |

| 3 | Ground | 6 | Ground |

AUX I/O

Female D-Type Connector

| Pin | Description | Pin | Description | Pin | Description | Pin | Description |

|---|---|---|---|---|---|---|---|

| 1 | RS232 TX | 11 | User Digital O/P 11+ | 21 | +5 V | 31 | User Digital O/P 4+ |

| 2 | RS232 RX | 12 | User Digital O/P 10- | 22 | User Digital I/P 3 | 32 | User Digital O/P 4- |

| 3 | Ground | 13 | User Digital O/P 10+ | 23 | User Digital I/P 2 | 33 | User Digital O/P 5+ |

| 4 | Differential I/P 2+ | 14 | User Digital O/P 9- | 24 | User Digital I/P 1 | 34 | User Digital O/P 5- |

| 5 | Differential I/P 2- | 15 | User Digital O/P 9+ | 25 | User Digital I/P 0 | 35 | User Digital O/P 6+ |

| 6 | Differential I/P 1- | 16 | User Digital O/P 8- | 26 | User Digital O/P 0 | 36 | User Digital O/P 6- |

| 7 | Differential I/P 1+ | 17 | User Digital O/P 8+ | 27 | User Digital O/P 1 | 37 | Ground |

| 8 | User Digital O/P 12- | 18 | User Digital O/P 7- | 28 | User Digital O/P 2 | - | - |

| 9 | User Digital O/P 12+ | 19 | User Digital O/P 7+ | 29 | User Digital O/P 3 | ||

| 10 | User Digital O/P 11- | 20 | +5 V | 30 | Ground |

USB

Type B USB Female

I/O

Female BNC Connector

5 V TTL

Motorized Linear Translation Stages

Thorlabs' motorized linear translation stages are offered in a range of maximum travel distances, from a stage with 20 µm of piezo translation to our 600 mm direct drive stage. Many of these stages can be assembled in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our multi-axis stages, which offer finer adjustment than our standard motorized translation stages. In addition to motorized linear translation stages, we offer motorized rotation stages and goniometers. We also offer manual translation stages.

Piezo Stages

These stages incorporate piezoelectric elements in a variety of drive mechanisms. ORIC® stages incorporate piezo inertia drives that use "stick-slip" friction properties to obtain extended travel ranges. Our Nanoflex™ translation stages use standard piezo chips along with manual actuators. Elliptec® stages use resonant piezo motors to push and pull the moving platform through resonant elliptical motion. Our LPS710E z-axis stage features a mechanically amplified piezo design and includes a matched controller.

| Piezoelectric Stages | ||||

|---|---|---|---|---|

| Product Family | ORIC® PDXZ1 Closed-Loop 4.5 mm Vertical Stage |

ORIC® PD2 Open-Loop 5 mm Stage |

ORIC® PDX2 Closed-Loop 5 mm Stage |

|

| Click Photo to Enlarge |

|

|

|

|

| Travel | 4.5 mm | 5 mm | ||

| Speed | 1 mm/s (Typ.)a | 10 mm/s (Typ. Max)b | 8 mm/s (Typ.)c | |

| Drive Type | Piezoelectric Inertia Drive | |||

| Possible Axis Configurations | Z | X, XY, XYZ | ||

| Mounting Surface Size |

45.0 mm x 42.0 mm | 13 mm x 13 mm | ||

| Additional Details | ||||

| Piezoelectric Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | ORIC® PD1 Open-Loop 20 mm Stage |

ORIC® PD1D Open-Loop 20 mm Monolithic XY Stage |

ORIC® PDX1 Closed-Loop 20 mm Stage |

ORIC® PDX1A Closed-Loop 20 mm Stage Low-Profile |

ORIC® PD3 Open-Loop 50 mm Stage |

|

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 20 mm | 50 mm | ||||

| Speed | 3 mm/s (Typ. Max)a | 20 mm/s (Typ. Max)c | 10 mm/s (Typ.)b | 10 mm/sd | ||

| Drive Type | Piezoelectric Inertia Drive | |||||

| Possible Axis Configurations | X, XY, XYZ | XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | |

| Mounting Surface Size |

30 mm x 30 mm | 80 mm x 30 mm | ||||

| Additional Details | ||||||

| Piezoelectric Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | Nanoflex™ 20 µm Stage with 5 mm Actuator |

