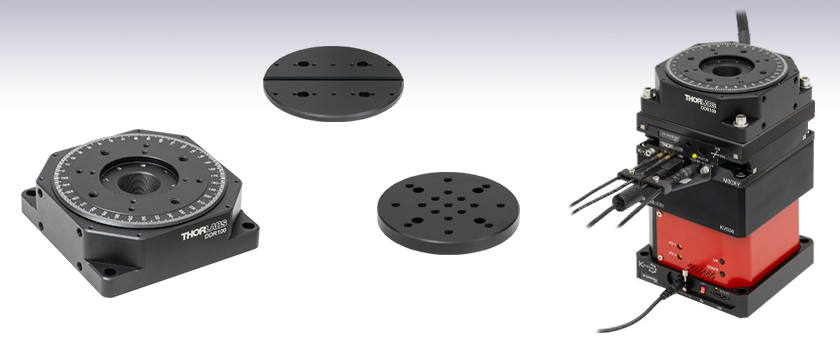

Direct Drive Rotation Stage

- 180 rpm (3 Hz) Velocity

- 5 kg Load Capacity

- Max Axial Wobble 60 µrad

NR360SP4

Grooved Adapter Plate

NR360SP9

Threaded Adapter Plate

DDR100

SM1-Threaded Center Hole

Adapter Plate Included

Application Idea

The DDR100 Rotation Stage can be

combined with the M30XY XY Stage and

the KVS30 30 mm Vertical Servo Stage

for an XYZ-yaw configuration.

Please Wait

| Key DDR100(/M) Specificationsa | |

|---|---|

| Travel Range | 360° Continuous |

| Velocity (Max) | 180 rpm (3 Hz) |

| Max Wobble (Axial) | 60 µrad |

| Bidirectional Repeatability | 60 µrad |

| Horizontal Load Capacity (Max)b | 5.0 kg |

| Vertical Load Capacity (Max)b | 2.0 kg (Mounted Centrally) |

| Min Achievable Incremental Movement | 70 µrad |

| Cable Length | 3.0 m (9.8') |

| Recommended Controllera | Benchtop: BBD30x; Rackmount: RBD201, MBD602 |

| Stage Dimensions (L x W x H) | 115 mm x 115 mm x 40 mm (4.53" x 4.53" x 1.58") |

Features

- 360° Continuous Rotation

- High Speeds Up to 180 rpm

- Low Profile: 40 mm (1.57")

- Integrated, Brushless DC Servo Motor Actuators

- High-Quality, Precision-Engineered Bearings

- Compatible with SM1 Lens Tubes and 30 mm Cage System Components

- Compatible with NR360SP4 and NR360SP9 Adapter Plates

The Thorlabs' DDR100(/M) low-profile, direct-drive rotary stage provides continuous rotation of a load up to 5 kg (11 lbs) with 2 µrad resolution and a maximum rotation speed of 180 rpm. An SM1-threaded central aperture allows an optical path to pass directly through the body of the stage.

This stage has a 3-phase, brushless DC motor integrated directly into the frame of the stage. This eliminates all forms of mechanical transmission providing high repeatability, rigidity and reliability. The winding design eliminates torque ripple due to magnetic cogging, enabling good velocity stability even at low speeds. The high magnetic pole count produces a large amount of torque (0.7 N•m). The high-resolution encoder mounted directly on the moving world provides high accuracy and repeatability, while the precision-engineered bearings and tight manufacturing tolerances produce very low axial wobble (60 µrad) and radial eccentricity (6 µm). An engraved scale with 1° graduations allows for coarse positioning.

The stage can be mounted horizontally on the work surface, or vertically on a Ø1" post (see the diagram to the right) or by using our AP90RL or VB01 right-angle brackets. It can also be mounted directly to the DDS300(/M) and DDS600(/M) translation stages. The top plate features an SM1-threaded (1.035"-40) through hole to allow Ø1" optics and our SM1 product line to be mounted. The rotating and non-rotating top surfaces, and the rear face, all feature an array of 4-40 tapped holes to integrate 30 mm cage assemblies and components.

