30 mm Lens Tubes

- Directly Accepts Ø30 mm Optics

- Compatible with All SM30-Threaded Components

- Stackable Design Enables Construction of Multi-Element Optical Systems

SM30L10

SM1A15

SM30RR

SM1L05

SM1A16

SM30L05

Easily Interface with

Other Lens Tube Sizes

Please Wait

| Ø30 mm Shortcuts |

|---|

| Fixed Lens Mounts Retaining Rings |

Features

- Easily Construct Multi-Element Optical Systems

- Mount Several Optics within the Same Tube Using Multiple Retaining Rings

- Adapters Provide Direct Compatibility with Our Ø1" or Ø2" Lens Tubes

- Directly Accepts Ø30 mm Optics

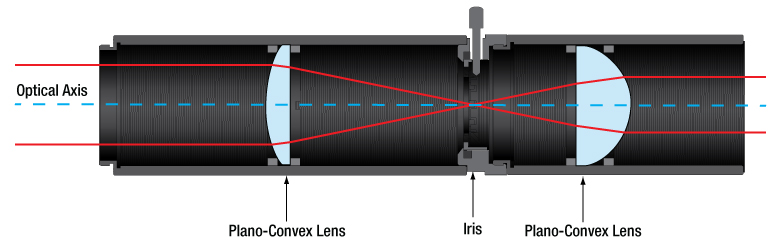

Lens tubes are ideal for creating compact optical subassemblies. The Ø30 mm lens tubes sold here can be used to house one or several optical elements. Optics are separated and secured by retaining rings that are positioned at the desired depth within the lens tube using a spanner wrench. These stackable lens tubes are compatible with all SM30-threaded (M30.5 x 0.5) components. The lens tubes ship with one retaining ring; additional retaining rings can be purchased separately. In addition to the Ø30 mm lens tubes featured on this page, Thorlabs also offers Ø1/2", Ø1", Ø1.5", Ø2", and Ø3" versions, each of which is equipped with an SM thread standard that depends on the tube diameter.

Adapters for SM30-threaded components are also available on this page. These can be used to switch from the Ø30 mm standard to either our Ø1" or Ø2" standard. Via a two-step process, it is also possible to switch to our Ø1/2" or Ø3" standards.

Threading specifications for Thorlabs' lens tube and cage system components can be found on the Threading Specs tab.

Click to Enlarge

When an engraved lens tube is attached to another lens tube, the engraving of the connected end is no longer visible.

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

Karin Fulford

(posted 2023-02-23 15:13:33.187) Can you make this part without the external threads and retention lip? Similar to SM1M30, but 30 mm diameter. jdelia

(posted 2023-02-28 11:50:56.0) Thank you for contacting Thorlabs. I have reached out to you directly to discuss the feasibility of your customized request. 宁 康

(posted 2020-05-09 17:42:51.203) 是否有直径为30 mm的开槽透镜套管,类似于SM1L20C形状。 YLohia

(posted 2020-05-11 10:24:38.0) Thank you for contacting Thorlabs. An applications engineer from our team in China (techsupport-cn@thorlabs.com) will reach out to you directly. martin.gersing

(posted 2016-09-28 15:47:25.307) Dear Thorlabs. I need to insert a collimator (length: 131mm, diameter: 30mm) into one of your 30mm Lens Tubes. Unfortunately the maximal length of those tubes is 80mm. Is there a possibility to combine several 30mm-tubes without reducing the inner diameter, so i can fit the whole collimator inside the tube and clamp it with a retainment ring? jlow

(posted 2016-09-29 04:08:14.0) Response from Jeremy at Thorlabs: Depending on your object and how you want to mount it, one could possibly use other mounting option to hold your collimator. I will contact you directly about this. cbrideau

(posted 2014-01-28 15:30:51.143) I need to adapt an M25x0.75 microscope objective to an M32x0.75 threaded port, and have the objective lowered down a bit. I was wondering if I could get an M32 to SM30 adapter so that I could screw an SM30 tube (L=1") into the M32 port, then get an SM30 to M25 adapter to attach the objective to the tube? Then I could crank the objective (which has an outer diameter of exactly 30mm) in and out of the SM30 tube to adjust my height. I'd be willing to pay the custom machining costs to have this done for quantity 1 for an adapter with M32 ext to SM30 int threads, and a second adapter for SM30 ext to M25 int. jlow