Nanoflex™ 25 µm Stage with 1.5 mm Actuator |

Elliptec® 28 mm Stage | Elliptec® 60 mm Stage | LPS710E 1.1 mm Vertical Stage | |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 20 µm + 5 mm Manual | 25 µm + 1.5 mm Manual | 28 mm | 60.0 mm | 1.1 mm | |

| Maximum Velocity | - | 180 mm/s | 90 mm/s | - | ||

| Drive Type | Piezo with Manual Actuator | Resonant Piezoelectric Motor | Amplified Piezo | |||

| Possible Axis Configurations | X, XY, XYZ | X | Z | |||

| Mounting Surface Size | 75 mm x 75 mm | 30 mm x 30 mm | 15 mm x 15 mm | 21 mm x 21 mm | ||

| Additional Details | ||||||

Stepper Motor Stages

These translation stages feature removable or integrated stepper motors and long travel ranges up to 300 mm. Many of these stages either have integrated multi-axis capability (PLSXY) or can be assembled into multi-axis configurations (PLSX, LNR Series, NRT Series, and LTS Series stages). The MLJ150 stage also offers high load capacity vertical translation.

| Stepper Motor Stages | |||||

|---|---|---|---|---|---|

| Product Family | PLSX with and without PLST(/M) Top Plate 1" Stage |

PLSXY with and without PLST(/M) Top Plate 1" Stage |

LNR Series 25 mm Stage |

LNR Series 50 mm Stage |

|

| Click Photo to Enlarge |

|

|

|

|

|

| Travel | 1" | 25 mm | 50 mm | ||

| Maximum Velocity | 7.0 mm/s | 2.0 mm/s | 50 mm/s | ||

| Possible Axis Configurations |

X, XY | X, XY, XYZ | X, XY, XYZ | ||

| Mounting Surface Size |

3" x 3" | 60 mm x 60 mm | 100 mm x 100 mm | ||

| Additional Details | |||||

| Stepper Motor Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | NRT Series 100 mm Stage |

NRT Series 150 mm Stage |

LTS Series 150 mm Stage |

LTS Series 300 mm Stage |

MLJ250 50 mm Vertical Stage |

|

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 100 mm | 150 mm | 150 mm | 300 mm | 50 mm | |

| Maximum Velocity | 30 mm/s | 50 mm/s | 3.0 mm/s | |||

| Possible Axis Configurations |

X, XY, XYZ | X, XY, XYZ | Z | |||

| Mounting Surface Size |

84 mm x 84 mm | 100 mm x 90 mm | 148 mm x 131 mm | |||

| Additional Details | ||||||

DC Servo Motor Stages

Thorlabs offers linear translation stages with removable or integrated DC servo motors. These stages feature low profiles and many can be assembled in multi-axis configurations.

| DC Servo Motor Stages | ||||

|---|---|---|---|---|

| Product Family | MT Series 12 mm Stages |

PT Series 25 mm Stages |

MTS Series 25 mm Stage |

MTS Series 50 mm Stage |

| Click Photo to Enlarge |

|

|

|

|

| Travel | 12 mm | 25 mm | 25 mm | 50 mm |

| Maximum Velocity | 2.6 mm/s | 2.4 mm/s | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | ||