Controller Options

We recommend the BBD30x One-, Two-, or Three-Channel Benchtop Brushless DC Motor Controllers (sold separately below) for this stage. These controllers provide a user-configurable, trapezoidal or S-curve acceleration/deceleration profile that enables fast, smooth positioning without vibration or shock. They are ideal for motion control applications demanding operation at high speeds (hundreds of mm/s) and high encoder resolution (50 nm). The design incorporates the latest digital and analog techniques as well as high-bandwidth, high-power servo control circuitry. The controllers ship with our Kinesis software for easy integration into an existing system. See below for a brief overview or click here to view the full presentation for these Brushless DC Motor Controllers.

We also offer the RBD201 Rackmount Controller for implementation into a 19" rack and the MBD602 Rackmount Controller Module designed for use with the MMR60x Motion Control 19" Modular Rack System. These controllers are compatible with the DDR100(/M) direct-drive rotation stage and allow for customizing more complex systems with multiple motor controls.

Adapter Plates

Adapter plates are available that fix to the rotating platform of the stage. The NR360SP4 Grooved Adapter Plate allows the stage to be used with our fiber launch systems product line. The NR360SP9 Threaded Adapter Plate has 17 1/4"-20 or M6 mounting holes and four #8 or M4 counterbored fixing holes and provides numerous options for attaching devices. See below for more details.

Joystick Options

Two optional joysticks are also available for remote positioning applications, the MJC2 Two-Axis Joystick and the MJC3 Three-Axis Joystick. See the presentation below for more details. Please note that in order to control two stages simultaneously, a multi-channel controller is required.

| Item # | DDR100(/M) |

|---|---|

| Travel Range | 360° Continuous |

| Velocity (Max) | 180 rpm (3 Hz) |

| Acceleration (Max)a | 7200°/s2 at 0.5 kg (1.1 lbs) Load 1800°/s2 at 2.0 kg (4.4 lbs) Load |

| Bidirectional Repeatability | 60 µrad |

| Backlashb | N/A |

| Encoder Resolution | 2.0 µrad (0.0001°) |

| Min Achievable Incremental Movement | 70 µrad |

| Recommended Loadc | 2 kg (4.4 lbs) |

| Horizontal Load Capacity (Max)c | 5.0 kg |

| Vertical Load Capacity (Max)c | 2.0 kg (Mounted Centrally) |

| Absolute On-Axis Accuracy | 250 µrad |

| Max Burst Torque (1 Sec) |

0.7 N•m |

| Continuous Torque | 0.5 N•m |

| Settling Time | 200 ms Typical |

| Velocity Stability | 0.5% |

| Max Wobble (Axial) | 60 µrad |

| Limit Switches | None |

| Central Aperture | SM1 Threaded (1.035"-40) |

| Adapter Plate Mounting Holes | 4-40 (8 places) |

| Operating Temperature Ranged | 5 to 40 °C (41 to 104 °F) |

| Motor Type | Brushless DC Rotary Motor |

| Cable Length | 3 m (9.8') |

| Dimensions | 115 mm x 115 mm x 40 mm (4.53" x 4.53" x 1.58") |

| Weight (Excluding Cables) |

2 kg (4.4 lbs) |

| Item # | BBD301 | BBD302 | BBD303 |

|---|---|---|---|

| Number of Channels | 1 | 2 | 3 |

| Drive Connector | 8 Pin DIN, Round, Female | ||

| Feedback Connector | 15-Pin D-Type, Female | ||

| Brushless Continuous Output | 2.5 A per Channel, 5 A Max All-Channel Total Output | ||

| Brushless Peak Output | 4.0 A per Channel, 5 A Max All-Channel Total Output | ||

