Vytran® Fiber Preparation Station: Stripping and Cleaning

- Strip and Clean Fiber Prior to Cleaving and Splicing

- Accepts Fibers with Cladding Diameters from 80 to 400 µm

- Designed for Use with the LDC401 Series of Fiber Cleavers, LFS4100 Splicer, and GPX Series of Glass Fiber Processors

FPS301

Fiber Stripping and Cleaning Station

A Fiber Holding Block with a Fiber Holder Insert installed is positioned next to the ultrasonic cleaner. The TMS blade inserts can be seen inside of the open thermo-mechanical stripper module.

Please Wait

Build Your System

- FPS301 Fiber Preparation Station for Fibers with Claddings from Ø80 to Ø400 µm

- Choose from Seven Interchangeable Thermo-Mechanical Stripper Blade Insert Sets for up to Ø400 µm Claddings (One Required)

- Choose Top and Bottom Inserts (One Top Insert and One Bottom Insert Required; See Fiber Holder Insert Tab for More Information)

Features

- Compatible with Fibers with Cladding Diameters from 80 to 400 µm

- Thermo-Mechanical Stripper with Adjustable Heating Time

- End Strip up to 1.4" (35.6 mm) of Single or Dual Acrylate Coated Fiber

- Ultrasonic Cleaning Bath for Removing Particulates from Stripped Fiber

- Cleaning Bath Accepts User-Supplied Acetone or Isopropyl Alcohol

- Fiber Holding Blocks and Fiber Holder Inserts Shared with Other Vytran®

Systems for Ease of Transfer Between Processes: - Includes Handset Controller and Vacuum Pump

The Vytran FPS301 Fiber Preparation Station is designed to strip and clean fibers before transferring them to the LDC401 Series of Cleavers, LFS4100 Splicer, GPX4000LZ CO2 Laser Glass Processor, GPX3400 and GPX3600 Automated Glass Processors, or GPX3800, GPX3850, and GPX3900 Automated Glass Processors with Integrated Cleaver for further processing. The thermo-mechanical stripper (TMS) uses a resistive heater located in its lower section to heat the fiber, softening the coating or buffer for stripping, and has an LED light to indicate when the heating process is complete. An internal vacuum provides a small holding force through holes in the bottom V-groove of the TMS, helping to gently seat the fiber in the groove.

To clean the fiber, the entire holding block can be moved from the stripping to the cleaning station by moving the fiber holding block, eliminating direct handling of the fiber at each step. After installing the holding block next to the ultrasonic cleaner, simply tilt it to dip the stripped end of the fiber into the solvent-filled ultrasonic cleaner, which can be filled with user-supplied acetone or isopropyl alcohol. An LED indicator light turns off when the cleaning process is complete. The cleaning process time can be set from 1 to 120 seconds using the included handset controller.

Accessories

The FPS301 requires one pair of Fiber Holder Inserts to be purchased separately. Our selection of top and bottom inserts are available below, listed with the maximum fiber sizes accepted by each insert. Two styles of bottom inserts are offered. The VHD series of standard inserts are shorter in length and sufficient if using the FPS301 as a standalone. The VHF Extended Bottom Inserts are longer, so that the end protrudes out of the side of the fiber holding block. This provides enough room for the VHT1 transfer clamp to be placed on the end of the insert, allowing the bottom insert, clamp, and fiber to be moved between other Vytran workstations without directly handling the fiber. The Fiber Holder Inserts tab has a selection guide to aid in choosing which pairs of fiber holder inserts are required based on the diameter of the fiber undergoing processing. Two fiber holding blocks are included with the FPS301, and the cleaning station can process the right and left fibers simultaneously. The system can be operated with a single holding block and fiber holder insert pair if desired. If planning to use both holding blocks, purchase two top inserts.

The blade sets used in the stripping station must be purchased separately. Standard wedge blades are available in four sizes that accommodate fibers with claddings from Ø80 to Ø125 µm and buffers up to Ø400 µm, while half-moon blades are available in three sizes that accommodate fibers with claddings from Ø200 to Ø400 µm and buffers up to Ø600 µm. Each wedge blade set consists of a top and bottom insert, and each insert has a flat blade at both ends. Each half-moon blade set has two top inserts and one bottom insert, and features semi-circular blades. Stripping is unidirectional and cannot be done from the left and right sides of the TMS station at the same time. Using the half-moon blades, the buffer can be stripped all the way around its perimeter in addition to the top and bottom. When a blade set is purchased with the FPS301, it will be installed in the system prior to shipping.