(posted 2014-01-29 10:34:00.0) Response from Jeremy at Thorlabs: I will contact you regarding a quote. |

- Stackable Design Enables Construction of Multi-Element Optical Systems

- SM30-Threaded (M30.5 x 0.5) Bore Accepts Ø30 mm Optics

- Compatible with All SM30-Threaded Components

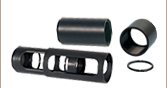

These stackable Ø30 mm lens tubes provide a fast and easy means for building compact optical assemblies. Their stackable design and direct interfacing with any SM30-threaded (M30.5 x 0.5) components provide flexibility for complex optomechanical assemblies. One SM30RR retaining ring is included with each lens tube. Additional retaining rings can be purchased separately.

| Item # | L | Internal Thread Depth |

|---|---|---|

| SM30L03 | 0.33" (8.4 mm) | 0.30" (7.6 mm) |

| SM30L05 | 0.53" (13.5 mm) | 0.50" (12.7 mm) |

| SM30L10 | 1.03" (26.2 mm) | 1.00" (25.4 mm) |

| SM30L20 | 2.03" (51.6 mm) | 2.00" (50.8 mm) |

| SM30L30 | 3.03" (77.0 mm) | 3.00" (76.2 mm) |

| Item # | Typical Application | Adapter Profile |

External Threads | Internal Threads | |

|---|---|---|---|---|---|

| SM1A15 | Step Up/Down Lens Tube Size | SM30 (M30.5 x 0.5) | SM1 (1.035"-40) | ||

| SM2A12 | Step Up/Down Lens Tube Size | SM30 (M30.5 x 0.5) | SM2 (2.035"-40) | ||

| SM1A16 | Step Up/Down Lens Tube Size | SM1 (1.035"-40) | SM30 (M30.5 x 0.5) | ||

| SM1A70 | Mount SL50-CLS2, SL50-2P2, or SL50-3P Scan Lens to LSK-GG4(/M), LSK-GR08(/M), or LSK-GR12(/M) Scan Head |

SM1 (1.035"-40) | SM30 (M30.5 x 0.5) | ||

| SM2A11 | Step Up/Down Lens Tube Size | SM2 (2.035"-40) | SM30 (M30.5 x 0.5) | ||

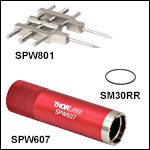

SM30RR: Retaining Rings

These retaining rings can be used to secure optics inside an SM30 Lens tube. One retaining ring is included in the lens tube; however, additional rings enable multiple optics to be secured inside the same lens tube.

SPW607: SM30 Spanner Wrench

The SPW607 Spanner Wrench is hollow enabling retaining rings for our SM30 lens tubes to be adjusted and installed without obscuring the beam path. The knurled grip on one end and the guide flanges on the other ensure safe adjustment of retaining rings without the risk of damage to optical elements.

SPW801: Adjustable Spanner Wrench

- Ranges from Ø0.12" (Ø3 mm) to Ø2.89" (Ø73.4 mm)

- One-Handed Operation Adjusts Spanning Range

- Replaceable Blades

The innovative design of the SPW801 Adjustable Spanner Wrench provides one-handed adjustment of the wrench blades, allowing for dynamic fine tuning of the blade separation to match spacing requirements exactly. The reversible blades contain an edge-offset fine point on one end and a flat blade on the opposing end (SPW102 replacement blades are available). This wrench is ideally suited for inserting the retaining rings into our Ø1/2", Ø1", Ø30 mm, Ø1.5", Ø2", and Ø3" lens tubes. Please note that the SPW801 wrench can withstand a maximum torque of 80 in-lbs.

Products Home

Products Home

Zoom

Zoom

Ø30 mm Lens Tubes

Ø30 mm Lens Tubes