| PWM Frequency | 40 kHz | ||

| Operating Modes | Position and Velocity | ||

| Control Algorithm | 16-Bit Digital PID Servo Loop with Velocity and Acceleration Feed Forward | ||

| Velocity Profile | Trapezoidal/S-Curve | ||

| Position Count | 32 Bit | ||

| Position Feedback | Incremental Encoder | ||

| Encoder Bandwidth | 2.5 MHz (10 M Counts/sec) | ||

| Encoder Supply | 5 V | ||

| AUX Control Connector | 37-Pin D-Type Female (User Digital IO, 5 V O/P) | ||

| Front Panel Display | 4.3" Full-Color LCD, 480 x 272 Pixels | ||

| Input Power Requirements |

250 VA Voltage: 100 to 240 VAC Frequency: 47 to 63 Hz Fuse: 3.15 A |

||

| Dimensions (W x D x H) |

(7.87" x 9.02" x 4.28") |

(9.84" x 10.99" x 4.28") |

(13.78" x 10.99" x 4.28") |

| Mass (Weight) | 1.20 kg (2.65 lbs) | 1.70 kg (3.75 lbs) | 2.20 kg (4.85 lbs) |

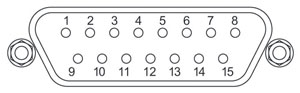

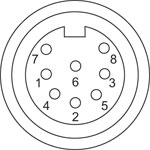

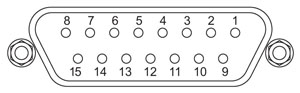

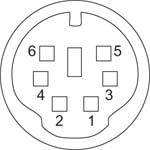

DDR100(/M) Stage Pin Out Descriptions

The flying leads are terminated in a male 15-pin D-Type and male 8-pin round DIN connector. Pin details are given below.

Feedback Connector

Motor Drive Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Not Used | 9 | Ground |

| 2 | Ground | 10 | Limit Switch + |

| 3 | Not Used | 11 | Limit Switch - |

| 4 | Enc Index - | 12 | Enc Index + |

| 5 | QB - | 13 | QB + |

| 6 | QA - | 14 | QA + |

| 7a | 5 V | 15 | Not Used |

| 8a | 5 V |

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Motor Phase B | 5 | Stage ID |

| 2 | GND | 6 | Enable |

| 3a | Unused (Motor Phase D) | 7 | Motor Phase C |

| 4 | Motor Phase A | 8a | +5 V |

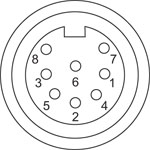

BBD30x Controller Pin Out Descriptions

MOTOR DRIVE

Female DIN Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Motor Phase B | 5 | Stage ID |

| 2 | GND | 6 | Enable |

| 3a | Unused (Motor Phase D) | 7 | Motor Phase C |

| 4 | Motor Phase A | 8a | +5 V |

FEEDBACK

Female D-Type Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Not Connected | 9 | GND |

| 2 | GND | 10 | Limit Switch + |

| 3 | Not Connected | 11 | Limit Switch - |

| 4 | Index - | 12 | Index + |

| 5 | QB - | 13 | QB + |

| 6 | QA - | 14 | QA + |

| 7a | 5 V | 15 | Not Connected |

| 8a | 5 V |

HANDSET

Female Mini DIN Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | RX (Controller Input) |