| Mounting Surface Size |

61 mm x 61 mm | 101.6 mm x 76.2 mm | 43 mm x 43 mm | |

| Additional Details | ||||

| DC Servo Motor Stages | ||||

|---|---|---|---|---|

| Product Family | M30 Series 30 mm Stage |

M30 Series 30 mm Monolithic XY Stage |

M150 Series 150 mm XY Stage |

KVS30 30 mm Vertical Stage |

| Click Photo to Enlarge |

|

|

|

|

| Travel | 30 mm | 150 mm | 30 mm | |

| Maximum Velocity | 2.4 mm/s | X-Axis: 170 mm/s Y-Axis: 230 mm/s |

8.0 mm/s | |

| Possible Axis Configurations | X, Z | XY, XZ | XY | Z |

| Mounting Surface Size |

115 mm x 115 mm | 272.4 mm x 272.4 mm | 116.2 mm x 116.2 mm | |

| Additional Details | ||||

Direct Drive Stages

These low-profile stages feature integrated brushless DC servo motors for high speed translation with zero backlash. When no power is applied, the platforms of these stages have very little inertia and are virtually free running. Hence these stages may not be suitable for applications where the stage's platform needs to remain in a set position when the power is off. We do not recommend mounting these stages vertically.

| Direct Drive Stages | |||||

|---|---|---|---|---|---|

| Product Family | DDS Series 50 mm Stage |

DDS Series 100 mm Stage |

DDS Series 220 mm Stage |

DDS Series 300 mm Stage |

DDS Series 600 mm Stage |

| Click Photo to Enlarge |

|

|

|

|

|

| Travel | 50 mm | 100 mm | 220 mm | 300 mm | 600 mm |

| Maximum Velocity | 500 mm/s | 300 mm/s | 400 mm/s | 400 mm/s | |

| Possible Axis Configurations | X, XY | X, XY | X | X | |

| Mounting Surface Size | 60 mm x 52 mm | 88 mm x 88 mm | 120 mm x 120 mm | ||

| Additional Details | |||||

| Posted Comments: | |

Junhao Zhang

(posted 2024-05-21 18:26:56.7) Hi,

My new DDS220/M always show error:

'Error 103419934-1 Motor Error Detected: Value = Current Limit Error(0)'

Do you know why is that and what's the solution?

Thank you,

Junhao Zhang cstroud

(posted 2024-05-24 06:23:15.0) Thanks for reaching out, I'm sorry that you're having issues with your stage. I will contact you directly to help troubleshoot this. Linhao Guo

(posted 2024-02-02 16:00:36.707) Is the brushless DC motor controllers contained in the DDS220? cstroud

(posted 2024-02-09 07:27:30.0) Thanks for reaching out. The DDS220 does not have an integrated controller. For this stage you will need the BBD300 series controller, which is sold separately. Peter Denninger

(posted 2023-10-04 11:46:17.377) Hi Thorlabs-Team,

i found a small error in your Auto CAD PDF drawing.

In the top part, there a four threads M4 (4X M4X0.7) but you labelled it as 5X M4X0.7 TAPPED HOLES.

In the corresponding manual under 3.5 it is correct.

Best regards,

Peter do'neill

(posted 2023-10-10 10:15:55.0) Response from Daniel at Thorlabs. Thanks for letting us know, I have let our web team know and they will fix the drawing and get the correction uploaded. James L

(posted 2023-06-14 18:17:48.62) Hi I am trying to control this stage using a controller. I know this is a BLDC, does the motor have any hall sensors? Also what are the encoder counts per revolution and # of pole pairs for the motor? Thank you. fguzman

(posted 2023-06-23 11:01:03.0) Thanks for your enquiry. This item has three limit switch reference magnets (centre and each end). This is a linear motor so counts per rev makes no sense but according to the APT protocol, where all encoder count conversion factors are listed, it should be 20000 counts per mm. Please contact your local tech support team for further help (techsupport@thorlabs.com). Aviva Mehlow

(posted 2023-04-14 11:00:58.737) We're integrating this motor into a larger device and I need to be able to control it via software. I'm on a short deadline, so could you send me an electronic copy of the handbook so I can start working on this before the stage arrives? JReeder

(posted 2023-04-18 03:12:43.0) Thank you for your enquiry. In order to control the DDS stage with the BBD controller via a 3rd party programming language, you will need to access the DLLs, which come with your installation of our Kinesis software. Once installed, all the required DLLs will be in the following folder along with files providing information on the particular methods: C:\Program Files\Thorlabs\Kinesis. We have reached out to you with further information on this. Airan Rodenas

(posted 2023-02-14 08:16:33.0) Dear Sir/Madam,

I need to buy as soon as possible a pair of DDS220/M for building an XY system for laser micro-machining.