| Compatible Vytran Fiber Processing Systems | |||||||

|---|---|---|---|---|---|---|---|

| Fiber Preparation Station (Strip and Clean) |

Large-Diameter Fiber Cleavers | Portable Large-Diameter Fiber Cleaver | Large-Diameter Fiber Splicer | CO2 Laser Glass Processing System (Splice and Taper) |

Automated Glass Processing Systems with Integrated Cleaver (Cleave, Splice, and Taper) |

Automated Glass Processing Systems (Splice and Taper) |

Recoaters, Proof Testers, and Recoaters with Proof Testers |

| FPS301 Specifications | |

|---|---|

| Accepted Fiber Buffer Diameters | Up to 600 µm |

| Accepted Fiber Cladding Diameters | 80 to 400 µma |

| Accepted Fiber Types | SM, PM, MM, Specialty Fibers Including Photonic Crystal Fiber (PCF) and Non-Circular Fiber, and Capillary Tubes |

| Thermo-Mechanical Stripper | |

| Accepted Coating Materials | Single or Dual Acrylate |

| Maximum Stripping Temperature | ~130 °F (54 °C) |

| Ultrasonic Cleaner | |

| Accepted Cleaning Solvents | Acetone or Isopropyl Alcohol |

| Cleaning Times | 1 to 120 s |

| General | |

| Operating Temperature | 0 to 40 °C (Non-Condensing) |

| Storage Temperature | -20 to 70 °C |

| Power | 90 to 250 VAC (47 to 63 Hz) |

| Size (L x W x H) | 10.14" x 5.39" x 6.76" (257 mm x 137 mm x 172 mm) |

| Weight | 8.8 lbs (4 kg) |

Fiber Holder Insert Selection Guide

Fiber Holder Inserts, which are designed to hold various sized fibers within the FPS301 Fiber Preparation Station, must be purchased separately. The bottom inserts have V-grooves to hold the fiber, while the top inserts each feature a recessed, flat surface that clamps the fiber against the V-groove in the bottom insert. Each top and bottom insert is sold individually, as the fiber diameter clamped by the left and right holding blocks may not be the same. One top insert and one bottom insert is required to operate the FPS301.

The table below indicates the maximum and minimum diameters that can be accommodated by different bottom inserts. During the stripping and cleaning processes, the fiber should always be clamped on the coating or buffer in order to avoid damaging the glass.

Two styles of bottom inserts are offered. The VHD series of standard inserts are shorter in length and sufficient if using the FPS301 as a standalone. The VHF Transfer Inserts are longer, so that the end protrudes out of the side of the fiber holding block. This provides enough room for the VHT1 transfer clamp to be placed on the end of the insert, allowing the bottom insert, clamp, and fiber to be moved between other Vytran® workstations without directly handling the fiber.

All of the V-Groove Inserts compatible with the FPS301 have vacuum holes, designed to aid in aligning small fiber within the groove. The FPS301 has an internal vacuum pump that provides a small holding force via these holes, keeping small fibers in place as the clamps are lowered.

Fiber Holder Insert Selection Chart

- First, select the bottom insert that matches your fiber size most closely.

Example: For a Ø200 µm fiber, the VHD160 or VHF160 insert is the closest match, since it is only 40 µm smaller. The next larger size is 250 µm, which is 50 µm too large. - The lower set of numbers in each cell shows the range of offsets that can be expected for any given combination of top and bottom inserts.

Example: If we choose a VHD160 bottom insert and a VHA00 top insert, we can use fiber as small as 112 µm, in which case the center of the fiber would sit 49 µm below the surface of the bottom insert. Alternatively, we can clamp a fiber as large as 208 µm, in which case the center of the fiber would sit 48 µm above the surface of the bottom insert. We could interpolate to find the offset experienced by our hypothetical 200 µm fiber, but it turns out that in a 60° V-groove, the offset is equal to the diameter difference. So in our example, that means that the center of our fiber is going to sit 40 µm above the bottom insert surface, since it is 40 µm larger than the fiber that the bottom insert was designed for (200 - 160 = 40).