4 | Supply Voltage for Handset 5 V |

| 2 | Ground | 5 | TX (Controller Output) |

| 3 | Ground | 6 | Ground |

AUX I/O

Female D-Type Connector

| Pin | Description | Pin | Description | Pin | Description | Pin | Description |

|---|---|---|---|---|---|---|---|

| 1 | RS232 TX | 11 | User Digital O/P 11+ | 21 | +5 V | 31 | User Digital O/P 4+ |

| 2 | RS232 RX | 12 | User Digital O/P 10- | 22 | User Digital I/P 3 | 32 | User Digital O/P 4- |

| 3 | Ground | 13 | User Digital O/P 10+ | 23 | User Digital I/P 2 | 33 | User Digital O/P 5+ |

| 4 | Differential I/P 2+ | 14 | User Digital O/P 9- | 24 | User Digital I/P 1 | 34 | User Digital O/P 5- |

| 5 | Differential I/P 2- | 15 | User Digital O/P 9+ | 25 | User Digital I/P 0 | 35 | User Digital O/P 6+ |

| 6 | Differential I/P 1- | 16 | User Digital O/P 8- | 26 | User Digital O/P 0 | 36 | User Digital O/P 6- |

| 7 | Differential I/P 1+ | 17 | User Digital O/P 8+ | 27 | User Digital O/P 1 | 37 | Ground |

| 8 | User Digital O/P 12- | 18 | User Digital O/P 7- | 28 | User Digital O/P 2 | - | - |

| 9 | User Digital O/P 12+ | 19 | User Digital O/P 7+ | 29 | User Digital O/P 3 | ||

| 10 | User Digital O/P 11- | 20 | +5 V | 30 | Ground |

USB

Type B USB Female

I/O

Female BNC Connector

5 V TTL

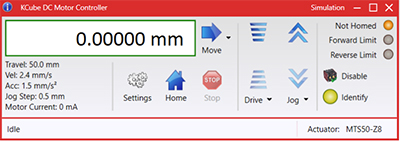

Software

Kinesis Version 1.14.50

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

Legacy Software

Select products are still capable of running the legacy APT™ software package. Information on software compatibility can be found in the product documentation (![]() ), and additional details about the APT software can be found here.

), and additional details about the APT software can be found here.

Thorlabs' Kinesis® software features new .NET controls which can be used by third-party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications.

C#

This programming language is designed to allow multiple programming paradigms, or languages, to be used, thus allowing for complex problems to be solved in an easy or efficient manner. It encompasses typing, imperative, declarative, functional, generic, object-oriented, and component-oriented programming. By providing functionality with this common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from the low-powered, single-axis to the high-powered, multi-axis systems and control all from a single, PC-based unified software interface.

The Kinesis System Software allows two methods of usage: graphical user interface (GUI) utilities for direct interaction and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

For a collection of example projects that can be compiled and run to demonstrate the different ways in which developers can build on the Kinesis motion control libraries, click on the links below. Please note that a separate integrated development environment (IDE) (e.g., Microsoft Visual Studio) will be required to execute the Quick Start examples. The C# example projects can be executed using the included .NET controls in the Kinesis software package (see the Kinesis Software tab for details).

|

Click Here for the Kinesis with C# Quick Start Guide Click Here for C# Example Projects Click Here for Quick Start Device Control Examples |

|

LabVIEW

LabVIEW can be used to communicate with any Kinesis- or APT-based controller via .NET controls. In LabVIEW, you build a user interface, known as a front panel, with a set of tools and objects and then add code using graphical representations of functions to control the front panel objects. The LabVIEW tutorial, provided below, provides some information on using the .NET controls to create control GUIs for Kinesis- and APT-driven devices within LabVIEW. It includes an overview with basic information about using controllers in LabVIEW and explains the setup procedure that needs to be completed before using a LabVIEW GUI to operate a device.

|

Click Here to View the LabVIEW Guide Click Here to View the Kinesis with LabVIEW Overview Page |

|

| Posted Comments: | |

Klaus Bartl

(posted 2021-10-29 07:32:33.13) Ist ist also possible to drive the DDR100 by the KBD101 Servo Controller? If yes, what's the max. burst torque when using the KBD101? cwright

(posted 2021-11-04 11:09:04.0) Response from Charles at Thorlabs: Thank you for your query. The only controllers capable of driving the DDR100 are the BBD series. The KBD101 will not recognise the unit. Henrik Madsen