How can I attach 2 DDS220/M together? do they have already the required holes of is there a join part I need to order also (as for the 100mm case).

For software control of both axes synchronously, whats the best recommendation?

Kind regards

Airán JReeder

(posted 2023-02-15 03:26:09.0) Thank you for your enquiry. I have reached out to you to put you in contact with your local sales team. Our sales offices can also be reached through their contact details at the following link: https://www.thorlabs.com/locations.cfm

The DDS220(/M) already has the required mounting holes in order to join the parts together in an XY configuration, no extra adaptor is required. They can be attached together as described in section 3.3.5 of the manual: https://www.thorlabs.com/drawings/9f5ae3d5b1f75e36-49005A39-9111-B709-D39ADFB44333DE84/DDS220_M-Manual.pdf.

In order to control both axes synchronously we would recommend that you purchase our BBD30X series controller, our Kinesis software can be used with the controller in order to perform synchronous movements. KC Woo

(posted 2019-08-02 04:07:36.613) Hi. I've been using DDS220 & BBD201 for years, and recently I've got some troubles while attempting to access the encoder functions with LabView control. Since it is written with 'linear optical encoders' in the specification, I expected that my device would work with rapid scanning (as in doi: 10.1063/1.3455809). However, I've faced with the error messages with code# 13021512 (Description: Encoder Not Found) (Notes: An attempt has been made to access encoder functionality when no encoded stage/actuator has been associated with this channel.), when I tried with the Invoke Node with the encoder methods such as 'CalibrateEnc'. Could you give me any advice on this problem. Thanks in advance. rmiron

(posted 2019-08-06 04:30:05.0) Response from Radu at Thorlabs: It is difficult to tell why this error is being raised without seeing your virtual instrument. I will contact you directly in order to troubleshoot your application. adri-vlc96

(posted 2018-04-16 12:23:41.867) Hi

I'm studying a cryogenic 3d printer which is using the motor DDS220/M, and with temperatures between -5 and -15 ºÇ the tolerances get bigger.

I understand that the ideal range is beetween 5 and 40ºÇ but which part of the motor work worse when the temperatures go down? Or maybe it is related with the decrease of the resistance of the cooper?

Thanks for your time. bhallewell

(posted 2018-05-15 08:32:57.0) Response from Ben at Thorlabs: Thank you for your email here. You will find on our website that the majority of our stages are rated at 5-40degC. Below 5degC, the greatest problem would be the build up of condensation which can potentially lead to a short within the hardware electronics. Jane.Yang

(posted 2017-09-29 17:14:38.563) What's the minimal velocity for this stage - smooth moving without "vibration" at low speed?

Thanks! bwood

(posted 2017-10-06 04:00:04.0) Response from Ben at Thorlabs: Thank you for your feedback, unfortunately it's hard to define a minimum velocity as it will be highly application specific. All brushless DC motor stages work based on a servo mechanism, (i.e. error feedback via an encoder), which needs to have certain level of velocity fluctuations when the stage is demanded to perform a constant speed in its sequence. This is due to the nature of the closed loop algorithm in the controller, which is in opposition to the resultant resistive force of the bearing carriage/rail, magnetic flux density fluctuations of the magnet rod (at various positions) and so on. The position loop PID algorithm needs to continuously overshoot and undershoot in following the demanded constant speed according to the feedback position error. As such we do not have any firm real world values as the PID parameters can be tuned for a specific application. arkadiusz.jarota

(posted 2017-03-30 08:08:44.583) Dear Thorlabs,

Do you have Labview drivers for DDS220/M delay stage for 64-bit Windows 10. We have drivers for 32 bit systems, but these are not working.