| Top Insert Item # | VHA00a | ||

|---|---|---|---|

| Accepted Diameter (Nominal) | ≤320 µm | 400 µm | |

| Bottom Insert Item # |

Accepted Diameter (Nominal) |

Min / Max Accepted Fiber Diameter (µm) Min / Max Fiber Offset (µm) |

|

| VHD080 | 80 µm | 57 / 100 -23 / 21 |

- |

| VHD125 | 125 µm | 88 / 161 -37 / 36 |

- |

| VHD160 or VHF160b |

160 µm | 112 / 208 -49 / 48 |

- |

| VHD250 or VHF250b |

250 µm | 177 / 320 -73 / 69 |

275 / 323 25 / 74 |

| VHD400 or VHF400b |

400 µm | 279 / 519 -122 / 119 |

377 / 517 -23 / 117 |

Each V-groove can accommodate a range of fiber sizes.

| Legend | ||

|---|---|---|

|

|

Best Fit | |

|

|

Second Best Fit: Try these options if the best fit does not incorporate your fiber sizes. | |

|

|

Third Best Fit: Try these options if the other two categories do not incorporate your fiber sizes. | |

Product DemonstrationsThorlabs has demonstration facilities for the Vytran® fiber glass processing systems offered on this page within our Morganville, New Jersey and Exeter, Devonshire offices. We invite you to schedule a visit to see these products in operation and to discuss the various options with a fiber processing specialist. Please schedule a demonstration at one of our locations below by contacting technical support. We welcome the opportunity for personal interaction during your visit! Thorlabs Vytran Europe

|

| Posted Comments: | |

| No Comments Posted |

Components

Included

- FPS301

- Handset Controller

- 12 V Power Supply

- Location-Specific AC Power Cord

- DC Power Cord

- Left and Right Insert Nests

- Vacuum Pump with Tubing and Power Cord

- Tool Kit with 0.035", 0.050", and 3/32" Hex Keys

Must be Purchased Separately

- TMS Blade Sets (One Required)

- Fiber Holder Top Inserts (One Required)

- Fiber Holder Bottom Inserts (One Required)

- Accepts Fiber with Cladding Diameters from 80 to 400 µm

- Strip Single or Dual Acrylate Coatings up to Ø600 µm

- Stripping and Cleaning Station

- Thermo-Mechanical Stripping

- Ultrasonic Cleaning Bath

- Includes Fiber Holding Blocks

- Includes Handset Controller

- Fiber Holder Inserts and TMS Blade Inserts Available Separately Below (Required for Operation)

This Vytran Fiber Stripping and Cleaning Station is designed to strip the coating and/or buffer off of fibers with cladding sizes from Ø80 to Ø400 µm. The thermo-mechanical stripper can remove single or dual acrylate coatings, and an ultrasonic cleaning bath is included to remove any particulates from the stripped fiber before transferring it to a cleaving or splicing station. The FPS301 is designed to be used with the LDC401 Series of Cleavers, LFS4100 Splicer, GPX3400 and GPX3600 Automated Glass Processors, GPX3800, GPX3850, and GPX3900 Automated Glass Processors with Integrated Cleaver, and GPX4000LZ CO2 Laser Glass Processor; all of these units use the same fiber holding blocks and transfer inserts, allowing the fiber to be moved from station to station with minimal direct handling of the fiber and while maintaining co-registration on each machine.

Fiber Holder Inserts and TMS Blade Inserts for a variety of fiber sizes are sold separately below. One top fiber holder insert, one bottom fiber holder insert, and one TMS blade insert set are required to operate the FPS301, dependent on the size(s) of fiber to be processed. More information can be found on the Fiber Holder Insert tab above.

A handset controller is included for setting the thermo-mechanical stripper heating time and ultrasonic cleaner run time. Each unit is shipped with a power supply and location-specific power cord.

| TMS Blade Insert Setsa | ||||

|---|---|---|---|---|

| Item # | Accepted Cladding Diameter | Max Buffer Diameter |

Blade Type | |

| End 1 | End 2 | |||

| CST080180 | 80 µm | 80 µm | 180 µm | Wedge |

| CSTM080125 | 80 µm | 125 µm | 250 µm | Wedge |

| CST125250 | 125 µm | 125 µm | 250 µm | Wedge |

| CST125400 | 125 µm | 125 µm | 400 µm | Wedge |

| CST200400U | 200 µm | 200 µm | 400 µm | Half-Moon |

| CST250400U | 250 µm | 250 µm | 400 µm | Half-Moon |

| CST400600U | 400 µm | 400 µm | 600 µm | Half-Moon |

- Thermo-Mechanical Stripper (TMS) Blade Insert Sets for FPS301 Fiber Stripping and Cleaning Station

- Blade Sets Include:

- Standard Wedge: One Top and One Bottom Insert

- Half-Moon: Two Top Inserts and One Bottom Insert

- For Fibers with Claddings from Ø80 to Ø400 µm and Buffers Up to Ø600 µm

- Pre-Installed if Ordered with the FPS301 Station

- Interchangeable by the User

Thorlabs offers seven sets of blades for stripping fiber. The maximum buffer diameter is limited by the size of the channel in the insert. When ordered with the FPS301, Thorlabs will install the TMS blade set in the thermo-mechanical stripper prior to shipping. Each wedge blade set consists of a top and bottom insert, and each insert has a flat blade at both ends. Each half-moon blade set has two top inserts and one bottom insert, and features semi-circular blades.