(posted 2020-04-03 06:21:55.75) What is the max eccentricity of the stage in terms of µm? DJayasuriya

(posted 2020-04-08 03:57:25.0) Response from Charles at Thorlabs: Thank you for your inquiry. We don't have a published spec for max eccentricity but we will get in touch with you directly to help with your application. user

(posted 2019-12-16 07:12:50.777) Hi,

I have a Thorlabs DDR100/M Direct Drive Rotation Stage and a BBD202 controller. It is used at an angular velocity of 8degrees/second and every 12 months I want to make sure the angular velicity remains at this speed. How do I best calibrate the system? cwright

(posted 2019-12-17 09:49:39.0) Response from Charles at Thorlabs: Hello Daniel, the stage includes a high resolution encoder and should not require calibration. The correct speed should be maintained unless there is a fault with the stage/controller. I will reach out to you directly to discuss your concerns. benjamin.judkewitz

(posted 2017-12-30 20:53:31.697) Can you please let me know what the maximum small-angle rotation frequency is? For example, we would like to rotate +/-5 deg at up to 100 Hz sinusoidal rotation angle. rmiron

(posted 2018-01-04 09:15:08.0) Response from Radu at Thorlabs: According to the specifications we posted on the website, the maximum frequency for sinusoidal rotation over that angular range is 6Hz for a 500g load and 3Hz for a 2kg load. A lesser weight would allow for a higher frequency, but without additional test data, it is difficult to say what the absolute maximum frequency would be. I will contact you directly in order to check whether we have any stage that can address your requirements. |

Rotation Mount and Stage Selection Guide

Thorlabs offers a wide variety of manual and motorized rotation mounts and stages. Rotation mounts are designed with an inner bore to mount a Ø1/2", Ø1", or Ø2" optic, while rotation stages are designed with mounting taps to attach a variety of components or systems. Motorized options are powered by a DC Servo motor, 2 phase stepper motor, piezo inertia motor, or an Elliptec™ resonant piezo motor. Each offers 360° of continuous rotation.

Manual Rotation Mounts

| Rotation Mounts for Ø1/2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | MRM05(/M) | RSP05(/M) | CRM05 | PRM05(/M)a | SRM05 | KS05RS | CT104 |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

| Features | Mini Series | Standard | External SM1 (1.035"-40) Threads |

Micrometer | 16 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Compatible with 30 mm Cage Translation Stages and 1/4" Translation Stagesb |

| Additional Details | |||||||

| Rotation Mounts for Ø1" Optics | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | RSP1(/M) | LRM1 | RSP1D(/M) | DLM1(/M) | CLR1(/M) | RSP1X15(/M) | RSP1X225(/M) | PRM1(/M)a |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

|

| Features | Standard | External SM1 (1.035"-40) Threads |

Adjustable Zero | Two Independently Rotating Carriages | Rotates Optic Within Fixed Lens Tube System |

Continuous 360° Rotation or 15° Increments |

Continuous 360° Rotation or 22.5° Increments |

Micrometer |

| Additional Details | ||||||||

| Rotation Mounts for Ø1" Optics | ||||||

|---|---|---|---|---|---|---|

| Item # | LM1-A & LM1-B(/M) |

CRM1T(/M) | CRM1LT(/M) | CRM1PT(/M) | KS1RS | K6XS |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Optic Carriage Rotates Within Mounting Ring | 30 mm Cage-Compatiblea | 30 mm Cage-Compatible for Thick Opticsa |

30 mm Cage-Compatible with Micrometera |

±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mounta |

| Additional Details | ||||||

| Rotation Mounts for Ø2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | RSP2(/M) | RSP2D(/M) | PRM2(/M) | LM2-A & LM2-B(/M) |