Best Regards,

Arkadiusz Jarota bwood

(posted 2017-03-30 11:52:30.0) Response from Ben at Thorlabs: Thank you for your question. The files required to operate the DDS220/M with LabView are included with Kinesis, our motion control software. As long as you have downloaded 64bit version of Kinesis, the files should be available. user

(posted 2016-05-10 12:38:19.193) What is the meaning of the pitch and yaw values? Is it wobbling if the load changes, is it a change of angle over the whole length of the stage, or is it just an initial error?

For example, if we use two 220mm stages in an x-y-configuration, the top stage positioned at an end, then the error of +-175µrad of the bottom stage would result in an error of +-19µm on the top platform. It would make a big difference if this is all wobbling or just an initial error. bhallewell

(posted 2016-05-12 03:29:02.0) Response from Ben at Thorlabs: Thank you for your question here. We define the pitch as how much the top plate tilts as the stage translates. Pitch is measured by moving the stage over its full travel range and taking an angular robust laser interferometry (RLI) measurement in the pitch axis at 20 equidistant points along the travel. This is repeated 10 times and the maximum discrepancy between minimum and maximum value taken. Yaw is measured using the same procedure.

We specify our Pitch/Yaw values assuming the stage is bolted to an optical table surface in a single axis configuration with a nominal torque of 70N.cm per screw. When mounted in XY, the torque of the bolt screws can either cause freedom of movement from the top plate contributing to system wobble or deflection of the stage due to over-tightening. The bearing rail/carriages are preloaded however heavier loads can increase this effect. I will contact you directly to discuss this further.

If you are considering purchase of a new XY stage assembly I would advise also taking a look at our DDS300-E option as this employs a stiffer bearing set & housings, with wider paired bearing ways when compared to the 220mm range.

http://www.thorlabs.de/newgrouppage9.cfm?objectgroup_ID=7975&pn=DDS300-E szwackerow

(posted 2016-04-25 12:52:13.64) The download link for the controller software for 32bit Windows does not work. Could you send me a working link? besembeson

(posted 2016-04-25 09:32:05.0) Response from Bweh at Thorlabs USA: The control software for these stage are available at the following link: http://www.thorlabs.com/software_pages/ViewSoftwarePage.cfm?Code=Motion_Control&viewtab=0. We will contact you to determine which link you used that wasn't active. johan.stigwall

(posted 2015-11-18 09:09:01.3) The pitch/yaw specs of the DDS220 is +- 0.01 degree which is equal to 175 µrad. The DDS300 on the other hand is specified as 100/150 µrad. Is the DDS300 really better in pitch/yaw, or is this difference only due to rounding error?

Another question: Is it possible to buy the DDS300 without controller and drive one DDS300 + one DDS220 using a two-channel BBD202 controller? msoulby

(posted 2015-11-18 06:04:36.0) Response from Mike at Thorlabs: The DDS300 is an updated version of the older DDS220, and thus the pitch and yaw specs have been improved. The BBD202 controller can control both a DDS220 and DDS300 on the separate channels. We will contact you directly with a quotation for only the DDS300 stage without the controller. dasaerod

(posted 2014-05-13 13:26:54.687) Dear Sir/Madam,

I am writing to you because I am considering to buy one of your translation stage (DDS220/M) to use for fibre bragg grating inscription. Once I read the characteristics some question has arisen to me.

First, I would like to know if this translation stage is able to work at speeds of 1 micron/s or less and what is the velocity error.

Second, I would like to know what is the exact meaning of flatness. In this case there are a variation of 5 microns, it means that the height of the stage can vary 5 microns during the whole travel (from 0 to 220 mm) or it is an oscillation of the height during the travel?