Except for the CSTM080125*, the blade sets are designed to strip the same size cladding on both the left and right ends, and can be interchanged by the user if necessary. For easy identification, the maximum buffer diameter is engraved on the blade inserts. We offer seven inserts from stock to accommodate standard and larger fiber sizes. TMS blade insert sets are available for cladding diameters up to Ø400 µm as a special by contacting Tech Support.

* The CSTM080125 blade set is designed to strip Ø80 µm cladding fiber on one end and Ø125 µm cladding fiber on the other. When ordered with the FPS301, it will be installed by default with the blades for Ø80 µm claddings (End 1) on the left and the blades for Ø125 µm claddings (End 2) on the right. If installing a CSTM080125, be sure to keep the Ø80 µm end of the bottom and top inserts aligned on the same side of the TMS stripper. If the Ø80 µm cladding blade is aligned with the Ø125 µm cladding blade when installed in the stripper, the system will not properly strip and the fiber may be damaged.

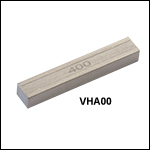

| Top Fiber Holder Insert | ||

|---|---|---|

| Item # | Side 1 Min/Max Accepted Diameter |

Side 2 Min/Max Accepted Diameter |

| VHA00 | 57 µm / 759 µma | 275 µm / 970 µm |

- One is Required to Use the FPS301

- Flat, Recessed Surface Clamps the Fiber Against the V-Groove

in the Bottom Insert (Sold in the Next Section) - Designed for Fiber Outer Diameters from 57 to 970 µm

- Compatible with Other Vytran Systems

The FPS301 fiber preparation station requires a pair of Top and Bottom Fiber Holder Inserts to be placed in each fiber holding block in order to clamp the fiber during processing. This top insert consists of a bar that has a recessed area on one side, designed to clamp the fiber against the V-groove in a bottom insert. The other side of the insert is flat and can be used to provide additional clamping force for fibers with very small diameters. The insert sits in the top section of the fiber holding block and can be paired with one of the bottom inserts (available below) to accommodate fibers with coating diameters in the 80 to 400 µm range supported by the FPS301.

Top inserts are sold individually and one top insert is required to use the FPS301. Two fiber holding blocks are included with the FPS301, but fibers can only be processed on one side of each station at a time; therefore the system can be operated with a single holding block and fiber holder insert pair if desired. If planning to use both holding blocks, purchase two top inserts.

| Fiber Holder Transfer Bottom Insertsa | ||

|---|---|---|

| Item # | Min/Max Accepted Diameter | Vacuum Holes |

| VHF160 | 112 µm / 208 µm | Yes |

| VHF250 | 177 µm / 320 µm | Yes |

| VHF400 | 279 µm / 519 µm | Yes |

| VHF500 | 346 µm / 795 µm | Yes |

| VHF750 | 516 µm / 1047 µm | Yes |

- One is Required if Using the FPS301 with Other Compatible Vytran Systems

- Transfer Inserts Can be Used with Transfer Clamps to Move Fiber Between Compatible Systems While Maintaining Registration

- Vacuum Suction to Aid in Positioning Fibers when Used in the FPS301

- Can Accept Graphite Tips that Provide Extra Support to the Fiber Tip in Splicing and Tapering Applications

- Interchangeable by the User

The FPS301 fiber preparation station requires Fiber Holder Inserts to be placed in the fiber holding blocks in order to clamp the fiber during the cleaning process. These extended inserts sit in the bottom section of the fiber holding blocks and come with a variety of groove sizes. They are compatible with the VHT1 transfer insert, which clamps over the fiber on the length of the insert that protrudes from the fiber holding block, allowing the fiber to be transferred between stations while maintaining coarse alignment. The extended inserts also accept graphite tips (available below) that provide additional support for fibers with coating diameters up to 400 µm when the FPS301 is used in conjunction with the LFS4100 Splicer, GPX4000LZ CO2 Laser Glass Processor, GPX3400 and GPX3600 Automated Glass Processors, or GPX3800, GPX3850, and GPX3900 Automated Glass Processors with Integrated Cleaver. See the Fiber Holder Insert tab above for a comparison of the available insert types and sizes.