LCRM2A(/M) | KS2RS | K6X2 |

| Click Photo to Enlarge |  |

|

|

|

|

|

|

| Features | Standard | Adjustable Zero |

Micrometer | Optic Carriage Rotates Within Mounting Ring | 60 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mount |

| Additional Details | |||||||

| Rotation Drive Mechanism and Adjustment Range | Manual, 360° Continuous | Coarse: Manual, 360° Continuous; Fine: ±7° Micrometer |

Manual, 360° Continuous | ||||

| Optic Mounting | Internally SM2-Threaded Carriage | Internal SM2 Threads in LM2-A |

Internally SM2-Threaded Carriage | ||||

| Maximum Accepted Optic Thickness | 0.51" (13 mm) | 0.54" (13.7 mm) | 0.48" (12.2 mm) | 0.46" (11.7 mm) | 0.52" (13.2 mm) | 0.47" (12 mm) | 0.53" (13.4 mm) |

| Post Mounting | 8-32 (M4) Tap | 8-32 (M4) Tap in LM2-B | 8-32 (M4) Tap | Four Counterbores for 8-32 (M4) Cap Screws | Six Counterbores for 8-32 (M4) Cap Screws | ||

| Cage System Compatibility | N/A | Four 4-40 (M3) Taps on Rotation Dial with 60 mm Spacing |

N/A | Four Bores for Ø6 mm Cage Rods with 60 mm Spacing |

N/A | N/A | |

Manual Rotation Stages

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | RP005(/M) | PR005(/M) | MSRP01(/M) | RP01(/M) | RP03(/M) | QRP02(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Standard | Two Hard Stops | ||||

| Additional Details | ||||||

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | XRNR1(/M) | XRR1(/M) | PR01(/M) | CR1(/M) | XYR1(/M) | OCT-XYR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Fine Rotation Adjuster and 2" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and 3" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and SM1-Threaded Central Aperture |

Fine Pitch Worm Gear | Rotation and 1/2" Linear XY Translation | |

| Additional Details | ||||||

Motorized Rotation Mounts and Stages

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | DDR25(/M) | PDR1C(/M) | PDR1(/M) | PDR1V(/M) | PDXR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM05 Lens Tubes, 16 mm Cage System, & 30 mm Cage System |

Compatible with 16 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

Vacuum-Compatible; Also Compatible with SM05 Lens Tubes & 30 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | K10CR1(/M) | PRM1Z8(/M)a | DDR100(/M) | ELL14 | HDR50(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM1 Lens Tubes & 30 mm Cage System | Compatible with SM1 Lens Tubes, 16 mm Cage System, 30 mm Cage System |

Compatible with SM1 Lens Tubes, Open Frame Design for OEM Applications |

Compatible with SM2 Lens Tubes |

|

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Tapped Platforms | ||

|---|---|---|

| Item # | PRMTZ8(/M)a | ELL18(/M)b |

| Click Photo to Enlarge |

|

|

| Features | Tapped Mounting Platform for Mounting Prisms or Other Optics | Tapped Mounting Platform, Open Frame Design for OEM Applications |

| Additional Details | ||

Characterized by high-speed rotation and high-positional accuracy, the DDR100(/M) stage is well-suited for applications where there is a need to rotate components at high speed within a cage or other system such as scanning, surface mapping and laser welding. Very precise, fine positioning and control is easily achieved through a combination of the stable closed-loop control system and a BBD series controller with associated joystick option (available below).

The DDR100(/M) arrives with a top plate. Once installed via the included 4-40 cap screws, the top plate will block the SM1-threaded hole in the rotation stage. However, the plate itself has eight 4-40 taps for securing optomechanical setups.