Best regards,

Dr David Saez Rodriguez bhallewell

(posted 2014-05-19 10:04:33.0) Response from Ben at Thorlabs: Thank you for your email & web feedback post. The DDS220/M contains a brushless DC servo motor which is optimised for precision motion at high acceleration & velocity through a PID closed-loop algorithm. This form of control will provide fluctuating motion at these low speeds. A piezo solution such as our NFL5DP20S/M platform would be more suitable for your low velocity requirement however would be limited in travel range. With regards to flatness, this is the vertical shift in the position of a single point on the top plate when the stage travels from 0 to 220mm. pascal.dufour

(posted 2013-04-03 14:57:33.34) What is the operating temperature range of the DDS220? tcohen

(posted 2013-04-04 12:29:00.0) Response from Tim at Thorlabs: We recommend using this stage within the temperature range of 5-40C. jlow

(posted 2012-10-10 17:00:00.0) Response from Jeremy at Thorlabs: The load capacity of the stage is dependent on the acceleration. If you lowered the acceleration by half, the load capacity will increase by two times. For example, if you set the acceleration of the bottom DDS220 to 2500mm/s^2, then you can put a maximum load of 3.6kg on the top DDS220. mingsong.chen

(posted 2012-10-09 12:16:25.0) Hello, for Dual-Axis Configuration of DDS220, what is the load capacity? I noticed that the load capacity for single DDS220 is 3kg, and the weight of DDS220 is 2.4kg, can I say that the load capacity of dual-axis of DDS220 (two DDS220) is (3-2.4)=0.6kg? Thanks. bdada

(posted 2011-11-03 10:20:00.0) Response from Buki at Thorlabs:

Thank you for participating in our Feedback forum. The DDS220/M stage does not work in environments up to 180 degrees Celcius and we do not recommend using it in a dusty environment. We will contact you to learn more about your application in order to recommend a more suitable product. a.lodermeyer.stud

(posted 2011-11-03 13:39:37.0) Dear Sir or Madam,

I've got two questions on your product DDS220/M:

1. Does it work at a temperature of around 180°C?

2. Does it word in dusty conditions? (i.e. when powder is in the working area of the linear stage)

Thank you very much for your support!

Best regards,

Alexander Lodermeyer

Bayerisches Laserzentrum, Erlangen, Germany |

Characterized by high-speed translation and high-positional accuracy, the DDS220(/M) stage is well-suited for surface mapping and characterization applications where there is a need to move a camera or probe at constant velocity while simultaneously capturing data. Very precise, fine positioning and control is easily achieved through a combination of the stable closed-loop control system and a BBD series controller with associated MJC2 or MJC3 joystick option (available below).

We recommend using our BBD Series Brushless DC Servo Motor Controllers with the stages above, selecting the controller with the required number of channels. If using a standalone stage, the BBD301 can be used; if also using a MJC2 joystick, the BBD302 is recommended. The BBD303 3-Channel Controller can be used for applications requiring additional accessories; all three channels can be controlled via the MJC3 joystick.

With a user-configurable, S-curve acceleration/deceleration profile that enables fast, smooth positioning without vibration or shock, these controllers are ideal for motion control applications demanding operation at high speeds (hundreds of mm/s) and high encoder resolution. Incorporating the latest digital and analog techniques as well as high-bandwidth, high-power servo control circuitry, each BBD series controller is designed to drive brushless DC servo motor products with continuous output currents of up to 2.5 A (Item # BBD301) or 5 A (Item #s BBD302 and BBD303).

These DC servo controllers are supported by Thorlabs' Kinesis® control and programming interface, enabling easy integration into automated motion control applications. For greater flexibility, both a USB and RS232 computer interface is provided, and automated PC control of the stage is supported with the supplied software development kit (SDK). The fully documented SDK supports all major development languages running on Windows and comes in the form of a conventional dynamic link library (DLL).

USB connectivity provides easy plug-and-play PC operation. Multiple units can be connected to a single PC via standard USB hub technology for multi-axis motion control applications. Combining this feature with our user-friendly software allows the user to program and carry out complex move sequences in a short space of time. For more information, please see the full Brushless DC Servo Motor Controller presentation.