Inserts are sold individually and one transfer bottom insert and VHT1 transfer clamp (available below) are needed if using the FPS301 to support a compatible Vytran station. Be sure to order a sufficient quantity of inserts to support your fiber processing needs (e.g., two transfer inserts and two transfer clamps are required for splicing applications). More information can be found in the web presentations for compatible stations (see links above). Please note that when using the FPS301 to support the LDC401A fiber cleaver, the extended inserts are only compatible with the cleaver's left fiber holding block.

Two fiber holding blocks are included with the FPS301, but fibers can only be processed on one side of each station at a time; therefore the system can be operated with a single holding block and fiber holder insert pair if desired. If planning to use both holding blocks, purchase two bottom inserts.

| Graphite V-Grooves | ||

|---|---|---|

| Item # | Accepted Diameter (Min / Max) |

Groove Length |

| VHG125 | 80 µm / 125 µm | 0.313" |

| VHG125L | 80 µm / 125 µm | 0.594" |

| VHG200 | 150 µm / 200 µm | 0.313" |

| VHG250 | 200 µm / 250 µm | 0.313" |

| VHG250L | 200 µm / 250 µm | 0.594" |

| VHG300 | 250 µm / 300 µm | 0.313" |

| VHG350 | 300 µm / 350 µm | 0.313" |

| VHG400 | 350 µm / 400 µm | 0.313" |

- One Transfer Clamp and One Graphite Tip Required for Fiber Holder Transfer Bottom Inserts

- Transfer Clamps Required to Transfer Fibers in VHF Inserts Between Compatible Vytran Systems

- Graphite V-Grooves for Supporting Smaller Fibers During Splicing or Tapering

- V-Grooves Accept Diameters from 80 to 400 µm

These Transfer Clamps and V-Grooves are used with the VHF Transfer Bottom Inserts sold directly above to move a single fiber between various Vytran systems with minimal loss of alignment. For example, a fiber can be placed in a transfer insert and cleaved using the LDC401 Fiber Cleaver. Then, the entire transfer insert and fiber can be moved to a splicer or glass processor for splicing.

The VHT1 clamp secures transfer inserts with a magnetic lid that prevents axial movement of the fiber and can be used to hold the insert during transport without touching the fiber itself. For fibers with diameters ≤400 µm, a graphite V-groove is available to support the fiber when splicing (please see the size table for more information). To provide extended support along the length of the fiber and reduce the amount of overhang during processing, we also offer 0.594" long V-grooves (Item #'s VHG125L and VHG250L). The graphite V-grooves are secured by tightening two setscrews on the transfer insert. For information on how to assemble transfer inserts, see the Fiber Holder Inserts tab.

| Fiber Holder Bottom Insertsa | ||

|---|---|---|

| Item # | Min/Max Accepted Diameter | Vacuum Holes |

| VHD080 | 57 µm / 100 µm | Yes |

| VHD125 | 88 µm / 161 µm | Yes |

| VHD160 | 112 µm / 208 µm | Yes |

| VHD250 | 177 µm / 320 µm | Yes |

| VHD400 | 279 µm / 519 µm | Yes |

- One is Required to Use the FPS301

- V-Groove Bottom Fiber Holder Inserts

- Clamp Fiber Outer Diameters from 57 to 519 µm when Used with Top Inserts (Sold Above)

- Vacuum Suction to Aid in Positioning Fibers when Used in the FPS301

- Interchangeable by the User

The FPS301 fiber preparation station requires one pair of Top and Bottom Fiber Holder Inserts to be placed in one of the fiber holding blocks in order to clamp the fiber during processing. Each insert is a bar with a V-Groove on one side and includes holes for vacuum suction to aid in positioning the fiber when used with the FPS301.

These inserts sit in the bottom section of the fiber holding blocks and come with a variety of groove sizes, outlined in the table to the right. See the Fiber Holder Insert tab above for a comparison of the available insert types and sizes.

Bottom inserts are sold individually, and one is required to use the FPS301. Two fiber holding blocks are included with the FPS301, but fibers can only be processed on one side of each station at a time; therefore the system can be operated with a single holding block and fiber holder insert pair if desired. If planning to use both holding blocks, purchase two bottom inserts.

Products Home

Products Home

Zoom

Zoom

Fiber Preparation Station

Fiber Preparation Station