- Adapter Plates for Mount Accessories

- Options Available with Keyway or Taps

- NR360SP9(/M): Seventeen 1/4"-20 (M6) Taps for Optomechanical Accessories

- NR360SP4(/M): 3 mm Keyway for Flexure Stage Accessories

- Includes 8-32 (M4) Cap Screws for Mounting onto the DDR100(/M) Stage

The NR360SP9(/M) Tapped Adapter Plate and NR360SP4(/M) Grooved Adapter Plate are designed to expand the functionality of the DDR100(/M) Rotation Stage. The NR360SP9 provides seventeen 1/4"-20 (M6) mounting holes for securing optomechanical setups. The NR360SP4 features a 3 mm wide keyway convenient for fiber launch applications and other Flexure Stage Accessories. Both adapters feature four #8 (M4) counterbores for attachment to the DDR100(/M) stage.

We recommend using our BBD Series Brushless DC Servo Motor Controllers with the stages above, selecting the controller with the required number of channels. If using a standalone stage, the BBD301 can be used; if also using a MJC2 joystick, the BBD302 is recommended. The BBD303 3-Channel Controller can be used for applications requiring additional accessories; all three channels can be controlled via the MJC3 joystick.

With a user-configurable, S-curve acceleration/deceleration profile that enables fast, smooth positioning without vibration or shock, these controllers are ideal for motion control applications demanding operation at high speeds (hundreds of mm/s) and high encoder resolution. Incorporating the latest digital and analog techniques as well as high-bandwidth, high-power servo control circuitry, each BBD series controller is designed to drive brushless DC servo motor products with continuous output currents of up to 2.5 A (Item # BBD301) or 5 A (Item #s BBD302 and BBD303).

These DC servo controllers are supported by Thorlabs' Kinesis® control and programming interface, enabling easy integration into automated motion control applications. For greater flexibility, both a USB and RS232 computer interface is provided, and automated PC control of the stage is supported with the supplied software development kit (SDK). The fully documented SDK supports all major development languages running on Windows and comes in the form of a conventional dynamic link library (DLL).

USB connectivity provides easy plug-and-play PC operation. Multiple units can be connected to a single PC via standard USB hub technology for multi-axis motion control applications. Combining this feature with our user-friendly software allows the user to program and carry out complex move sequences in a short space of time. For more information, please see the full Brushless DC Servo Motor Controller presentation.

- High-Reliability Joysticks Utilizing USB HID Protocol

- 2-Axis or 3-Axis Control Via a Joystick Knob

- Two Different Modes for Fast or High Precision Moves

- Speed Dial for Sensitivity Adjustment

- Allows Remote Manual Control

- Can be Reprogrammed using a PC

- Ergonomic Design

The MJC2 and MJC3 Joysticks have been designed for microscope users and provide intuitive, tactile, manual positioning of a stage. The joysticks feature a two-axis joystick knob for XY control or a three-axis joystick knob for XYZ control, respectively. Both joystick knobs can be moved left or right and up or down, with the MJC3 joystick knob also twisting clockwise or counterclockwise for third axis control. A push button to switch between fast or high-precision movement and a speed dial to fine tune speed control are also integrated into the joysticks. In most applications, the default parameter settings saved within the controller allow the joystick to be used out-of-the-box with no need for further setup. This operation mode eliminates the need for connection to a host PC and allows for true remote operation. Parameter settings can also be reprogrammed and saved to a paired controller using a PC, allowing the controller to be disconnected from the computer and remote operation continued.

The MJC2 and MJC3 Joysticks are compatible with our Benchtop Brushless DC Servo Controllers, Rack-Mounted Brushless DC Servo Controller, Rack-Mounted Brushless DC Servo Controller Module, and Stepper Motor Controllers. The joysticks have both a Mini-DIN and a USB Type-C port and are each shipped complete with two cables, a 6-pin Mini-DIN plug to plug cable and a USB 3.1 Type-A to Type-C cable, for use with these controllers as well as setups utilizing the USB HID class. For more information about configuring and setting up the joystick over USB HID, please see the manual by clicking on the red Docs icon (![]() ) below.

) below.

Products Home

Products Home

Zoom

Zoom

Rotation Stage: Direct Drive

Rotation Stage: Direct Drive