- High-Reliability Joysticks Utilizing USB HID Protocol

- 2-Axis or 3-Axis Control Via a Joystick Knob

- Two Different Modes for Fast or High Precision Moves

- Speed Dial for Sensitivity Adjustment

- Allows Remote Manual Control

- Can be Reprogrammed using a PC

- Ergonomic Design

The MJC2 and MJC3 Joysticks have been designed for microscope users and provide intuitive, tactile, manual positioning of a stage. The joysticks feature a two-axis joystick knob for XY control or a three-axis joystick knob for XYZ control, respectively. Both joystick knobs can be moved left or right and up or down, with the MJC3 joystick knob also twisting clockwise or counterclockwise for third axis control. A push button to switch between fast or high-precision movement and a speed dial to fine tune speed control are also integrated into the joysticks. In most applications, the default parameter settings saved within the controller allow the joystick to be used out-of-the-box with no need for further setup. This operation mode eliminates the need for connection to a host PC and allows for true remote operation. Parameter settings can also be reprogrammed and saved to a paired controller using a PC, allowing the controller to be disconnected from the computer and remote operation continued.

The MJC2 and MJC3 Joysticks are compatible with our Benchtop Brushless DC Servo Controllers, Rack-Mounted Brushless DC Servo Controller, Rack-Mounted Brushless DC Servo Control Module, and Stepper Motor Controllers. The joysticks have both a Mini-DIN and a USB Type-C port and are each shipped complete with two cables, a 6-pin Mini-DIN plug to plug cable and a USB 3.1 Type-A to Type-C cable, for use with these controllers as well as setups utilizing the USB HID class. For more information about configuring and setting up the joystick over USB HID, please see the manual by clicking on the red Docs icon (![]() ) below.

) below.

- Single Plate to Mount MicroBlock or NanoMax Directly to the DDS220(/M) Stage

- Resulting Overall Deck Height: 112.5 mm

- Resulting Overall Optical Height: 125.0 mm

- Bolts Supplied for Mounting to DDS220(/M) Stage

This mounting plate enables our MAX300 and MBT61x series of 3-axis stages to be mounted on the DDS220(/M) stage.

The 3-axis stage can be positioned quickly by the DDS220(/M), before the MBT/MAX micrometer drives are used for fine manipulation of the device.

Click to Enlarge

Click to Enlarge DDS220 Stage with DDSA01 End Mounting Plates Fitted

Click to Enlarge

Click to Enlarge DDS220 Stage with DDSA01 End Mounting Plates and DDSA02 Grooved Mounting Plates Fitted

- End Mounting Plates with Nine 1/4"-20 (M6) Mounting Holes to Fix Accessories at Either End of Travel

- Grooved Mounting Plate with Sixteen 1/4"-20 (M6) Mounting Holes

- DDSA02(/M) Compatible with Flexure Stage Accessories

Two accessory plates are offered for use with the DDS220(/M) Direct Drive Stage featured above. The DDSA01(/M) Mounting Plate bolts to either end of the stage using two user-supplied 1/4"-20 (M6) bolts and allows accessories to be fixed at either end of travel.

A second accessory plate, the DDSA02(/M) Grooved Mounting Plate, can be attached to the moving platform of the direct drive stage using the four included 1/4"-20 (M6) bolts. This plate features an array of sixteen 1/4"-20 (M6) mounting holes and a standard 3 mm groove. The DDSA02(/M) has sixteen 6-32 (M3) taps that can be used to mount flexure stage accessories via mounting cleats. When used in conjunction with a DDSA01(/M) End Mounting Plate, the DDSA02(/M) grooved mounting plate can also be used at either end of the stage travel and is ideal for optical delay line applications.

Products Home

Products Home

Zoom

Zoom

220 mm Travel DC Servo Stage

220 mm Travel DC Servo Stage